Diesel Particulate Filter Cleaning vs Regeneration Efficiency

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPF Technology Evolution and Objectives

Diesel Particulate Filters (DPFs) emerged in the early 1980s as a response to increasingly stringent emission regulations targeting particulate matter from diesel engines. The initial DPF designs were simple ceramic honeycomb structures with limited filtration efficiency and durability. These early systems lacked sophisticated regeneration mechanisms, often leading to filter clogging and performance degradation over relatively short operational periods.

The evolution of DPF technology accelerated significantly in the late 1990s when European and North American regulatory bodies introduced more comprehensive emission standards. This regulatory pressure catalyzed substantial investments in research and development, resulting in the introduction of second-generation DPFs featuring improved substrate materials, enhanced coating technologies, and more effective regeneration strategies.

By the early 2000s, active regeneration systems began to emerge, utilizing fuel injection or electrical heating elements to initiate the combustion of accumulated particulate matter. This marked a critical advancement in DPF technology, as it addressed one of the most significant challenges: maintaining filter performance over extended operational periods without requiring frequent manual cleaning interventions.

The technological trajectory continued with the development of passive-active hybrid systems in the mid-2000s, which combined the benefits of continuous passive regeneration during normal operation with supplementary active regeneration during unfavorable conditions. This approach optimized fuel efficiency while maintaining robust emission control performance across diverse operational scenarios.

Recent technological innovations have focused on enhancing the relationship between cleaning methodologies and regeneration efficiency. Advanced sensor technologies now enable real-time monitoring of filter loading conditions, allowing for more precise timing of regeneration events. Computational fluid dynamics modeling has facilitated the optimization of filter geometries and substrate materials, resulting in designs that balance filtration efficiency with regeneration effectiveness.

The current technological objective centers on developing DPF systems that maintain optimal performance throughout their operational lifetime while minimizing the frequency and energy requirements of both regeneration events and manual cleaning interventions. This includes exploring novel catalyst formulations that lower regeneration temperature thresholds, advanced substrate materials with improved thermal stability, and intelligent control algorithms that adapt regeneration strategies based on operational conditions.

Looking forward, the industry aims to achieve a paradigm shift from periodic maintenance to predictive maintenance models, where cleaning interventions are precisely timed based on actual filter condition rather than predetermined service intervals. This evolution seeks to maximize filter lifespan, minimize operational disruptions, and optimize the balance between cleaning effectiveness and regeneration efficiency across diverse operational environments.

The evolution of DPF technology accelerated significantly in the late 1990s when European and North American regulatory bodies introduced more comprehensive emission standards. This regulatory pressure catalyzed substantial investments in research and development, resulting in the introduction of second-generation DPFs featuring improved substrate materials, enhanced coating technologies, and more effective regeneration strategies.

By the early 2000s, active regeneration systems began to emerge, utilizing fuel injection or electrical heating elements to initiate the combustion of accumulated particulate matter. This marked a critical advancement in DPF technology, as it addressed one of the most significant challenges: maintaining filter performance over extended operational periods without requiring frequent manual cleaning interventions.

The technological trajectory continued with the development of passive-active hybrid systems in the mid-2000s, which combined the benefits of continuous passive regeneration during normal operation with supplementary active regeneration during unfavorable conditions. This approach optimized fuel efficiency while maintaining robust emission control performance across diverse operational scenarios.

Recent technological innovations have focused on enhancing the relationship between cleaning methodologies and regeneration efficiency. Advanced sensor technologies now enable real-time monitoring of filter loading conditions, allowing for more precise timing of regeneration events. Computational fluid dynamics modeling has facilitated the optimization of filter geometries and substrate materials, resulting in designs that balance filtration efficiency with regeneration effectiveness.

The current technological objective centers on developing DPF systems that maintain optimal performance throughout their operational lifetime while minimizing the frequency and energy requirements of both regeneration events and manual cleaning interventions. This includes exploring novel catalyst formulations that lower regeneration temperature thresholds, advanced substrate materials with improved thermal stability, and intelligent control algorithms that adapt regeneration strategies based on operational conditions.

Looking forward, the industry aims to achieve a paradigm shift from periodic maintenance to predictive maintenance models, where cleaning interventions are precisely timed based on actual filter condition rather than predetermined service intervals. This evolution seeks to maximize filter lifespan, minimize operational disruptions, and optimize the balance between cleaning effectiveness and regeneration efficiency across diverse operational environments.

Market Demand Analysis for DPF Solutions

The global market for Diesel Particulate Filter (DPF) solutions has experienced significant growth over the past decade, driven primarily by increasingly stringent emission regulations across major automotive markets. The demand for effective DPF cleaning and regeneration technologies has surged as diesel vehicles continue to represent a substantial portion of commercial and passenger vehicle fleets worldwide, particularly in Europe and emerging markets.

Current market analysis indicates that the global DPF market was valued at approximately $12 billion in 2022, with projections suggesting a compound annual growth rate of 8.3% through 2028. This growth trajectory is supported by several key demand factors, including the implementation of Euro 7 standards in Europe, China 6 emissions standards, and similar regulatory frameworks in North America and other regions that mandate lower particulate matter emissions.

The commercial vehicle segment represents the largest market share for DPF solutions, accounting for over 60% of the total market value. This dominance stems from the higher soot accumulation rates in commercial diesel engines and the critical need for reliable cleaning and regeneration systems to maintain operational efficiency and compliance with emissions standards.

Fleet operators and vehicle owners are increasingly seeking cost-effective maintenance solutions that maximize DPF lifespan while minimizing vehicle downtime. Market research indicates that the average DPF replacement cost ranges from $1,500 to $4,000 depending on vehicle type, creating strong economic incentives for efficient cleaning and regeneration technologies that can extend filter life.

The aftermarket segment for DPF cleaning services has witnessed particularly robust growth, expanding at approximately 9.5% annually as the global diesel vehicle parc ages and requires more frequent maintenance. This trend has spurred innovation in both on-vehicle regeneration systems and off-vehicle cleaning technologies, with customers increasingly valuing solutions that offer complete soot removal without damaging the filter substrate.

Regional market analysis reveals that Europe currently leads the DPF solutions market with approximately 38% share, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging markets such as India, Brazil, and Southeast Asian countries, where diesel vehicle adoption remains strong and emission regulations are progressively tightening.

The market is also witnessing a shift toward integrated solutions that combine advanced sensors, predictive maintenance capabilities, and more efficient regeneration technologies. This trend aligns with broader industry movements toward connected vehicle ecosystems and data-driven maintenance approaches, creating new value propositions for both OEMs and aftermarket service providers in the DPF solutions space.

Current market analysis indicates that the global DPF market was valued at approximately $12 billion in 2022, with projections suggesting a compound annual growth rate of 8.3% through 2028. This growth trajectory is supported by several key demand factors, including the implementation of Euro 7 standards in Europe, China 6 emissions standards, and similar regulatory frameworks in North America and other regions that mandate lower particulate matter emissions.

The commercial vehicle segment represents the largest market share for DPF solutions, accounting for over 60% of the total market value. This dominance stems from the higher soot accumulation rates in commercial diesel engines and the critical need for reliable cleaning and regeneration systems to maintain operational efficiency and compliance with emissions standards.

Fleet operators and vehicle owners are increasingly seeking cost-effective maintenance solutions that maximize DPF lifespan while minimizing vehicle downtime. Market research indicates that the average DPF replacement cost ranges from $1,500 to $4,000 depending on vehicle type, creating strong economic incentives for efficient cleaning and regeneration technologies that can extend filter life.

The aftermarket segment for DPF cleaning services has witnessed particularly robust growth, expanding at approximately 9.5% annually as the global diesel vehicle parc ages and requires more frequent maintenance. This trend has spurred innovation in both on-vehicle regeneration systems and off-vehicle cleaning technologies, with customers increasingly valuing solutions that offer complete soot removal without damaging the filter substrate.

Regional market analysis reveals that Europe currently leads the DPF solutions market with approximately 38% share, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging markets such as India, Brazil, and Southeast Asian countries, where diesel vehicle adoption remains strong and emission regulations are progressively tightening.

The market is also witnessing a shift toward integrated solutions that combine advanced sensors, predictive maintenance capabilities, and more efficient regeneration technologies. This trend aligns with broader industry movements toward connected vehicle ecosystems and data-driven maintenance approaches, creating new value propositions for both OEMs and aftermarket service providers in the DPF solutions space.

Current DPF Cleaning Challenges

Despite significant advancements in Diesel Particulate Filter (DPF) technology, the industry continues to face substantial challenges in cleaning and maintenance processes that directly impact regeneration efficiency. Current cleaning methods often fail to completely remove accumulated ash and soot, particularly in the microscopic channels of the filter substrate, leading to gradual performance degradation over multiple cleaning cycles.

The most prevalent challenge is the inability to achieve consistent cleaning quality across the entire filter structure. Traditional cleaning methods such as compressed air blowing and thermal treatment demonstrate uneven cleaning patterns, with peripheral areas receiving more thorough cleaning while central regions remain partially clogged. This inconsistency creates unbalanced flow distribution during subsequent operation, reducing overall filtration efficiency and accelerating localized thermal stress.

Chemical cleaning solutions present their own set of complications, including potential damage to the catalyst coatings essential for passive regeneration processes. Studies indicate that aggressive chemical cleaners can reduce catalyst effectiveness by up to 30%, significantly compromising the filter's ability to self-regenerate during normal operation conditions. This degradation necessitates more frequent active regeneration cycles, increasing fuel consumption and operational costs.

Temperature management during cleaning procedures represents another critical challenge. Excessive thermal gradients during cleaning can create microfractures in the ceramic substrate, compromising structural integrity and creating bypass channels that reduce filtration efficiency. Conversely, insufficient temperatures fail to adequately remove carbonaceous deposits, particularly those deeply embedded within the filter walls.

Workshop-level cleaning procedures suffer from standardization issues, with significant variations in equipment calibration, process duration, and quality control measures across service providers. This inconsistency makes it difficult for fleet operators to maintain predictable maintenance schedules and costs. Industry surveys reveal that up to 40% of cleaned DPFs require premature replacement due to inadequate cleaning procedures.

The economic implications of these challenges are substantial. Ineffective cleaning not only shortens filter lifespan but also increases vehicle downtime and maintenance costs. The average service life reduction due to improper cleaning is estimated at 20-30%, representing significant additional expenses for commercial fleet operators who typically manage hundreds of vehicles requiring regular DPF maintenance.

Environmental regulations continue to tighten globally, placing greater demands on DPF performance and longevity. Current cleaning technologies struggle to restore filters to near-original condition, creating a growing gap between regulatory expectations and practical maintenance capabilities in real-world operations.

The most prevalent challenge is the inability to achieve consistent cleaning quality across the entire filter structure. Traditional cleaning methods such as compressed air blowing and thermal treatment demonstrate uneven cleaning patterns, with peripheral areas receiving more thorough cleaning while central regions remain partially clogged. This inconsistency creates unbalanced flow distribution during subsequent operation, reducing overall filtration efficiency and accelerating localized thermal stress.

Chemical cleaning solutions present their own set of complications, including potential damage to the catalyst coatings essential for passive regeneration processes. Studies indicate that aggressive chemical cleaners can reduce catalyst effectiveness by up to 30%, significantly compromising the filter's ability to self-regenerate during normal operation conditions. This degradation necessitates more frequent active regeneration cycles, increasing fuel consumption and operational costs.

Temperature management during cleaning procedures represents another critical challenge. Excessive thermal gradients during cleaning can create microfractures in the ceramic substrate, compromising structural integrity and creating bypass channels that reduce filtration efficiency. Conversely, insufficient temperatures fail to adequately remove carbonaceous deposits, particularly those deeply embedded within the filter walls.

Workshop-level cleaning procedures suffer from standardization issues, with significant variations in equipment calibration, process duration, and quality control measures across service providers. This inconsistency makes it difficult for fleet operators to maintain predictable maintenance schedules and costs. Industry surveys reveal that up to 40% of cleaned DPFs require premature replacement due to inadequate cleaning procedures.

The economic implications of these challenges are substantial. Ineffective cleaning not only shortens filter lifespan but also increases vehicle downtime and maintenance costs. The average service life reduction due to improper cleaning is estimated at 20-30%, representing significant additional expenses for commercial fleet operators who typically manage hundreds of vehicles requiring regular DPF maintenance.

Environmental regulations continue to tighten globally, placing greater demands on DPF performance and longevity. Current cleaning technologies struggle to restore filters to near-original condition, creating a growing gap between regulatory expectations and practical maintenance capabilities in real-world operations.

Current DPF Regeneration Methods

01 Thermal regeneration methods for DPF cleaning

Thermal regeneration involves raising the temperature of the diesel particulate filter to burn off accumulated soot and particulate matter. This can be achieved through various methods including post-injection of fuel, use of fuel burners, or electrical heating elements. The process typically requires temperatures above 550°C to effectively oxidize the carbon deposits. Proper thermal management is crucial to prevent filter damage while ensuring complete regeneration.- Thermal regeneration methods for DPF cleaning: Thermal regeneration involves raising the temperature of the diesel particulate filter (DPF) to burn off accumulated soot and particulate matter. This can be achieved through various methods including post-injection of fuel, intake air heating, or using fuel burners. The process typically requires temperatures above 550°C to effectively oxidize the carbon deposits. Proper thermal management is crucial to ensure complete regeneration while preventing damage to the filter substrate from excessive temperatures.

- Catalyst-assisted regeneration techniques: Incorporating catalytic materials into the DPF system significantly lowers the regeneration temperature requirements and improves efficiency. Noble metals like platinum and palladium, as well as base metal oxides, can be coated on the filter substrate to promote oxidation of particulate matter at lower temperatures. Some systems use fuel-borne catalysts that mix with the soot during engine operation, making it more reactive and easier to burn off during regeneration cycles. These catalyst systems enable more frequent and less energy-intensive regeneration events.

- Advanced control strategies for regeneration efficiency: Sophisticated control algorithms optimize the regeneration process by monitoring multiple parameters including exhaust temperature, backpressure, soot load estimation, and driving conditions. These systems can adaptively determine the optimal timing and duration of regeneration events to maximize efficiency while minimizing fuel consumption. Some advanced systems incorporate predictive models that account for driving patterns and environmental conditions to schedule regeneration during favorable operating conditions, improving overall system efficiency and filter longevity.

- Physical cleaning methods and technologies: Beyond in-situ regeneration, various physical cleaning methods have been developed for deep cleaning of DPFs, especially for removing ash that cannot be eliminated through standard regeneration. These include compressed air reverse flow systems, ultrasonic cleaning, and liquid-based cleaning processes using specialized detergents or solvents. Some systems combine multiple cleaning approaches, such as pneumatic pulsation with chemical soaking, to address both organic soot and inorganic ash deposits. These off-vehicle cleaning technologies are particularly important for extending the service life of DPFs in heavy-duty applications.

- Efficiency monitoring and diagnostic systems: Advanced sensor technologies and diagnostic algorithms continuously monitor DPF performance and regeneration efficiency. These systems track parameters such as differential pressure across the filter, exhaust gas temperature, and particulate matter sensors to assess filter loading and regeneration effectiveness. Some systems incorporate machine learning algorithms to adapt to changing engine conditions and aging of the filter. Real-time monitoring enables early detection of regeneration issues, allowing for timely intervention to prevent filter damage and maintain optimal emission control performance.

02 Catalyst-assisted regeneration techniques

Catalytic materials can be incorporated into diesel particulate filters to lower the soot oxidation temperature, improving regeneration efficiency. These catalysts, including precious metals like platinum and palladium or metal oxides, enable passive regeneration at lower exhaust temperatures. Some systems use fuel-borne catalysts that mix with the soot, making it more susceptible to oxidation. Catalyst-assisted methods reduce energy consumption and thermal stress on the filter while improving overall regeneration efficiency.Expand Specific Solutions03 Control strategies for optimizing DPF regeneration

Advanced control algorithms and sensors are employed to optimize the timing and conditions for DPF regeneration. These systems monitor parameters such as back pressure, soot load, exhaust temperature, and driving conditions to determine the optimal regeneration strategy. Adaptive control systems can adjust regeneration parameters based on real-time data, improving efficiency while minimizing fuel consumption. Some systems incorporate predictive models to anticipate regeneration needs based on driving patterns and filter conditions.Expand Specific Solutions04 Physical cleaning methods for DPF maintenance

Physical cleaning techniques are used for deep cleaning of diesel particulate filters, especially when regeneration alone is insufficient. These methods include compressed air cleaning, water-based washing, ultrasonic cleaning, and mechanical agitation. Some systems combine multiple physical approaches with chemical treatments to remove both organic and inorganic deposits. These techniques are particularly important for addressing ash accumulation, which cannot be removed through conventional regeneration processes.Expand Specific Solutions05 Innovative DPF designs for improved regeneration efficiency

Novel filter designs incorporate features specifically aimed at enhancing regeneration efficiency. These include optimized cell structures, advanced substrate materials, and improved flow distribution patterns. Some designs feature variable porosity or asymmetric channel configurations to balance filtration efficiency with regeneration performance. Multi-layer filter structures can separate different types of particulates and facilitate more efficient cleaning. These innovative designs aim to reduce regeneration frequency while maintaining or improving filtration performance.Expand Specific Solutions

Key Industry Players in DPF Market

The Diesel Particulate Filter (DPF) cleaning and regeneration efficiency market is in a growth phase, driven by increasingly stringent emission regulations worldwide. The market size is expanding steadily as diesel vehicles remain prevalent in commercial transportation sectors despite the rise of alternative powertrains. Leading automotive manufacturers like GM, Nissan, Peugeot, and Volvo are investing in advanced DPF technologies, while specialized component suppliers such as Bosch, Johnson Matthey, and IBIDEN are developing more efficient filter materials and regeneration systems. Academic institutions like Jilin University and Beijing Jiaotong University are contributing research to improve efficiency, while companies like Corning and Hangzhou Xianlan focus on innovative ceramic substrate technologies that enhance filter performance and durability while reducing regeneration frequency.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed advanced catalytic DPF technologies that significantly enhance both cleaning efficiency and regeneration performance. Their CRT® (Continuously Regenerating Trap) system utilizes a platinum-based catalyst that converts NO to NO2, which then oxidizes particulate matter at much lower temperatures (250-300°C) than traditional systems. This enables more frequent passive regeneration cycles, reducing the need for active regeneration. Johnson Matthey's latest generation filters incorporate advanced cordierite and silicon carbide substrates with optimized porosity structures, achieving over 99% particulate matter capture efficiency while maintaining lower backpressure[4]. Their proprietary catalyst formulations include rare earth metals that enhance oxidation activity and thermal stability, extending catalyst lifespan by up to 40% compared to conventional formulations. For cleaning applications, Johnson Matthey has developed specialized chemical cleaning processes that restore filter performance to near-original levels without damaging the substrate or catalyst coatings, achieving approximately 95% restoration of original filtration capacity and pressure drop characteristics[5].

Strengths: Industry-leading catalyst technology enables superior passive regeneration at lower temperatures. Advanced substrate materials offer excellent filtration efficiency with reduced backpressure. Weaknesses: Premium catalyst formulations increase initial system cost. Some specialized cleaning processes require proprietary equipment and chemicals.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has pioneered a comprehensive DPF management system specifically designed for heavy-duty applications. Their technology employs a multi-stage regeneration approach that combines continuous passive regeneration with strategically timed active regeneration events. Volvo's system utilizes advanced thermal management techniques to maintain optimal exhaust temperatures, incorporating waste heat recovery systems that redirect thermal energy to assist regeneration processes. Their DPF technology features a proprietary catalyst formulation that reduces the passive regeneration temperature threshold to approximately 270°C, significantly expanding the operational window for passive cleaning[2]. For active regeneration, Volvo employs a hydrocarbon dosing system that precisely injects fuel into the exhaust stream, achieving temperatures of 550-650°C while minimizing fuel consumption. The system incorporates predictive algorithms that analyze route data and driving patterns to schedule regenerations during optimal operational conditions, reducing disruption to vehicle operation and extending filter service life by up to 30% compared to conventional systems[3].

Strengths: Exceptional durability in heavy-duty applications with extended service intervals. Sophisticated thermal management reduces regeneration frequency. Weaknesses: System optimization primarily focused on long-haul operations; may be less efficient in urban stop-and-go driving cycles. Higher initial cost compared to simpler DPF systems.

Critical Patents in DPF Cleaning Technology

Exhaust purification system with a diesel particulate filter and a method of cleaning said filter

PatentActiveEP2109710A1

Innovation

- A method involving a controllable supercharger in the exhaust conduit upstream of the catalytic converter, which varies the exhaust flow rate during fuel injection to ensure rapid evaporation and complete combustion of diesel fuel, thereby minimizing fuel quantity and optimizing regeneration efficiency without disrupting the EGR system.

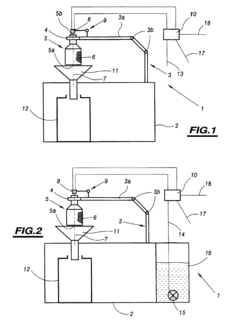

Process and apparatus for cleaning a particle filter and process for treating the effluent produced from cleaning

PatentInactiveEP1060780A1

Innovation

- A method involving the disassembly of the exhaust line, reversal of the particulate filter for controlled passage of cleaning fluids, including water and compressed air, to dissociate and remove residues, followed by reassembly and regeneration, allowing for effective cleaning without replacement.

Environmental Regulations Impact on DPF Development

Environmental regulations have been the primary driving force behind the evolution of Diesel Particulate Filter (DPF) technology over the past two decades. The progressive tightening of emission standards, particularly in the European Union, United States, and Japan, has necessitated increasingly sophisticated DPF systems with enhanced cleaning and regeneration capabilities.

The introduction of Euro 6 standards in Europe and Tier 3/LEV III regulations in the United States marked a significant turning point, reducing permissible particulate matter emissions by over 80% compared to previous standards. These stringent requirements have directly influenced DPF design parameters, pushing manufacturers to develop filters with higher filtration efficiency while maintaining acceptable back pressure levels.

Regulatory frameworks have also shaped the development trajectory of regeneration technologies. The need to meet real-world driving emission tests (RDE) has compelled engineers to create more adaptive regeneration systems that can function effectively across diverse operating conditions. This has led to the emergence of multi-mode regeneration strategies that combine passive and active approaches to optimize efficiency while minimizing fuel penalties.

The regulatory emphasis on durability has similarly impacted cleaning technologies. Current standards in most developed markets require emission control systems to maintain performance for up to 150,000 miles or 10 years. This longevity requirement has catalyzed research into more effective cleaning methods that can preserve filter substrate integrity over extended service intervals.

Regional variations in emission standards have created distinct technological pathways. European regulations have traditionally focused on NOx and PM reduction simultaneously, leading to integrated systems that coordinate DPF regeneration with SCR (Selective Catalytic Reduction) operation. In contrast, North American standards have placed greater emphasis on system robustness under extreme conditions, influencing cleaning technology development for severe-duty applications.

Looking forward, upcoming regulations like Euro 7 and California's Advanced Clean Trucks rule will further transform DPF technology. These regulations are expected to introduce more stringent particulate number limits and expand monitoring requirements, potentially necessitating more frequent regeneration cycles and more sophisticated cleaning technologies to maintain compliance throughout the vehicle lifecycle.

The regulatory landscape has also begun addressing non-exhaust particulate emissions, which may eventually expand the scope of DPF applications beyond traditional combustion engine vehicles to include hybrid powertrains and specialized industrial equipment.

The introduction of Euro 6 standards in Europe and Tier 3/LEV III regulations in the United States marked a significant turning point, reducing permissible particulate matter emissions by over 80% compared to previous standards. These stringent requirements have directly influenced DPF design parameters, pushing manufacturers to develop filters with higher filtration efficiency while maintaining acceptable back pressure levels.

Regulatory frameworks have also shaped the development trajectory of regeneration technologies. The need to meet real-world driving emission tests (RDE) has compelled engineers to create more adaptive regeneration systems that can function effectively across diverse operating conditions. This has led to the emergence of multi-mode regeneration strategies that combine passive and active approaches to optimize efficiency while minimizing fuel penalties.

The regulatory emphasis on durability has similarly impacted cleaning technologies. Current standards in most developed markets require emission control systems to maintain performance for up to 150,000 miles or 10 years. This longevity requirement has catalyzed research into more effective cleaning methods that can preserve filter substrate integrity over extended service intervals.

Regional variations in emission standards have created distinct technological pathways. European regulations have traditionally focused on NOx and PM reduction simultaneously, leading to integrated systems that coordinate DPF regeneration with SCR (Selective Catalytic Reduction) operation. In contrast, North American standards have placed greater emphasis on system robustness under extreme conditions, influencing cleaning technology development for severe-duty applications.

Looking forward, upcoming regulations like Euro 7 and California's Advanced Clean Trucks rule will further transform DPF technology. These regulations are expected to introduce more stringent particulate number limits and expand monitoring requirements, potentially necessitating more frequent regeneration cycles and more sophisticated cleaning technologies to maintain compliance throughout the vehicle lifecycle.

The regulatory landscape has also begun addressing non-exhaust particulate emissions, which may eventually expand the scope of DPF applications beyond traditional combustion engine vehicles to include hybrid powertrains and specialized industrial equipment.

Cost-Benefit Analysis of DPF Maintenance Approaches

The economic implications of DPF maintenance strategies require careful analysis to determine optimal approaches for fleet operators and individual vehicle owners. When comparing physical cleaning methods versus regeneration processes, several cost factors must be considered across the entire maintenance lifecycle.

Initial investment costs differ significantly between these approaches. Physical cleaning equipment requires substantial capital expenditure for commercial cleaning stations, including ultrasonic cleaners, pneumatic systems, and specialized inspection equipment. Conversely, regeneration systems are typically integrated into vehicle designs, though aftermarket regeneration solutions may require additional investment.

Operational expenses present another critical dimension. Physical cleaning involves labor costs, cleaning solutions, disposal of hazardous materials, and potential transportation expenses when outsourcing to specialized service providers. Regeneration processes primarily incur fuel penalties, as active regeneration can increase consumption by 2-5% during the regeneration cycle, representing a recurring but distributed cost.

Maintenance frequency significantly impacts total ownership costs. Physical cleaning is typically required every 80,000-150,000 miles depending on operating conditions, while regeneration occurs continuously during normal operation, with active regeneration triggered every 300-500 miles under optimal conditions. This difference in intervention frequency directly affects vehicle downtime and associated productivity losses.

Long-term reliability considerations reveal that physical cleaning, when performed correctly, can restore DPF functionality to near-original specifications, potentially extending filter lifespan by 30-50%. Regeneration alone may lead to ash accumulation over time, which cannot be removed through thermal processes, eventually necessitating physical cleaning or replacement despite regular regeneration.

Environmental compliance costs must also factor into the analysis. Improper disposal of cleaning waste can result in regulatory penalties, while incomplete regeneration may lead to emissions violations and associated fines. Both approaches must be executed properly to maintain compliance with increasingly stringent environmental regulations.

The optimal maintenance strategy often involves a hybrid approach, utilizing regeneration as the primary maintenance method while incorporating scheduled physical cleaning at appropriate intervals. This balanced methodology typically delivers the lowest total cost of ownership while maximizing filter performance and vehicle uptime across the operational lifecycle.

Initial investment costs differ significantly between these approaches. Physical cleaning equipment requires substantial capital expenditure for commercial cleaning stations, including ultrasonic cleaners, pneumatic systems, and specialized inspection equipment. Conversely, regeneration systems are typically integrated into vehicle designs, though aftermarket regeneration solutions may require additional investment.

Operational expenses present another critical dimension. Physical cleaning involves labor costs, cleaning solutions, disposal of hazardous materials, and potential transportation expenses when outsourcing to specialized service providers. Regeneration processes primarily incur fuel penalties, as active regeneration can increase consumption by 2-5% during the regeneration cycle, representing a recurring but distributed cost.

Maintenance frequency significantly impacts total ownership costs. Physical cleaning is typically required every 80,000-150,000 miles depending on operating conditions, while regeneration occurs continuously during normal operation, with active regeneration triggered every 300-500 miles under optimal conditions. This difference in intervention frequency directly affects vehicle downtime and associated productivity losses.

Long-term reliability considerations reveal that physical cleaning, when performed correctly, can restore DPF functionality to near-original specifications, potentially extending filter lifespan by 30-50%. Regeneration alone may lead to ash accumulation over time, which cannot be removed through thermal processes, eventually necessitating physical cleaning or replacement despite regular regeneration.

Environmental compliance costs must also factor into the analysis. Improper disposal of cleaning waste can result in regulatory penalties, while incomplete regeneration may lead to emissions violations and associated fines. Both approaches must be executed properly to maintain compliance with increasingly stringent environmental regulations.

The optimal maintenance strategy often involves a hybrid approach, utilizing regeneration as the primary maintenance method while incorporating scheduled physical cleaning at appropriate intervals. This balanced methodology typically delivers the lowest total cost of ownership while maximizing filter performance and vehicle uptime across the operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!