Ethyl Acetate in Paints and Coatings: Safety Considerations

JUN 27, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background

Ethyl acetate, a colorless liquid with a characteristic sweet odor, has been a staple in the paints and coatings industry for decades. This versatile organic compound, with the chemical formula CH3COOC2H5, is derived from the esterification of ethanol and acetic acid. Its discovery dates back to 1759 when the French chemist Count de Lauraguais first synthesized it.

In the context of paints and coatings, ethyl acetate has gained prominence due to its excellent solvency properties. It effectively dissolves a wide range of resins, polymers, and other coating components, making it an ideal choice for formulating high-performance products. The compound's low boiling point of 77.1°C (170.8°F) contributes to its rapid evaporation rate, which is crucial for fast-drying paints and coatings.

Historically, the use of ethyl acetate in the paints and coatings industry has evolved alongside advancements in chemical engineering and environmental regulations. In the early 20th century, it became increasingly popular as a replacement for more toxic solvents. Its relatively low toxicity compared to alternatives like methyl ethyl ketone (MEK) or toluene made it an attractive option for manufacturers seeking to improve workplace safety.

The physical and chemical properties of ethyl acetate play a significant role in its widespread adoption. With a density of 0.897 g/cm³ at 20°C, it is lighter than water, which influences its behavior in formulations. Its moderate polarity allows it to dissolve both polar and non-polar substances, enhancing its versatility in various coating systems.

From an environmental perspective, ethyl acetate is considered less harmful than many other organic solvents. It is biodegradable and does not persist in the environment for extended periods. However, it is classified as a volatile organic compound (VOC), which has led to increased scrutiny in recent years due to air quality concerns.

The safety profile of ethyl acetate is generally favorable when compared to other solvents used in the industry. It has a relatively high flash point of -4°C (24.8°F), which reduces the risk of fire and explosion during handling and storage. Nevertheless, proper safety measures are essential due to its flammability and potential for forming explosive mixtures with air.

In recent years, the focus on sustainable and eco-friendly coatings has influenced the role of ethyl acetate in formulations. While it remains a popular choice, there is ongoing research into bio-based alternatives and low-VOC formulations that could potentially replace or reduce the use of traditional solvents like ethyl acetate in certain applications.

In the context of paints and coatings, ethyl acetate has gained prominence due to its excellent solvency properties. It effectively dissolves a wide range of resins, polymers, and other coating components, making it an ideal choice for formulating high-performance products. The compound's low boiling point of 77.1°C (170.8°F) contributes to its rapid evaporation rate, which is crucial for fast-drying paints and coatings.

Historically, the use of ethyl acetate in the paints and coatings industry has evolved alongside advancements in chemical engineering and environmental regulations. In the early 20th century, it became increasingly popular as a replacement for more toxic solvents. Its relatively low toxicity compared to alternatives like methyl ethyl ketone (MEK) or toluene made it an attractive option for manufacturers seeking to improve workplace safety.

The physical and chemical properties of ethyl acetate play a significant role in its widespread adoption. With a density of 0.897 g/cm³ at 20°C, it is lighter than water, which influences its behavior in formulations. Its moderate polarity allows it to dissolve both polar and non-polar substances, enhancing its versatility in various coating systems.

From an environmental perspective, ethyl acetate is considered less harmful than many other organic solvents. It is biodegradable and does not persist in the environment for extended periods. However, it is classified as a volatile organic compound (VOC), which has led to increased scrutiny in recent years due to air quality concerns.

The safety profile of ethyl acetate is generally favorable when compared to other solvents used in the industry. It has a relatively high flash point of -4°C (24.8°F), which reduces the risk of fire and explosion during handling and storage. Nevertheless, proper safety measures are essential due to its flammability and potential for forming explosive mixtures with air.

In recent years, the focus on sustainable and eco-friendly coatings has influenced the role of ethyl acetate in formulations. While it remains a popular choice, there is ongoing research into bio-based alternatives and low-VOC formulations that could potentially replace or reduce the use of traditional solvents like ethyl acetate in certain applications.

Market Analysis

The market for ethyl acetate in paints and coatings has been experiencing steady growth, driven by increasing demand for eco-friendly and low-VOC (volatile organic compound) products. This solvent plays a crucial role in the formulation of various coatings, including lacquers, enamels, and varnishes, due to its excellent solvency and fast evaporation rate.

The global ethyl acetate market size in the paints and coatings sector is projected to expand significantly over the next few years. This growth is attributed to the rising construction activities, automotive production, and furniture manufacturing industries, which are major consumers of paints and coatings. Additionally, the shift towards water-based and powder coatings has created new opportunities for ethyl acetate as a co-solvent in these formulations.

In terms of regional distribution, Asia-Pacific dominates the market, with China and India being the largest consumers. The rapid industrialization and urbanization in these countries have led to increased demand for paints and coatings across various end-use industries. North America and Europe follow, with a focus on high-performance and environmentally friendly coatings driving the demand for ethyl acetate.

The market is characterized by stringent regulations regarding VOC emissions, particularly in developed regions. This has led to a growing emphasis on safety considerations in the use of ethyl acetate. Manufacturers are increasingly investing in research and development to improve the safety profile of ethyl acetate-based formulations while maintaining performance characteristics.

Key market trends include the development of bio-based ethyl acetate, which aligns with the growing consumer preference for sustainable products. This trend is expected to create new growth avenues in the paints and coatings sector, especially in regions with strict environmental regulations.

The competitive landscape of the ethyl acetate market in paints and coatings is fragmented, with several large multinational companies and regional players vying for market share. Major players are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position.

Despite the positive growth outlook, the market faces challenges related to raw material price volatility and the availability of substitutes. However, the ongoing research into improving the safety profile of ethyl acetate and its applications in advanced coating technologies is expected to sustain market growth in the coming years.

The global ethyl acetate market size in the paints and coatings sector is projected to expand significantly over the next few years. This growth is attributed to the rising construction activities, automotive production, and furniture manufacturing industries, which are major consumers of paints and coatings. Additionally, the shift towards water-based and powder coatings has created new opportunities for ethyl acetate as a co-solvent in these formulations.

In terms of regional distribution, Asia-Pacific dominates the market, with China and India being the largest consumers. The rapid industrialization and urbanization in these countries have led to increased demand for paints and coatings across various end-use industries. North America and Europe follow, with a focus on high-performance and environmentally friendly coatings driving the demand for ethyl acetate.

The market is characterized by stringent regulations regarding VOC emissions, particularly in developed regions. This has led to a growing emphasis on safety considerations in the use of ethyl acetate. Manufacturers are increasingly investing in research and development to improve the safety profile of ethyl acetate-based formulations while maintaining performance characteristics.

Key market trends include the development of bio-based ethyl acetate, which aligns with the growing consumer preference for sustainable products. This trend is expected to create new growth avenues in the paints and coatings sector, especially in regions with strict environmental regulations.

The competitive landscape of the ethyl acetate market in paints and coatings is fragmented, with several large multinational companies and regional players vying for market share. Major players are focusing on product innovation, strategic partnerships, and mergers and acquisitions to strengthen their market position.

Despite the positive growth outlook, the market faces challenges related to raw material price volatility and the availability of substitutes. However, the ongoing research into improving the safety profile of ethyl acetate and its applications in advanced coating technologies is expected to sustain market growth in the coming years.

Technical Challenges

The use of ethyl acetate in paints and coatings presents several technical challenges related to safety considerations. One of the primary concerns is the high volatility of ethyl acetate, which contributes to its flammability and potential for creating explosive atmospheres. This characteristic necessitates careful handling, storage, and application procedures to minimize fire and explosion risks in manufacturing facilities and during product use.

Another significant challenge is the potential for worker exposure to ethyl acetate vapors. Inhalation of these vapors can lead to respiratory irritation, headaches, and in severe cases, central nervous system depression. Developing effective ventilation systems and personal protective equipment (PPE) that do not interfere with the application process while ensuring worker safety is a complex engineering problem.

The reactivity of ethyl acetate with certain materials poses additional technical hurdles. It can degrade some plastics and rubbers, which complicates the selection of storage containers, application equipment, and even the surfaces to which the paints or coatings are applied. This reactivity also raises concerns about long-term stability and shelf life of products containing ethyl acetate.

Environmental considerations add another layer of complexity to the use of ethyl acetate in paints and coatings. As a volatile organic compound (VOC), ethyl acetate contributes to air pollution and the formation of ground-level ozone. Developing formulations that maintain desired performance characteristics while reducing VOC content to meet increasingly stringent environmental regulations is an ongoing challenge for the industry.

The potential for ethyl acetate to act as a solvent for other hazardous substances in paints and coatings is also a significant safety concern. This property can increase the bioavailability of toxic components, potentially enhancing their harmful effects. Formulating products that minimize this synergistic effect while maintaining the desired solvent properties of ethyl acetate requires advanced chemical engineering and toxicological understanding.

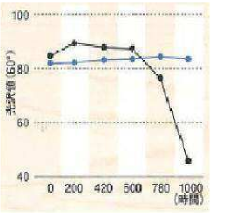

Ensuring the stability of paint and coating formulations containing ethyl acetate under various environmental conditions is another technical challenge. Temperature fluctuations, humidity, and exposure to light can affect the evaporation rate and chemical stability of ethyl acetate, potentially altering the performance and safety profile of the final product. Developing robust formulations that maintain consistency across diverse application environments is crucial for product reliability and safety.

Lastly, the development of accurate and reliable methods for detecting and monitoring ethyl acetate levels in both workplace atmospheres and finished products presents ongoing technical challenges. These methods are essential for ensuring compliance with safety regulations and maintaining quality control throughout the manufacturing and application processes.

Another significant challenge is the potential for worker exposure to ethyl acetate vapors. Inhalation of these vapors can lead to respiratory irritation, headaches, and in severe cases, central nervous system depression. Developing effective ventilation systems and personal protective equipment (PPE) that do not interfere with the application process while ensuring worker safety is a complex engineering problem.

The reactivity of ethyl acetate with certain materials poses additional technical hurdles. It can degrade some plastics and rubbers, which complicates the selection of storage containers, application equipment, and even the surfaces to which the paints or coatings are applied. This reactivity also raises concerns about long-term stability and shelf life of products containing ethyl acetate.

Environmental considerations add another layer of complexity to the use of ethyl acetate in paints and coatings. As a volatile organic compound (VOC), ethyl acetate contributes to air pollution and the formation of ground-level ozone. Developing formulations that maintain desired performance characteristics while reducing VOC content to meet increasingly stringent environmental regulations is an ongoing challenge for the industry.

The potential for ethyl acetate to act as a solvent for other hazardous substances in paints and coatings is also a significant safety concern. This property can increase the bioavailability of toxic components, potentially enhancing their harmful effects. Formulating products that minimize this synergistic effect while maintaining the desired solvent properties of ethyl acetate requires advanced chemical engineering and toxicological understanding.

Ensuring the stability of paint and coating formulations containing ethyl acetate under various environmental conditions is another technical challenge. Temperature fluctuations, humidity, and exposure to light can affect the evaporation rate and chemical stability of ethyl acetate, potentially altering the performance and safety profile of the final product. Developing robust formulations that maintain consistency across diverse application environments is crucial for product reliability and safety.

Lastly, the development of accurate and reliable methods for detecting and monitoring ethyl acetate levels in both workplace atmospheres and finished products presents ongoing technical challenges. These methods are essential for ensuring compliance with safety regulations and maintaining quality control throughout the manufacturing and application processes.

Current Safety Solutions

01 Safety measures in industrial processes

Ethyl acetate safety in industrial processes involves implementing proper handling procedures, ventilation systems, and protective equipment. This includes using closed systems, monitoring vapor concentrations, and providing adequate personal protective equipment to workers to minimize exposure risks.- Safety measures in industrial processes: Ethyl acetate safety in industrial processes involves implementing proper handling procedures, ventilation systems, and protective equipment. Measures include using closed systems, monitoring vapor concentrations, and providing adequate training for workers to minimize exposure risks and prevent accidents.

- Environmental impact and disposal: Proper disposal and management of ethyl acetate waste are crucial for environmental safety. This includes implementing recycling processes, using appropriate treatment methods, and adhering to regulations for safe disposal to minimize environmental contamination and reduce potential health hazards.

- Fire and explosion prevention: Ethyl acetate is highly flammable, necessitating specific fire and explosion prevention measures. These include proper storage in fire-resistant containers, implementing adequate fire suppression systems, and maintaining safe distances from ignition sources to minimize the risk of accidents in industrial settings.

- Personal protective equipment (PPE): The use of appropriate personal protective equipment is essential when handling ethyl acetate. This includes wearing chemical-resistant gloves, safety goggles, and respiratory protection to minimize skin contact, eye exposure, and inhalation of vapors, thereby reducing potential health risks associated with ethyl acetate exposure.

- Health effects and exposure limits: Understanding the health effects of ethyl acetate exposure and adhering to established exposure limits is crucial for worker safety. This involves monitoring workplace air quality, implementing engineering controls to reduce exposure, and providing regular health assessments for workers to prevent long-term health issues associated with ethyl acetate exposure.

02 Environmental impact and disposal

Proper disposal and management of ethyl acetate waste are crucial for environmental safety. This includes implementing recovery and recycling processes, treating waste streams, and using appropriate containment methods to prevent soil and water contamination.Expand Specific Solutions03 Fire and explosion prevention

Due to its flammable nature, ethyl acetate requires specific fire and explosion prevention measures. This includes proper storage in fire-resistant containers, implementing grounding and bonding procedures, and using explosion-proof electrical equipment in areas where ethyl acetate is handled or stored.Expand Specific Solutions04 Health hazards and exposure control

Ethyl acetate can pose health risks through inhalation, skin contact, and ingestion. Safety measures include implementing exposure limits, providing proper ventilation, using appropriate personal protective equipment, and establishing emergency response procedures for accidental exposure.Expand Specific Solutions05 Safe handling in laboratory settings

In laboratory environments, ethyl acetate safety involves proper storage, handling, and disposal practices. This includes using fume hoods, wearing appropriate personal protective equipment, following proper labeling and storage protocols, and implementing spill response procedures.Expand Specific Solutions

Industry Leaders

The ethyl acetate market in paints and coatings is in a mature stage, with a global market size estimated to be over $3 billion. The industry is characterized by established players and steady growth, driven by increasing demand in construction and automotive sectors. Technologically, ethyl acetate production is well-developed, with major companies like Celanese, Eastman Chemical, and BASF leading in production capacity and innovation. These firms are focusing on improving safety and sustainability aspects, developing low-VOC formulations and bio-based alternatives. Emerging players from Asia, such as Sinopec and Kuraray, are also gaining market share, intensifying competition and driving further advancements in safety and efficiency.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has taken a proactive stance on ethyl acetate safety in paints and coatings. The company has developed Eastman Tetrashield™ protective resin systems that enable the formulation of high-performance coatings with reduced VOC content, including lower levels of ethyl acetate[13]. For applications requiring ethyl acetate, Eastman has implemented advanced process safety management systems and conducts regular risk assessments to ensure safe handling and storage. The company's Eastman 168™ non-phthalate plasticizer technology allows for the formulation of coatings with improved flexibility and durability, potentially reducing the need for ethyl acetate in certain applications[14]. Eastman also provides extensive technical support and safety guidance to customers, including detailed material safety data sheets and handling protocols. The company's research efforts are focused on developing green chemistry solutions that could potentially replace ethyl acetate in various coating formulations[15].

Strengths: Innovative resin systems, comprehensive safety management, and ongoing green chemistry research. Weaknesses: Potential cost implications for new technologies and the need for extensive reformulation efforts in some product lines.

BASF Corp.

Technical Solution: BASF has developed innovative water-based coating systems that significantly reduce the use of ethyl acetate and other volatile organic compounds (VOCs). Their Acronal® EDGE technology utilizes self-crosslinking polymer dispersions to create low-VOC paints with excellent performance characteristics[1]. This approach addresses safety concerns by minimizing worker exposure to ethyl acetate vapors during application. Additionally, BASF has introduced bio-based solvents as alternatives to ethyl acetate in certain coating formulations, further enhancing safety profiles[2]. The company also employs advanced process safety management systems in its production facilities to mitigate risks associated with ethyl acetate handling and storage[3].

Strengths: Reduced VOC emissions, improved worker safety, and sustainable alternatives. Weaknesses: Potential higher costs and need for reformulation of existing products.

Key Safety Innovations

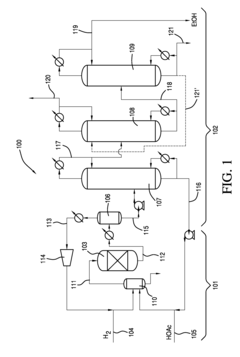

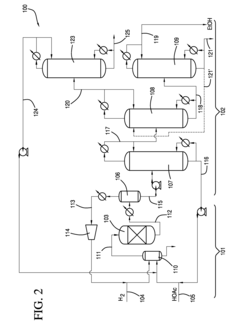

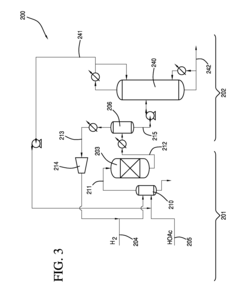

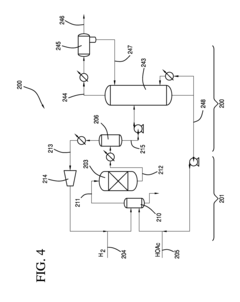

Process for producing an ethyl acetate solvent and co-production of ethanol

PatentInactiveUS20110190531A1

Innovation

- A process involving the hydrogenation of acetic acid in the presence of a catalyst, followed by a series of distillation columns to separate and recover ethanol and ethyl acetate solvent, with specific catalyst compositions and conditions to optimize ethanol and ethyl acetate production, including the use of platinum-based catalysts and modified silica supports.

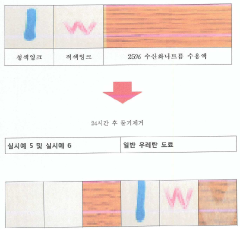

Ceramic painting composition for eco-friendly wood

PatentInactiveKR1020150048428A

Innovation

- A ceramic paint composition for wood based on a liquid urethane resin, incorporating fine ceramics and specific solvents, solvents, and additives to enhance weather resistance, heat resistance, and durability, while being free from substances causing sick house syndrome.

Regulatory Framework

The regulatory framework surrounding the use of ethyl acetate in paints and coatings is complex and multifaceted, reflecting the compound's widespread industrial application and potential safety concerns. At the international level, organizations such as the World Health Organization (WHO) and the International Labour Organization (ILO) provide guidelines on the safe handling and exposure limits of ethyl acetate in occupational settings.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for ethyl acetate in the workplace. The current OSHA PEL is set at 400 parts per million (ppm) as an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) recommends a lower exposure limit of 400 ppm as a 10-hour time-weighted average.

The Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA) and the Clean Air Act. As a volatile organic compound (VOC), ethyl acetate is subject to emission control regulations aimed at reducing air pollution. Many states have implemented their own VOC regulations for paints and coatings, often more stringent than federal standards.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of ethyl acetate. Manufacturers and importers are required to register the substance and provide safety data. The Classification, Labelling and Packaging (CLP) Regulation sets standards for hazard communication on product labels and safety data sheets.

Asian countries have also implemented regulations for ethyl acetate in paints and coatings. Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances provide frameworks for assessing and managing chemical risks, including those associated with ethyl acetate use.

Industry-specific standards, such as those set by the American Coatings Association and the European Council of the Paint, Printing Ink and Artists' Colours Industry, provide additional guidance on the safe use of ethyl acetate in paints and coatings. These standards often address issues such as proper ventilation, personal protective equipment, and safe storage practices.

As awareness of environmental and health impacts grows, regulatory bodies are continually reviewing and updating their frameworks. This dynamic regulatory landscape necessitates ongoing vigilance from manufacturers and users of paints and coatings containing ethyl acetate to ensure compliance and maintain safety standards.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for ethyl acetate in the workplace. The current OSHA PEL is set at 400 parts per million (ppm) as an 8-hour time-weighted average. The National Institute for Occupational Safety and Health (NIOSH) recommends a lower exposure limit of 400 ppm as a 10-hour time-weighted average.

The Environmental Protection Agency (EPA) regulates ethyl acetate under the Toxic Substances Control Act (TSCA) and the Clean Air Act. As a volatile organic compound (VOC), ethyl acetate is subject to emission control regulations aimed at reducing air pollution. Many states have implemented their own VOC regulations for paints and coatings, often more stringent than federal standards.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of ethyl acetate. Manufacturers and importers are required to register the substance and provide safety data. The Classification, Labelling and Packaging (CLP) Regulation sets standards for hazard communication on product labels and safety data sheets.

Asian countries have also implemented regulations for ethyl acetate in paints and coatings. Japan's Chemical Substances Control Law and China's Measures for Environmental Management of New Chemical Substances provide frameworks for assessing and managing chemical risks, including those associated with ethyl acetate use.

Industry-specific standards, such as those set by the American Coatings Association and the European Council of the Paint, Printing Ink and Artists' Colours Industry, provide additional guidance on the safe use of ethyl acetate in paints and coatings. These standards often address issues such as proper ventilation, personal protective equipment, and safe storage practices.

As awareness of environmental and health impacts grows, regulatory bodies are continually reviewing and updating their frameworks. This dynamic regulatory landscape necessitates ongoing vigilance from manufacturers and users of paints and coatings containing ethyl acetate to ensure compliance and maintain safety standards.

Environmental Impact

The environmental impact of ethyl acetate in paints and coatings is a crucial consideration for manufacturers, regulators, and consumers alike. As a volatile organic compound (VOC), ethyl acetate contributes to air pollution and the formation of ground-level ozone when released into the atmosphere. This can lead to respiratory issues and other health problems in humans, as well as damage to vegetation and ecosystems.

In the context of paints and coatings, the primary environmental concern is the emission of ethyl acetate during application and drying processes. These emissions can contribute to indoor air pollution in enclosed spaces, potentially affecting the health of workers and occupants. Outdoors, the release of ethyl acetate can contribute to smog formation and air quality degradation in urban areas.

Water pollution is another potential environmental impact of ethyl acetate use in paints and coatings. Improper disposal of paint waste or cleaning solvents containing ethyl acetate can lead to contamination of water sources. While ethyl acetate is biodegradable and has low toxicity to aquatic life compared to some other solvents, high concentrations can still have adverse effects on aquatic ecosystems.

The production of ethyl acetate also has environmental implications. The manufacturing process typically involves the reaction of ethanol with acetic acid, both of which are derived from petrochemical sources. This reliance on fossil fuels contributes to carbon emissions and resource depletion. However, there are ongoing efforts to develop bio-based ethyl acetate production methods using renewable feedstocks, which could potentially reduce the environmental footprint of its manufacture.

In response to environmental concerns, many countries have implemented regulations to limit VOC emissions from paints and coatings. These regulations have driven the development of low-VOC and zero-VOC formulations, which often involve reducing or eliminating the use of solvents like ethyl acetate. Water-based paints and powder coatings have gained popularity as more environmentally friendly alternatives.

The lifecycle environmental impact of ethyl acetate in paints and coatings extends beyond its immediate use. The disposal of paint cans and other containers that have contained ethyl acetate-based products requires proper handling to prevent environmental contamination. Recycling programs for paint and solvent containers can help mitigate this impact, but they are not universally available or utilized.

In the context of paints and coatings, the primary environmental concern is the emission of ethyl acetate during application and drying processes. These emissions can contribute to indoor air pollution in enclosed spaces, potentially affecting the health of workers and occupants. Outdoors, the release of ethyl acetate can contribute to smog formation and air quality degradation in urban areas.

Water pollution is another potential environmental impact of ethyl acetate use in paints and coatings. Improper disposal of paint waste or cleaning solvents containing ethyl acetate can lead to contamination of water sources. While ethyl acetate is biodegradable and has low toxicity to aquatic life compared to some other solvents, high concentrations can still have adverse effects on aquatic ecosystems.

The production of ethyl acetate also has environmental implications. The manufacturing process typically involves the reaction of ethanol with acetic acid, both of which are derived from petrochemical sources. This reliance on fossil fuels contributes to carbon emissions and resource depletion. However, there are ongoing efforts to develop bio-based ethyl acetate production methods using renewable feedstocks, which could potentially reduce the environmental footprint of its manufacture.

In response to environmental concerns, many countries have implemented regulations to limit VOC emissions from paints and coatings. These regulations have driven the development of low-VOC and zero-VOC formulations, which often involve reducing or eliminating the use of solvents like ethyl acetate. Water-based paints and powder coatings have gained popularity as more environmentally friendly alternatives.

The lifecycle environmental impact of ethyl acetate in paints and coatings extends beyond its immediate use. The disposal of paint cans and other containers that have contained ethyl acetate-based products requires proper handling to prevent environmental contamination. Recycling programs for paint and solvent containers can help mitigate this impact, but they are not universally available or utilized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!