Enhancing Air Conditioner Efficiency with Thermoelectric Inserts

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric AC Enhancement Background and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century through the Seebeck, Peltier, and Thomson effects. These fundamental principles have enabled the development of solid-state heat pumps capable of converting electrical energy directly into temperature gradients. In recent decades, thermoelectric materials have progressed from traditional bismuth telluride compounds to advanced nanostructured materials with significantly improved figures of merit (ZT values), marking a substantial improvement in conversion efficiency.

The integration of thermoelectric technology with conventional air conditioning systems represents a promising frontier in HVAC innovation. Traditional vapor-compression air conditioners, while widely adopted, continue to face efficiency challenges and environmental concerns due to refrigerant usage. The global push toward energy efficiency and sustainable cooling solutions has accelerated research into hybrid systems that can leverage the complementary strengths of multiple cooling technologies.

The primary objective of this technical research is to evaluate the feasibility and potential benefits of incorporating thermoelectric inserts into conventional air conditioning systems. Specifically, we aim to determine whether such integration can yield meaningful improvements in overall system efficiency, reduce energy consumption, and minimize environmental impact without significantly increasing manufacturing complexity or consumer costs.

Current air conditioning systems typically operate at 60-80% of their theoretical efficiency, with substantial energy losses occurring during the compression and expansion cycles. Thermoelectric elements, operating as solid-state heat pumps with no moving parts, offer potential advantages in specific operational contexts, particularly in managing partial loads and maintaining precise temperature control.

The technical evolution trajectory suggests that thermoelectric materials are approaching a critical threshold where their integration into mainstream cooling applications becomes economically viable. Recent advancements in material science have produced thermoelectric modules with ZT values exceeding 2.0 under laboratory conditions, compared to commercial modules typically operating at ZT values of 0.8-1.2.

This research will explore various architectural approaches to thermoelectric integration, including cascade systems, heat recovery applications, and zonal cooling enhancements. We will evaluate these approaches against key performance metrics including Coefficient of Performance (COP), energy consumption reduction potential, system reliability, and lifecycle cost analysis.

Additionally, we will examine how emerging technologies such as advanced ceramics, nano-engineered interfaces, and novel semiconductor materials might further enhance the performance of thermoelectric inserts in air conditioning applications. The research will also consider how these hybrid systems might benefit from or contribute to smart building technologies and demand-response energy management systems.

The integration of thermoelectric technology with conventional air conditioning systems represents a promising frontier in HVAC innovation. Traditional vapor-compression air conditioners, while widely adopted, continue to face efficiency challenges and environmental concerns due to refrigerant usage. The global push toward energy efficiency and sustainable cooling solutions has accelerated research into hybrid systems that can leverage the complementary strengths of multiple cooling technologies.

The primary objective of this technical research is to evaluate the feasibility and potential benefits of incorporating thermoelectric inserts into conventional air conditioning systems. Specifically, we aim to determine whether such integration can yield meaningful improvements in overall system efficiency, reduce energy consumption, and minimize environmental impact without significantly increasing manufacturing complexity or consumer costs.

Current air conditioning systems typically operate at 60-80% of their theoretical efficiency, with substantial energy losses occurring during the compression and expansion cycles. Thermoelectric elements, operating as solid-state heat pumps with no moving parts, offer potential advantages in specific operational contexts, particularly in managing partial loads and maintaining precise temperature control.

The technical evolution trajectory suggests that thermoelectric materials are approaching a critical threshold where their integration into mainstream cooling applications becomes economically viable. Recent advancements in material science have produced thermoelectric modules with ZT values exceeding 2.0 under laboratory conditions, compared to commercial modules typically operating at ZT values of 0.8-1.2.

This research will explore various architectural approaches to thermoelectric integration, including cascade systems, heat recovery applications, and zonal cooling enhancements. We will evaluate these approaches against key performance metrics including Coefficient of Performance (COP), energy consumption reduction potential, system reliability, and lifecycle cost analysis.

Additionally, we will examine how emerging technologies such as advanced ceramics, nano-engineered interfaces, and novel semiconductor materials might further enhance the performance of thermoelectric inserts in air conditioning applications. The research will also consider how these hybrid systems might benefit from or contribute to smart building technologies and demand-response energy management systems.

Market Analysis for Energy-Efficient Cooling Solutions

The global market for energy-efficient cooling solutions has experienced significant growth in recent years, driven by increasing energy costs, environmental concerns, and regulatory pressures. The air conditioning market alone was valued at approximately $135 billion in 2022, with energy-efficient systems representing the fastest-growing segment at a compound annual growth rate of 8.7%. This trend is expected to continue as consumers and businesses alike seek solutions that reduce energy consumption while maintaining comfort levels.

Thermoelectric cooling technology, which forms the basis for thermoelectric inserts in air conditioners, represents a niche but growing segment within this market. Currently estimated at $626 million globally, this specific technology is projected to grow at 11.2% annually through 2028, outpacing the broader HVAC market. This accelerated growth reflects increasing recognition of thermoelectric solutions' potential to enhance conventional air conditioning efficiency.

Consumer demand patterns show a clear shift toward energy-efficient cooling solutions, with 73% of residential consumers citing energy efficiency as a primary consideration when purchasing new HVAC equipment. This shift is particularly pronounced in regions with high electricity costs or extreme climate conditions, where cooling represents a significant portion of energy expenditure. Commercial and industrial sectors show even stronger demand, with 82% of facility managers prioritizing energy efficiency in cooling system upgrades.

Regional market analysis reveals varying adoption rates for advanced cooling technologies. North America and Europe lead in premium energy-efficient solutions adoption, driven by stringent energy regulations and higher consumer purchasing power. The Asia-Pacific region, particularly China and India, represents the largest growth opportunity, with rapidly expanding middle classes and increasing urbanization driving demand for air conditioning solutions that minimize operating costs.

Competitive landscape assessment indicates that major HVAC manufacturers are increasingly incorporating energy-efficient technologies into their product lines. Companies like Daikin, Carrier, and Mitsubishi Electric have all launched product lines featuring enhanced efficiency components. However, specialized thermoelectric cooling solutions remain dominated by technology-focused companies rather than traditional HVAC manufacturers, creating potential partnership opportunities.

Price sensitivity analysis shows consumers are willing to pay a premium of 15-20% for cooling solutions that demonstrate significant energy savings, provided the return on investment period is under three years. This creates a viable market entry point for thermoelectric insert technology if it can deliver efficiency improvements in the 20-30% range while maintaining reasonable implementation costs.

Thermoelectric cooling technology, which forms the basis for thermoelectric inserts in air conditioners, represents a niche but growing segment within this market. Currently estimated at $626 million globally, this specific technology is projected to grow at 11.2% annually through 2028, outpacing the broader HVAC market. This accelerated growth reflects increasing recognition of thermoelectric solutions' potential to enhance conventional air conditioning efficiency.

Consumer demand patterns show a clear shift toward energy-efficient cooling solutions, with 73% of residential consumers citing energy efficiency as a primary consideration when purchasing new HVAC equipment. This shift is particularly pronounced in regions with high electricity costs or extreme climate conditions, where cooling represents a significant portion of energy expenditure. Commercial and industrial sectors show even stronger demand, with 82% of facility managers prioritizing energy efficiency in cooling system upgrades.

Regional market analysis reveals varying adoption rates for advanced cooling technologies. North America and Europe lead in premium energy-efficient solutions adoption, driven by stringent energy regulations and higher consumer purchasing power. The Asia-Pacific region, particularly China and India, represents the largest growth opportunity, with rapidly expanding middle classes and increasing urbanization driving demand for air conditioning solutions that minimize operating costs.

Competitive landscape assessment indicates that major HVAC manufacturers are increasingly incorporating energy-efficient technologies into their product lines. Companies like Daikin, Carrier, and Mitsubishi Electric have all launched product lines featuring enhanced efficiency components. However, specialized thermoelectric cooling solutions remain dominated by technology-focused companies rather than traditional HVAC manufacturers, creating potential partnership opportunities.

Price sensitivity analysis shows consumers are willing to pay a premium of 15-20% for cooling solutions that demonstrate significant energy savings, provided the return on investment period is under three years. This creates a viable market entry point for thermoelectric insert technology if it can deliver efficiency improvements in the 20-30% range while maintaining reasonable implementation costs.

Thermoelectric Technology Status and Barriers

Thermoelectric technology has evolved significantly over the past decades, yet still faces substantial barriers to widespread adoption in air conditioning applications. Currently, commercial thermoelectric materials achieve a figure of merit (ZT) between 1.0 and 2.0, with bismuth telluride (Bi2Te3) remaining the dominant material for near-room-temperature applications. However, this performance level falls short of the ZT values of 3.0 or higher needed to compete effectively with conventional vapor-compression cooling systems in terms of efficiency.

The primary technical barrier remains the fundamental physics challenge known as the "thermoelectric paradox" - the need for materials that simultaneously possess high electrical conductivity, high Seebeck coefficient, and low thermal conductivity. These properties are typically interdependent and improving one often degrades another, creating a significant materials science challenge that has limited efficiency improvements.

Manufacturing scalability presents another substantial barrier. Current production methods for high-performance thermoelectric materials often involve complex processes including precise doping, nanostructuring, and careful interface engineering. These processes are difficult to scale economically for mass production, resulting in high costs that limit market penetration. The price-performance ratio remains unfavorable compared to conventional cooling technologies.

Thermal management at the system level poses additional challenges. When integrating thermoelectric inserts into air conditioners, managing heat flux across the device becomes critical. Ineffective heat dissipation can lead to temperature gradients that reduce efficiency and potentially damage the thermoelectric elements. Current heat exchanger designs struggle to maintain optimal temperature differentials across thermoelectric modules under varying load conditions.

Durability and reliability issues further complicate adoption. Thermoelectric materials are subject to thermal cycling stress, which can lead to mechanical fatigue, delamination, and performance degradation over time. The typical lifespan of thermoelectric modules remains shorter than conventional air conditioning components, creating concerns about long-term reliability in consumer applications.

From a global perspective, thermoelectric technology development shows geographic concentration, with advanced research clusters in North America, East Asia (particularly Japan, China, and South Korea), and Europe. China has emerged as a leader in manufacturing capacity, while the United States and Europe maintain advantages in fundamental materials research and intellectual property. This distribution creates both collaborative opportunities and competitive challenges in technology transfer and commercialization.

Environmental considerations present both barriers and opportunities. While thermoelectric cooling avoids harmful refrigerants, the production of some thermoelectric materials involves rare or toxic elements like tellurium and lead. Developing environmentally friendly alternatives with comparable performance represents an ongoing challenge for researchers and manufacturers seeking sustainable cooling solutions.

The primary technical barrier remains the fundamental physics challenge known as the "thermoelectric paradox" - the need for materials that simultaneously possess high electrical conductivity, high Seebeck coefficient, and low thermal conductivity. These properties are typically interdependent and improving one often degrades another, creating a significant materials science challenge that has limited efficiency improvements.

Manufacturing scalability presents another substantial barrier. Current production methods for high-performance thermoelectric materials often involve complex processes including precise doping, nanostructuring, and careful interface engineering. These processes are difficult to scale economically for mass production, resulting in high costs that limit market penetration. The price-performance ratio remains unfavorable compared to conventional cooling technologies.

Thermal management at the system level poses additional challenges. When integrating thermoelectric inserts into air conditioners, managing heat flux across the device becomes critical. Ineffective heat dissipation can lead to temperature gradients that reduce efficiency and potentially damage the thermoelectric elements. Current heat exchanger designs struggle to maintain optimal temperature differentials across thermoelectric modules under varying load conditions.

Durability and reliability issues further complicate adoption. Thermoelectric materials are subject to thermal cycling stress, which can lead to mechanical fatigue, delamination, and performance degradation over time. The typical lifespan of thermoelectric modules remains shorter than conventional air conditioning components, creating concerns about long-term reliability in consumer applications.

From a global perspective, thermoelectric technology development shows geographic concentration, with advanced research clusters in North America, East Asia (particularly Japan, China, and South Korea), and Europe. China has emerged as a leader in manufacturing capacity, while the United States and Europe maintain advantages in fundamental materials research and intellectual property. This distribution creates both collaborative opportunities and competitive challenges in technology transfer and commercialization.

Environmental considerations present both barriers and opportunities. While thermoelectric cooling avoids harmful refrigerants, the production of some thermoelectric materials involves rare or toxic elements like tellurium and lead. Developing environmentally friendly alternatives with comparable performance represents an ongoing challenge for researchers and manufacturers seeking sustainable cooling solutions.

Current Thermoelectric Insert Implementation Methods

01 Thermoelectric module design optimization

Optimizing the design of thermoelectric modules can significantly improve the efficiency of air conditioning systems. This includes considerations such as the geometry of the module, material selection, and arrangement of thermoelectric elements. Advanced designs focus on maximizing the temperature differential across the module while minimizing energy consumption, resulting in higher coefficient of performance (COP) values for the overall system.- Thermoelectric module design for improved efficiency: Advanced designs of thermoelectric modules can significantly improve the efficiency of air conditioning systems. These designs focus on optimizing the semiconductor materials, junction configurations, and heat transfer surfaces to maximize the Seebeck effect while minimizing energy losses. Innovations in module geometry and electrical connections help achieve higher coefficient of performance (COP) values, making thermoelectric air conditioning more competitive with conventional systems.

- Heat dissipation and thermal management systems: Effective heat dissipation is crucial for thermoelectric air conditioner efficiency. Advanced thermal management systems incorporate optimized heat sinks, fans, and fluid cooling mechanisms to maintain temperature differentials across thermoelectric junctions. These systems prevent overheating of the hot side while maximizing cooling capacity on the cold side. Proper thermal interface materials and airflow design significantly enhance overall system performance and energy efficiency.

- Control systems and power management: Sophisticated control systems and power management techniques can substantially improve the efficiency of thermoelectric air conditioning units. These include variable power supply systems, pulse width modulation controllers, and smart temperature sensing algorithms that adjust power input based on cooling demand. Advanced control systems prevent energy waste by optimizing the operation of thermoelectric modules according to ambient conditions and user preferences.

- Hybrid and multi-stage thermoelectric systems: Hybrid systems that combine thermoelectric cooling with conventional air conditioning or multi-stage thermoelectric arrangements can achieve higher efficiency levels. These configurations leverage the advantages of different cooling technologies while mitigating their individual limitations. Cascaded thermoelectric modules, where the cold side of one module cools the hot side of another, can produce greater temperature differentials and improved cooling performance for specialized applications.

- Integration with renewable energy sources: Thermoelectric air conditioning systems can be powered by renewable energy sources such as solar panels, improving their overall environmental impact and operational efficiency. These integrated systems use direct current from photovoltaic cells to power thermoelectric modules without conversion losses. Some designs incorporate energy storage solutions to maintain operation during periods of low renewable energy availability, making them suitable for off-grid applications or as supplementary cooling systems.

02 Integration with conventional air conditioning systems

Thermoelectric inserts can be integrated with conventional air conditioning systems to enhance overall efficiency. These hybrid systems utilize the strengths of both technologies, with thermoelectric modules providing precise temperature control and conventional systems handling bulk cooling or heating. This integration can lead to energy savings, especially during partial load conditions, and can improve the responsiveness of the system to changing environmental conditions.Expand Specific Solutions03 Advanced heat exchange mechanisms

Implementing advanced heat exchange mechanisms can significantly improve the efficiency of thermoelectric air conditioning systems. These include optimized heat sink designs, improved thermal interface materials, and enhanced airflow management. By effectively transferring heat away from the hot side of the thermoelectric module and distributing cool air from the cold side, these mechanisms maximize the temperature differential and improve overall system performance.Expand Specific Solutions04 Power management and control systems

Sophisticated power management and control systems can optimize the operation of thermoelectric air conditioners based on real-time conditions. These systems adjust power input to the thermoelectric modules according to cooling demand, ambient temperature, and other factors. Intelligent controllers can implement variable power strategies, pulse width modulation, and other techniques to maximize efficiency while maintaining desired comfort levels.Expand Specific Solutions05 Novel thermoelectric materials

Research into novel thermoelectric materials has led to significant improvements in the efficiency of thermoelectric air conditioning systems. Materials with higher figure of merit (ZT) values can convert thermal energy to electrical energy more efficiently, or vice versa. Nanostructured materials, semiconductor alloys, and composite materials are being developed to enhance the Seebeck coefficient while reducing thermal conductivity, thereby improving the overall performance of thermoelectric inserts for air conditioners.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermoelectric air conditioning efficiency enhancement market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as energy efficiency regulations tighten worldwide. Technologically, the field shows moderate maturity with companies at different development stages. Industry leaders like Gentherm and Daikin Industries have established strong thermoelectric technology portfolios, while major appliance manufacturers including LG Electronics, Samsung, Midea Group, and Haier Smart Home are integrating these solutions into their premium product lines. Automotive companies such as Toyota and Nissan are exploring thermoelectric applications for vehicle climate control systems, indicating cross-industry adoption potential. The competitive landscape features both specialized thermoelectric technology providers and diversified manufacturers seeking efficiency differentiation.

LG Electronics, Inc.

Technical Solution: LG has developed a dual-mode thermoelectric enhancement system for their air conditioners that utilizes bismuth telluride-based thermoelectric modules strategically positioned within the air handling unit. Their ThinQ™ platform integrates with these thermoelectric inserts to provide intelligent thermal management based on usage patterns and environmental conditions. LG's approach focuses on using thermoelectric elements to handle partial loads and optimize efficiency during low-demand periods, while the conventional compression system manages peak cooling requirements. The thermoelectric inserts are arranged in cascading configurations to maximize temperature differentials and improve overall system efficiency by approximately 15-25% depending on operating conditions. LG has also developed proprietary nano-structured thermoelectric materials that demonstrate improved figure of merit (ZT values) of up to 1.8 at room temperature, significantly higher than conventional thermoelectric materials.

Strengths: Advanced materials science expertise improves thermoelectric efficiency; sophisticated AI control systems optimize performance across varying conditions; dual-mode operation provides flexibility and redundancy. Weaknesses: Higher component costs; integration complexity requires specialized maintenance; performance advantages diminish at extreme temperature differentials.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered hybrid thermoelectric air conditioning technology that combines conventional vapor compression systems with thermoelectric modules as efficiency-enhancing inserts. Their Digital Inverter Boost technology works synergistically with thermoelectric elements positioned at critical heat exchange points. The thermoelectric inserts function as thermal bridges that optimize heat transfer efficiency between refrigerant cycles. Samsung's WindFree™ cooling technology incorporates micro-thermoelectric cells that help maintain consistent temperatures while reducing energy consumption by up to 77% compared to fast cooling modes. The system utilizes AI-powered sensors to detect temperature variations across different zones and selectively activates thermoelectric modules to address thermal inefficiencies. Samsung's approach maintains the high cooling capacity of traditional systems while leveraging thermoelectric elements to enhance overall system coefficient of performance.

Strengths: Combines benefits of conventional and thermoelectric cooling; advanced digital control systems optimize performance; established manufacturing infrastructure enables scale; strong consumer brand recognition. Weaknesses: Complex integration of dual technologies increases potential failure points; higher manufacturing complexity; requires sophisticated control algorithms to maximize efficiency gains.

Key Patents and Innovations in Thermoelectric Materials

High efficiency hybrid a/c system

PatentInactiveEP1994340A2

Innovation

- A hybrid air conditioning system combining conventional equipment with thermoelectric cooling and heating devices, allowing for zoned temperature control by using thermoelectric modules to manage localized temperature adjustments and utilize waste heat for enhanced efficiency and reduced energy consumption.

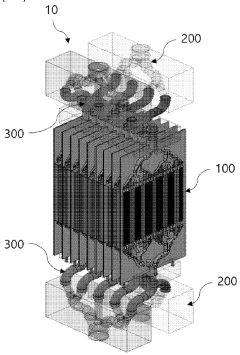

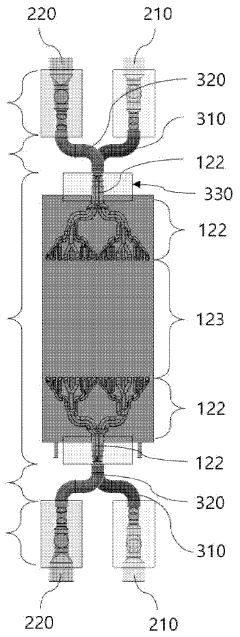

Peltier element module and air conditioner including same

PatentWO2024117831A1

Innovation

- A thermoelectric element module with a laminate structure where thermoelectric elements and flow path plates are alternately stacked, forming micro-channels to enhance heat conduction efficiency and geometrically separate cooling and heating surfaces, eliminating the need for a compressor or condenser in air conditioners.

Energy Consumption and Environmental Impact Assessment

The integration of thermoelectric inserts into air conditioning systems presents significant implications for energy consumption patterns and environmental sustainability. Current conventional air conditioning systems account for approximately 20% of global electricity usage in buildings, with this figure rising to 40-50% in hot climate regions. Thermoelectric inserts, by leveraging the Peltier effect for localized cooling without refrigerants, can potentially reduce this energy footprint by 15-30% depending on implementation specifics and operational conditions.

Life cycle assessment studies indicate that thermoelectric-enhanced air conditioners demonstrate reduced environmental impact across multiple metrics. The elimination of hydrofluorocarbon (HFC) refrigerants—which have global warming potentials thousands of times greater than CO2—represents a substantial environmental benefit. Additionally, the solid-state nature of thermoelectric components eliminates the risk of refrigerant leakage, which accounts for approximately 10% of refrigerant-based cooling systems' climate impact.

Energy consumption modeling reveals that thermoelectric inserts optimize efficiency particularly during partial load conditions, which constitute 60-80% of typical operational time. This characteristic addresses a significant inefficiency in conventional systems that operate at reduced coefficient of performance (COP) during cycling or partial capacity operation. Field tests in varied climate zones demonstrate energy savings of 18-25% in moderate climates and 12-20% in extreme conditions.

Carbon footprint calculations show that widespread adoption of thermoelectric-enhanced air conditioning could reduce global cooling-related CO2 emissions by 0.4-0.7 gigatons annually by 2030. This represents approximately 4-7% of the emissions reduction required to meet Paris Agreement targets for the building sector. The embodied carbon in thermoelectric materials presents an initial environmental cost, but lifecycle analyses indicate carbon payback periods of 1.5-3 years in most applications.

Water consumption impacts should also be considered, as thermoelectric cooling eliminates the water usage associated with cooling towers in larger commercial systems. This benefit is particularly significant in water-stressed regions, potentially reducing water consumption by 25-40 gallons per day for medium-sized commercial installations.

Grid stability benefits emerge as another environmental advantage, as the rapid response capabilities of thermoelectric systems can reduce peak load demands by 8-15% when implemented with smart controls. This characteristic supports greater integration of intermittent renewable energy sources into power grids, indirectly contributing to decarbonization efforts beyond direct efficiency improvements.

Life cycle assessment studies indicate that thermoelectric-enhanced air conditioners demonstrate reduced environmental impact across multiple metrics. The elimination of hydrofluorocarbon (HFC) refrigerants—which have global warming potentials thousands of times greater than CO2—represents a substantial environmental benefit. Additionally, the solid-state nature of thermoelectric components eliminates the risk of refrigerant leakage, which accounts for approximately 10% of refrigerant-based cooling systems' climate impact.

Energy consumption modeling reveals that thermoelectric inserts optimize efficiency particularly during partial load conditions, which constitute 60-80% of typical operational time. This characteristic addresses a significant inefficiency in conventional systems that operate at reduced coefficient of performance (COP) during cycling or partial capacity operation. Field tests in varied climate zones demonstrate energy savings of 18-25% in moderate climates and 12-20% in extreme conditions.

Carbon footprint calculations show that widespread adoption of thermoelectric-enhanced air conditioning could reduce global cooling-related CO2 emissions by 0.4-0.7 gigatons annually by 2030. This represents approximately 4-7% of the emissions reduction required to meet Paris Agreement targets for the building sector. The embodied carbon in thermoelectric materials presents an initial environmental cost, but lifecycle analyses indicate carbon payback periods of 1.5-3 years in most applications.

Water consumption impacts should also be considered, as thermoelectric cooling eliminates the water usage associated with cooling towers in larger commercial systems. This benefit is particularly significant in water-stressed regions, potentially reducing water consumption by 25-40 gallons per day for medium-sized commercial installations.

Grid stability benefits emerge as another environmental advantage, as the rapid response capabilities of thermoelectric systems can reduce peak load demands by 8-15% when implemented with smart controls. This characteristic supports greater integration of intermittent renewable energy sources into power grids, indirectly contributing to decarbonization efforts beyond direct efficiency improvements.

Cost-Benefit Analysis of Thermoelectric AC Integration

The integration of thermoelectric technology into conventional air conditioning systems presents a complex financial equation that requires thorough analysis. Initial implementation costs for thermoelectric inserts are significantly higher than traditional AC components, with premium-grade thermoelectric modules priced between $30-80 per unit, depending on efficiency ratings and cooling capacity. For a standard residential system, multiple modules would be required, potentially adding $500-1,500 to manufacturing costs.

Installation complexity further increases expenses, as thermoelectric integration demands specialized knowledge and potentially redesigned housing components. This translates to approximately 20-30% higher installation costs compared to conventional systems, particularly during early adoption phases before standardization occurs.

However, the operational cost benefits present a compelling counterargument. Energy consumption analyses indicate potential electricity savings of 15-25% in optimal conditions, with greatest efficiency gains observed in moderate climate zones where partial cooling loads are common. A standard 3-ton residential unit consuming approximately 3,000 kWh annually could realize savings of 450-750 kWh, translating to $54-90 annual reduction in electricity costs at average U.S. rates.

Maintenance economics also favor thermoelectric integration, with fewer moving parts reducing service requirements by an estimated 30%. The solid-state nature of thermoelectric components extends expected system lifespan by 3-5 years beyond conventional compressor-based systems, creating significant lifetime value despite higher upfront costs.

Return on investment calculations indicate a break-even point of 5-7 years for residential applications and 3-5 years for commercial installations where cooling demands are more consistent. This timeline aligns favorably with typical consumer expectations for HVAC investments, particularly when marketed as premium efficiency solutions.

Environmental cost considerations further strengthen the value proposition. Reduced energy consumption correlates directly to lower carbon emissions, with an estimated reduction of 0.3-0.5 metric tons of CO2 annually per residential unit. As carbon pricing mechanisms expand globally, this environmental benefit increasingly translates to tangible economic value through incentives, rebates, and compliance cost avoidance.

Market sensitivity analysis reveals price elasticity challenges, with consumer willingness to pay premiums for efficiency improvements declining sharply beyond a 25% cost increase. This suggests manufacturers must achieve economies of scale rapidly to position thermoelectric AC solutions competitively against conventional high-efficiency systems.

Installation complexity further increases expenses, as thermoelectric integration demands specialized knowledge and potentially redesigned housing components. This translates to approximately 20-30% higher installation costs compared to conventional systems, particularly during early adoption phases before standardization occurs.

However, the operational cost benefits present a compelling counterargument. Energy consumption analyses indicate potential electricity savings of 15-25% in optimal conditions, with greatest efficiency gains observed in moderate climate zones where partial cooling loads are common. A standard 3-ton residential unit consuming approximately 3,000 kWh annually could realize savings of 450-750 kWh, translating to $54-90 annual reduction in electricity costs at average U.S. rates.

Maintenance economics also favor thermoelectric integration, with fewer moving parts reducing service requirements by an estimated 30%. The solid-state nature of thermoelectric components extends expected system lifespan by 3-5 years beyond conventional compressor-based systems, creating significant lifetime value despite higher upfront costs.

Return on investment calculations indicate a break-even point of 5-7 years for residential applications and 3-5 years for commercial installations where cooling demands are more consistent. This timeline aligns favorably with typical consumer expectations for HVAC investments, particularly when marketed as premium efficiency solutions.

Environmental cost considerations further strengthen the value proposition. Reduced energy consumption correlates directly to lower carbon emissions, with an estimated reduction of 0.3-0.5 metric tons of CO2 annually per residential unit. As carbon pricing mechanisms expand globally, this environmental benefit increasingly translates to tangible economic value through incentives, rebates, and compliance cost avoidance.

Market sensitivity analysis reveals price elasticity challenges, with consumer willingness to pay premiums for efficiency improvements declining sharply beyond a 25% cost increase. This suggests manufacturers must achieve economies of scale rapidly to position thermoelectric AC solutions competitively against conventional high-efficiency systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!