Diesel Particulate Filter vs Catalytic Converter: Effectiveness

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emission Control Technology Background and Objectives

Emission control technologies have evolved significantly over the past several decades in response to increasingly stringent environmental regulations and growing awareness of air pollution impacts. The journey began in the 1970s with the introduction of basic catalytic converters designed to reduce harmful emissions from gasoline engines. These early systems primarily targeted carbon monoxide (CO) and hydrocarbon (HC) emissions through oxidation processes. The technology landscape expanded in the 1980s with the development of three-way catalytic converters capable of simultaneously addressing nitrogen oxides (NOx) alongside CO and HC.

For diesel engines, emission control followed a different trajectory due to their distinct combustion characteristics and emission profiles. The 1990s saw the emergence of diesel oxidation catalysts (DOCs), while the early 2000s marked a pivotal moment with the introduction of diesel particulate filters (DPFs) specifically designed to capture soot particles. This technological evolution has been primarily driven by progressive regulatory frameworks such as the Euro standards in Europe, EPA regulations in the United States, and similar measures in other regions.

The current technological landscape presents a dual approach to emission control: catalytic converters predominantly serving gasoline engines and DPF systems addressing diesel particulate matter. Catalytic converters utilize precious metals like platinum, palladium, and rhodium to facilitate chemical reactions that convert harmful gases into less harmful substances. Meanwhile, DPFs employ ceramic or silicon carbide substrates with microscopic channels to physically trap particulate matter while allowing exhaust gases to pass through.

The primary objective of modern emission control technologies is to achieve comprehensive reduction of regulated pollutants while maintaining engine performance and fuel efficiency. For catalytic converters, this means optimizing conversion efficiency across various operating conditions. For DPFs, the challenge involves balancing filtration efficiency with pressure drop considerations and developing effective regeneration strategies to prevent filter clogging.

Looking forward, emission control technology aims to address increasingly complex challenges. These include reducing emissions during cold starts and low-temperature operation, minimizing the environmental impact of manufacturing processes, decreasing reliance on precious metals, and extending system durability. Additionally, there is growing interest in developing technologies capable of capturing greenhouse gases and ultra-fine particles that remain unregulated in many jurisdictions.

The effectiveness comparison between DPFs and catalytic converters represents a critical area of investigation, as each technology addresses different aspects of the emission control challenge. Understanding their relative strengths, limitations, and potential synergies is essential for developing next-generation systems that can meet future regulatory requirements while supporting the transition to more sustainable transportation solutions.

For diesel engines, emission control followed a different trajectory due to their distinct combustion characteristics and emission profiles. The 1990s saw the emergence of diesel oxidation catalysts (DOCs), while the early 2000s marked a pivotal moment with the introduction of diesel particulate filters (DPFs) specifically designed to capture soot particles. This technological evolution has been primarily driven by progressive regulatory frameworks such as the Euro standards in Europe, EPA regulations in the United States, and similar measures in other regions.

The current technological landscape presents a dual approach to emission control: catalytic converters predominantly serving gasoline engines and DPF systems addressing diesel particulate matter. Catalytic converters utilize precious metals like platinum, palladium, and rhodium to facilitate chemical reactions that convert harmful gases into less harmful substances. Meanwhile, DPFs employ ceramic or silicon carbide substrates with microscopic channels to physically trap particulate matter while allowing exhaust gases to pass through.

The primary objective of modern emission control technologies is to achieve comprehensive reduction of regulated pollutants while maintaining engine performance and fuel efficiency. For catalytic converters, this means optimizing conversion efficiency across various operating conditions. For DPFs, the challenge involves balancing filtration efficiency with pressure drop considerations and developing effective regeneration strategies to prevent filter clogging.

Looking forward, emission control technology aims to address increasingly complex challenges. These include reducing emissions during cold starts and low-temperature operation, minimizing the environmental impact of manufacturing processes, decreasing reliance on precious metals, and extending system durability. Additionally, there is growing interest in developing technologies capable of capturing greenhouse gases and ultra-fine particles that remain unregulated in many jurisdictions.

The effectiveness comparison between DPFs and catalytic converters represents a critical area of investigation, as each technology addresses different aspects of the emission control challenge. Understanding their relative strengths, limitations, and potential synergies is essential for developing next-generation systems that can meet future regulatory requirements while supporting the transition to more sustainable transportation solutions.

Market Demand Analysis for Emission Reduction Systems

The global emission reduction systems market has experienced significant growth in recent years, driven primarily by increasingly stringent environmental regulations across major economies. The market for diesel particulate filters (DPFs) and catalytic converters is projected to reach $45.2 billion by 2025, with a compound annual growth rate of 8.3% from 2020. This growth trajectory reflects the urgent need for effective emission control technologies in both automotive and industrial sectors.

Consumer demand for cleaner vehicles has risen substantially, with surveys indicating that over 65% of new vehicle buyers now consider environmental impact as a significant factor in their purchasing decisions. This shift in consumer preference has compelled manufacturers to invest heavily in advanced emission reduction technologies, particularly in markets with high diesel vehicle penetration.

The commercial vehicle segment represents a particularly robust market for emission reduction systems. With diesel engines remaining the dominant power source for heavy-duty applications, the need for effective particulate matter and NOx reduction has created a sustained demand for both DPFs and selective catalytic reduction (SCR) systems. Fleet operators face increasing pressure to comply with emissions standards while maintaining operational efficiency, creating a delicate balance between compliance costs and performance.

Regional market analysis reveals significant variations in demand patterns. European markets show the highest adoption rates for advanced DPF systems, driven by Euro 6/VI standards, while emerging economies in Asia are experiencing the fastest growth rates as they implement equivalent regulations. North American markets have seen steady demand growth following the implementation of EPA Tier 3 and CARB standards.

The aftermarket segment for replacement filters and converters has emerged as a substantial revenue stream, valued at approximately $12.7 billion annually. This segment is expected to grow as the global vehicle fleet ages and emission system maintenance becomes increasingly critical for regulatory compliance.

Industrial applications beyond automotive represent an expanding market opportunity, with power generation, marine, and off-road equipment sectors implementing similar emission reduction technologies. These sectors are projected to account for 22% of the total market by 2025, up from 17% in 2020.

Market research indicates that consumers and fleet operators increasingly prioritize total cost of ownership over initial purchase price, creating opportunities for premium emission reduction systems that offer improved durability and reduced maintenance requirements. This trend has accelerated development of next-generation materials and designs focused on extending service intervals and reducing regeneration frequency.

Consumer demand for cleaner vehicles has risen substantially, with surveys indicating that over 65% of new vehicle buyers now consider environmental impact as a significant factor in their purchasing decisions. This shift in consumer preference has compelled manufacturers to invest heavily in advanced emission reduction technologies, particularly in markets with high diesel vehicle penetration.

The commercial vehicle segment represents a particularly robust market for emission reduction systems. With diesel engines remaining the dominant power source for heavy-duty applications, the need for effective particulate matter and NOx reduction has created a sustained demand for both DPFs and selective catalytic reduction (SCR) systems. Fleet operators face increasing pressure to comply with emissions standards while maintaining operational efficiency, creating a delicate balance between compliance costs and performance.

Regional market analysis reveals significant variations in demand patterns. European markets show the highest adoption rates for advanced DPF systems, driven by Euro 6/VI standards, while emerging economies in Asia are experiencing the fastest growth rates as they implement equivalent regulations. North American markets have seen steady demand growth following the implementation of EPA Tier 3 and CARB standards.

The aftermarket segment for replacement filters and converters has emerged as a substantial revenue stream, valued at approximately $12.7 billion annually. This segment is expected to grow as the global vehicle fleet ages and emission system maintenance becomes increasingly critical for regulatory compliance.

Industrial applications beyond automotive represent an expanding market opportunity, with power generation, marine, and off-road equipment sectors implementing similar emission reduction technologies. These sectors are projected to account for 22% of the total market by 2025, up from 17% in 2020.

Market research indicates that consumers and fleet operators increasingly prioritize total cost of ownership over initial purchase price, creating opportunities for premium emission reduction systems that offer improved durability and reduced maintenance requirements. This trend has accelerated development of next-generation materials and designs focused on extending service intervals and reducing regeneration frequency.

Current State and Challenges in DPF and Catalytic Converter Technologies

The global landscape of emission control technologies has evolved significantly over the past decades, with Diesel Particulate Filters (DPFs) and Catalytic Converters representing two cornerstone technologies. Currently, these systems face distinct technical challenges while operating under increasingly stringent regulatory frameworks worldwide.

DPF technology has reached maturity in most developed markets, with filtration efficiencies exceeding 95% for particulate matter. However, contemporary DPF systems still struggle with regeneration optimization—the process of burning accumulated soot. Passive regeneration systems remain temperature-dependent, requiring sustained exhaust temperatures above 550°C, which is difficult to achieve in urban driving cycles. Active regeneration systems, while more reliable, increase fuel consumption by 2-4% and create thermal stress that reduces filter longevity.

Catalytic converters have achieved near-universal adoption in gasoline vehicles, with three-way catalytic converters (TWCs) demonstrating conversion efficiencies of 98% for hydrocarbons, carbon monoxide, and nitrogen oxides under optimal conditions. For diesel applications, selective catalytic reduction (SCR) systems have become the dominant NOx reduction technology, achieving 85-95% efficiency. However, these systems face challenges with cold-start emissions, as catalysts require temperatures of 200-300°C to reach light-off temperature.

Material constraints represent a significant challenge for both technologies. Platinum group metals (PGMs) used in catalytic converters face supply constraints and price volatility, with prices increasing over 300% in the past decade. Similarly, cordierite and silicon carbide used in DPFs experience thermal durability issues under repeated regeneration cycles, with thermal shock resistance remaining a key development focus.

Geographically, technological innovation in these fields shows distinct patterns. European manufacturers lead in DPF advancement, with companies in Germany and France holding approximately 60% of relevant patents. Catalytic converter technology development is more distributed, with significant research clusters in Japan, the United States, and increasingly, China, which has emerged as a major player due to its stringent emissions policies implemented since 2018.

Integration challenges persist as manufacturers attempt to combine these technologies into comprehensive exhaust aftertreatment systems. The packaging constraints of modern vehicles, coupled with the need for optimal thermal management between components, create significant engineering challenges. Current systems often require complex control algorithms and multiple sensors, increasing system complexity and potential failure points.

Durability testing indicates that while both technologies can meet regulatory requirements when new, performance degradation over vehicle lifetime remains problematic, particularly in regions with poor fuel quality or extreme operating conditions. This has prompted research into more robust catalyst formulations and filter materials capable of maintaining performance across diverse operating environments.

DPF technology has reached maturity in most developed markets, with filtration efficiencies exceeding 95% for particulate matter. However, contemporary DPF systems still struggle with regeneration optimization—the process of burning accumulated soot. Passive regeneration systems remain temperature-dependent, requiring sustained exhaust temperatures above 550°C, which is difficult to achieve in urban driving cycles. Active regeneration systems, while more reliable, increase fuel consumption by 2-4% and create thermal stress that reduces filter longevity.

Catalytic converters have achieved near-universal adoption in gasoline vehicles, with three-way catalytic converters (TWCs) demonstrating conversion efficiencies of 98% for hydrocarbons, carbon monoxide, and nitrogen oxides under optimal conditions. For diesel applications, selective catalytic reduction (SCR) systems have become the dominant NOx reduction technology, achieving 85-95% efficiency. However, these systems face challenges with cold-start emissions, as catalysts require temperatures of 200-300°C to reach light-off temperature.

Material constraints represent a significant challenge for both technologies. Platinum group metals (PGMs) used in catalytic converters face supply constraints and price volatility, with prices increasing over 300% in the past decade. Similarly, cordierite and silicon carbide used in DPFs experience thermal durability issues under repeated regeneration cycles, with thermal shock resistance remaining a key development focus.

Geographically, technological innovation in these fields shows distinct patterns. European manufacturers lead in DPF advancement, with companies in Germany and France holding approximately 60% of relevant patents. Catalytic converter technology development is more distributed, with significant research clusters in Japan, the United States, and increasingly, China, which has emerged as a major player due to its stringent emissions policies implemented since 2018.

Integration challenges persist as manufacturers attempt to combine these technologies into comprehensive exhaust aftertreatment systems. The packaging constraints of modern vehicles, coupled with the need for optimal thermal management between components, create significant engineering challenges. Current systems often require complex control algorithms and multiple sensors, increasing system complexity and potential failure points.

Durability testing indicates that while both technologies can meet regulatory requirements when new, performance degradation over vehicle lifetime remains problematic, particularly in regions with poor fuel quality or extreme operating conditions. This has prompted research into more robust catalyst formulations and filter materials capable of maintaining performance across diverse operating environments.

Comparative Analysis of DPF and Catalytic Converter Solutions

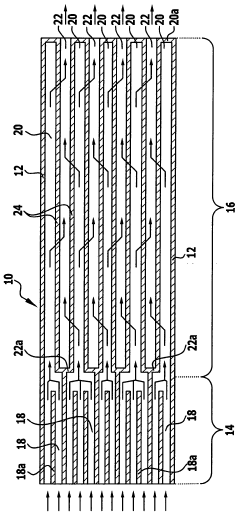

01 DPF and Catalytic Converter Integration

Integration of diesel particulate filters (DPF) with catalytic converters enhances the overall effectiveness of exhaust aftertreatment systems. This combination allows for simultaneous reduction of particulate matter and harmful gases. The integrated systems can be designed with optimized flow patterns to ensure maximum contact between exhaust gases and catalytic surfaces, improving filtration efficiency and reducing backpressure on the engine.- DPF and Catalytic Converter Integration: Integration of diesel particulate filters (DPF) with catalytic converters enhances overall exhaust treatment effectiveness. Combined systems can simultaneously reduce particulate matter and convert harmful gases like NOx, CO, and hydrocarbons. These integrated systems optimize space usage in exhaust systems while improving filtration efficiency and catalytic conversion rates, leading to better emissions control in diesel engines.

- Regeneration Techniques for DPF Systems: Various regeneration techniques are employed to maintain the effectiveness of diesel particulate filters by removing accumulated soot. These include active regeneration using fuel injection or heating elements, passive regeneration utilizing catalytic coatings, and forced regeneration during maintenance. Effective regeneration strategies prevent filter clogging, maintain back pressure at acceptable levels, and extend the operational life of the filtration system.

- Catalyst Formulations for Enhanced Performance: Advanced catalyst formulations significantly improve the effectiveness of both diesel particulate filters and catalytic converters. These formulations include precious metals like platinum, palladium, and rhodium, as well as base metal oxides and zeolites. The specific composition and coating methods affect conversion efficiency, thermal stability, and resistance to poisoning, ultimately determining the system's ability to meet stringent emission standards.

- System Design and Configuration Optimization: The physical design and configuration of diesel particulate filters and catalytic converters significantly impact their effectiveness. Factors such as substrate material selection, cell density, wall thickness, and overall geometry influence filtration efficiency and pressure drop characteristics. Optimized system layouts, including the positioning of components within the exhaust stream and thermal management strategies, can enhance performance while minimizing fuel consumption penalties.

- Monitoring and Control Systems for Emissions Treatment: Advanced monitoring and control systems are essential for maintaining the effectiveness of diesel particulate filters and catalytic converters. These systems utilize sensors to measure parameters such as temperature, pressure differential, and exhaust gas composition. The collected data enables real-time adjustments to engine operation and regeneration strategies, ensuring optimal performance of the emissions treatment system throughout varying operating conditions and over the vehicle's lifetime.

02 Catalyst Coating Technologies

Advanced catalyst coating technologies significantly improve the effectiveness of both DPFs and catalytic converters. These coatings typically contain precious metals like platinum, palladium, and rhodium that facilitate chemical reactions to convert harmful emissions into less harmful substances. Innovations in coating distribution, adherence methods, and catalyst formulations have led to improved conversion efficiency at lower temperatures and extended durability under various operating conditions.Expand Specific Solutions03 Regeneration Strategies for DPF Systems

Effective regeneration strategies are crucial for maintaining DPF performance over time. These strategies include active regeneration using fuel injection or heating elements to raise exhaust temperatures, passive regeneration utilizing catalytic reactions at normal operating temperatures, and combined approaches. Advanced control systems monitor soot loading and trigger appropriate regeneration cycles to prevent clogging while optimizing fuel efficiency and system longevity.Expand Specific Solutions04 Temperature Management Systems

Temperature management is critical for optimizing the effectiveness of both DPFs and catalytic converters. Systems that maintain appropriate operating temperatures ensure efficient catalytic reactions while preventing thermal damage. These include thermal insulation technologies, exhaust gas recirculation control, and strategic placement of components within the exhaust system. Advanced thermal management also helps reduce cold-start emissions when catalytic converters are below their light-off temperature.Expand Specific Solutions05 Sensor and Control Systems

Advanced sensor and control systems significantly enhance the effectiveness of DPF and catalytic converter operations. These systems utilize pressure sensors, temperature sensors, and exhaust gas composition analyzers to monitor performance in real-time. Sophisticated control algorithms adjust engine parameters and aftertreatment operations based on sensor data, optimizing emission reduction across various driving conditions while minimizing fuel consumption penalties associated with regeneration events.Expand Specific Solutions

Technical Deep Dive: Filtration vs Catalytic Conversion Mechanisms

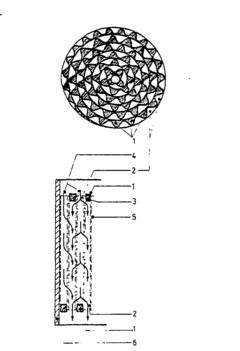

Diesel particulate filter component

PatentWO2008113507A1

Innovation

- A diesel particulate filter component with an integrated oxidation catalytic converter section having a larger catalytically active area than the filter section, achieved by increasing the number and area of exhaust gas flow channels in the oxidation catalytic converter section, allowing for more efficient combustion of hydrocarbons and soot particles without additives, thus reducing regeneration time.

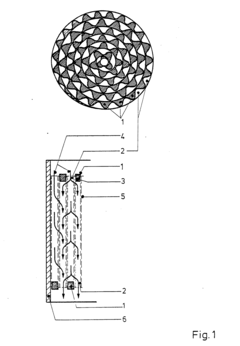

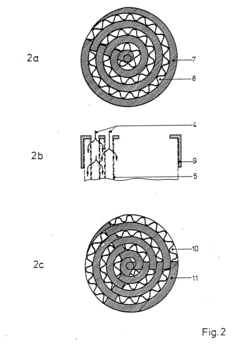

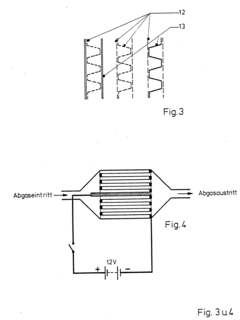

Catalytic filter for the purification of Diesel exhaust gas

PatentInactiveEP0035053A1

Innovation

- A metal mesh filter arrangement with alternating corrugated or folded screen fabric and flat, closed, or perforated layers, coated with catalysis-promoting metal oxides, which acts as both a filter and catalyst support, ensuring effective filtration and catalytic conversion of exhaust gases.

Regulatory Framework and Compliance Standards

The regulatory landscape governing emission control technologies has evolved significantly over the past decades, with increasingly stringent standards driving innovation in both Diesel Particulate Filters (DPFs) and Catalytic Converters. The European Union's Euro standards represent one of the most comprehensive regulatory frameworks, progressing from Euro 1 in 1992 to the current Euro 6d, with each iteration imposing stricter limits on particulate matter (PM) and nitrogen oxides (NOx) emissions.

In the United States, the Environmental Protection Agency (EPA) has established Tier 3 emission standards, which require vehicles to reduce tailpipe emissions by approximately 70% compared to previous standards. Additionally, the California Air Resources Board (CARB) often implements even more stringent requirements, influencing nationwide standards through its significant market presence.

For diesel vehicles specifically, the implementation of DPFs became virtually mandatory with the introduction of Euro 5 standards in Europe and similar regulations worldwide. These standards established PM emission limits that were practically unachievable without filtration technology, effectively mandating DPF installation across new diesel vehicle fleets.

Compliance testing methodologies have also evolved significantly, moving from laboratory-based New European Driving Cycle (NEDC) to the more realistic Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests. This shift addresses the previously criticized gap between laboratory results and real-world emissions performance.

Enforcement mechanisms have strengthened considerably following the 2015 diesel emissions scandal, with manufacturers facing potential fines of up to €30,000 per non-compliant vehicle in Europe. In the US, penalties can reach $37,500 per vehicle, as demonstrated by the unprecedented settlements exceeding $15 billion in recent enforcement actions.

Looking forward, upcoming regulations such as Euro 7 (expected by 2025) and equivalent standards in other regions will likely further reduce permissible emission limits and expand the scope of regulated pollutants. These regulations are increasingly technology-neutral, focusing on outcomes rather than prescribing specific solutions, which may influence the competitive landscape between DPFs and catalytic converters.

The regulatory framework also increasingly addresses lifecycle considerations, with emerging standards for durability requirements extending the mandatory functional lifespan of emission control systems from 160,000 km to potentially 200,000 km or beyond, significantly impacting the total cost of ownership calculations for different emission control technologies.

In the United States, the Environmental Protection Agency (EPA) has established Tier 3 emission standards, which require vehicles to reduce tailpipe emissions by approximately 70% compared to previous standards. Additionally, the California Air Resources Board (CARB) often implements even more stringent requirements, influencing nationwide standards through its significant market presence.

For diesel vehicles specifically, the implementation of DPFs became virtually mandatory with the introduction of Euro 5 standards in Europe and similar regulations worldwide. These standards established PM emission limits that were practically unachievable without filtration technology, effectively mandating DPF installation across new diesel vehicle fleets.

Compliance testing methodologies have also evolved significantly, moving from laboratory-based New European Driving Cycle (NEDC) to the more realistic Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests. This shift addresses the previously criticized gap between laboratory results and real-world emissions performance.

Enforcement mechanisms have strengthened considerably following the 2015 diesel emissions scandal, with manufacturers facing potential fines of up to €30,000 per non-compliant vehicle in Europe. In the US, penalties can reach $37,500 per vehicle, as demonstrated by the unprecedented settlements exceeding $15 billion in recent enforcement actions.

Looking forward, upcoming regulations such as Euro 7 (expected by 2025) and equivalent standards in other regions will likely further reduce permissible emission limits and expand the scope of regulated pollutants. These regulations are increasingly technology-neutral, focusing on outcomes rather than prescribing specific solutions, which may influence the competitive landscape between DPFs and catalytic converters.

The regulatory framework also increasingly addresses lifecycle considerations, with emerging standards for durability requirements extending the mandatory functional lifespan of emission control systems from 160,000 km to potentially 200,000 km or beyond, significantly impacting the total cost of ownership calculations for different emission control technologies.

Environmental Impact and Sustainability Assessment

The environmental impact of diesel exhaust control technologies extends far beyond mere regulatory compliance, representing a critical factor in global efforts to combat climate change and protect public health. Diesel Particulate Filters (DPFs) and Catalytic Converters demonstrate significantly different environmental footprints throughout their lifecycle, with important implications for sustainability.

DPFs exhibit superior performance in particulate matter (PM) reduction, capturing over 95% of diesel soot particles, including the most hazardous PM2.5 and ultrafine particles that pose severe respiratory health risks. This exceptional filtration efficiency translates to substantial reductions in black carbon emissions, which are potent short-lived climate forcers with a global warming potential up to 3,200 times that of CO2 over a 20-year period.

Catalytic converters, while less effective at PM reduction, excel at neutralizing gaseous pollutants including nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). Three-way catalytic converters can reduce these emissions by 90% under optimal conditions, contributing significantly to improved air quality and reduced formation of ground-level ozone.

From a lifecycle perspective, both technologies present sustainability challenges. The manufacturing processes for both systems require precious metals including platinum, palladium, and rhodium, whose extraction involves significant environmental disruption, water consumption, and energy expenditure. However, advanced recycling programs have achieved recovery rates exceeding 95% for these precious metals, substantially mitigating the environmental impact of raw material acquisition.

Energy consumption patterns differ markedly between the two systems. DPFs typically impose a 1-3% fuel economy penalty due to increased backpressure in the exhaust system, though regeneration cycles can temporarily increase this to 5-7%. This translates to higher lifetime carbon emissions compared to catalytic converters, which generally impose minimal fuel economy penalties under normal operating conditions.

Long-term environmental cost-benefit analyses favor integrated systems combining both technologies. While initial manufacturing impacts are higher for combined systems, the cumulative environmental benefits over a vehicle's operational lifetime—particularly in dense urban environments—outweigh these initial costs by preventing significant quantities of health-damaging pollutants from entering the atmosphere and reducing associated healthcare and environmental remediation costs.

DPFs exhibit superior performance in particulate matter (PM) reduction, capturing over 95% of diesel soot particles, including the most hazardous PM2.5 and ultrafine particles that pose severe respiratory health risks. This exceptional filtration efficiency translates to substantial reductions in black carbon emissions, which are potent short-lived climate forcers with a global warming potential up to 3,200 times that of CO2 over a 20-year period.

Catalytic converters, while less effective at PM reduction, excel at neutralizing gaseous pollutants including nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). Three-way catalytic converters can reduce these emissions by 90% under optimal conditions, contributing significantly to improved air quality and reduced formation of ground-level ozone.

From a lifecycle perspective, both technologies present sustainability challenges. The manufacturing processes for both systems require precious metals including platinum, palladium, and rhodium, whose extraction involves significant environmental disruption, water consumption, and energy expenditure. However, advanced recycling programs have achieved recovery rates exceeding 95% for these precious metals, substantially mitigating the environmental impact of raw material acquisition.

Energy consumption patterns differ markedly between the two systems. DPFs typically impose a 1-3% fuel economy penalty due to increased backpressure in the exhaust system, though regeneration cycles can temporarily increase this to 5-7%. This translates to higher lifetime carbon emissions compared to catalytic converters, which generally impose minimal fuel economy penalties under normal operating conditions.

Long-term environmental cost-benefit analyses favor integrated systems combining both technologies. While initial manufacturing impacts are higher for combined systems, the cumulative environmental benefits over a vehicle's operational lifetime—particularly in dense urban environments—outweigh these initial costs by preventing significant quantities of health-damaging pollutants from entering the atmosphere and reducing associated healthcare and environmental remediation costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!