Discovering New Uses for Ethyl Acetate in Biotechnology

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Biotech: Background and Objectives

Ethyl acetate, a versatile organic compound, has been a staple in various industries for decades. Its journey in biotechnology began in the mid-20th century when researchers discovered its potential as a solvent for biological processes. Since then, the evolution of ethyl acetate's applications in biotechnology has been marked by continuous innovation and exploration.

The primary objective of this technical research is to uncover novel applications for ethyl acetate within the biotechnology sector. This endeavor is driven by the compound's unique properties, including its low toxicity, high volatility, and excellent solvency for a wide range of organic substances. These characteristics make ethyl acetate an attractive candidate for various biotech processes, from extraction and purification to reaction media and beyond.

As we delve into the current landscape of ethyl acetate in biotechnology, it's crucial to recognize the growing demand for sustainable and efficient processes in the industry. This demand has sparked renewed interest in finding alternative uses for common chemicals, with ethyl acetate emerging as a promising candidate due to its relatively benign environmental impact and cost-effectiveness.

The biotechnology sector has witnessed significant advancements in recent years, with breakthroughs in areas such as gene editing, protein engineering, and biocatalysis. These developments have opened up new possibilities for the application of solvents like ethyl acetate in more sophisticated and targeted ways. For instance, there is increasing interest in using ethyl acetate as a medium for enzymatic reactions or as a component in novel drug delivery systems.

Furthermore, the global push towards green chemistry and sustainable manufacturing processes has placed additional emphasis on finding environmentally friendly alternatives to traditional solvents. Ethyl acetate, being biodegradable and derived from renewable resources, aligns well with these sustainability goals. This alignment positions ethyl acetate as a potential key player in the development of more eco-friendly biotech processes.

As we embark on this exploration of new uses for ethyl acetate in biotechnology, our aim is to identify innovative applications that can enhance the efficiency, sustainability, and effectiveness of biotech processes. This research will not only focus on direct applications but also consider potential synergies with emerging technologies and methodologies in the field. By doing so, we hope to uncover opportunities that could revolutionize certain aspects of biotechnology and contribute to the industry's ongoing evolution.

The primary objective of this technical research is to uncover novel applications for ethyl acetate within the biotechnology sector. This endeavor is driven by the compound's unique properties, including its low toxicity, high volatility, and excellent solvency for a wide range of organic substances. These characteristics make ethyl acetate an attractive candidate for various biotech processes, from extraction and purification to reaction media and beyond.

As we delve into the current landscape of ethyl acetate in biotechnology, it's crucial to recognize the growing demand for sustainable and efficient processes in the industry. This demand has sparked renewed interest in finding alternative uses for common chemicals, with ethyl acetate emerging as a promising candidate due to its relatively benign environmental impact and cost-effectiveness.

The biotechnology sector has witnessed significant advancements in recent years, with breakthroughs in areas such as gene editing, protein engineering, and biocatalysis. These developments have opened up new possibilities for the application of solvents like ethyl acetate in more sophisticated and targeted ways. For instance, there is increasing interest in using ethyl acetate as a medium for enzymatic reactions or as a component in novel drug delivery systems.

Furthermore, the global push towards green chemistry and sustainable manufacturing processes has placed additional emphasis on finding environmentally friendly alternatives to traditional solvents. Ethyl acetate, being biodegradable and derived from renewable resources, aligns well with these sustainability goals. This alignment positions ethyl acetate as a potential key player in the development of more eco-friendly biotech processes.

As we embark on this exploration of new uses for ethyl acetate in biotechnology, our aim is to identify innovative applications that can enhance the efficiency, sustainability, and effectiveness of biotech processes. This research will not only focus on direct applications but also consider potential synergies with emerging technologies and methodologies in the field. By doing so, we hope to uncover opportunities that could revolutionize certain aspects of biotechnology and contribute to the industry's ongoing evolution.

Market Analysis for Ethyl Acetate in Biotechnology

The market for ethyl acetate in biotechnology is experiencing significant growth, driven by its versatile applications and increasing demand for sustainable solutions. As a solvent with low toxicity and high biodegradability, ethyl acetate is finding new uses across various biotechnology sectors, including pharmaceuticals, food processing, and biofuel production.

In the pharmaceutical industry, ethyl acetate is widely used as a solvent for drug synthesis and extraction processes. The growing emphasis on green chemistry and sustainable manufacturing practices has led to increased adoption of ethyl acetate as an environmentally friendly alternative to traditional solvents. This trend is expected to continue, with the pharmaceutical sector remaining a key driver of market growth.

The food and beverage industry represents another significant market for ethyl acetate in biotechnology. Its application in flavor extraction and as a food additive has seen steady growth, particularly in the production of natural and organic products. As consumer preferences shift towards clean label and natural ingredients, the demand for ethyl acetate in food processing is projected to rise.

Biofuel production is emerging as a promising new application area for ethyl acetate. Its use in the production of biodiesel and other biofuels aligns with the global push for renewable energy sources. This sector is expected to contribute substantially to market growth in the coming years as governments worldwide implement policies to reduce carbon emissions and promote sustainable energy solutions.

The global market for ethyl acetate in biotechnology is characterized by regional variations in demand and production. Asia-Pacific, particularly China and India, leads in terms of production capacity and consumption, driven by rapid industrialization and a growing biotechnology sector. North America and Europe follow, with established biotechnology industries and stringent environmental regulations favoring the use of eco-friendly solvents like ethyl acetate.

Market analysts project a compound annual growth rate (CAGR) for ethyl acetate in biotechnology applications to exceed the overall chemical industry average over the next five years. This growth is attributed to increasing research and development activities in biotechnology, expanding applications in existing industries, and the emergence of new use cases in fields such as biomaterials and tissue engineering.

However, the market faces challenges, including price volatility of raw materials and competition from alternative solvents. Fluctuations in the prices of ethanol and acetic acid, the primary raw materials for ethyl acetate production, can impact market dynamics. Additionally, ongoing research into novel green solvents may introduce new competitors in specific application areas.

In the pharmaceutical industry, ethyl acetate is widely used as a solvent for drug synthesis and extraction processes. The growing emphasis on green chemistry and sustainable manufacturing practices has led to increased adoption of ethyl acetate as an environmentally friendly alternative to traditional solvents. This trend is expected to continue, with the pharmaceutical sector remaining a key driver of market growth.

The food and beverage industry represents another significant market for ethyl acetate in biotechnology. Its application in flavor extraction and as a food additive has seen steady growth, particularly in the production of natural and organic products. As consumer preferences shift towards clean label and natural ingredients, the demand for ethyl acetate in food processing is projected to rise.

Biofuel production is emerging as a promising new application area for ethyl acetate. Its use in the production of biodiesel and other biofuels aligns with the global push for renewable energy sources. This sector is expected to contribute substantially to market growth in the coming years as governments worldwide implement policies to reduce carbon emissions and promote sustainable energy solutions.

The global market for ethyl acetate in biotechnology is characterized by regional variations in demand and production. Asia-Pacific, particularly China and India, leads in terms of production capacity and consumption, driven by rapid industrialization and a growing biotechnology sector. North America and Europe follow, with established biotechnology industries and stringent environmental regulations favoring the use of eco-friendly solvents like ethyl acetate.

Market analysts project a compound annual growth rate (CAGR) for ethyl acetate in biotechnology applications to exceed the overall chemical industry average over the next five years. This growth is attributed to increasing research and development activities in biotechnology, expanding applications in existing industries, and the emergence of new use cases in fields such as biomaterials and tissue engineering.

However, the market faces challenges, including price volatility of raw materials and competition from alternative solvents. Fluctuations in the prices of ethanol and acetic acid, the primary raw materials for ethyl acetate production, can impact market dynamics. Additionally, ongoing research into novel green solvents may introduce new competitors in specific application areas.

Current Applications and Challenges in Biotech

Ethyl acetate has found numerous applications in biotechnology, primarily due to its unique chemical properties and versatility. In the pharmaceutical industry, it serves as a crucial solvent for the extraction and purification of various bioactive compounds. Its low toxicity and high selectivity make it an ideal choice for isolating natural products from plant materials and microbial fermentation broths. Additionally, ethyl acetate plays a significant role in the production of antibiotics, where it is used in the crystallization process to obtain pure drug substances.

In the field of genetic engineering and molecular biology, ethyl acetate is employed in DNA and RNA extraction protocols. Its ability to dissolve lipids and denature proteins makes it effective in lysing cells and separating nucleic acids from other cellular components. This application has become increasingly important with the growing demand for genomic and transcriptomic analyses in both research and clinical settings.

The food and beverage industry also utilizes ethyl acetate in biotechnological processes. It is used as an extraction solvent for natural flavors and fragrances, enabling the production of high-quality food additives and perfumes. Moreover, ethyl acetate's role in the production of biodegradable plastics has gained attention, as it can be used as a solvent in the synthesis of polylactic acid (PLA), a biodegradable polymer derived from renewable resources.

Despite its widespread use, the application of ethyl acetate in biotechnology faces several challenges. One of the primary concerns is its volatility, which can lead to solvent loss during processing and potential environmental emissions. This necessitates the development of more efficient containment and recovery systems to minimize waste and ensure worker safety. Additionally, the flammability of ethyl acetate poses safety risks in large-scale industrial applications, requiring stringent safety measures and specialized handling procedures.

Another challenge lies in the optimization of ethyl acetate-based processes for improved efficiency and sustainability. As the biotechnology industry moves towards greener practices, there is a growing need to reduce solvent consumption and develop more environmentally friendly alternatives. This has led to research into supercritical fluid extraction techniques and the exploration of bio-based solvents that could potentially replace or complement ethyl acetate in certain applications.

Furthermore, the regulatory landscape surrounding the use of solvents in biotechnology is becoming increasingly complex. Stricter guidelines for solvent residues in pharmaceutical products and food additives require more sophisticated purification and quality control methods. This challenge extends to the development of analytical techniques capable of detecting trace amounts of ethyl acetate in final products, ensuring compliance with regulatory standards across different industries and geographical regions.

In the field of genetic engineering and molecular biology, ethyl acetate is employed in DNA and RNA extraction protocols. Its ability to dissolve lipids and denature proteins makes it effective in lysing cells and separating nucleic acids from other cellular components. This application has become increasingly important with the growing demand for genomic and transcriptomic analyses in both research and clinical settings.

The food and beverage industry also utilizes ethyl acetate in biotechnological processes. It is used as an extraction solvent for natural flavors and fragrances, enabling the production of high-quality food additives and perfumes. Moreover, ethyl acetate's role in the production of biodegradable plastics has gained attention, as it can be used as a solvent in the synthesis of polylactic acid (PLA), a biodegradable polymer derived from renewable resources.

Despite its widespread use, the application of ethyl acetate in biotechnology faces several challenges. One of the primary concerns is its volatility, which can lead to solvent loss during processing and potential environmental emissions. This necessitates the development of more efficient containment and recovery systems to minimize waste and ensure worker safety. Additionally, the flammability of ethyl acetate poses safety risks in large-scale industrial applications, requiring stringent safety measures and specialized handling procedures.

Another challenge lies in the optimization of ethyl acetate-based processes for improved efficiency and sustainability. As the biotechnology industry moves towards greener practices, there is a growing need to reduce solvent consumption and develop more environmentally friendly alternatives. This has led to research into supercritical fluid extraction techniques and the exploration of bio-based solvents that could potentially replace or complement ethyl acetate in certain applications.

Furthermore, the regulatory landscape surrounding the use of solvents in biotechnology is becoming increasingly complex. Stricter guidelines for solvent residues in pharmaceutical products and food additives require more sophisticated purification and quality control methods. This challenge extends to the development of analytical techniques capable of detecting trace amounts of ethyl acetate in final products, ensuring compliance with regulatory standards across different industries and geographical regions.

Existing Biotech Solutions Utilizing Ethyl Acetate

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in various chemical processes and industries. It serves as a solvent, reactant, or intermediate in the production of other chemicals, pharmaceuticals, and materials. Its versatility makes it valuable in diverse applications across different sectors.

- Ethyl acetate in extraction and separation processes: Ethyl acetate is employed in extraction and separation processes for various compounds. Its properties make it suitable for liquid-liquid extraction, azeotropic distillation, and other separation techniques. These processes are used in the purification of chemicals and the isolation of specific compounds.

- Environmental and safety considerations for ethyl acetate: The use and handling of ethyl acetate involve environmental and safety considerations. This includes methods for reducing emissions, improving workplace safety, and developing more sustainable production processes. Efforts are made to minimize the environmental impact and ensure safe handling of ethyl acetate in industrial settings.

- Novel applications and formulations of ethyl acetate: Research into new applications and formulations of ethyl acetate is ongoing. This includes its use in novel materials, coatings, and specialty chemicals. Innovations focus on exploiting the unique properties of ethyl acetate to develop new products and improve existing processes across various industries.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes as a solvent, reactant, or intermediate. It finds applications in the production of pharmaceuticals, polymers, and other organic compounds. The patents describe specific uses and reaction conditions involving ethyl acetate.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

Ethyl acetate is employed in extraction and separation processes for various substances. The patents describe methods for using ethyl acetate to isolate or purify compounds from mixtures, including natural products and synthetic materials.Expand Specific Solutions04 Ethyl acetate-based formulations and compositions

Various formulations and compositions containing ethyl acetate are described. These include adhesives, coatings, cleaning solutions, and other products where ethyl acetate serves as a key ingredient or solvent.Expand Specific Solutions05 Environmental and safety considerations for ethyl acetate use

Patents addressing environmental and safety aspects of ethyl acetate use are included. These cover topics such as emission control, waste treatment, and safe handling practices for ethyl acetate in industrial settings.Expand Specific Solutions

Key Industry Players and Competitors

The biotechnology sector's exploration of new uses for ethyl acetate is in an early growth stage, with a rapidly expanding market driven by increasing demand for sustainable and bio-based solutions. The global market for ethyl acetate in biotechnology applications is projected to grow significantly in the coming years. Technologically, the field is evolving rapidly, with companies like Boehringer Ingelheim, Evonik Operations, and Eastman Chemical leading research efforts. Academic institutions such as Rice University and the University of Florida are also contributing to advancements. While the technology is not yet fully mature, collaborative efforts between industry and academia are accelerating progress, indicating a promising future for ethyl acetate in biotechnology applications.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed innovative applications of ethyl acetate in biotechnology, focusing on its use as a green solvent in biocatalysis and as a building block for bio-based materials. The company has engineered a novel process that utilizes ethyl acetate as a key intermediate in the production of biodegradable polymers. This approach involves the enzymatic polymerization of ethyl acetate derivatives, resulting in materials with tunable properties suitable for various applications, from packaging to biomedical devices[9]. Evonik has also explored the use of ethyl acetate in the development of sustainable coating technologies, leveraging its low toxicity and high solvency. Their research has led to the creation of bio-based coatings with improved durability and environmental profile. Furthermore, the company is investigating the potential of ethyl acetate as a platform chemical for the synthesis of other value-added products through biotechnological routes[10].

Strengths: Sustainable materials production, versatility in applications, and potential for circular economy solutions. Weaknesses: Competition from established petrochemical-based materials and potential scale-up challenges.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed innovative applications of ethyl acetate in biotechnology, focusing on its use as a green solvent for biocatalysis and enzyme-mediated reactions. Their approach involves utilizing ethyl acetate's unique properties to enhance enzyme stability and activity in organic media. The company has engineered a biphasic reaction system where ethyl acetate serves as both a substrate and an extraction solvent, allowing for continuous product removal and improved reaction efficiency[1]. This system has been particularly effective in the production of chiral pharmaceutical intermediates and fine chemicals. Eastman has also explored the use of ethyl acetate in the purification of biomolecules, leveraging its selective solubility properties to develop more efficient and environmentally friendly separation processes[3].

Strengths: Improved reaction efficiency, reduced environmental impact, and potential for continuous processing. Weaknesses: May require specialized equipment and process optimization for each application.

Innovative Research on Ethyl Acetate in Biotechnology

Homogeneous iron catalysts for the conversion of ethanol to ethyl acetate and hydrogen

PatentWO2019027965A1

Innovation

- A process utilizing a homogeneous iron catalyst with a tridentate pincer ligand for dehydrogenative coupling of ethanol at moderate temperatures, producing ethyl acetate efficiently and selectively, with iron loadings as low as 0.001 mol%, allowing for continuous operation and easy separation of ethyl acetate from the catalyst.

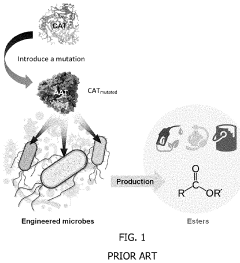

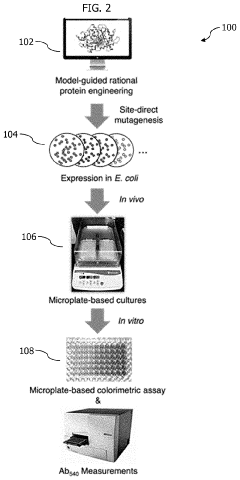

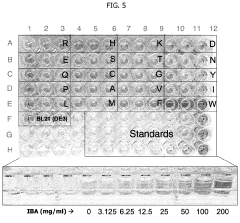

Methods for Producing Designer Esters and Assessing Alcohol Acyltransferase Specificity for Ester Biosynthesis

PatentActiveUS20230235368A1

Innovation

- A high-throughput microbial screening platform using preselected plasmids and a colorimetric assay is developed to identify AATs for ester biosynthesis, involving in situ fermentation with a solvent overlay and subsequent measurement of ester concentration through an iron-hydroxamic acid complex, allowing for rapid and efficient selection of AATs and synthesis of butyryl-CoA derived esters by modularly designing ester biosynthesis pathways.

Environmental Impact and Sustainability Considerations

The use of ethyl acetate in biotechnology applications raises important environmental and sustainability considerations. As a widely used solvent in various industrial processes, its potential impact on ecosystems and human health must be carefully evaluated.

Ethyl acetate is generally considered to have lower toxicity compared to many other organic solvents. However, its release into the environment can still have adverse effects. When released into the atmosphere, it contributes to the formation of ground-level ozone and photochemical smog, which can harm plant life and human respiratory health. In aquatic environments, ethyl acetate can be toxic to fish and other organisms at high concentrations.

From a sustainability perspective, the production of ethyl acetate traditionally relies on petrochemical sources. This dependency on non-renewable resources raises concerns about long-term availability and environmental impact. However, recent advancements in biotechnology have opened up possibilities for more sustainable production methods. Bioethanol-based ethyl acetate production, for instance, offers a renewable alternative that could significantly reduce the carbon footprint of its manufacturing process.

Waste management is another crucial aspect to consider. Proper handling and disposal of ethyl acetate-containing waste are essential to prevent environmental contamination. Many biotechnology applications involve the use of ethyl acetate in extraction processes, which can generate significant amounts of waste. Implementing efficient solvent recovery and recycling systems can minimize waste generation and reduce the overall environmental impact.

The potential for biodegradation is a positive attribute of ethyl acetate. Under appropriate conditions, it can be broken down by microorganisms in the environment, reducing its long-term persistence. This characteristic makes it a more environmentally friendly option compared to some other solvents used in biotechnology.

As the biotechnology industry explores new uses for ethyl acetate, it is crucial to conduct comprehensive life cycle assessments. These assessments should consider the entire process from production to disposal, including energy consumption, water usage, and potential emissions. Such analyses can help identify areas for improvement and guide the development of more sustainable practices.

Regulatory compliance is an essential consideration for the use of ethyl acetate in biotechnology. Many countries have strict regulations governing the use and disposal of organic solvents. Adhering to these regulations not only ensures legal compliance but also promotes responsible environmental stewardship.

In conclusion, while ethyl acetate offers several advantages for biotechnology applications, its environmental impact and sustainability aspects must be carefully managed. Ongoing research into greener production methods, efficient recycling techniques, and improved waste management strategies will be crucial in maximizing the benefits of ethyl acetate while minimizing its environmental footprint.

Ethyl acetate is generally considered to have lower toxicity compared to many other organic solvents. However, its release into the environment can still have adverse effects. When released into the atmosphere, it contributes to the formation of ground-level ozone and photochemical smog, which can harm plant life and human respiratory health. In aquatic environments, ethyl acetate can be toxic to fish and other organisms at high concentrations.

From a sustainability perspective, the production of ethyl acetate traditionally relies on petrochemical sources. This dependency on non-renewable resources raises concerns about long-term availability and environmental impact. However, recent advancements in biotechnology have opened up possibilities for more sustainable production methods. Bioethanol-based ethyl acetate production, for instance, offers a renewable alternative that could significantly reduce the carbon footprint of its manufacturing process.

Waste management is another crucial aspect to consider. Proper handling and disposal of ethyl acetate-containing waste are essential to prevent environmental contamination. Many biotechnology applications involve the use of ethyl acetate in extraction processes, which can generate significant amounts of waste. Implementing efficient solvent recovery and recycling systems can minimize waste generation and reduce the overall environmental impact.

The potential for biodegradation is a positive attribute of ethyl acetate. Under appropriate conditions, it can be broken down by microorganisms in the environment, reducing its long-term persistence. This characteristic makes it a more environmentally friendly option compared to some other solvents used in biotechnology.

As the biotechnology industry explores new uses for ethyl acetate, it is crucial to conduct comprehensive life cycle assessments. These assessments should consider the entire process from production to disposal, including energy consumption, water usage, and potential emissions. Such analyses can help identify areas for improvement and guide the development of more sustainable practices.

Regulatory compliance is an essential consideration for the use of ethyl acetate in biotechnology. Many countries have strict regulations governing the use and disposal of organic solvents. Adhering to these regulations not only ensures legal compliance but also promotes responsible environmental stewardship.

In conclusion, while ethyl acetate offers several advantages for biotechnology applications, its environmental impact and sustainability aspects must be carefully managed. Ongoing research into greener production methods, efficient recycling techniques, and improved waste management strategies will be crucial in maximizing the benefits of ethyl acetate while minimizing its environmental footprint.

Regulatory Framework for Ethyl Acetate in Biotech

The regulatory framework for ethyl acetate in biotechnology is a complex and evolving landscape that requires careful navigation by industry stakeholders. At the global level, the use of ethyl acetate in biotech applications is governed by various international bodies and agreements, such as the World Health Organization (WHO) and the International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH). These organizations provide guidelines and standards that inform national regulatory policies.

In the United States, the Food and Drug Administration (FDA) plays a central role in regulating ethyl acetate's use in biotechnology. The FDA classifies ethyl acetate as a Generally Recognized as Safe (GRAS) substance when used as a food additive or in food contact materials. However, its use in biotech applications, particularly in pharmaceutical manufacturing, is subject to more stringent oversight under the Current Good Manufacturing Practice (cGMP) regulations.

The Environmental Protection Agency (EPA) also has jurisdiction over ethyl acetate, particularly concerning its environmental impact and worker safety. Under the Toxic Substances Control Act (TSCA), the EPA monitors the production, use, and disposal of ethyl acetate to ensure environmental protection and public health.

In the European Union, the European Medicines Agency (EMA) and the European Food Safety Authority (EFSA) are key regulatory bodies. The EU's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation applies to ethyl acetate, requiring manufacturers and importers to register the substance and provide safety information. For biotech applications, compliance with Good Manufacturing Practice (GMP) guidelines is mandatory.

Emerging markets, such as China and India, are developing their regulatory frameworks for biotechnology and chemical use. China's National Medical Products Administration (NMPA) and India's Central Drugs Standard Control Organization (CDSCO) have established guidelines for the use of solvents like ethyl acetate in biotech processes, often aligning with international standards while addressing local concerns.

As the biotechnology industry continues to innovate, regulatory bodies are adapting their frameworks to accommodate new uses of ethyl acetate. This includes developing specific guidelines for novel bioprocessing techniques, such as continuous manufacturing, where ethyl acetate may play a role. Additionally, there is an increasing focus on sustainability and green chemistry, prompting regulators to encourage the use of environmentally friendly solvents and processes.

Compliance with these regulatory frameworks is crucial for companies seeking to leverage ethyl acetate in biotechnology applications. This often involves extensive documentation, rigorous testing, and adherence to quality control measures throughout the product lifecycle. As new applications for ethyl acetate in biotechnology emerge, companies must stay abreast of regulatory changes and engage proactively with authorities to ensure compliance and facilitate innovation.

In the United States, the Food and Drug Administration (FDA) plays a central role in regulating ethyl acetate's use in biotechnology. The FDA classifies ethyl acetate as a Generally Recognized as Safe (GRAS) substance when used as a food additive or in food contact materials. However, its use in biotech applications, particularly in pharmaceutical manufacturing, is subject to more stringent oversight under the Current Good Manufacturing Practice (cGMP) regulations.

The Environmental Protection Agency (EPA) also has jurisdiction over ethyl acetate, particularly concerning its environmental impact and worker safety. Under the Toxic Substances Control Act (TSCA), the EPA monitors the production, use, and disposal of ethyl acetate to ensure environmental protection and public health.

In the European Union, the European Medicines Agency (EMA) and the European Food Safety Authority (EFSA) are key regulatory bodies. The EU's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation applies to ethyl acetate, requiring manufacturers and importers to register the substance and provide safety information. For biotech applications, compliance with Good Manufacturing Practice (GMP) guidelines is mandatory.

Emerging markets, such as China and India, are developing their regulatory frameworks for biotechnology and chemical use. China's National Medical Products Administration (NMPA) and India's Central Drugs Standard Control Organization (CDSCO) have established guidelines for the use of solvents like ethyl acetate in biotech processes, often aligning with international standards while addressing local concerns.

As the biotechnology industry continues to innovate, regulatory bodies are adapting their frameworks to accommodate new uses of ethyl acetate. This includes developing specific guidelines for novel bioprocessing techniques, such as continuous manufacturing, where ethyl acetate may play a role. Additionally, there is an increasing focus on sustainability and green chemistry, prompting regulators to encourage the use of environmentally friendly solvents and processes.

Compliance with these regulatory frameworks is crucial for companies seeking to leverage ethyl acetate in biotechnology applications. This often involves extensive documentation, rigorous testing, and adherence to quality control measures throughout the product lifecycle. As new applications for ethyl acetate in biotechnology emerge, companies must stay abreast of regulatory changes and engage proactively with authorities to ensure compliance and facilitate innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!