Ethyl Acetate in Rubber Manufacturing: A Deep Dive

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Evolution

The evolution of ethyl acetate in rubber manufacturing has been marked by significant advancements and shifts in application methods over the years. Initially introduced as a solvent in the early 20th century, ethyl acetate quickly gained prominence due to its excellent solvency properties and relatively low toxicity compared to other organic solvents.

In the 1950s and 1960s, the rubber industry saw a surge in the use of ethyl acetate, particularly in the production of adhesives and coatings for rubber products. This period marked the beginning of its widespread adoption in rubber manufacturing processes, as manufacturers recognized its ability to dissolve various rubber compounds effectively.

The 1970s brought about increased awareness of environmental concerns, leading to the development of more efficient application techniques for ethyl acetate. Spray coating methods were refined, allowing for more precise control over solvent usage and reducing waste. This era also saw the introduction of recovery systems to capture and recycle ethyl acetate vapors, addressing both economic and environmental considerations.

During the 1980s and 1990s, the focus shifted towards optimizing the use of ethyl acetate in specific rubber applications. Researchers developed specialized formulations that enhanced the solvent's effectiveness in particular rubber compounds, leading to improvements in product quality and manufacturing efficiency. This period also saw the integration of ethyl acetate into more advanced rubber processing techniques, such as solution polymerization and microencapsulation.

The turn of the millennium brought renewed interest in sustainable manufacturing practices. This led to further innovations in ethyl acetate application, including the development of low-VOC (volatile organic compound) formulations and water-based alternatives that incorporated ethyl acetate as a co-solvent. These advancements aimed to maintain the beneficial properties of ethyl acetate while reducing its environmental impact.

In recent years, the evolution of ethyl acetate in rubber manufacturing has been characterized by a focus on precision and automation. Advanced dispensing systems and computer-controlled application processes have emerged, allowing for more accurate and consistent use of the solvent. Additionally, there has been growing interest in exploring the potential of ethyl acetate in novel rubber manufacturing techniques, such as 3D printing of rubber components.

Looking ahead, the trajectory of ethyl acetate in rubber manufacturing is likely to be influenced by ongoing research into bio-based alternatives and green chemistry principles. While traditional petrochemical-derived ethyl acetate remains dominant, efforts to develop sustainable production methods from renewable resources are gaining traction, potentially reshaping the future landscape of this versatile solvent in the rubber industry.

In the 1950s and 1960s, the rubber industry saw a surge in the use of ethyl acetate, particularly in the production of adhesives and coatings for rubber products. This period marked the beginning of its widespread adoption in rubber manufacturing processes, as manufacturers recognized its ability to dissolve various rubber compounds effectively.

The 1970s brought about increased awareness of environmental concerns, leading to the development of more efficient application techniques for ethyl acetate. Spray coating methods were refined, allowing for more precise control over solvent usage and reducing waste. This era also saw the introduction of recovery systems to capture and recycle ethyl acetate vapors, addressing both economic and environmental considerations.

During the 1980s and 1990s, the focus shifted towards optimizing the use of ethyl acetate in specific rubber applications. Researchers developed specialized formulations that enhanced the solvent's effectiveness in particular rubber compounds, leading to improvements in product quality and manufacturing efficiency. This period also saw the integration of ethyl acetate into more advanced rubber processing techniques, such as solution polymerization and microencapsulation.

The turn of the millennium brought renewed interest in sustainable manufacturing practices. This led to further innovations in ethyl acetate application, including the development of low-VOC (volatile organic compound) formulations and water-based alternatives that incorporated ethyl acetate as a co-solvent. These advancements aimed to maintain the beneficial properties of ethyl acetate while reducing its environmental impact.

In recent years, the evolution of ethyl acetate in rubber manufacturing has been characterized by a focus on precision and automation. Advanced dispensing systems and computer-controlled application processes have emerged, allowing for more accurate and consistent use of the solvent. Additionally, there has been growing interest in exploring the potential of ethyl acetate in novel rubber manufacturing techniques, such as 3D printing of rubber components.

Looking ahead, the trajectory of ethyl acetate in rubber manufacturing is likely to be influenced by ongoing research into bio-based alternatives and green chemistry principles. While traditional petrochemical-derived ethyl acetate remains dominant, efforts to develop sustainable production methods from renewable resources are gaining traction, potentially reshaping the future landscape of this versatile solvent in the rubber industry.

Rubber Industry Demand

The rubber industry has experienced significant growth in recent years, driven by increasing demand across various sectors. The automotive industry remains a primary consumer of rubber products, with tire manufacturing accounting for a substantial portion of the market. As global vehicle production continues to rise, particularly in emerging economies, the demand for rubber in automotive applications is expected to maintain its upward trajectory.

In addition to automotive applications, the construction and industrial sectors have shown a growing appetite for rubber products. The expansion of infrastructure projects worldwide has led to increased demand for rubber-based materials in construction, such as seals, gaskets, and insulation. Similarly, the industrial sector relies heavily on rubber components for machinery, equipment, and various manufacturing processes.

The healthcare industry has also emerged as a significant driver of rubber demand, particularly in the production of medical gloves, tubing, and other essential medical equipment. The COVID-19 pandemic has further accelerated this trend, highlighting the critical role of rubber products in ensuring public health and safety.

Environmental concerns and sustainability initiatives have begun to shape the rubber industry's landscape. There is a growing demand for eco-friendly rubber alternatives and recycled rubber products, driven by both consumer preferences and regulatory pressures. This shift has prompted manufacturers to explore innovative production methods and materials to meet these evolving market requirements.

The Asia-Pacific region, led by countries such as China and India, continues to dominate the global rubber market in terms of both production and consumption. The rapid industrialization and urbanization in these countries have fueled the demand for rubber across various applications. However, mature markets in North America and Europe remain significant consumers, particularly in high-value, specialized rubber products.

The increasing adoption of electric vehicles (EVs) presents both challenges and opportunities for the rubber industry. While traditional rubber components may see reduced demand in EVs, new applications are emerging, such as specialized tires and noise-dampening materials tailored for electric powertrains.

As the rubber industry evolves, there is a growing emphasis on developing advanced rubber compounds with enhanced properties. These include improved durability, heat resistance, and chemical compatibility, driven by the demands of increasingly sophisticated end-use applications across industries.

In addition to automotive applications, the construction and industrial sectors have shown a growing appetite for rubber products. The expansion of infrastructure projects worldwide has led to increased demand for rubber-based materials in construction, such as seals, gaskets, and insulation. Similarly, the industrial sector relies heavily on rubber components for machinery, equipment, and various manufacturing processes.

The healthcare industry has also emerged as a significant driver of rubber demand, particularly in the production of medical gloves, tubing, and other essential medical equipment. The COVID-19 pandemic has further accelerated this trend, highlighting the critical role of rubber products in ensuring public health and safety.

Environmental concerns and sustainability initiatives have begun to shape the rubber industry's landscape. There is a growing demand for eco-friendly rubber alternatives and recycled rubber products, driven by both consumer preferences and regulatory pressures. This shift has prompted manufacturers to explore innovative production methods and materials to meet these evolving market requirements.

The Asia-Pacific region, led by countries such as China and India, continues to dominate the global rubber market in terms of both production and consumption. The rapid industrialization and urbanization in these countries have fueled the demand for rubber across various applications. However, mature markets in North America and Europe remain significant consumers, particularly in high-value, specialized rubber products.

The increasing adoption of electric vehicles (EVs) presents both challenges and opportunities for the rubber industry. While traditional rubber components may see reduced demand in EVs, new applications are emerging, such as specialized tires and noise-dampening materials tailored for electric powertrains.

As the rubber industry evolves, there is a growing emphasis on developing advanced rubber compounds with enhanced properties. These include improved durability, heat resistance, and chemical compatibility, driven by the demands of increasingly sophisticated end-use applications across industries.

Technical Challenges

The use of ethyl acetate in rubber manufacturing presents several technical challenges that require careful consideration and innovative solutions. One of the primary issues is the volatility of ethyl acetate, which can lead to significant material loss during processing. This not only impacts the cost-effectiveness of production but also raises environmental concerns due to the release of volatile organic compounds (VOCs) into the atmosphere.

Another challenge lies in achieving uniform dispersion of ethyl acetate within the rubber matrix. Inconsistent distribution can result in localized areas of high concentration, potentially affecting the final product's properties and performance. This issue is particularly critical in applications where precise control over the rubber's characteristics is essential, such as in automotive or aerospace industries.

The interaction between ethyl acetate and various rubber compounds poses additional complexities. Different types of rubber may react differently with ethyl acetate, leading to variations in curing times, cross-linking density, and overall material properties. Engineers must carefully calibrate formulations to account for these interactions, which can be a time-consuming and resource-intensive process.

Temperature control during the manufacturing process is another significant challenge. Ethyl acetate's low boiling point (77.1°C) means that it can easily evaporate at typical rubber processing temperatures. This necessitates the development of specialized equipment and processes to maintain the solvent's presence throughout the manufacturing cycle, ensuring its intended effects on the rubber compound are achieved.

The storage and handling of ethyl acetate also present safety concerns. Its flammability and potential to form explosive mixtures with air require stringent safety protocols and specialized storage facilities. This adds complexity to the manufacturing process and increases operational costs for rubber producers.

Furthermore, the regulatory landscape surrounding the use of volatile organic solvents like ethyl acetate is becoming increasingly stringent. Manufacturers must navigate a complex web of environmental regulations, which may vary across different regions and countries. This regulatory pressure drives the need for more efficient solvent recovery systems and exploration of alternative, more environmentally friendly processing aids.

Lastly, the quality control and testing of rubber products manufactured with ethyl acetate present unique challenges. Residual solvent content must be carefully monitored to ensure it falls within acceptable limits for the final product's intended use. Developing reliable and efficient testing methods that can detect trace amounts of ethyl acetate in diverse rubber formulations remains an ongoing technical challenge for the industry.

Another challenge lies in achieving uniform dispersion of ethyl acetate within the rubber matrix. Inconsistent distribution can result in localized areas of high concentration, potentially affecting the final product's properties and performance. This issue is particularly critical in applications where precise control over the rubber's characteristics is essential, such as in automotive or aerospace industries.

The interaction between ethyl acetate and various rubber compounds poses additional complexities. Different types of rubber may react differently with ethyl acetate, leading to variations in curing times, cross-linking density, and overall material properties. Engineers must carefully calibrate formulations to account for these interactions, which can be a time-consuming and resource-intensive process.

Temperature control during the manufacturing process is another significant challenge. Ethyl acetate's low boiling point (77.1°C) means that it can easily evaporate at typical rubber processing temperatures. This necessitates the development of specialized equipment and processes to maintain the solvent's presence throughout the manufacturing cycle, ensuring its intended effects on the rubber compound are achieved.

The storage and handling of ethyl acetate also present safety concerns. Its flammability and potential to form explosive mixtures with air require stringent safety protocols and specialized storage facilities. This adds complexity to the manufacturing process and increases operational costs for rubber producers.

Furthermore, the regulatory landscape surrounding the use of volatile organic solvents like ethyl acetate is becoming increasingly stringent. Manufacturers must navigate a complex web of environmental regulations, which may vary across different regions and countries. This regulatory pressure drives the need for more efficient solvent recovery systems and exploration of alternative, more environmentally friendly processing aids.

Lastly, the quality control and testing of rubber products manufactured with ethyl acetate present unique challenges. Residual solvent content must be carefully monitored to ensure it falls within acceptable limits for the final product's intended use. Developing reliable and efficient testing methods that can detect trace amounts of ethyl acetate in diverse rubber formulations remains an ongoing technical challenge for the industry.

Current EA Solutions

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate, which is an important industrial solvent and chemical intermediate.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in diverse chemical processes, such as solvent extraction, as a reaction medium, and in the production of other chemicals. Its properties make it suitable for various industrial applications, including pharmaceuticals and polymer manufacturing.

- Ethyl acetate in coating and adhesive formulations: Ethyl acetate is employed in the formulation of coatings, adhesives, and related products. Its use as a solvent in these applications contributes to improved performance characteristics and processing efficiency.

- Ethyl acetate in environmental and sustainable processes: Research focuses on developing environmentally friendly processes involving ethyl acetate, including its production from renewable resources and its use in green chemistry applications. These efforts aim to reduce environmental impact and improve sustainability in chemical industries.

- Analytical methods and quality control for ethyl acetate: Various analytical techniques and quality control methods are developed for ethyl acetate, ensuring its purity and suitability for different applications. These methods include spectroscopic analysis, chromatography, and other advanced analytical tools.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in diverse chemical processes, such as extraction, crystallization, and as a reaction medium. Its properties make it suitable for use in the production of pharmaceuticals, polymers, and other chemical compounds.Expand Specific Solutions03 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is employed in the formulation of coatings, paints, and adhesives. Its fast evaporation rate and solvency properties make it valuable in these applications, contributing to the performance and characteristics of the final products.Expand Specific Solutions04 Recovery and recycling of ethyl acetate

Methods for recovering and recycling ethyl acetate from industrial processes are described. These techniques aim to reduce waste, improve process efficiency, and minimize environmental impact by reusing the solvent in various applications.Expand Specific Solutions05 Ethyl acetate as a green solvent alternative

Ethyl acetate is explored as an environmentally friendly alternative to more hazardous solvents in various industrial and laboratory applications. Its relatively low toxicity and biodegradability make it attractive for use in green chemistry initiatives.Expand Specific Solutions

Key Industry Players

The ethyl acetate in rubber manufacturing market is in a growth phase, driven by increasing demand in automotive and industrial applications. The global market size is expanding, with projections indicating steady growth over the coming years. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficiency and sustainability. Key players like Michelin, SABIC, and Braskem are investing in research and development to enhance product performance and eco-friendliness. Chinese companies such as Sinopec and PetroChina are also making significant strides, leveraging their petrochemical expertise. Japanese firms like Mitsui Chemicals and JSR Corp are contributing advanced materials and specialty chemicals, further intensifying the competitive landscape in this evolving sector.

Société de Technologie Michelin

Technical Solution: Michelin has developed an innovative approach to incorporating ethyl acetate in rubber manufacturing, focusing on improving tire performance and sustainability. Their process involves using ethyl acetate as a solvent in the production of solution-styrene-butadiene rubber (SSBR), which is crucial for high-performance tires. This method allows for better control of the polymer microstructure, resulting in improved tire grip and rolling resistance[1]. Michelin's technique also involves using ethyl acetate in a closed-loop system, where the solvent is recovered and reused, significantly reducing environmental impact and production costs[2]. Additionally, they have implemented a novel curing process that utilizes ethyl acetate to enhance the cross-linking of rubber compounds, leading to improved durability and reduced tire weight[3].

Strengths: Improved tire performance, reduced environmental impact, cost-effective production. Weaknesses: Potential complexity in implementing closed-loop systems, initial investment costs for new equipment.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a groundbreaking approach to utilizing ethyl acetate in rubber manufacturing, particularly focusing on the production of synthetic rubber. Their process involves using ethyl acetate as a green solvent in the polymerization of butadiene and styrene to produce solution styrene-butadiene rubber (SSBR)[1]. This method allows for better control of the molecular weight distribution and microstructure of the polymer, resulting in improved rubber properties such as wear resistance and low rolling resistance[2]. Sinopec has also implemented a novel recovery system that enables the efficient recycling of ethyl acetate, significantly reducing waste and environmental impact[3]. Furthermore, they have developed a proprietary catalyst system that works synergistically with ethyl acetate to enhance the polymerization process, leading to higher yields and improved product quality[4].

Strengths: Improved rubber properties, environmentally friendly process, efficient solvent recovery. Weaknesses: Potential higher initial costs, need for specialized equipment and expertise.

EA Innovations Review

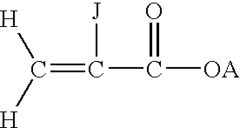

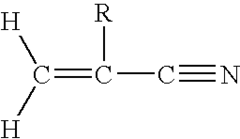

Weatherable styrenic blends with improved translucency

PatentInactiveUS6720386B2

Innovation

- The development of an acrylate-styrene-acrylonitrile (ASA) composition featuring a matrix phase of vinyl carboxylic acid ester, vinyl aromatic, and vinyl cyanide monomers with a graft copolymer comprising a substrate rubber and superstrate copolymer, utilizing a PMMA/MMASAN terpolymer matrix and a butyl acrylate rubber graft phase, optimizing weight percentages for enhanced translucency and colorability.

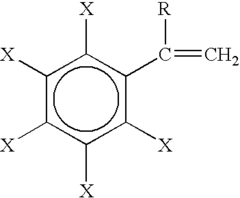

Impact-modified molding composition and method

PatentInactiveUS20100093915A1

Innovation

- A method for preparing ASA resin with a discontinuous elastomeric phase and a rigid thermoplastic phase, where at least a portion of the rigid thermoplastic phase is grafted to the elastomeric phase, involving the polymerization of specific monomers in multiple stages to minimize residual crosslinking agents, thereby reducing haze and maintaining high productivity at lower mold temperatures.

Environmental Impact

The use of ethyl acetate in rubber manufacturing processes has significant environmental implications that warrant careful consideration. As a volatile organic compound (VOC), ethyl acetate contributes to air pollution and the formation of ground-level ozone when released into the atmosphere. This can lead to respiratory issues and other health concerns for both workers and surrounding communities. Additionally, the production and disposal of ethyl acetate can result in water pollution if not properly managed, potentially affecting aquatic ecosystems and drinking water sources.

From a lifecycle perspective, the environmental impact of ethyl acetate extends beyond its immediate use in rubber manufacturing. The production of ethyl acetate typically involves petrochemical processes, which contribute to greenhouse gas emissions and resource depletion. Furthermore, the transportation and storage of this chemical compound pose risks of accidental spills or leaks, which can have localized environmental consequences.

However, it is important to note that ethyl acetate is generally considered less harmful than many other solvents used in industrial processes. It has a relatively low toxicity profile and is biodegradable, which mitigates some of its long-term environmental effects. Many regulatory bodies classify ethyl acetate as a low-risk solvent, and it is often preferred over more hazardous alternatives.

In response to environmental concerns, the rubber manufacturing industry has been exploring ways to minimize the environmental impact of ethyl acetate usage. This includes implementing more efficient application methods to reduce overall consumption, improving solvent recovery and recycling systems, and investing in better emission control technologies. Some manufacturers are also investigating bio-based alternatives to ethyl acetate, derived from renewable resources, which could potentially offer a more sustainable solution.

The regulatory landscape surrounding ethyl acetate use is evolving, with increasing pressure on industries to reduce VOC emissions. This has led to the development of low-VOC and VOC-free rubber manufacturing processes, which aim to eliminate or significantly reduce the use of solvents like ethyl acetate. While these alternatives often come with their own set of challenges, they represent a growing trend towards more environmentally friendly manufacturing practices in the rubber industry.

As the industry continues to balance performance requirements with environmental responsibility, ongoing research and development efforts are focused on finding optimal solutions that maintain product quality while minimizing ecological impact. This includes exploring novel formulations, advanced process technologies, and alternative materials that could potentially replace or reduce the need for ethyl acetate in rubber manufacturing.

From a lifecycle perspective, the environmental impact of ethyl acetate extends beyond its immediate use in rubber manufacturing. The production of ethyl acetate typically involves petrochemical processes, which contribute to greenhouse gas emissions and resource depletion. Furthermore, the transportation and storage of this chemical compound pose risks of accidental spills or leaks, which can have localized environmental consequences.

However, it is important to note that ethyl acetate is generally considered less harmful than many other solvents used in industrial processes. It has a relatively low toxicity profile and is biodegradable, which mitigates some of its long-term environmental effects. Many regulatory bodies classify ethyl acetate as a low-risk solvent, and it is often preferred over more hazardous alternatives.

In response to environmental concerns, the rubber manufacturing industry has been exploring ways to minimize the environmental impact of ethyl acetate usage. This includes implementing more efficient application methods to reduce overall consumption, improving solvent recovery and recycling systems, and investing in better emission control technologies. Some manufacturers are also investigating bio-based alternatives to ethyl acetate, derived from renewable resources, which could potentially offer a more sustainable solution.

The regulatory landscape surrounding ethyl acetate use is evolving, with increasing pressure on industries to reduce VOC emissions. This has led to the development of low-VOC and VOC-free rubber manufacturing processes, which aim to eliminate or significantly reduce the use of solvents like ethyl acetate. While these alternatives often come with their own set of challenges, they represent a growing trend towards more environmentally friendly manufacturing practices in the rubber industry.

As the industry continues to balance performance requirements with environmental responsibility, ongoing research and development efforts are focused on finding optimal solutions that maintain product quality while minimizing ecological impact. This includes exploring novel formulations, advanced process technologies, and alternative materials that could potentially replace or reduce the need for ethyl acetate in rubber manufacturing.

Safety Regulations

The use of ethyl acetate in rubber manufacturing is subject to stringent safety regulations due to its flammable and potentially hazardous nature. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA) have established comprehensive guidelines for handling and storing this solvent. These regulations primarily focus on minimizing fire risks, preventing exposure to workers, and ensuring proper disposal.

OSHA mandates that workplaces using ethyl acetate must implement specific safety measures, including proper ventilation systems, personal protective equipment (PPE), and regular air quality monitoring. The permissible exposure limit (PEL) for ethyl acetate is set at 400 parts per million (ppm) for an 8-hour time-weighted average. Employers are required to provide appropriate respiratory protection if exposure levels exceed this limit.

Fire safety is a critical concern when working with ethyl acetate. The National Fire Protection Association (NFPA) classifies it as a Class IB flammable liquid. As such, rubber manufacturing facilities must adhere to strict storage and handling protocols. This includes using explosion-proof electrical equipment, implementing proper grounding and bonding procedures, and maintaining adequate fire suppression systems.

Environmental regulations also play a significant role in the use of ethyl acetate in rubber manufacturing. The Environmental Protection Agency (EPA) regulates its emissions under the Clean Air Act as a volatile organic compound (VOC). Manufacturers must comply with emission limits and may be required to implement control technologies to reduce atmospheric releases.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of ethyl acetate. Manufacturers and importers must register the substance and provide safety data sheets detailing its properties, hazards, and safe handling procedures. The Classification, Labeling, and Packaging (CLP) regulation further requires proper labeling and packaging of ethyl acetate to communicate hazards effectively.

Waste management is another crucial aspect of safety regulations. The Resource Conservation and Recovery Act (RCRA) in the United States classifies spent ethyl acetate as a hazardous waste. Rubber manufacturers must comply with specific disposal requirements, including proper containment, labeling, and transportation of waste materials to authorized treatment facilities.

To ensure compliance with these regulations, rubber manufacturing facilities often implement comprehensive safety management systems. These systems typically include regular employee training, documented standard operating procedures, emergency response plans, and periodic audits. Many companies also adopt voluntary standards, such as ISO 45001 for occupational health and safety management, to further enhance their safety practices.

OSHA mandates that workplaces using ethyl acetate must implement specific safety measures, including proper ventilation systems, personal protective equipment (PPE), and regular air quality monitoring. The permissible exposure limit (PEL) for ethyl acetate is set at 400 parts per million (ppm) for an 8-hour time-weighted average. Employers are required to provide appropriate respiratory protection if exposure levels exceed this limit.

Fire safety is a critical concern when working with ethyl acetate. The National Fire Protection Association (NFPA) classifies it as a Class IB flammable liquid. As such, rubber manufacturing facilities must adhere to strict storage and handling protocols. This includes using explosion-proof electrical equipment, implementing proper grounding and bonding procedures, and maintaining adequate fire suppression systems.

Environmental regulations also play a significant role in the use of ethyl acetate in rubber manufacturing. The Environmental Protection Agency (EPA) regulates its emissions under the Clean Air Act as a volatile organic compound (VOC). Manufacturers must comply with emission limits and may be required to implement control technologies to reduce atmospheric releases.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of ethyl acetate. Manufacturers and importers must register the substance and provide safety data sheets detailing its properties, hazards, and safe handling procedures. The Classification, Labeling, and Packaging (CLP) regulation further requires proper labeling and packaging of ethyl acetate to communicate hazards effectively.

Waste management is another crucial aspect of safety regulations. The Resource Conservation and Recovery Act (RCRA) in the United States classifies spent ethyl acetate as a hazardous waste. Rubber manufacturers must comply with specific disposal requirements, including proper containment, labeling, and transportation of waste materials to authorized treatment facilities.

To ensure compliance with these regulations, rubber manufacturing facilities often implement comprehensive safety management systems. These systems typically include regular employee training, documented standard operating procedures, emergency response plans, and periodic audits. Many companies also adopt voluntary standards, such as ISO 45001 for occupational health and safety management, to further enhance their safety practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!