How Surface Engineering Affects Structural Ceramics' Energy Efficiency

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Engineering Background and Objectives

Surface engineering has emerged as a transformative approach in the field of structural ceramics, evolving significantly over the past three decades. Initially focused on basic coating techniques, this discipline has expanded to encompass sophisticated methodologies including chemical vapor deposition, physical vapor deposition, thermal spraying, and laser-based surface treatments. These advancements have revolutionized how ceramic materials interact with their environments, particularly in high-temperature and high-stress applications.

The evolution of surface engineering for structural ceramics has been driven by increasing demands for energy efficiency across multiple industries. As global energy consumption continues to rise and environmental regulations become more stringent, the need for materials that can operate efficiently under extreme conditions has become paramount. Structural ceramics, with their inherent thermal stability and mechanical strength, represent ideal candidates for energy-intensive applications, but their performance is often limited by surface-related failures.

Current technological trends in this field are moving toward multi-functional surface treatments that simultaneously address multiple performance parameters. These include wear resistance, thermal barrier properties, corrosion protection, and reduced friction coefficients. The integration of nanotechnology has further expanded possibilities, enabling precise control over surface properties at the nanoscale, resulting in unprecedented improvements in energy efficiency.

The primary objective of surface engineering for structural ceramics is to enhance energy efficiency through strategic modification of surface properties without compromising the bulk material's inherent advantages. This involves developing surfaces that minimize energy losses through reduced friction, improved thermal management, and extended component lifespans. By tailoring ceramic surfaces at the micro and nano levels, engineers aim to reduce energy consumption in applications ranging from gas turbines and heat exchangers to cutting tools and automotive components.

Another critical goal is to overcome the traditional limitations of ceramic materials, particularly their brittleness and susceptibility to catastrophic failure. Surface engineering techniques can introduce compressive stresses, heal surface flaws, or create gradient structures that significantly improve toughness and reliability. These improvements directly translate to energy savings through reduced material waste, longer service intervals, and higher operating efficiencies.

Looking forward, the field is targeting the development of adaptive and self-healing surface systems that can respond dynamically to changing operational conditions. This represents the next frontier in ceramic surface engineering, with potential to revolutionize energy efficiency across multiple sectors by creating materials that maintain optimal performance throughout their operational lifetime, regardless of environmental challenges.

The evolution of surface engineering for structural ceramics has been driven by increasing demands for energy efficiency across multiple industries. As global energy consumption continues to rise and environmental regulations become more stringent, the need for materials that can operate efficiently under extreme conditions has become paramount. Structural ceramics, with their inherent thermal stability and mechanical strength, represent ideal candidates for energy-intensive applications, but their performance is often limited by surface-related failures.

Current technological trends in this field are moving toward multi-functional surface treatments that simultaneously address multiple performance parameters. These include wear resistance, thermal barrier properties, corrosion protection, and reduced friction coefficients. The integration of nanotechnology has further expanded possibilities, enabling precise control over surface properties at the nanoscale, resulting in unprecedented improvements in energy efficiency.

The primary objective of surface engineering for structural ceramics is to enhance energy efficiency through strategic modification of surface properties without compromising the bulk material's inherent advantages. This involves developing surfaces that minimize energy losses through reduced friction, improved thermal management, and extended component lifespans. By tailoring ceramic surfaces at the micro and nano levels, engineers aim to reduce energy consumption in applications ranging from gas turbines and heat exchangers to cutting tools and automotive components.

Another critical goal is to overcome the traditional limitations of ceramic materials, particularly their brittleness and susceptibility to catastrophic failure. Surface engineering techniques can introduce compressive stresses, heal surface flaws, or create gradient structures that significantly improve toughness and reliability. These improvements directly translate to energy savings through reduced material waste, longer service intervals, and higher operating efficiencies.

Looking forward, the field is targeting the development of adaptive and self-healing surface systems that can respond dynamically to changing operational conditions. This represents the next frontier in ceramic surface engineering, with potential to revolutionize energy efficiency across multiple sectors by creating materials that maintain optimal performance throughout their operational lifetime, regardless of environmental challenges.

Market Demand Analysis for Energy-Efficient Ceramics

The global market for energy-efficient ceramics has experienced significant growth in recent years, driven by increasing energy costs, stringent environmental regulations, and a growing focus on sustainability across industries. Surface-engineered structural ceramics, in particular, have emerged as critical materials for applications requiring high performance under extreme conditions while maintaining energy efficiency.

Energy consumption in industrial sectors accounts for approximately 30% of global energy use, with thermal processes being major contributors. This has created a substantial demand for advanced ceramic materials that can reduce energy losses through improved thermal management, reduced friction, and enhanced durability. The market for these specialized ceramics is projected to grow at a compound annual growth rate of 7.2% through 2028.

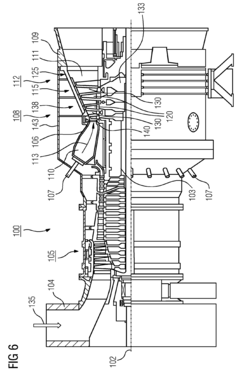

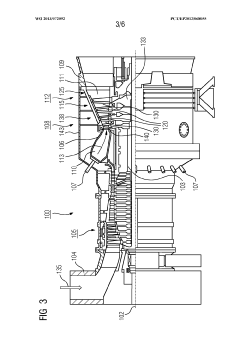

Key market segments driving demand include aerospace, automotive, energy generation, electronics, and industrial manufacturing. In aerospace, surface-engineered ceramics are increasingly sought for thermal barrier coatings that improve fuel efficiency in jet engines. The automotive industry is adopting these materials for powertrain components to meet stringent emission standards while improving vehicle performance.

The energy generation sector represents one of the largest markets for energy-efficient ceramics, particularly in renewable energy applications. Solar thermal systems, fuel cells, and high-temperature energy storage solutions all benefit from advanced ceramic materials with engineered surfaces that optimize energy conversion and retention.

Regional analysis indicates that Asia-Pacific currently leads the market, with China and Japan being major consumers and producers. North America and Europe follow closely, with demand primarily driven by high-tech industries and stringent energy efficiency regulations. Emerging economies in South America and Africa are showing increasing interest as they develop their industrial bases.

Consumer preferences are shifting toward products with demonstrated sustainability credentials, creating pull-through demand for components made with energy-efficient materials. This trend is particularly evident in consumer electronics and household appliances, where energy ratings significantly influence purchasing decisions.

Market barriers include the higher initial cost of advanced ceramics compared to traditional materials, technical challenges in scaling up production, and limited awareness of long-term cost benefits among potential end-users. However, total cost of ownership analyses consistently demonstrate that the energy savings and extended service life of surface-engineered ceramics offset higher acquisition costs.

Industry forecasts suggest that as production technologies mature and economies of scale are achieved, the price gap between conventional and energy-efficient ceramics will narrow, further accelerating market adoption. The development of new surface engineering techniques that can be applied cost-effectively at industrial scales represents a significant market opportunity.

Energy consumption in industrial sectors accounts for approximately 30% of global energy use, with thermal processes being major contributors. This has created a substantial demand for advanced ceramic materials that can reduce energy losses through improved thermal management, reduced friction, and enhanced durability. The market for these specialized ceramics is projected to grow at a compound annual growth rate of 7.2% through 2028.

Key market segments driving demand include aerospace, automotive, energy generation, electronics, and industrial manufacturing. In aerospace, surface-engineered ceramics are increasingly sought for thermal barrier coatings that improve fuel efficiency in jet engines. The automotive industry is adopting these materials for powertrain components to meet stringent emission standards while improving vehicle performance.

The energy generation sector represents one of the largest markets for energy-efficient ceramics, particularly in renewable energy applications. Solar thermal systems, fuel cells, and high-temperature energy storage solutions all benefit from advanced ceramic materials with engineered surfaces that optimize energy conversion and retention.

Regional analysis indicates that Asia-Pacific currently leads the market, with China and Japan being major consumers and producers. North America and Europe follow closely, with demand primarily driven by high-tech industries and stringent energy efficiency regulations. Emerging economies in South America and Africa are showing increasing interest as they develop their industrial bases.

Consumer preferences are shifting toward products with demonstrated sustainability credentials, creating pull-through demand for components made with energy-efficient materials. This trend is particularly evident in consumer electronics and household appliances, where energy ratings significantly influence purchasing decisions.

Market barriers include the higher initial cost of advanced ceramics compared to traditional materials, technical challenges in scaling up production, and limited awareness of long-term cost benefits among potential end-users. However, total cost of ownership analyses consistently demonstrate that the energy savings and extended service life of surface-engineered ceramics offset higher acquisition costs.

Industry forecasts suggest that as production technologies mature and economies of scale are achieved, the price gap between conventional and energy-efficient ceramics will narrow, further accelerating market adoption. The development of new surface engineering techniques that can be applied cost-effectively at industrial scales represents a significant market opportunity.

Current State and Challenges in Ceramic Surface Engineering

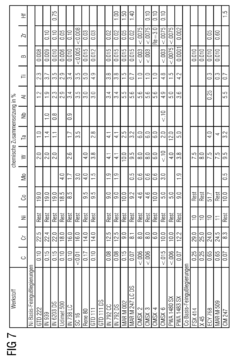

Surface engineering for structural ceramics has witnessed significant advancements globally, yet remains constrained by several technical and practical challenges. Current state-of-the-art techniques include physical vapor deposition (PVD), chemical vapor deposition (CVD), thermal spraying, and sol-gel methods, each offering distinct advantages for enhancing ceramic surface properties related to energy efficiency. These methods have enabled the development of thermal barrier coatings that can withstand temperatures exceeding 1200°C while providing thermal insulation.

The geographical distribution of ceramic surface engineering expertise shows concentration in industrialized regions, with Japan, Germany, and the United States leading in patent filings and research publications. China has emerged as a rapidly growing contributor, particularly in manufacturing scale-up and cost reduction strategies. Academic-industrial collaborations have accelerated in recent years, with notable research clusters forming around materials science institutes in Europe and Asia.

Despite progress, significant technical challenges persist. Adhesion between coating layers and ceramic substrates remains problematic, with thermal expansion coefficient mismatches causing delamination during thermal cycling. This issue is particularly acute in energy applications where temperature fluctuations are common. Current solutions provide limited durability, with most advanced coatings requiring replacement after 10,000-15,000 hours of operation in high-temperature environments.

Uniformity in coating thickness presents another major challenge, especially for components with complex geometries. Existing deposition techniques struggle to maintain consistent coverage on intricate surfaces, leading to performance variations and reduced energy efficiency. Advanced plasma-assisted techniques show promise but remain costly for large-scale implementation.

Material compatibility issues continue to constrain innovation, as many high-performance coating materials interact unfavorably with ceramic substrates under operational conditions. This chemical incompatibility accelerates degradation and reduces the energy-saving potential of engineered surfaces. Research into diffusion barrier interlayers has shown promise but adds complexity and cost to manufacturing processes.

Cost-effectiveness represents a significant barrier to widespread adoption. Current high-performance surface treatments can increase component costs by 30-200%, limiting their application to high-value sectors. Manufacturing scalability remains challenging, with most advanced techniques requiring specialized equipment and controlled environments that are difficult to integrate into existing production lines.

Environmental considerations also pose challenges, as many current surface engineering processes utilize hazardous materials or generate significant waste. Regulatory pressures are driving research toward more sustainable alternatives, though these typically offer reduced performance compared to established methods.

The geographical distribution of ceramic surface engineering expertise shows concentration in industrialized regions, with Japan, Germany, and the United States leading in patent filings and research publications. China has emerged as a rapidly growing contributor, particularly in manufacturing scale-up and cost reduction strategies. Academic-industrial collaborations have accelerated in recent years, with notable research clusters forming around materials science institutes in Europe and Asia.

Despite progress, significant technical challenges persist. Adhesion between coating layers and ceramic substrates remains problematic, with thermal expansion coefficient mismatches causing delamination during thermal cycling. This issue is particularly acute in energy applications where temperature fluctuations are common. Current solutions provide limited durability, with most advanced coatings requiring replacement after 10,000-15,000 hours of operation in high-temperature environments.

Uniformity in coating thickness presents another major challenge, especially for components with complex geometries. Existing deposition techniques struggle to maintain consistent coverage on intricate surfaces, leading to performance variations and reduced energy efficiency. Advanced plasma-assisted techniques show promise but remain costly for large-scale implementation.

Material compatibility issues continue to constrain innovation, as many high-performance coating materials interact unfavorably with ceramic substrates under operational conditions. This chemical incompatibility accelerates degradation and reduces the energy-saving potential of engineered surfaces. Research into diffusion barrier interlayers has shown promise but adds complexity and cost to manufacturing processes.

Cost-effectiveness represents a significant barrier to widespread adoption. Current high-performance surface treatments can increase component costs by 30-200%, limiting their application to high-value sectors. Manufacturing scalability remains challenging, with most advanced techniques requiring specialized equipment and controlled environments that are difficult to integrate into existing production lines.

Environmental considerations also pose challenges, as many current surface engineering processes utilize hazardous materials or generate significant waste. Regulatory pressures are driving research toward more sustainable alternatives, though these typically offer reduced performance compared to established methods.

Current Surface Engineering Solutions for Energy Efficiency

01 Advanced ceramic compositions for thermal efficiency

Advanced ceramic materials with specific compositions can significantly improve thermal efficiency in various applications. These ceramics typically feature enhanced thermal insulation properties, reduced heat loss, and improved energy conservation. The compositions may include specialized additives or novel formulations that optimize thermal conductivity characteristics, allowing for better energy management in high-temperature environments.- Advanced ceramic compositions for thermal efficiency: Specialized ceramic compositions are developed to enhance thermal efficiency in structural applications. These materials feature optimized thermal conductivity properties that minimize heat loss and improve energy conservation. The compositions often incorporate specific additives or modified microstructures that contribute to superior insulation capabilities while maintaining structural integrity under high-temperature conditions.

- Ceramic manufacturing processes for energy-efficient structures: Innovative manufacturing techniques for structural ceramics focus on reducing energy consumption during production while enhancing the energy efficiency of the final product. These processes include optimized sintering methods, novel forming techniques, and precision control systems that minimize waste and energy input. The resulting ceramic structures exhibit improved performance characteristics with reduced environmental impact.

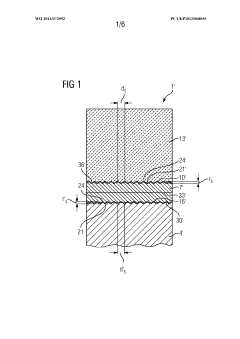

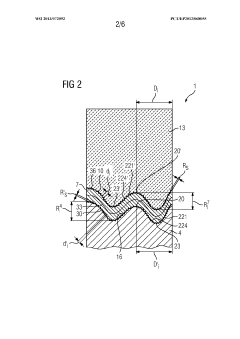

- Ceramic coatings and layers for energy conservation: Specialized ceramic coatings and multi-layer systems are designed to enhance energy efficiency in various applications. These coatings provide thermal barrier properties, reduce friction, and improve wear resistance, contributing to overall energy conservation. The technology incorporates advanced ceramic materials applied as thin films or composite layers that significantly improve the performance and longevity of underlying structures.

- Structural ceramic systems for building energy efficiency: Ceramic-based building components and systems are designed specifically to improve energy efficiency in construction applications. These include specialized wall systems, flooring materials, and structural elements that provide superior thermal insulation and energy management. The ceramic structures incorporate features such as controlled porosity, reflective properties, or phase-change capabilities that contribute to reduced heating and cooling requirements in buildings.

- Smart ceramic materials for adaptive energy management: Advanced ceramic materials with responsive or adaptive properties enable dynamic energy management in structural applications. These smart ceramics can adjust their thermal, optical, or electrical properties in response to environmental changes or external stimuli. The technology incorporates elements such as phase-change materials, piezoelectric components, or thermochromic features that optimize energy efficiency under varying conditions.

02 Structural ceramic manufacturing techniques for energy conservation

Innovative manufacturing processes for structural ceramics can lead to products with superior energy efficiency properties. These techniques may involve specialized sintering methods, precise temperature control during formation, or novel molding approaches that create optimized microstructures. The resulting ceramics demonstrate improved thermal performance, reduced energy consumption during operation, and enhanced durability in demanding environments.Expand Specific Solutions03 Ceramic coatings and layers for energy-efficient applications

Specialized ceramic coatings and multi-layered structures can be applied to various substrates to enhance energy efficiency. These coatings provide thermal barrier properties, reduce heat transfer, and improve overall system performance. The layered ceramic structures may incorporate porosity control, gradient compositions, or specialized interfaces that optimize thermal management while maintaining structural integrity under operational conditions.Expand Specific Solutions04 Energy-efficient ceramic systems for industrial applications

Structural ceramics designed specifically for industrial settings offer significant energy savings through improved thermal management. These systems may include specialized kiln furniture, heat exchangers, or process equipment components that reduce energy consumption in manufacturing operations. The ceramic materials are engineered to withstand harsh industrial environments while providing superior thermal efficiency, resulting in reduced operational costs and environmental impact.Expand Specific Solutions05 Novel ceramic structures and designs for energy conservation

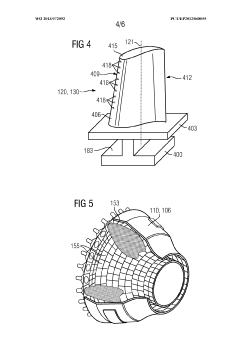

Innovative structural designs and architectural configurations of ceramic components can maximize energy efficiency in various applications. These designs may feature optimized geometries, controlled porosity, or specialized internal structures that enhance thermal insulation while maintaining mechanical strength. The novel ceramic structures enable more efficient energy use in buildings, industrial processes, and transportation systems through improved thermal management capabilities.Expand Specific Solutions

Key Technical Innovations in Ceramic Surface Modification

Surface with specially formed depressions and component

PatentInactiveEP2586985A1

Innovation

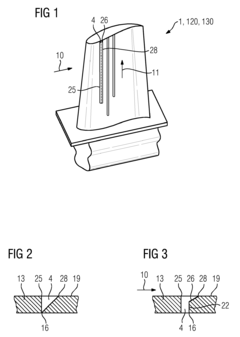

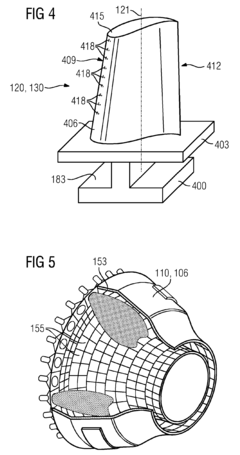

- The introduction of elongated depressions on the surface of ceramic and metal components, angled at 90° ± 20° to the flow direction, which widen from the bottom to the surface and have a constant cross-section transverse to their longitudinal direction, improving chipping resistance and aerodynamics, and can be created during the coating process or using laser techniques.

Layer system having a structured substrate surface and process for the production thereof

PatentWO2013072092A1

Innovation

- A layer system with a substrate surface roughness greater than the interface between layers, achieved by structuring the substrate surface to enhance the ceramic coating's adhesion and durability, using a metallic adhesion promoter layer with increased roughness to support a ceramic thermal barrier coating.

Environmental Impact Assessment

Surface engineering of structural ceramics significantly impacts environmental sustainability across multiple dimensions. The manufacturing processes involved in ceramic surface treatments often require substantial energy inputs, particularly for high-temperature treatments like thermal spraying, chemical vapor deposition, and plasma-enhanced processes. These energy-intensive operations contribute to greenhouse gas emissions when powered by fossil fuel sources, creating a carbon footprint that must be considered in lifecycle assessments.

However, the environmental equation becomes more favorable when considering the operational phase of surface-engineered ceramics. Enhanced surface properties lead to improved wear resistance and extended component lifespans, reducing the frequency of replacement and associated material consumption. This longevity effect translates to reduced raw material extraction, processing, and manufacturing emissions over time, creating a positive environmental offset against initial production impacts.

Water consumption represents another critical environmental consideration. Certain surface engineering techniques, particularly wet chemical processes and aqueous-based treatments, require significant water resources and generate wastewater containing potentially harmful chemicals. Advanced treatment facilities can mitigate these impacts, but implementation varies globally based on regulatory frameworks and available infrastructure.

The chemical compounds utilized in surface engineering processes present additional environmental concerns. Some treatments involve volatile organic compounds (VOCs), heavy metals, or other potentially hazardous substances that require careful management to prevent air, soil, and water contamination. The transition toward more environmentally benign alternatives, including water-based systems and bio-inspired surface treatments, represents a promising trend in reducing these chemical impacts.

Waste generation throughout the surface engineering lifecycle demands attention, from production residues to end-of-life disposal considerations. While ceramic materials themselves are generally inert, specialized coatings or surface modifications may complicate recycling efforts or introduce potential leaching concerns in disposal environments. Developing effective recycling protocols for composite ceramic systems remains an ongoing challenge.

Energy efficiency improvements delivered by surface-engineered ceramics in applications like thermal barrier coatings, tribological interfaces, and catalytic surfaces can yield substantial environmental benefits through reduced operational energy consumption. These downstream energy savings often outweigh the initial environmental investment, particularly in energy-intensive sectors like transportation, power generation, and industrial processing, where even marginal efficiency improvements translate to significant emission reductions over operational lifetimes.

However, the environmental equation becomes more favorable when considering the operational phase of surface-engineered ceramics. Enhanced surface properties lead to improved wear resistance and extended component lifespans, reducing the frequency of replacement and associated material consumption. This longevity effect translates to reduced raw material extraction, processing, and manufacturing emissions over time, creating a positive environmental offset against initial production impacts.

Water consumption represents another critical environmental consideration. Certain surface engineering techniques, particularly wet chemical processes and aqueous-based treatments, require significant water resources and generate wastewater containing potentially harmful chemicals. Advanced treatment facilities can mitigate these impacts, but implementation varies globally based on regulatory frameworks and available infrastructure.

The chemical compounds utilized in surface engineering processes present additional environmental concerns. Some treatments involve volatile organic compounds (VOCs), heavy metals, or other potentially hazardous substances that require careful management to prevent air, soil, and water contamination. The transition toward more environmentally benign alternatives, including water-based systems and bio-inspired surface treatments, represents a promising trend in reducing these chemical impacts.

Waste generation throughout the surface engineering lifecycle demands attention, from production residues to end-of-life disposal considerations. While ceramic materials themselves are generally inert, specialized coatings or surface modifications may complicate recycling efforts or introduce potential leaching concerns in disposal environments. Developing effective recycling protocols for composite ceramic systems remains an ongoing challenge.

Energy efficiency improvements delivered by surface-engineered ceramics in applications like thermal barrier coatings, tribological interfaces, and catalytic surfaces can yield substantial environmental benefits through reduced operational energy consumption. These downstream energy savings often outweigh the initial environmental investment, particularly in energy-intensive sectors like transportation, power generation, and industrial processing, where even marginal efficiency improvements translate to significant emission reductions over operational lifetimes.

Cost-Benefit Analysis of Advanced Surface Treatments

The implementation of advanced surface treatments for structural ceramics requires careful economic evaluation to determine their viability in industrial applications. When analyzing the cost-benefit ratio of these treatments, initial investment costs must be weighed against long-term operational savings and performance improvements.

Surface engineering techniques such as plasma spraying, chemical vapor deposition, and sol-gel methods typically involve significant upfront capital expenditure for equipment acquisition and installation. For instance, establishing a plasma spray coating facility can cost between $500,000 to $2 million depending on scale and sophistication. Additionally, specialized personnel training and process optimization may add 15-20% to initial implementation costs.

Operational expenses include raw materials, energy consumption, maintenance, and quality control. Advanced ceramic coatings often utilize expensive precursors such as rare earth elements or specialized compounds, contributing to ongoing production costs. However, these expenses must be evaluated against the substantial benefits in energy efficiency that properly engineered surfaces provide.

Energy savings represent the primary economic benefit of surface-engineered ceramics. Thermal barrier coatings can reduce heat transfer by 30-50%, translating to significant energy conservation in high-temperature applications. In industrial furnaces, this can yield annual energy savings of 15-25%, with payback periods typically ranging from 8 months to 3 years depending on operation intensity and energy prices.

Lifecycle extension constitutes another major economic advantage. Surface-treated ceramics demonstrate 2-5 times longer service life in harsh environments compared to untreated counterparts. This extended durability significantly reduces replacement frequency and associated downtime costs, which often exceed the direct material costs by a factor of 3-4 in continuous production environments.

Environmental compliance benefits must also factor into the economic equation. As emissions regulations tighten globally, the reduced energy consumption of surface-engineered ceramics can substantially lower carbon tax liabilities and compliance costs. Companies implementing these technologies report 10-30% reductions in regulatory compliance expenses.

Market differentiation provides additional economic value that is harder to quantify but nonetheless significant. Products incorporating advanced ceramic surface treatments often command premium pricing, with margins typically 15-40% higher than conventional alternatives, particularly in aerospace, medical, and high-performance industrial applications.

The cost-benefit analysis ultimately reveals that while advanced surface treatments require substantial initial investment, their economic justification strengthens over time as energy prices rise and environmental regulations become more stringent. Organizations adopting a total cost of ownership approach rather than focusing solely on acquisition costs are more likely to recognize the compelling economic case for implementing these technologies.

Surface engineering techniques such as plasma spraying, chemical vapor deposition, and sol-gel methods typically involve significant upfront capital expenditure for equipment acquisition and installation. For instance, establishing a plasma spray coating facility can cost between $500,000 to $2 million depending on scale and sophistication. Additionally, specialized personnel training and process optimization may add 15-20% to initial implementation costs.

Operational expenses include raw materials, energy consumption, maintenance, and quality control. Advanced ceramic coatings often utilize expensive precursors such as rare earth elements or specialized compounds, contributing to ongoing production costs. However, these expenses must be evaluated against the substantial benefits in energy efficiency that properly engineered surfaces provide.

Energy savings represent the primary economic benefit of surface-engineered ceramics. Thermal barrier coatings can reduce heat transfer by 30-50%, translating to significant energy conservation in high-temperature applications. In industrial furnaces, this can yield annual energy savings of 15-25%, with payback periods typically ranging from 8 months to 3 years depending on operation intensity and energy prices.

Lifecycle extension constitutes another major economic advantage. Surface-treated ceramics demonstrate 2-5 times longer service life in harsh environments compared to untreated counterparts. This extended durability significantly reduces replacement frequency and associated downtime costs, which often exceed the direct material costs by a factor of 3-4 in continuous production environments.

Environmental compliance benefits must also factor into the economic equation. As emissions regulations tighten globally, the reduced energy consumption of surface-engineered ceramics can substantially lower carbon tax liabilities and compliance costs. Companies implementing these technologies report 10-30% reductions in regulatory compliance expenses.

Market differentiation provides additional economic value that is harder to quantify but nonetheless significant. Products incorporating advanced ceramic surface treatments often command premium pricing, with margins typically 15-40% higher than conventional alternatives, particularly in aerospace, medical, and high-performance industrial applications.

The cost-benefit analysis ultimately reveals that while advanced surface treatments require substantial initial investment, their economic justification strengthens over time as energy prices rise and environmental regulations become more stringent. Organizations adopting a total cost of ownership approach rather than focusing solely on acquisition costs are more likely to recognize the compelling economic case for implementing these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!