Development of induction motor models for predictive maintenance

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Modeling Background and Objectives

Induction motors have been a cornerstone of industrial applications for over a century, powering everything from manufacturing equipment to HVAC systems. As these motors have become increasingly critical to various industries, the need for effective maintenance strategies has grown in parallel. The development of induction motor models for predictive maintenance represents a significant leap forward in this domain, combining traditional engineering principles with modern data analytics and machine learning techniques.

The evolution of induction motor modeling can be traced back to the early 20th century, with the fundamental principles established by pioneers like Nikola Tesla. However, the advent of digital technology and advanced computational methods in recent decades has revolutionized our approach to motor analysis and prediction. The primary objective of developing these models is to enhance the reliability, efficiency, and longevity of induction motors while minimizing downtime and maintenance costs.

Predictive maintenance, as opposed to reactive or scheduled maintenance, aims to forecast potential failures before they occur. This proactive approach relies heavily on accurate modeling of motor behavior under various operating conditions. The models developed for this purpose must account for a wide range of factors, including electrical characteristics, mechanical properties, thermal dynamics, and environmental influences.

The current technological landscape offers unprecedented opportunities for creating sophisticated induction motor models. The integration of sensors, Internet of Things (IoT) devices, and big data analytics has enabled real-time monitoring and analysis of motor performance. This wealth of data, combined with advanced algorithms, allows for the creation of highly accurate predictive models that can detect subtle changes in motor behavior indicative of impending issues.

As we look towards the future, the development of induction motor models for predictive maintenance is expected to incorporate emerging technologies such as artificial intelligence and digital twins. These advancements promise to further refine our ability to predict and prevent motor failures, ultimately leading to more efficient and reliable industrial operations.

The objectives of developing these models extend beyond mere failure prediction. They aim to optimize motor performance, reduce energy consumption, and extend the operational lifespan of motors. Additionally, these models serve as valuable tools for design engineers, enabling them to create more robust and efficient motors tailored to specific application requirements.

In conclusion, the development of induction motor models for predictive maintenance represents a critical area of technological advancement. It combines historical knowledge with cutting-edge technology to address the pressing needs of modern industry, promising significant improvements in reliability, efficiency, and cost-effectiveness across a wide range of applications.

The evolution of induction motor modeling can be traced back to the early 20th century, with the fundamental principles established by pioneers like Nikola Tesla. However, the advent of digital technology and advanced computational methods in recent decades has revolutionized our approach to motor analysis and prediction. The primary objective of developing these models is to enhance the reliability, efficiency, and longevity of induction motors while minimizing downtime and maintenance costs.

Predictive maintenance, as opposed to reactive or scheduled maintenance, aims to forecast potential failures before they occur. This proactive approach relies heavily on accurate modeling of motor behavior under various operating conditions. The models developed for this purpose must account for a wide range of factors, including electrical characteristics, mechanical properties, thermal dynamics, and environmental influences.

The current technological landscape offers unprecedented opportunities for creating sophisticated induction motor models. The integration of sensors, Internet of Things (IoT) devices, and big data analytics has enabled real-time monitoring and analysis of motor performance. This wealth of data, combined with advanced algorithms, allows for the creation of highly accurate predictive models that can detect subtle changes in motor behavior indicative of impending issues.

As we look towards the future, the development of induction motor models for predictive maintenance is expected to incorporate emerging technologies such as artificial intelligence and digital twins. These advancements promise to further refine our ability to predict and prevent motor failures, ultimately leading to more efficient and reliable industrial operations.

The objectives of developing these models extend beyond mere failure prediction. They aim to optimize motor performance, reduce energy consumption, and extend the operational lifespan of motors. Additionally, these models serve as valuable tools for design engineers, enabling them to create more robust and efficient motors tailored to specific application requirements.

In conclusion, the development of induction motor models for predictive maintenance represents a critical area of technological advancement. It combines historical knowledge with cutting-edge technology to address the pressing needs of modern industry, promising significant improvements in reliability, efficiency, and cost-effectiveness across a wide range of applications.

Predictive Maintenance Market Analysis

The predictive maintenance market for induction motors has been experiencing significant growth in recent years, driven by the increasing adoption of Industry 4.0 technologies and the growing emphasis on operational efficiency across various industrial sectors. This market segment is characterized by a strong demand for solutions that can reduce downtime, optimize maintenance schedules, and extend the lifespan of critical equipment.

The global predictive maintenance market, which includes induction motor applications, was valued at approximately $4 billion in 2020 and is projected to reach over $12 billion by 2026, with a compound annual growth rate (CAGR) of around 25%. This growth is primarily fueled by the manufacturing, energy, and transportation sectors, where induction motors play a crucial role in various processes and operations.

In the manufacturing industry, which accounts for a substantial portion of the market, predictive maintenance solutions for induction motors are being increasingly adopted to minimize production disruptions and improve overall equipment effectiveness (OEE). The energy sector, particularly power generation and distribution, is another key driver of market growth, as utilities seek to enhance the reliability and efficiency of their motor-driven systems.

The transportation sector, including automotive and aerospace industries, is also contributing significantly to the market expansion. In these industries, predictive maintenance models for induction motors are being utilized to ensure the safety and reliability of critical systems, such as electric vehicle powertrains and aircraft components.

Geographically, North America and Europe currently dominate the predictive maintenance market for induction motors, owing to their advanced industrial infrastructure and early adoption of IoT and AI technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in smart manufacturing, and government initiatives promoting Industry 4.0 adoption.

The market is characterized by a mix of established industrial technology providers and innovative startups specializing in predictive maintenance solutions. Key players are focusing on developing advanced analytics platforms, integrating machine learning algorithms, and leveraging edge computing to enhance the accuracy and real-time capabilities of their predictive maintenance models for induction motors.

As the market continues to evolve, there is a growing trend towards the development of more sophisticated and specialized predictive maintenance solutions tailored to specific industries and motor types. This specialization is expected to drive further market segmentation and create new opportunities for niche players in the coming years.

The global predictive maintenance market, which includes induction motor applications, was valued at approximately $4 billion in 2020 and is projected to reach over $12 billion by 2026, with a compound annual growth rate (CAGR) of around 25%. This growth is primarily fueled by the manufacturing, energy, and transportation sectors, where induction motors play a crucial role in various processes and operations.

In the manufacturing industry, which accounts for a substantial portion of the market, predictive maintenance solutions for induction motors are being increasingly adopted to minimize production disruptions and improve overall equipment effectiveness (OEE). The energy sector, particularly power generation and distribution, is another key driver of market growth, as utilities seek to enhance the reliability and efficiency of their motor-driven systems.

The transportation sector, including automotive and aerospace industries, is also contributing significantly to the market expansion. In these industries, predictive maintenance models for induction motors are being utilized to ensure the safety and reliability of critical systems, such as electric vehicle powertrains and aircraft components.

Geographically, North America and Europe currently dominate the predictive maintenance market for induction motors, owing to their advanced industrial infrastructure and early adoption of IoT and AI technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing investments in smart manufacturing, and government initiatives promoting Industry 4.0 adoption.

The market is characterized by a mix of established industrial technology providers and innovative startups specializing in predictive maintenance solutions. Key players are focusing on developing advanced analytics platforms, integrating machine learning algorithms, and leveraging edge computing to enhance the accuracy and real-time capabilities of their predictive maintenance models for induction motors.

As the market continues to evolve, there is a growing trend towards the development of more sophisticated and specialized predictive maintenance solutions tailored to specific industries and motor types. This specialization is expected to drive further market segmentation and create new opportunities for niche players in the coming years.

Current Challenges in Motor Health Monitoring

Motor health monitoring is a critical aspect of predictive maintenance for induction motors, yet it faces several significant challenges in its current state. One of the primary obstacles is the complexity of accurately detecting and diagnosing faults in real-time operational environments. The dynamic nature of motor operations, coupled with varying load conditions and environmental factors, makes it difficult to distinguish between normal operational fluctuations and early signs of potential failures.

Another challenge lies in the selection and integration of appropriate sensors for comprehensive motor health monitoring. While various sensing technologies are available, including vibration sensors, current sensors, and thermal imaging, each has its limitations in terms of accuracy, reliability, and cost-effectiveness. Determining the optimal combination of sensors and their placement to capture all relevant data without overwhelming the system with unnecessary information remains a significant hurdle.

Data interpretation and analysis present another set of challenges. The vast amount of data generated by multiple sensors requires sophisticated algorithms and processing capabilities to extract meaningful insights. Developing robust models that can accurately interpret this data, identify patterns indicative of potential issues, and predict future failures with a high degree of confidence is an ongoing challenge in the field.

The issue of false alarms and missed detections further complicates motor health monitoring. Overly sensitive systems may trigger frequent false alarms, leading to unnecessary maintenance interventions and reduced operational efficiency. Conversely, systems that are not sensitive enough may fail to detect critical issues in their early stages, potentially resulting in catastrophic failures and costly downtime.

Standardization and interoperability pose additional challenges in the industry. The lack of universally accepted standards for motor health monitoring systems makes it difficult to compare and integrate solutions from different vendors. This fragmentation can lead to compatibility issues and hinder the widespread adoption of advanced monitoring technologies across diverse industrial settings.

Furthermore, the cost-benefit analysis of implementing comprehensive motor health monitoring systems remains a challenge for many organizations. While the long-term benefits of predictive maintenance are clear, the initial investment in sensors, data acquisition systems, and analytics platforms can be substantial. Justifying these costs, particularly for smaller operations or in industries with tight profit margins, requires careful consideration and clear demonstration of return on investment.

Lastly, the shortage of skilled personnel capable of interpreting complex motor health data and making informed maintenance decisions presents an ongoing challenge. As monitoring systems become more sophisticated, there is an increasing need for specialized training and expertise to effectively utilize these tools and translate data insights into actionable maintenance strategies.

Another challenge lies in the selection and integration of appropriate sensors for comprehensive motor health monitoring. While various sensing technologies are available, including vibration sensors, current sensors, and thermal imaging, each has its limitations in terms of accuracy, reliability, and cost-effectiveness. Determining the optimal combination of sensors and their placement to capture all relevant data without overwhelming the system with unnecessary information remains a significant hurdle.

Data interpretation and analysis present another set of challenges. The vast amount of data generated by multiple sensors requires sophisticated algorithms and processing capabilities to extract meaningful insights. Developing robust models that can accurately interpret this data, identify patterns indicative of potential issues, and predict future failures with a high degree of confidence is an ongoing challenge in the field.

The issue of false alarms and missed detections further complicates motor health monitoring. Overly sensitive systems may trigger frequent false alarms, leading to unnecessary maintenance interventions and reduced operational efficiency. Conversely, systems that are not sensitive enough may fail to detect critical issues in their early stages, potentially resulting in catastrophic failures and costly downtime.

Standardization and interoperability pose additional challenges in the industry. The lack of universally accepted standards for motor health monitoring systems makes it difficult to compare and integrate solutions from different vendors. This fragmentation can lead to compatibility issues and hinder the widespread adoption of advanced monitoring technologies across diverse industrial settings.

Furthermore, the cost-benefit analysis of implementing comprehensive motor health monitoring systems remains a challenge for many organizations. While the long-term benefits of predictive maintenance are clear, the initial investment in sensors, data acquisition systems, and analytics platforms can be substantial. Justifying these costs, particularly for smaller operations or in industries with tight profit margins, requires careful consideration and clear demonstration of return on investment.

Lastly, the shortage of skilled personnel capable of interpreting complex motor health data and making informed maintenance decisions presents an ongoing challenge. As monitoring systems become more sophisticated, there is an increasing need for specialized training and expertise to effectively utilize these tools and translate data insights into actionable maintenance strategies.

Existing Predictive Maintenance Solutions

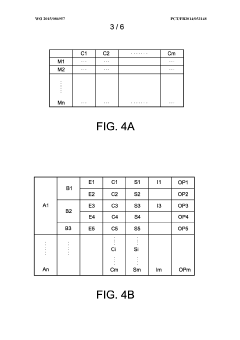

01 Mathematical modeling of induction motors

This approach involves developing mathematical models to represent the behavior and characteristics of induction motors. These models typically include equations describing the electrical and mechanical aspects of the motor, such as voltage, current, torque, and speed relationships. Mathematical modeling helps in analyzing motor performance, predicting behavior under various operating conditions, and optimizing design parameters.- Mathematical modeling of induction motors: This approach involves developing mathematical models to represent the behavior and characteristics of induction motors. These models can include equations for electromagnetic fields, rotor dynamics, and electrical circuits. They are used for performance analysis, design optimization, and control system development.

- Simulation and analysis of induction motor performance: Various simulation techniques and software tools are used to analyze induction motor performance under different operating conditions. These simulations can predict motor efficiency, torque characteristics, and thermal behavior, helping engineers optimize motor designs and control strategies.

- Advanced control strategies for induction motors: This category focuses on developing and implementing sophisticated control algorithms for induction motors. These may include vector control, direct torque control, and adaptive control techniques to improve motor performance, efficiency, and responsiveness in various applications.

- Fault detection and diagnosis models: These models are designed to identify and diagnose various faults in induction motors, such as bearing failures, rotor bar breakages, and stator winding issues. They often employ signal processing techniques, machine learning algorithms, and expert systems to analyze motor data and detect anomalies.

- Energy efficiency modeling and optimization: This approach focuses on developing models to analyze and improve the energy efficiency of induction motors. These models consider factors such as motor design, operating conditions, and control strategies to minimize energy losses and maximize overall system efficiency.

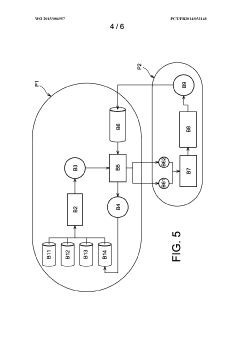

02 Simulation and digital twin models

Simulation models and digital twins are used to create virtual representations of induction motors. These models allow for testing and analysis of motor performance in various scenarios without the need for physical prototypes. They can incorporate real-time data and machine learning algorithms to improve accuracy and predictive capabilities, enabling better design, optimization, and maintenance strategies.Expand Specific Solutions03 Thermal modeling of induction motors

Thermal modeling focuses on understanding and predicting the heat generation and distribution within induction motors. These models consider factors such as winding temperatures, cooling systems, and thermal resistance. Accurate thermal modeling is crucial for optimizing motor design, preventing overheating, and ensuring long-term reliability and efficiency of the motor.Expand Specific Solutions04 Fault detection and diagnosis models

These models are designed to identify and analyze potential faults in induction motors. They use various techniques such as signal processing, pattern recognition, and artificial intelligence to detect abnormalities in motor operation. Fault detection models help in predictive maintenance, reducing downtime, and improving overall motor reliability.Expand Specific Solutions05 Efficiency and performance optimization models

These models focus on improving the efficiency and performance of induction motors. They typically involve analyzing and optimizing various parameters such as winding design, magnetic circuit, and control strategies. The goal is to maximize power output while minimizing losses, leading to more energy-efficient and cost-effective motor designs.Expand Specific Solutions

Key Players in Motor Diagnostics Industry

The development of induction motor models for predictive maintenance is in a growth phase, with increasing market size due to the rising demand for efficient industrial operations. The technology's maturity is advancing, with key players like Cummins, Inc. and Schneider Electric Industries SASU leading innovation. Companies such as Sentient Science Corp. and Huizhian Information Technology Co Ltd. are leveraging AI and machine learning to enhance predictive capabilities. Academic institutions like Zhejiang University and Xi'an University of Technology are contributing to research advancements. The competitive landscape is diverse, including both established industrial giants and specialized technology firms, indicating a dynamic and evolving market.

KT Corp.

Technical Solution: KT Corp. has developed an innovative induction motor model for predictive maintenance leveraging their expertise in telecommunications and IoT technologies. Their approach focuses on creating a highly connected and responsive monitoring system for industrial motors. KT's model utilizes a dense network of IoT sensors to capture a wide range of motor parameters, including electrical, mechanical, and environmental data[10]. The system employs advanced signal processing techniques and machine learning algorithms, particularly ensemble methods like Random Forest and XGBoost, to analyze the high-dimensional sensor data and identify patterns indicative of potential failures. A unique aspect of KT's approach is the integration of 5G network technology, enabling ultra-low latency communication between sensors and central processing units. This allows for near real-time analysis and rapid response to detected anomalies. Additionally, KT has implemented blockchain technology to ensure the integrity and traceability of maintenance records and sensor data[11].

Strengths: Utilization of advanced telecommunications technology for ultra-low latency monitoring; blockchain integration for data integrity. Weaknesses: May require significant infrastructure upgrades for full implementation; potential challenges in adapting to legacy industrial environments.

Schneider Electric Industries SASU

Technical Solution: Schneider Electric has developed a comprehensive induction motor model for predictive maintenance as part of their EcoStruxure Machine platform. Their approach combines real-time monitoring with advanced analytics to provide actionable insights for maintenance planning. The system utilizes a range of sensors, including current transformers, voltage sensors, and accelerometers, to capture detailed motor performance data[7]. Schneider's model employs machine learning algorithms, particularly gradient boosting and long short-term memory (LSTM) networks, to analyze temporal patterns and predict potential failures. A key feature of their system is the integration with cloud-based analytics platforms, allowing for scalable processing of large datasets and continuous model improvement. Schneider Electric also incorporates augmented reality technologies for maintenance guidance, enabling technicians to visualize motor health status and receive step-by-step repair instructions in real-time[9].

Strengths: Integration with cloud-based analytics for scalable processing; augmented reality features for maintenance support. Weaknesses: Dependence on cloud connectivity may pose challenges in some industrial environments; potential cybersecurity concerns with cloud-based systems.

Advanced Motor Modeling Innovations

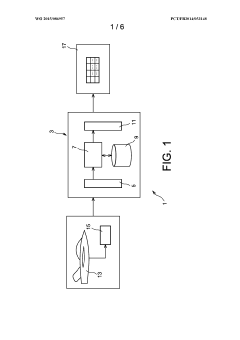

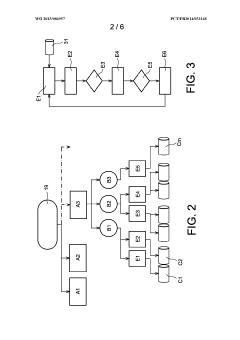

System for predictive maintenance of induction motor

PatentPendingIN202211074089A

Innovation

- A predictive maintenance system that uses current and voltage sensors, a pulse generator, and a processor to analyze motor torque profiles through Fast Fourier Transform, correcting phase angle values and identifying diagnostically informative spectrum components, independent of voltage amplitude and frequency, for remote detection of mechanical failures.

Forecasting maintenance operations to be applied to an engine

PatentWO2015086957A2

Innovation

- A method that simulates damage counter consumption using a learning database to predict maintenance operations by iteratively drawing simulation missions and applying maintenance strategies, allowing for flexible and cost-effective planning without requiring statistical knowledge.

Industrial IoT Integration for Motor Monitoring

The integration of Industrial Internet of Things (IIoT) technologies for motor monitoring represents a significant advancement in predictive maintenance strategies for induction motors. This approach leverages interconnected sensors, data analytics, and cloud computing to provide real-time insights into motor performance and health. By implementing IIoT solutions, organizations can continuously monitor critical parameters such as temperature, vibration, current, and voltage, enabling early detection of potential issues and optimizing maintenance schedules.

IIoT integration for motor monitoring typically involves the deployment of smart sensors throughout the motor system. These sensors collect high-resolution data on various operational aspects, including electrical characteristics, mechanical vibrations, and thermal conditions. The data is then transmitted through secure communication protocols to centralized platforms or edge computing devices for processing and analysis.

Advanced analytics algorithms, often incorporating machine learning techniques, process the collected data to identify patterns, anomalies, and trends indicative of motor degradation or impending failures. These algorithms can detect subtle changes in motor behavior that may not be apparent through traditional monitoring methods, allowing for more accurate predictions of maintenance needs and potential failures.

Cloud-based platforms play a crucial role in IIoT motor monitoring systems, providing scalable storage and computing resources for data aggregation, analysis, and visualization. These platforms often offer user-friendly dashboards and reporting tools, enabling maintenance teams to access real-time motor health information and historical performance data from any location with internet connectivity.

The implementation of IIoT for motor monitoring also facilitates the development of digital twin models. These virtual representations of physical motors can be continuously updated with real-time data, allowing for simulation and prediction of motor behavior under various operating conditions. This capability enhances the accuracy of predictive maintenance models and supports optimization of motor performance and energy efficiency.

Furthermore, IIoT integration enables the creation of comprehensive asset management systems that extend beyond individual motors to encompass entire production lines or facilities. By correlating motor performance data with other operational metrics, organizations can gain deeper insights into overall system efficiency and identify opportunities for process improvements and cost reductions.

IIoT integration for motor monitoring typically involves the deployment of smart sensors throughout the motor system. These sensors collect high-resolution data on various operational aspects, including electrical characteristics, mechanical vibrations, and thermal conditions. The data is then transmitted through secure communication protocols to centralized platforms or edge computing devices for processing and analysis.

Advanced analytics algorithms, often incorporating machine learning techniques, process the collected data to identify patterns, anomalies, and trends indicative of motor degradation or impending failures. These algorithms can detect subtle changes in motor behavior that may not be apparent through traditional monitoring methods, allowing for more accurate predictions of maintenance needs and potential failures.

Cloud-based platforms play a crucial role in IIoT motor monitoring systems, providing scalable storage and computing resources for data aggregation, analysis, and visualization. These platforms often offer user-friendly dashboards and reporting tools, enabling maintenance teams to access real-time motor health information and historical performance data from any location with internet connectivity.

The implementation of IIoT for motor monitoring also facilitates the development of digital twin models. These virtual representations of physical motors can be continuously updated with real-time data, allowing for simulation and prediction of motor behavior under various operating conditions. This capability enhances the accuracy of predictive maintenance models and supports optimization of motor performance and energy efficiency.

Furthermore, IIoT integration enables the creation of comprehensive asset management systems that extend beyond individual motors to encompass entire production lines or facilities. By correlating motor performance data with other operational metrics, organizations can gain deeper insights into overall system efficiency and identify opportunities for process improvements and cost reductions.

Cost-Benefit Analysis of Predictive Maintenance

The implementation of predictive maintenance strategies for induction motors presents a compelling cost-benefit proposition for industrial organizations. By leveraging advanced modeling techniques and data analytics, companies can significantly reduce unplanned downtime, extend equipment lifespan, and optimize maintenance schedules.

One of the primary benefits of predictive maintenance is the substantial reduction in maintenance costs. Traditional reactive maintenance approaches often result in costly emergency repairs and production losses. In contrast, predictive maintenance allows for planned interventions, reducing the need for expensive rush orders and overtime labor. Studies have shown that predictive maintenance can lead to a 25-30% reduction in maintenance costs and a 70-75% decrease in breakdowns.

The improved reliability and uptime of induction motors directly translate to increased productivity and revenue. By minimizing unexpected failures, organizations can maintain consistent production schedules, meet customer demands more effectively, and avoid penalties associated with missed deadlines. The potential increase in overall equipment effectiveness (OEE) can result in a 20-25% boost in production capacity.

Energy efficiency is another significant benefit of predictive maintenance for induction motors. Well-maintained motors operate at peak efficiency, consuming less energy and reducing utility costs. This not only contributes to cost savings but also aligns with sustainability goals, potentially leading to additional benefits such as carbon credits or improved corporate image.

However, the implementation of predictive maintenance systems does require initial investments. These costs include the installation of sensors, data acquisition systems, and analytics platforms. Additionally, staff training and the potential need for specialized personnel to interpret data and manage the system must be considered. The typical payback period for such investments ranges from 12 to 18 months, depending on the scale and complexity of the operation.

Long-term cost savings extend beyond direct maintenance expenses. By predicting and preventing failures, organizations can avoid costly secondary damage to related equipment and systems. Furthermore, the extended lifespan of induction motors due to optimized maintenance reduces the frequency of capital expenditures for replacements.

Risk mitigation is an often-overlooked benefit of predictive maintenance. By reducing the likelihood of catastrophic failures, companies can minimize safety risks, potential environmental incidents, and associated legal liabilities. This proactive approach can lead to reduced insurance premiums and improved regulatory compliance.

In conclusion, while the initial investment in predictive maintenance for induction motors may seem substantial, the long-term benefits significantly outweigh the costs. Organizations that successfully implement these strategies can expect to see improvements in operational efficiency, cost reduction, and overall competitiveness in their respective industries.

One of the primary benefits of predictive maintenance is the substantial reduction in maintenance costs. Traditional reactive maintenance approaches often result in costly emergency repairs and production losses. In contrast, predictive maintenance allows for planned interventions, reducing the need for expensive rush orders and overtime labor. Studies have shown that predictive maintenance can lead to a 25-30% reduction in maintenance costs and a 70-75% decrease in breakdowns.

The improved reliability and uptime of induction motors directly translate to increased productivity and revenue. By minimizing unexpected failures, organizations can maintain consistent production schedules, meet customer demands more effectively, and avoid penalties associated with missed deadlines. The potential increase in overall equipment effectiveness (OEE) can result in a 20-25% boost in production capacity.

Energy efficiency is another significant benefit of predictive maintenance for induction motors. Well-maintained motors operate at peak efficiency, consuming less energy and reducing utility costs. This not only contributes to cost savings but also aligns with sustainability goals, potentially leading to additional benefits such as carbon credits or improved corporate image.

However, the implementation of predictive maintenance systems does require initial investments. These costs include the installation of sensors, data acquisition systems, and analytics platforms. Additionally, staff training and the potential need for specialized personnel to interpret data and manage the system must be considered. The typical payback period for such investments ranges from 12 to 18 months, depending on the scale and complexity of the operation.

Long-term cost savings extend beyond direct maintenance expenses. By predicting and preventing failures, organizations can avoid costly secondary damage to related equipment and systems. Furthermore, the extended lifespan of induction motors due to optimized maintenance reduces the frequency of capital expenditures for replacements.

Risk mitigation is an often-overlooked benefit of predictive maintenance. By reducing the likelihood of catastrophic failures, companies can minimize safety risks, potential environmental incidents, and associated legal liabilities. This proactive approach can lead to reduced insurance premiums and improved regulatory compliance.

In conclusion, while the initial investment in predictive maintenance for induction motors may seem substantial, the long-term benefits significantly outweigh the costs. Organizations that successfully implement these strategies can expect to see improvements in operational efficiency, cost reduction, and overall competitiveness in their respective industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!