Efficiency metrics for induction motor agricultural machinery

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Efficiency in Agriculture: Background and Objectives

Induction motors have been a cornerstone of agricultural machinery for decades, powering a wide range of equipment from irrigation systems to harvesting machines. The efficiency of these motors plays a crucial role in the overall productivity and sustainability of modern farming practices. As global agriculture faces increasing pressure to optimize resource utilization and reduce environmental impact, the focus on induction motor efficiency has intensified.

The evolution of induction motor technology in agriculture has been marked by continuous improvements in design, materials, and control systems. Early agricultural applications relied on simple, robust motors that prioritized reliability over efficiency. However, as energy costs rose and environmental concerns grew, the industry began to shift towards more efficient solutions. This transition has been driven by both regulatory pressures and the economic imperative to reduce operational costs in farming.

The primary objective of enhancing induction motor efficiency in agricultural machinery is to maximize power output while minimizing energy consumption. This goal aligns with broader agricultural trends towards precision farming and sustainable practices. Improved motor efficiency translates directly into reduced electricity usage, lower operating costs, and decreased carbon footprint for farming operations.

Current technological advancements in induction motor design for agricultural applications focus on several key areas. These include the use of high-grade electrical steels to reduce core losses, optimized winding designs to minimize copper losses, and advanced cooling systems to maintain optimal operating temperatures. Additionally, the integration of variable frequency drives (VFDs) has allowed for better speed control and energy management, particularly in applications with varying load requirements.

The development of efficiency metrics for induction motors in agricultural machinery is essential for standardizing performance evaluations and guiding further improvements. These metrics typically consider factors such as power factor, full-load efficiency, and part-load performance across different operating conditions. The International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have established standards that provide frameworks for assessing and classifying motor efficiency.

As the agricultural sector continues to embrace automation and smart farming technologies, the role of efficient induction motors becomes even more critical. The integration of Internet of Things (IoT) sensors and data analytics is enabling real-time monitoring and optimization of motor performance in the field. This convergence of motor technology with digital systems presents new opportunities for enhancing efficiency and reliability in agricultural operations.

The evolution of induction motor technology in agriculture has been marked by continuous improvements in design, materials, and control systems. Early agricultural applications relied on simple, robust motors that prioritized reliability over efficiency. However, as energy costs rose and environmental concerns grew, the industry began to shift towards more efficient solutions. This transition has been driven by both regulatory pressures and the economic imperative to reduce operational costs in farming.

The primary objective of enhancing induction motor efficiency in agricultural machinery is to maximize power output while minimizing energy consumption. This goal aligns with broader agricultural trends towards precision farming and sustainable practices. Improved motor efficiency translates directly into reduced electricity usage, lower operating costs, and decreased carbon footprint for farming operations.

Current technological advancements in induction motor design for agricultural applications focus on several key areas. These include the use of high-grade electrical steels to reduce core losses, optimized winding designs to minimize copper losses, and advanced cooling systems to maintain optimal operating temperatures. Additionally, the integration of variable frequency drives (VFDs) has allowed for better speed control and energy management, particularly in applications with varying load requirements.

The development of efficiency metrics for induction motors in agricultural machinery is essential for standardizing performance evaluations and guiding further improvements. These metrics typically consider factors such as power factor, full-load efficiency, and part-load performance across different operating conditions. The International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have established standards that provide frameworks for assessing and classifying motor efficiency.

As the agricultural sector continues to embrace automation and smart farming technologies, the role of efficient induction motors becomes even more critical. The integration of Internet of Things (IoT) sensors and data analytics is enabling real-time monitoring and optimization of motor performance in the field. This convergence of motor technology with digital systems presents new opportunities for enhancing efficiency and reliability in agricultural operations.

Market Analysis for Efficient Agricultural Machinery

The market for efficient agricultural machinery, particularly those utilizing induction motors, has been experiencing significant growth in recent years. This trend is driven by the increasing demand for higher productivity, reduced operational costs, and improved sustainability in the agricultural sector. Farmers and agricultural businesses are increasingly recognizing the importance of energy-efficient equipment in maintaining competitiveness and reducing their environmental footprint.

The global market for agricultural machinery is projected to reach substantial value in the coming years, with a considerable portion attributed to energy-efficient equipment. Induction motor-powered machinery, known for its reliability and efficiency, is expected to play a crucial role in this market expansion. Regions such as North America, Europe, and Asia-Pacific are leading in the adoption of efficient agricultural machinery, with emerging economies showing rapid growth potential.

Key market drivers include the rising costs of energy and labor, stringent environmental regulations, and government incentives for adopting energy-efficient technologies. Additionally, the increasing focus on precision agriculture and smart farming practices is fueling the demand for advanced, efficient machinery that can integrate with digital technologies and IoT systems.

The market for efficient induction motor agricultural machinery spans various equipment types, including tractors, harvesters, irrigation systems, and processing equipment. Each segment presents unique opportunities and challenges, with tractors and harvesters showing particularly strong growth potential due to their widespread use and significant impact on overall farm efficiency.

Consumer preferences are shifting towards machinery that offers not only energy efficiency but also improved performance, durability, and ease of maintenance. This trend is pushing manufacturers to innovate and develop more advanced induction motor technologies that can meet these diverse requirements.

However, the market also faces certain challenges. The high initial cost of energy-efficient machinery can be a barrier for small and medium-sized farms, particularly in developing regions. Additionally, the lack of awareness about the long-term benefits of energy-efficient equipment and the need for specialized skills for operation and maintenance can slow market penetration in some areas.

Despite these challenges, the overall market outlook remains positive. The increasing emphasis on sustainable agriculture, coupled with technological advancements in motor design and control systems, is expected to drive continued growth in the efficient agricultural machinery market. As awareness grows and economies of scale are achieved, the adoption of energy-efficient induction motor machinery is likely to accelerate, reshaping the agricultural landscape and contributing to more sustainable farming practices worldwide.

The global market for agricultural machinery is projected to reach substantial value in the coming years, with a considerable portion attributed to energy-efficient equipment. Induction motor-powered machinery, known for its reliability and efficiency, is expected to play a crucial role in this market expansion. Regions such as North America, Europe, and Asia-Pacific are leading in the adoption of efficient agricultural machinery, with emerging economies showing rapid growth potential.

Key market drivers include the rising costs of energy and labor, stringent environmental regulations, and government incentives for adopting energy-efficient technologies. Additionally, the increasing focus on precision agriculture and smart farming practices is fueling the demand for advanced, efficient machinery that can integrate with digital technologies and IoT systems.

The market for efficient induction motor agricultural machinery spans various equipment types, including tractors, harvesters, irrigation systems, and processing equipment. Each segment presents unique opportunities and challenges, with tractors and harvesters showing particularly strong growth potential due to their widespread use and significant impact on overall farm efficiency.

Consumer preferences are shifting towards machinery that offers not only energy efficiency but also improved performance, durability, and ease of maintenance. This trend is pushing manufacturers to innovate and develop more advanced induction motor technologies that can meet these diverse requirements.

However, the market also faces certain challenges. The high initial cost of energy-efficient machinery can be a barrier for small and medium-sized farms, particularly in developing regions. Additionally, the lack of awareness about the long-term benefits of energy-efficient equipment and the need for specialized skills for operation and maintenance can slow market penetration in some areas.

Despite these challenges, the overall market outlook remains positive. The increasing emphasis on sustainable agriculture, coupled with technological advancements in motor design and control systems, is expected to drive continued growth in the efficient agricultural machinery market. As awareness grows and economies of scale are achieved, the adoption of energy-efficient induction motor machinery is likely to accelerate, reshaping the agricultural landscape and contributing to more sustainable farming practices worldwide.

Current Challenges in Induction Motor Efficiency for Farm Equipment

The current challenges in induction motor efficiency for farm equipment are multifaceted and stem from various technical, environmental, and operational factors. One of the primary issues is the need for motors to operate efficiently across a wide range of speeds and loads, which is characteristic of agricultural machinery. Farm equipment often experiences fluctuating power demands due to varying soil conditions, crop densities, and terrain, making it difficult to optimize motor performance consistently.

Another significant challenge is the harsh operating environment typical in agricultural settings. Exposure to dust, moisture, and extreme temperatures can degrade motor components over time, leading to reduced efficiency and increased energy consumption. This necessitates the development of robust motor designs that can maintain high efficiency levels despite these adverse conditions.

The integration of advanced control systems and power electronics presents both opportunities and challenges. While these technologies can potentially improve motor efficiency, they also introduce complexity and potential points of failure. Ensuring the reliability and durability of these systems in rugged farm environments remains a significant hurdle.

Energy recovery and regenerative braking systems, which could significantly enhance overall efficiency, are not yet widely implemented in agricultural machinery. The development and integration of such systems pose technical challenges, particularly in terms of energy storage and management in mobile applications.

Weight and size constraints also play a crucial role in the efficiency equation. Farm equipment requires powerful motors, but excessive weight can lead to soil compaction and reduced overall efficiency. Balancing power output with motor size and weight remains an ongoing challenge for engineers and designers.

The need for improved thermal management is another critical issue. Efficient heat dissipation is essential for maintaining motor performance and longevity, especially in enclosed or compact motor designs often found in modern agricultural machinery.

Lastly, the cost-effectiveness of implementing high-efficiency motors and advanced control systems in farm equipment remains a significant barrier. While more efficient motors can lead to long-term energy savings, the initial investment can be prohibitive for many farmers, particularly in developing regions. Striking a balance between efficiency gains and economic viability is a persistent challenge for manufacturers and policymakers alike.

Another significant challenge is the harsh operating environment typical in agricultural settings. Exposure to dust, moisture, and extreme temperatures can degrade motor components over time, leading to reduced efficiency and increased energy consumption. This necessitates the development of robust motor designs that can maintain high efficiency levels despite these adverse conditions.

The integration of advanced control systems and power electronics presents both opportunities and challenges. While these technologies can potentially improve motor efficiency, they also introduce complexity and potential points of failure. Ensuring the reliability and durability of these systems in rugged farm environments remains a significant hurdle.

Energy recovery and regenerative braking systems, which could significantly enhance overall efficiency, are not yet widely implemented in agricultural machinery. The development and integration of such systems pose technical challenges, particularly in terms of energy storage and management in mobile applications.

Weight and size constraints also play a crucial role in the efficiency equation. Farm equipment requires powerful motors, but excessive weight can lead to soil compaction and reduced overall efficiency. Balancing power output with motor size and weight remains an ongoing challenge for engineers and designers.

The need for improved thermal management is another critical issue. Efficient heat dissipation is essential for maintaining motor performance and longevity, especially in enclosed or compact motor designs often found in modern agricultural machinery.

Lastly, the cost-effectiveness of implementing high-efficiency motors and advanced control systems in farm equipment remains a significant barrier. While more efficient motors can lead to long-term energy savings, the initial investment can be prohibitive for many farmers, particularly in developing regions. Striking a balance between efficiency gains and economic viability is a persistent challenge for manufacturers and policymakers alike.

Existing Efficiency Metrics and Measurement Methods

01 Motor control strategies for efficiency improvement

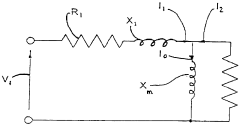

Various control strategies can be implemented to improve the efficiency of induction motors. These may include vector control, direct torque control, and adaptive control algorithms. Such methods optimize the motor's performance by precisely controlling the magnetic flux and torque, resulting in reduced energy losses and improved overall efficiency.- Motor control techniques for efficiency improvement: Various control techniques are employed to enhance induction motor efficiency. These include advanced algorithms for optimizing motor operation, adaptive control systems that adjust to changing load conditions, and intelligent control strategies that minimize energy losses. Such techniques often involve real-time monitoring and adjustment of motor parameters to maintain peak efficiency across different operating conditions.

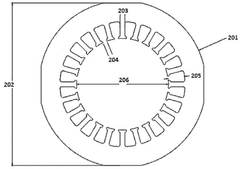

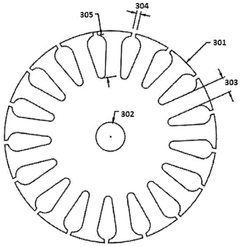

- Design optimization for high-efficiency motors: Improving induction motor efficiency through design optimization involves several approaches. These include using advanced materials for rotor and stator construction, optimizing the geometry of motor components, and implementing innovative cooling systems. Design enhancements focus on reducing losses in the motor, such as copper losses, iron losses, and mechanical losses, thereby increasing overall efficiency.

- Power factor correction and harmonics reduction: Techniques for improving power factor and reducing harmonics contribute significantly to induction motor efficiency. These methods include the use of power factor correction capacitors, active front-end converters, and harmonic filters. By minimizing reactive power and harmonic distortions, these approaches reduce energy losses and improve the overall system efficiency.

- Thermal management and cooling innovations: Effective thermal management is crucial for maintaining high efficiency in induction motors. Innovative cooling techniques, such as advanced fan designs, liquid cooling systems, and heat pipe technologies, help dissipate heat more efficiently. Improved thermal management reduces resistance losses and extends motor life, contributing to sustained high efficiency over time.

- Efficiency monitoring and predictive maintenance: Implementing advanced monitoring systems and predictive maintenance strategies helps maintain high efficiency in induction motors. These systems use sensors, data analytics, and machine learning algorithms to detect efficiency drops, predict potential failures, and optimize maintenance schedules. By ensuring motors operate at peak efficiency and addressing issues proactively, overall system performance and longevity are improved.

02 Design optimization for high-efficiency motors

Improving induction motor efficiency through design optimization involves enhancing the motor's electromagnetic and mechanical components. This may include using high-quality core materials, optimizing slot and winding designs, and implementing advanced cooling systems. These design improvements can significantly reduce losses and increase the motor's overall efficiency.Expand Specific Solutions03 Power factor correction and harmonics reduction

Implementing power factor correction techniques and reducing harmonics can significantly improve induction motor efficiency. This may involve using capacitor banks, active filters, or advanced inverter designs to minimize reactive power consumption and harmonic distortions, resulting in improved power quality and reduced losses in the motor system.Expand Specific Solutions04 Efficiency monitoring and predictive maintenance

Continuous monitoring of motor efficiency and implementing predictive maintenance strategies can help maintain optimal performance. This may include using sensors, data analytics, and machine learning algorithms to detect efficiency degradation, predict potential failures, and schedule maintenance activities, ensuring the motor operates at peak efficiency throughout its lifecycle.Expand Specific Solutions05 Energy recovery and regenerative systems

Incorporating energy recovery and regenerative systems can improve the overall efficiency of induction motor applications. These systems capture and reuse energy during braking or deceleration phases, converting kinetic energy back into electrical energy. This approach can significantly reduce energy consumption in applications with frequent start-stop cycles or variable load conditions.Expand Specific Solutions

Key Players in Agricultural Induction Motor Manufacturing

The efficiency metrics for induction motor agricultural machinery market is in a growth phase, driven by increasing demand for precision agriculture and smart farming solutions. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Deere & Co., AGCO Corp., and Claas Selbstfahrende Erntemaschinen GmbH leading innovation in motor efficiency and control systems. Major players such as ABB Group, Schneider Electric, and Mitsubishi Electric are contributing to the development of advanced motor technologies, while research institutions like China Agricultural University and Kunming University of Science & Technology are driving academic advancements in this area.

Deere & Co.

Technical Solution: Deere & Co. has developed advanced efficiency metrics for induction motors in agricultural machinery, focusing on power density and thermal management. Their approach includes the use of high-efficiency induction motors with optimized stator and rotor designs, coupled with advanced control algorithms. The company has implemented a system that continuously monitors motor performance, including temperature, current, and voltage, to ensure optimal efficiency across various operating conditions[1]. Deere's solution also incorporates regenerative braking technology, which recovers energy during deceleration and converts it back into usable electricity, significantly improving overall system efficiency[2].

Strengths: Comprehensive approach integrating hardware and software solutions, extensive field testing capabilities. Weaknesses: Potentially higher initial cost due to advanced technology integration.

ABB Oy

Technical Solution: ABB Oy has developed a comprehensive efficiency metric system for induction motors used in agricultural machinery. Their approach focuses on high-precision measurement and analysis of motor performance parameters. ABB's solution incorporates advanced power electronics and digital twin technology to create a virtual model of each motor, enabling real-time efficiency optimization[5]. The system uses a combination of current, voltage, and magnetic field sensors to accurately measure motor losses and calculate efficiency across different operating points. ABB has also implemented an innovative stator winding design that reduces copper losses and improves overall motor efficiency[6].

Strengths: High-precision measurement capabilities, integration of digital twin technology for predictive maintenance. Weaknesses: May require specialized training for operators to fully utilize advanced features.

Innovative Approaches to Induction Motor Efficiency Assessment

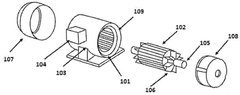

An optimized induction motor with an improved core design with IE3 and IE4 efficiency class

PatentWO2025078953A1

Innovation

- The development of an optimized induction motor with a specially designed core, featuring specific dimensions and configurations for the stator and rotor, aimed at achieving IE3 and IE4 efficiency classes with reduced material usage.

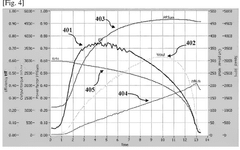

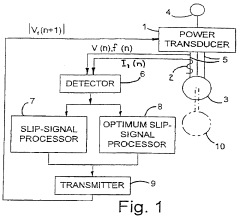

Efficiency control system for an induction motor

PatentInactiveUS5796237A

Innovation

- An efficiency control system that calculates actual and optimum slip values based on voltage, current, and frequency signals from the induction motor, using these calculations to generate a voltage command signal that adjusts the electrical power supplied to maintain optimal slip and maximize efficiency.

Environmental Impact of Efficient Agricultural Motors

The environmental impact of efficient agricultural motors, particularly induction motors used in agricultural machinery, is a critical consideration in the pursuit of sustainable farming practices. These motors play a vital role in various agricultural operations, from irrigation systems to harvesting equipment, and their efficiency directly influences energy consumption and environmental footprint.

Efficient induction motors in agricultural machinery contribute significantly to reducing greenhouse gas emissions. By optimizing energy conversion and minimizing power losses, these motors consume less electricity, thereby decreasing the carbon footprint associated with agricultural operations. This reduction in energy consumption translates to lower CO2 emissions, aligning with global efforts to mitigate climate change impacts in the agricultural sector.

Water conservation is another crucial environmental benefit of efficient agricultural motors. In irrigation systems, for instance, high-efficiency motors enable precise control over water distribution, reducing waste and overuse. This not only conserves water resources but also minimizes the energy required for pumping and distribution, creating a dual environmental benefit.

The use of efficient motors also leads to a reduction in noise pollution, a often overlooked environmental concern in agricultural settings. Lower noise levels contribute to a healthier ecosystem, minimizing disturbances to local wildlife and improving working conditions for farm laborers.

Furthermore, the longevity and reliability of efficient induction motors result in less frequent replacements, reducing the environmental impact associated with manufacturing and disposing of agricultural equipment. This decrease in material consumption and waste generation contributes to a more sustainable agricultural industry.

Efficient motors also enable more precise agricultural practices, such as variable-rate application of fertilizers and pesticides. This precision reduces the overall use of these chemicals, minimizing soil and water contamination and promoting healthier ecosystems.

The adoption of efficient motors in agricultural machinery aligns with circular economy principles. These motors often incorporate recyclable materials and are designed for easier maintenance and repair, extending their lifecycle and reducing the overall environmental impact of agricultural operations.

In conclusion, the environmental impact of efficient agricultural motors extends beyond mere energy savings. Their implementation contributes to reduced emissions, water conservation, noise reduction, and overall sustainability in farming practices, playing a crucial role in the transition towards more environmentally friendly agriculture.

Efficient induction motors in agricultural machinery contribute significantly to reducing greenhouse gas emissions. By optimizing energy conversion and minimizing power losses, these motors consume less electricity, thereby decreasing the carbon footprint associated with agricultural operations. This reduction in energy consumption translates to lower CO2 emissions, aligning with global efforts to mitigate climate change impacts in the agricultural sector.

Water conservation is another crucial environmental benefit of efficient agricultural motors. In irrigation systems, for instance, high-efficiency motors enable precise control over water distribution, reducing waste and overuse. This not only conserves water resources but also minimizes the energy required for pumping and distribution, creating a dual environmental benefit.

The use of efficient motors also leads to a reduction in noise pollution, a often overlooked environmental concern in agricultural settings. Lower noise levels contribute to a healthier ecosystem, minimizing disturbances to local wildlife and improving working conditions for farm laborers.

Furthermore, the longevity and reliability of efficient induction motors result in less frequent replacements, reducing the environmental impact associated with manufacturing and disposing of agricultural equipment. This decrease in material consumption and waste generation contributes to a more sustainable agricultural industry.

Efficient motors also enable more precise agricultural practices, such as variable-rate application of fertilizers and pesticides. This precision reduces the overall use of these chemicals, minimizing soil and water contamination and promoting healthier ecosystems.

The adoption of efficient motors in agricultural machinery aligns with circular economy principles. These motors often incorporate recyclable materials and are designed for easier maintenance and repair, extending their lifecycle and reducing the overall environmental impact of agricultural operations.

In conclusion, the environmental impact of efficient agricultural motors extends beyond mere energy savings. Their implementation contributes to reduced emissions, water conservation, noise reduction, and overall sustainability in farming practices, playing a crucial role in the transition towards more environmentally friendly agriculture.

Standardization of Efficiency Metrics for Agricultural Motors

The standardization of efficiency metrics for agricultural motors is a critical step towards improving the overall performance and sustainability of agricultural machinery. This process involves establishing uniform methods for measuring and reporting the efficiency of induction motors used in various agricultural applications. By creating a standardized framework, manufacturers, farmers, and policymakers can make informed decisions based on comparable data across different motor models and brands.

One of the primary challenges in developing standardized efficiency metrics is accounting for the diverse operating conditions encountered in agricultural settings. Factors such as varying load profiles, environmental conditions, and specific application requirements must be considered to create meaningful and representative metrics. To address this, a comprehensive approach that incorporates both laboratory testing and field performance data is essential.

The standardization process typically begins with the identification of key performance indicators (KPIs) that accurately reflect motor efficiency in agricultural contexts. These may include parameters such as power factor, torque characteristics, and energy consumption under different load conditions. Additionally, metrics that consider the motor's performance over extended periods, such as seasonal efficiency ratings, can provide valuable insights into long-term operational costs and environmental impact.

To ensure widespread adoption and relevance, the development of standardized metrics often involves collaboration between industry stakeholders, research institutions, and regulatory bodies. This collaborative approach helps to balance the technical requirements with practical considerations, ensuring that the resulting standards are both scientifically sound and implementable in real-world scenarios.

The implementation of standardized efficiency metrics can drive innovation in motor design and manufacturing processes. By establishing clear benchmarks, manufacturers are incentivized to develop more efficient motors that meet or exceed the standardized performance criteria. This, in turn, can lead to the development of advanced technologies such as improved magnetic materials, optimized winding designs, and more sophisticated control systems.

Furthermore, standardized metrics facilitate the creation of energy efficiency labeling programs for agricultural motors. These programs provide farmers with easily understandable information about motor performance, enabling them to make cost-effective and environmentally conscious purchasing decisions. Such labeling schemes have proven successful in other industries, such as household appliances, in driving market transformation towards more energy-efficient products.

One of the primary challenges in developing standardized efficiency metrics is accounting for the diverse operating conditions encountered in agricultural settings. Factors such as varying load profiles, environmental conditions, and specific application requirements must be considered to create meaningful and representative metrics. To address this, a comprehensive approach that incorporates both laboratory testing and field performance data is essential.

The standardization process typically begins with the identification of key performance indicators (KPIs) that accurately reflect motor efficiency in agricultural contexts. These may include parameters such as power factor, torque characteristics, and energy consumption under different load conditions. Additionally, metrics that consider the motor's performance over extended periods, such as seasonal efficiency ratings, can provide valuable insights into long-term operational costs and environmental impact.

To ensure widespread adoption and relevance, the development of standardized metrics often involves collaboration between industry stakeholders, research institutions, and regulatory bodies. This collaborative approach helps to balance the technical requirements with practical considerations, ensuring that the resulting standards are both scientifically sound and implementable in real-world scenarios.

The implementation of standardized efficiency metrics can drive innovation in motor design and manufacturing processes. By establishing clear benchmarks, manufacturers are incentivized to develop more efficient motors that meet or exceed the standardized performance criteria. This, in turn, can lead to the development of advanced technologies such as improved magnetic materials, optimized winding designs, and more sophisticated control systems.

Furthermore, standardized metrics facilitate the creation of energy efficiency labeling programs for agricultural motors. These programs provide farmers with easily understandable information about motor performance, enabling them to make cost-effective and environmentally conscious purchasing decisions. Such labeling schemes have proven successful in other industries, such as household appliances, in driving market transformation towards more energy-efficient products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!