Control systems for induction motor energy optimization

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Control Evolution and Objectives

Induction motors have been a cornerstone of industrial applications since their invention in the late 19th century. The evolution of control systems for these motors has been driven by the increasing demand for energy efficiency and performance optimization. Initially, induction motors were operated with simple on-off controls, which provided limited speed regulation and resulted in significant energy losses.

The advent of variable frequency drives (VFDs) in the 1960s marked a significant milestone in induction motor control. VFDs allowed for precise speed control and improved energy efficiency by adjusting the frequency and voltage supplied to the motor. This technology laid the foundation for more sophisticated control strategies that would follow.

In the 1980s and 1990s, the development of microprocessors and digital signal processors (DSPs) revolutionized motor control systems. These advancements enabled the implementation of complex control algorithms, such as vector control and direct torque control (DTC). Vector control, also known as field-oriented control (FOC), provided superior dynamic performance by decoupling the torque and flux components of the motor current.

The turn of the millennium saw a shift towards more intelligent and adaptive control systems. Sensorless control techniques emerged, eliminating the need for expensive speed sensors and improving reliability. Additionally, the integration of artificial intelligence and machine learning algorithms began to enhance motor control systems' ability to adapt to changing operating conditions and optimize performance in real-time.

Recent years have witnessed a focus on holistic energy optimization strategies. Modern control systems for induction motors now incorporate advanced features such as loss minimization algorithms, predictive maintenance capabilities, and integration with industrial Internet of Things (IIoT) platforms. These developments aim to maximize energy efficiency not just at the motor level, but across entire industrial processes.

The primary objectives of contemporary induction motor control systems for energy optimization include minimizing electrical losses, improving dynamic response, enhancing reliability, and reducing overall energy consumption. Achieving these goals requires a multifaceted approach that combines advanced control algorithms, high-performance hardware, and intelligent software solutions.

Looking ahead, the future of induction motor control systems is likely to be shaped by emerging technologies such as wide-bandgap semiconductors, edge computing, and advanced analytics. These innovations promise to further push the boundaries of energy efficiency and performance optimization in industrial applications.

The advent of variable frequency drives (VFDs) in the 1960s marked a significant milestone in induction motor control. VFDs allowed for precise speed control and improved energy efficiency by adjusting the frequency and voltage supplied to the motor. This technology laid the foundation for more sophisticated control strategies that would follow.

In the 1980s and 1990s, the development of microprocessors and digital signal processors (DSPs) revolutionized motor control systems. These advancements enabled the implementation of complex control algorithms, such as vector control and direct torque control (DTC). Vector control, also known as field-oriented control (FOC), provided superior dynamic performance by decoupling the torque and flux components of the motor current.

The turn of the millennium saw a shift towards more intelligent and adaptive control systems. Sensorless control techniques emerged, eliminating the need for expensive speed sensors and improving reliability. Additionally, the integration of artificial intelligence and machine learning algorithms began to enhance motor control systems' ability to adapt to changing operating conditions and optimize performance in real-time.

Recent years have witnessed a focus on holistic energy optimization strategies. Modern control systems for induction motors now incorporate advanced features such as loss minimization algorithms, predictive maintenance capabilities, and integration with industrial Internet of Things (IIoT) platforms. These developments aim to maximize energy efficiency not just at the motor level, but across entire industrial processes.

The primary objectives of contemporary induction motor control systems for energy optimization include minimizing electrical losses, improving dynamic response, enhancing reliability, and reducing overall energy consumption. Achieving these goals requires a multifaceted approach that combines advanced control algorithms, high-performance hardware, and intelligent software solutions.

Looking ahead, the future of induction motor control systems is likely to be shaped by emerging technologies such as wide-bandgap semiconductors, edge computing, and advanced analytics. These innovations promise to further push the boundaries of energy efficiency and performance optimization in industrial applications.

Energy Efficiency Market Drivers

The global drive for energy efficiency has become a significant market driver for induction motor control systems optimization. As industries and governments worldwide increasingly focus on reducing energy consumption and carbon emissions, the demand for more efficient motor systems has surged. This trend is particularly evident in industrial sectors, where electric motors account for a substantial portion of energy usage.

Regulatory frameworks and policies play a crucial role in shaping this market. Many countries have implemented stringent energy efficiency standards for electric motors, such as the International Electrotechnical Commission (IEC) standards and the U.S. Department of Energy's regulations. These standards mandate the use of high-efficiency motors and drive systems, creating a strong incentive for industries to adopt advanced control systems for induction motor energy optimization.

The rising cost of energy is another key factor driving the market for energy-efficient motor control systems. As electricity prices continue to increase globally, industries are seeking ways to reduce their operational costs. Optimized induction motor control systems offer a compelling solution by significantly reducing energy consumption, leading to substantial cost savings over the lifetime of the equipment.

Environmental concerns and corporate sustainability goals are also fueling the demand for energy-efficient motor systems. Many companies are setting ambitious targets to reduce their carbon footprint, and optimizing motor efficiency is a tangible way to achieve these goals. This has led to increased investment in advanced control technologies that can maximize the energy efficiency of induction motors.

The Industrial Internet of Things (IIoT) and Industry 4.0 trends are further accelerating the adoption of sophisticated motor control systems. These technologies enable real-time monitoring, predictive maintenance, and dynamic optimization of motor performance, enhancing overall energy efficiency. The integration of smart sensors and data analytics in motor control systems allows for more precise energy management and operational improvements.

Moreover, government incentives and rebate programs for energy-efficient equipment are stimulating market growth. Many countries offer financial incentives to industries that upgrade to high-efficiency motor systems, making the investment in advanced control technologies more attractive. This support is particularly important in emerging economies, where the potential for energy savings in industrial sectors is substantial.

The growing awareness of the long-term benefits of energy-efficient motor systems is also driving market expansion. While the initial investment in advanced control systems may be higher, the significant energy savings and reduced maintenance costs over time are increasingly recognized as valuable by industry decision-makers. This shift in perspective is leading to a greater willingness to invest in optimized induction motor control systems across various industrial applications.

Regulatory frameworks and policies play a crucial role in shaping this market. Many countries have implemented stringent energy efficiency standards for electric motors, such as the International Electrotechnical Commission (IEC) standards and the U.S. Department of Energy's regulations. These standards mandate the use of high-efficiency motors and drive systems, creating a strong incentive for industries to adopt advanced control systems for induction motor energy optimization.

The rising cost of energy is another key factor driving the market for energy-efficient motor control systems. As electricity prices continue to increase globally, industries are seeking ways to reduce their operational costs. Optimized induction motor control systems offer a compelling solution by significantly reducing energy consumption, leading to substantial cost savings over the lifetime of the equipment.

Environmental concerns and corporate sustainability goals are also fueling the demand for energy-efficient motor systems. Many companies are setting ambitious targets to reduce their carbon footprint, and optimizing motor efficiency is a tangible way to achieve these goals. This has led to increased investment in advanced control technologies that can maximize the energy efficiency of induction motors.

The Industrial Internet of Things (IIoT) and Industry 4.0 trends are further accelerating the adoption of sophisticated motor control systems. These technologies enable real-time monitoring, predictive maintenance, and dynamic optimization of motor performance, enhancing overall energy efficiency. The integration of smart sensors and data analytics in motor control systems allows for more precise energy management and operational improvements.

Moreover, government incentives and rebate programs for energy-efficient equipment are stimulating market growth. Many countries offer financial incentives to industries that upgrade to high-efficiency motor systems, making the investment in advanced control technologies more attractive. This support is particularly important in emerging economies, where the potential for energy savings in industrial sectors is substantial.

The growing awareness of the long-term benefits of energy-efficient motor systems is also driving market expansion. While the initial investment in advanced control systems may be higher, the significant energy savings and reduced maintenance costs over time are increasingly recognized as valuable by industry decision-makers. This shift in perspective is leading to a greater willingness to invest in optimized induction motor control systems across various industrial applications.

Current Challenges in Motor Energy Optimization

Induction motor energy optimization faces several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of motor dynamics and the difficulty in accurately modeling and predicting motor behavior under varying load conditions. This complexity makes it challenging to develop control systems that can consistently achieve optimal energy efficiency across a wide range of operational scenarios.

Another major challenge is the trade-off between energy efficiency and performance. While reducing energy consumption is a key goal, it must be balanced against maintaining or improving motor performance, including factors such as torque output, speed control, and response time. Achieving this balance often requires sophisticated control algorithms and advanced sensing technologies, which can increase system complexity and cost.

The variability of power supply quality presents an additional hurdle for energy optimization efforts. Voltage fluctuations, harmonics, and other power quality issues can significantly impact motor efficiency and complicate the implementation of optimization strategies. Developing control systems that can effectively adapt to these variations while maintaining optimal energy usage is a ongoing challenge in the field.

Furthermore, the integration of energy optimization systems with existing motor installations poses practical difficulties. Many industrial environments have legacy motor systems that may not be easily compatible with advanced control technologies. Retrofitting these systems with energy-efficient controls often requires significant investment and potential disruption to operations, creating barriers to widespread adoption.

The rapid pace of technological advancement in power electronics and digital control systems also presents a challenge. As new technologies emerge, control systems for induction motor energy optimization must evolve to leverage these advancements effectively. This requires continuous research and development efforts to stay at the forefront of energy efficiency technologies.

Additionally, the lack of standardization in energy optimization approaches across different industries and applications complicates the development of universally applicable solutions. Each sector may have unique requirements and constraints, necessitating customized optimization strategies and making it difficult to develop off-the-shelf solutions that can be widely deployed.

Lastly, the increasing emphasis on sustainability and environmental regulations adds another layer of complexity to motor energy optimization. Control systems must not only focus on energy efficiency but also consider factors such as reducing carbon emissions and complying with evolving environmental standards. This multifaceted approach to optimization requires a holistic understanding of both technical and regulatory landscapes, further challenging researchers and engineers in the field.

Another major challenge is the trade-off between energy efficiency and performance. While reducing energy consumption is a key goal, it must be balanced against maintaining or improving motor performance, including factors such as torque output, speed control, and response time. Achieving this balance often requires sophisticated control algorithms and advanced sensing technologies, which can increase system complexity and cost.

The variability of power supply quality presents an additional hurdle for energy optimization efforts. Voltage fluctuations, harmonics, and other power quality issues can significantly impact motor efficiency and complicate the implementation of optimization strategies. Developing control systems that can effectively adapt to these variations while maintaining optimal energy usage is a ongoing challenge in the field.

Furthermore, the integration of energy optimization systems with existing motor installations poses practical difficulties. Many industrial environments have legacy motor systems that may not be easily compatible with advanced control technologies. Retrofitting these systems with energy-efficient controls often requires significant investment and potential disruption to operations, creating barriers to widespread adoption.

The rapid pace of technological advancement in power electronics and digital control systems also presents a challenge. As new technologies emerge, control systems for induction motor energy optimization must evolve to leverage these advancements effectively. This requires continuous research and development efforts to stay at the forefront of energy efficiency technologies.

Additionally, the lack of standardization in energy optimization approaches across different industries and applications complicates the development of universally applicable solutions. Each sector may have unique requirements and constraints, necessitating customized optimization strategies and making it difficult to develop off-the-shelf solutions that can be widely deployed.

Lastly, the increasing emphasis on sustainability and environmental regulations adds another layer of complexity to motor energy optimization. Control systems must not only focus on energy efficiency but also consider factors such as reducing carbon emissions and complying with evolving environmental standards. This multifaceted approach to optimization requires a holistic understanding of both technical and regulatory landscapes, further challenging researchers and engineers in the field.

State-of-the-Art Energy Optimization Techniques

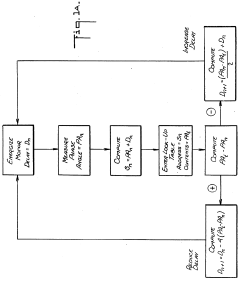

01 Vector control systems for induction motors

Vector control systems are used to improve the performance and efficiency of induction motors. These systems provide precise control of motor speed and torque by manipulating the magnetic flux and current vectors. Advanced algorithms and sensors are employed to estimate motor parameters and optimize control in real-time, resulting in enhanced energy efficiency and dynamic response.- Vector control systems for induction motors: Advanced control techniques using vector control algorithms to improve the performance and efficiency of induction motors. These systems provide precise control of motor torque and speed, enhancing energy efficiency and dynamic response in various applications.

- Energy-efficient motor drive systems: Innovative drive systems designed to optimize energy consumption in induction motors. These systems incorporate advanced power electronics, intelligent control algorithms, and energy recovery mechanisms to minimize losses and improve overall system efficiency.

- Sensorless control techniques for induction motors: Control methods that eliminate the need for physical sensors, reducing system complexity and cost. These techniques use advanced estimation algorithms to determine motor parameters and operating conditions, enabling efficient control without additional hardware.

- Adaptive control systems for induction motors: Intelligent control systems that can adapt to changing motor parameters and operating conditions. These systems use real-time parameter estimation and optimization algorithms to maintain optimal performance and energy efficiency across various operating points.

- Fault detection and diagnosis in induction motor control systems: Advanced monitoring and diagnostic techniques integrated into motor control systems. These methods use signal processing, machine learning, and model-based approaches to detect and diagnose faults in real-time, improving system reliability and preventing energy waste due to faulty operation.

02 Energy-efficient control strategies for induction motors

Various control strategies are implemented to maximize the energy efficiency of induction motors. These include flux optimization, slip control, and loss minimization algorithms. By adjusting the motor's operating parameters based on load conditions, these strategies reduce power consumption and improve overall system efficiency, particularly in variable speed applications.Expand Specific Solutions03 Sensorless control techniques for induction motors

Sensorless control methods eliminate the need for physical speed or position sensors in induction motor systems. These techniques use advanced estimation algorithms to determine motor speed and rotor position based on electrical measurements. Sensorless control reduces system cost, improves reliability, and enables more compact motor designs while maintaining accurate speed and torque control.Expand Specific Solutions04 Fault detection and diagnosis in induction motor control systems

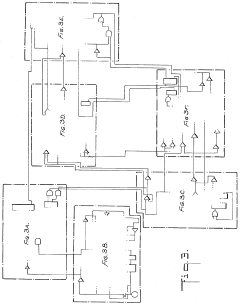

Control systems for induction motors incorporate fault detection and diagnosis capabilities to improve reliability and prevent damage. These systems use advanced signal processing and machine learning techniques to analyze motor parameters and identify potential faults such as bearing failures, stator winding issues, or rotor bar problems. Early detection allows for predictive maintenance and reduces downtime.Expand Specific Solutions05 Integration of power electronics in induction motor control

Modern induction motor control systems integrate advanced power electronic devices and topologies. These include the use of multilevel inverters, matrix converters, and wide-bandgap semiconductors. The integration of power electronics enables more precise control, higher switching frequencies, and improved overall system efficiency. Additionally, these systems often incorporate regenerative braking capabilities to recover energy during deceleration.Expand Specific Solutions

Key Players in Motor Control Industry

The control systems for induction motor energy optimization market is in a growth phase, driven by increasing demand for energy-efficient solutions across industries. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with major players like Honda Motor Co., Robert Bosch GmbH, and Tula Technology leading innovation. Universities such as Huazhong University of Science & Technology and Tianjin University are contributing to research and development. While established companies dominate, emerging players and startups are also entering the market, fostering competition and driving further technological advancements in motor control systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an innovative control system for induction motor energy optimization, primarily focused on hybrid and electric vehicle applications. Their approach utilizes a sophisticated model-based control strategy combined with machine learning algorithms for continuous efficiency improvement. The system employs a unique harmonic injection technique to reduce core losses and improve torque density, achieving up to 8% higher efficiency compared to conventional sinusoidal control methods [13][15]. Honda's control strategy also incorporates a dynamic field weakening algorithm that optimizes motor operation across a wide speed range, maximizing efficiency and extending the vehicle's driving range. Additionally, their system features an advanced thermal management technique that uses predictive models to optimize motor performance while preventing overheating [14].

Strengths: High efficiency across a wide speed range, excellent performance in automotive applications, and advanced thermal management. Weaknesses: May require significant computational resources; potential challenges in adapting to non-automotive applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced control system for induction motor energy optimization, utilizing a combination of field-oriented control (FOC) and model predictive control (MPC) techniques. Their system employs real-time parameter estimation to adapt to motor variations and load changes, ensuring optimal efficiency across a wide operating range. The control algorithm incorporates a sophisticated loss minimization strategy that balances copper and iron losses, achieving up to 15% energy savings compared to conventional scalar control methods [1][3]. Additionally, Bosch's system integrates power factor correction and harmonic reduction features, further enhancing overall system efficiency and power quality [5].

Strengths: Highly adaptive control, significant energy savings, and improved power quality. Weaknesses: Complexity of implementation and potential higher initial costs.

Innovative Control Algorithms for Energy Efficiency

Induction motor control system

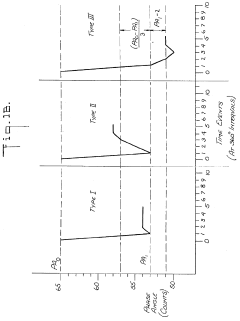

PatentInactiveUS4950970A

Innovation

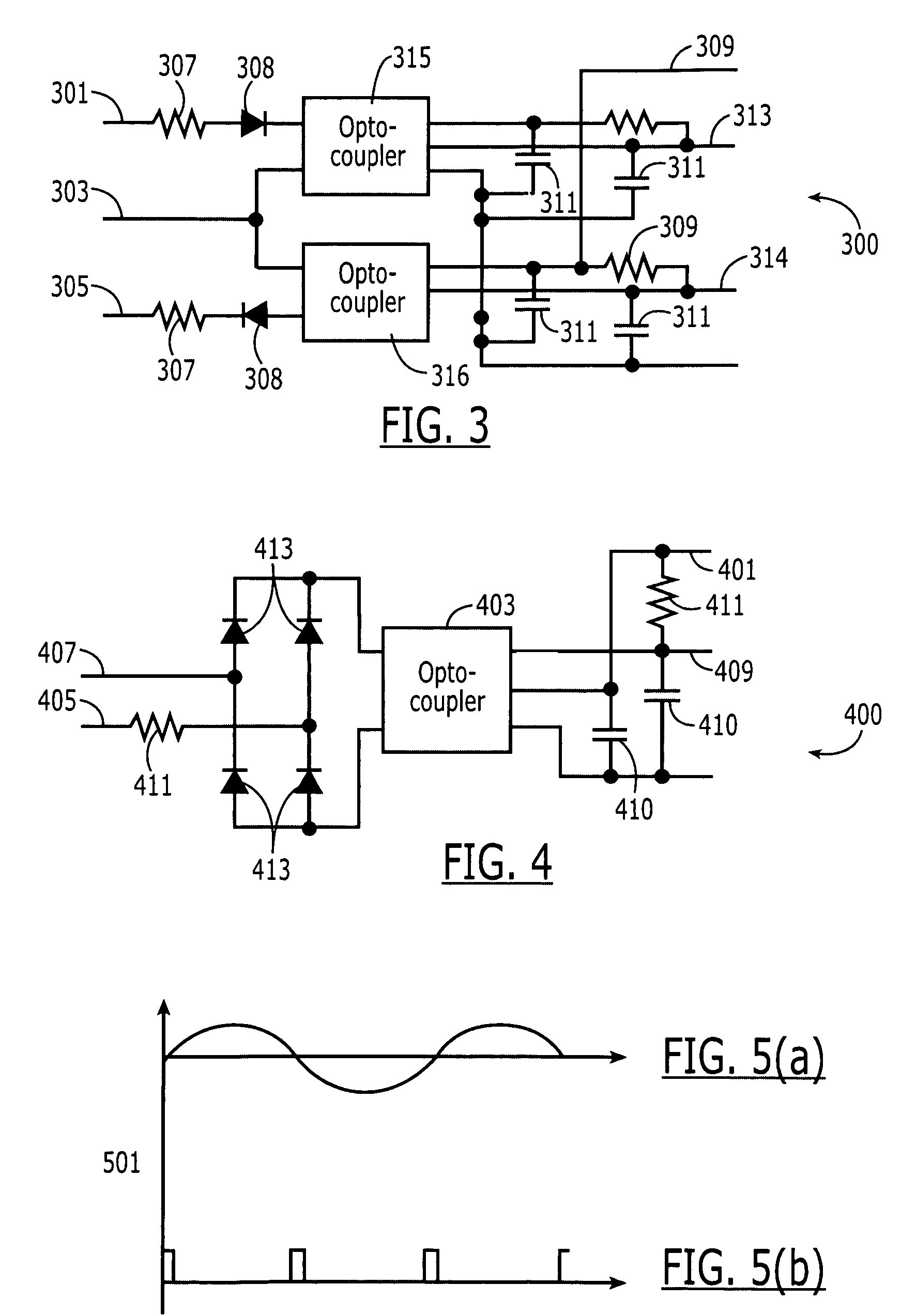

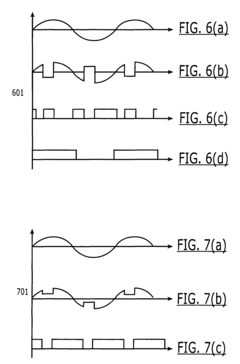

- A method using the equation y=mx+b to approximate changes in phase angle and firing delay with motor load, allowing for dynamic adjustment of firing delay to maximize energy savings through a 'perturbation' technique, where additional delays are introduced to evaluate phase angle behavior and adjust settings until optimal energy efficiency is achieved.

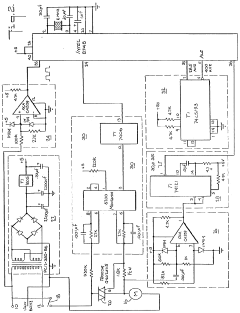

Energy-saving controller for three-phase induction motors

PatentActiveUS8217618B2

Innovation

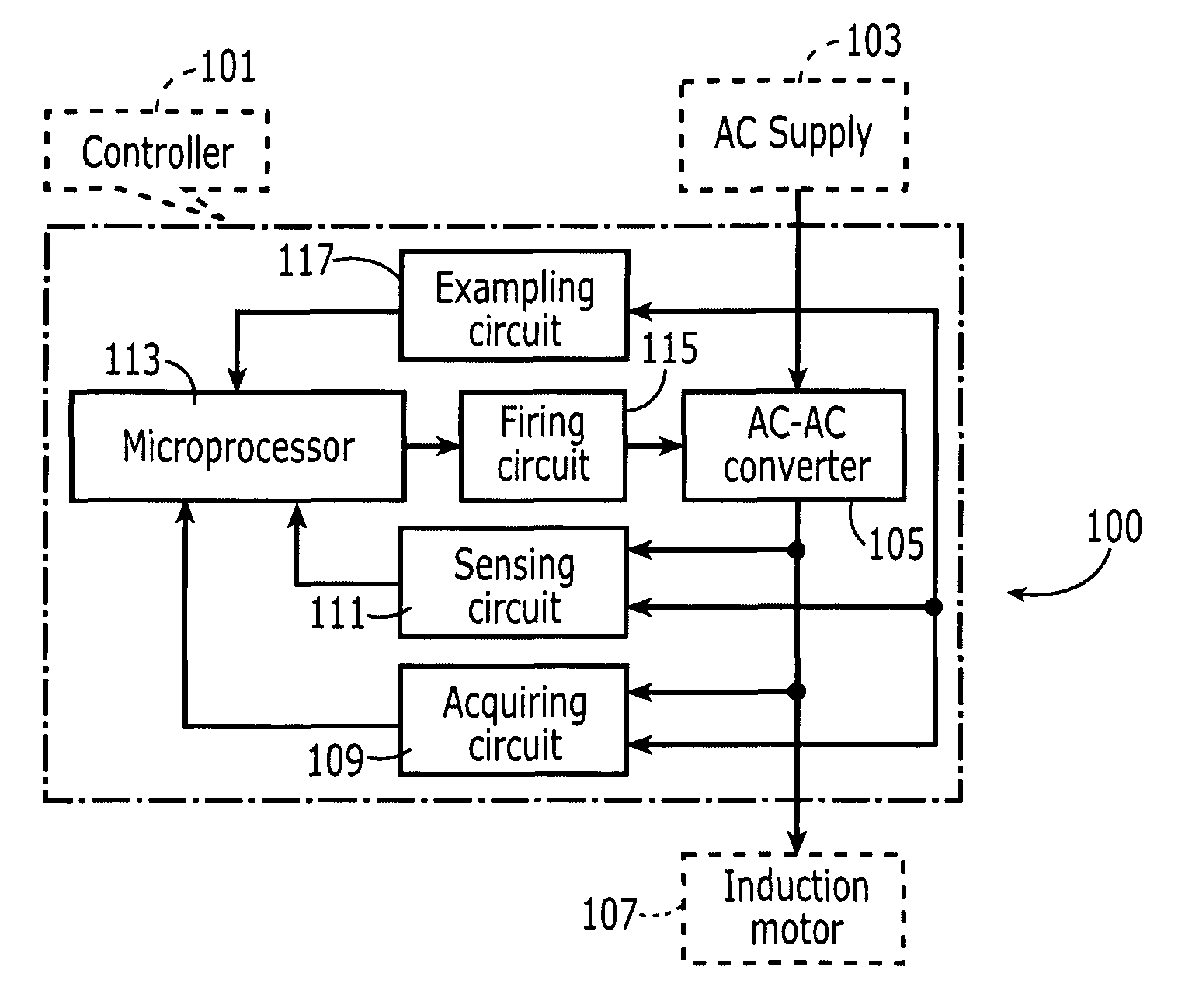

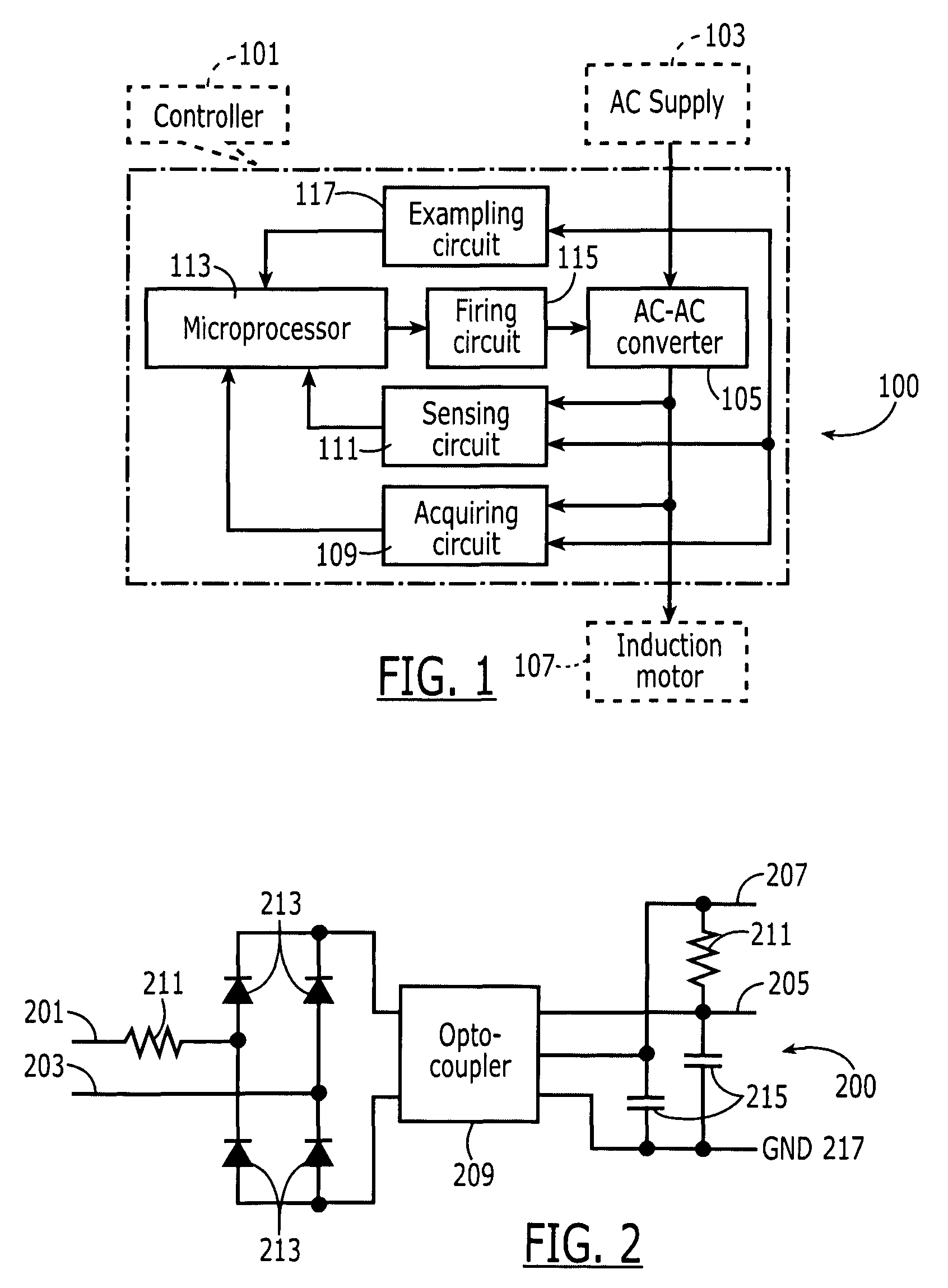

- A controller system for three-phase induction motors that includes an examining circuit for zero-passing points of source voltages, a sensing circuit for load variations, an acquiring circuit for motor current, a processing unit for computing firing angles, and an AC to AC converter to adjust voltage and maintain high efficiency and power factor under light or variable loads.

Industrial Standards and Regulations

The industrial landscape for induction motor energy optimization is heavily influenced by a complex web of standards and regulations. These guidelines are designed to ensure energy efficiency, safety, and environmental sustainability across various sectors. The International Electrotechnical Commission (IEC) plays a pivotal role in setting global standards for electric motors, with IEC 60034-30-1 being particularly significant. This standard defines efficiency classes for induction motors, ranging from IE1 (standard efficiency) to IE4 (super premium efficiency), with ongoing discussions about introducing an IE5 class.

In the United States, the Department of Energy (DOE) has implemented stringent regulations through the Energy Policy and Conservation Act. These regulations mandate minimum efficiency standards for various types of electric motors, including induction motors. The most recent updates to these standards have pushed manufacturers to adopt more advanced control systems and motor designs to meet increasingly demanding efficiency requirements.

The European Union has also been at the forefront of motor efficiency regulations with its Ecodesign Directive. This directive sets minimum energy performance standards (MEPS) for electric motors and drives, encouraging the adoption of high-efficiency motors and advanced control systems. The EU's approach has been particularly influential, often serving as a model for other regions developing their own efficiency standards.

In the context of control systems for induction motor energy optimization, these regulations have spurred innovation in variable frequency drives (VFDs) and other advanced control technologies. Standards such as EN 50598-2 in Europe and IEEE 1566 in the United States provide guidelines for the energy efficiency of motor systems, including the impact of control devices. These standards not only set performance benchmarks but also define testing methods to ensure compliance.

The industrial Internet of Things (IIoT) and Industry 4.0 initiatives have further complicated the regulatory landscape. As control systems become more interconnected and data-driven, new standards are emerging to address cybersecurity concerns and ensure interoperability. The IEC 62443 series, for instance, provides a framework for industrial automation and control system security, which is increasingly relevant for advanced motor control systems.

Compliance with these standards and regulations is not just a legal requirement but also a competitive necessity in the global market. Manufacturers and system integrators must navigate this complex regulatory environment while continuously innovating to improve energy efficiency and performance. As energy costs and environmental concerns continue to drive policy, it is likely that these standards will become even more stringent, further pushing the boundaries of induction motor control system optimization.

In the United States, the Department of Energy (DOE) has implemented stringent regulations through the Energy Policy and Conservation Act. These regulations mandate minimum efficiency standards for various types of electric motors, including induction motors. The most recent updates to these standards have pushed manufacturers to adopt more advanced control systems and motor designs to meet increasingly demanding efficiency requirements.

The European Union has also been at the forefront of motor efficiency regulations with its Ecodesign Directive. This directive sets minimum energy performance standards (MEPS) for electric motors and drives, encouraging the adoption of high-efficiency motors and advanced control systems. The EU's approach has been particularly influential, often serving as a model for other regions developing their own efficiency standards.

In the context of control systems for induction motor energy optimization, these regulations have spurred innovation in variable frequency drives (VFDs) and other advanced control technologies. Standards such as EN 50598-2 in Europe and IEEE 1566 in the United States provide guidelines for the energy efficiency of motor systems, including the impact of control devices. These standards not only set performance benchmarks but also define testing methods to ensure compliance.

The industrial Internet of Things (IIoT) and Industry 4.0 initiatives have further complicated the regulatory landscape. As control systems become more interconnected and data-driven, new standards are emerging to address cybersecurity concerns and ensure interoperability. The IEC 62443 series, for instance, provides a framework for industrial automation and control system security, which is increasingly relevant for advanced motor control systems.

Compliance with these standards and regulations is not just a legal requirement but also a competitive necessity in the global market. Manufacturers and system integrators must navigate this complex regulatory environment while continuously innovating to improve energy efficiency and performance. As energy costs and environmental concerns continue to drive policy, it is likely that these standards will become even more stringent, further pushing the boundaries of induction motor control system optimization.

Economic Impact of Motor Efficiency Improvements

The economic impact of motor efficiency improvements in induction motor control systems is substantial and far-reaching. These advancements not only benefit individual businesses but also contribute to broader economic and environmental goals.

At the industrial level, improved motor efficiency translates directly into reduced energy consumption. This leads to significant cost savings for businesses, particularly in energy-intensive industries where motors account for a large portion of electricity usage. The reduction in operational costs enhances profitability and competitiveness, allowing companies to allocate resources to other areas such as research and development or workforce expansion.

The adoption of energy-efficient motor control systems also stimulates innovation and growth in the manufacturing sector. As demand for these technologies increases, manufacturers invest in developing more advanced and efficient solutions, creating a virtuous cycle of innovation. This drives job creation in engineering, production, and related fields, contributing to overall economic growth.

From a macroeconomic perspective, widespread implementation of efficient motor control systems can lead to reduced national energy demand. This has implications for energy infrastructure planning and investment, potentially reducing the need for new power generation facilities and associated costs. It also enhances energy security by decreasing reliance on imported energy sources.

The environmental benefits of motor efficiency improvements also have economic implications. Reduced energy consumption leads to lower greenhouse gas emissions, helping countries meet their climate change commitments. This can result in avoided costs related to climate change mitigation and adaptation measures. Additionally, it positions countries and businesses favorably in an increasingly environmentally conscious global market.

In the context of global competitiveness, nations and industries that lead in motor efficiency technology gain a strategic advantage. They can export their expertise and products, capturing market share in the growing global market for energy-efficient solutions. This contributes to positive trade balances and economic growth.

The economic impact extends to the consumer level as well. Improved industrial efficiency can lead to lower prices for goods and services, benefiting consumers and potentially stimulating economic activity through increased disposable income. Moreover, the development of efficient motor technologies for industrial applications often leads to spin-off innovations in consumer products, further driving economic activity and improving quality of life.

At the industrial level, improved motor efficiency translates directly into reduced energy consumption. This leads to significant cost savings for businesses, particularly in energy-intensive industries where motors account for a large portion of electricity usage. The reduction in operational costs enhances profitability and competitiveness, allowing companies to allocate resources to other areas such as research and development or workforce expansion.

The adoption of energy-efficient motor control systems also stimulates innovation and growth in the manufacturing sector. As demand for these technologies increases, manufacturers invest in developing more advanced and efficient solutions, creating a virtuous cycle of innovation. This drives job creation in engineering, production, and related fields, contributing to overall economic growth.

From a macroeconomic perspective, widespread implementation of efficient motor control systems can lead to reduced national energy demand. This has implications for energy infrastructure planning and investment, potentially reducing the need for new power generation facilities and associated costs. It also enhances energy security by decreasing reliance on imported energy sources.

The environmental benefits of motor efficiency improvements also have economic implications. Reduced energy consumption leads to lower greenhouse gas emissions, helping countries meet their climate change commitments. This can result in avoided costs related to climate change mitigation and adaptation measures. Additionally, it positions countries and businesses favorably in an increasingly environmentally conscious global market.

In the context of global competitiveness, nations and industries that lead in motor efficiency technology gain a strategic advantage. They can export their expertise and products, capturing market share in the growing global market for energy-efficient solutions. This contributes to positive trade balances and economic growth.

The economic impact extends to the consumer level as well. Improved industrial efficiency can lead to lower prices for goods and services, benefiting consumers and potentially stimulating economic activity through increased disposable income. Moreover, the development of efficient motor technologies for industrial applications often leads to spin-off innovations in consumer products, further driving economic activity and improving quality of life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!