Ethyl Acetate Recycling: New Technologies and Approaches

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Recycling Evolution and Objectives

Ethyl acetate recycling has evolved significantly over the past few decades, driven by environmental concerns, economic factors, and technological advancements. The journey began in the mid-20th century when industrial processes started recognizing the importance of solvent recovery. Initially, simple distillation methods were employed to separate ethyl acetate from waste streams, but these processes were energy-intensive and often inefficient.

As environmental regulations tightened in the 1970s and 1980s, there was a growing emphasis on reducing volatile organic compound (VOC) emissions. This led to the development of more sophisticated recovery techniques, such as azeotropic distillation and extractive distillation. These methods allowed for higher purity recovery of ethyl acetate, making recycling more economically viable for industries.

The 1990s saw the introduction of membrane-based separation technologies, which offered a less energy-intensive alternative to traditional distillation. Pervaporation and vapor permeation techniques began to gain traction, particularly for separating ethyl acetate from water in aqueous waste streams. These membrane technologies provided a more selective and efficient means of recovery, albeit with limitations in terms of throughput and membrane durability.

Entering the 21st century, the focus shifted towards developing more sustainable and integrated recycling approaches. Adsorption technologies, using materials like activated carbon and zeolites, emerged as promising methods for ethyl acetate recovery. These techniques offered advantages in terms of energy efficiency and the ability to handle dilute streams effectively.

Recent years have witnessed a surge in research into advanced oxidation processes and biological treatment methods for ethyl acetate-containing wastewater. These approaches aim to degrade ethyl acetate into harmless byproducts when recovery is not feasible, aligning with circular economy principles.

The primary objectives of current ethyl acetate recycling research and development are multifaceted. Firstly, there is a strong drive to improve energy efficiency in recovery processes, reducing the carbon footprint associated with recycling operations. Secondly, researchers are focusing on enhancing the purity of recovered ethyl acetate to meet stringent quality requirements for reuse in various industries.

Another key objective is to develop more versatile recycling technologies that can handle complex mixtures and varying concentrations of ethyl acetate in waste streams. This includes exploring hybrid systems that combine different separation techniques to achieve optimal performance across a range of operating conditions.

As environmental regulations tightened in the 1970s and 1980s, there was a growing emphasis on reducing volatile organic compound (VOC) emissions. This led to the development of more sophisticated recovery techniques, such as azeotropic distillation and extractive distillation. These methods allowed for higher purity recovery of ethyl acetate, making recycling more economically viable for industries.

The 1990s saw the introduction of membrane-based separation technologies, which offered a less energy-intensive alternative to traditional distillation. Pervaporation and vapor permeation techniques began to gain traction, particularly for separating ethyl acetate from water in aqueous waste streams. These membrane technologies provided a more selective and efficient means of recovery, albeit with limitations in terms of throughput and membrane durability.

Entering the 21st century, the focus shifted towards developing more sustainable and integrated recycling approaches. Adsorption technologies, using materials like activated carbon and zeolites, emerged as promising methods for ethyl acetate recovery. These techniques offered advantages in terms of energy efficiency and the ability to handle dilute streams effectively.

Recent years have witnessed a surge in research into advanced oxidation processes and biological treatment methods for ethyl acetate-containing wastewater. These approaches aim to degrade ethyl acetate into harmless byproducts when recovery is not feasible, aligning with circular economy principles.

The primary objectives of current ethyl acetate recycling research and development are multifaceted. Firstly, there is a strong drive to improve energy efficiency in recovery processes, reducing the carbon footprint associated with recycling operations. Secondly, researchers are focusing on enhancing the purity of recovered ethyl acetate to meet stringent quality requirements for reuse in various industries.

Another key objective is to develop more versatile recycling technologies that can handle complex mixtures and varying concentrations of ethyl acetate in waste streams. This includes exploring hybrid systems that combine different separation techniques to achieve optimal performance across a range of operating conditions.

Market Demand Analysis for Ethyl Acetate Recycling

The global market for ethyl acetate recycling has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on waste management. The demand for ethyl acetate recycling technologies is primarily fueled by industries such as pharmaceuticals, paints and coatings, adhesives, and printing inks, where ethyl acetate is extensively used as a solvent.

In the pharmaceutical sector, the push for sustainable practices and cost reduction has led to a surge in demand for ethyl acetate recycling solutions. As drug manufacturers strive to minimize waste and reduce their environmental footprint, the adoption of recycling technologies has become a priority. This trend is expected to continue, with the pharmaceutical industry projected to be a major driver of market growth in the coming years.

The paints and coatings industry, another significant consumer of ethyl acetate, has also shown a strong inclination towards recycling. With volatile organic compound (VOC) emissions becoming increasingly regulated, manufacturers are seeking ways to recover and reuse solvents like ethyl acetate. This not only helps in compliance with environmental regulations but also offers substantial cost savings in raw material procurement.

The adhesives and sealants market, which relies heavily on ethyl acetate as a solvent, is another key contributor to the growing demand for recycling technologies. As sustainability becomes a core focus for many adhesive manufacturers, the implementation of solvent recovery systems has gained traction. This trend is particularly pronounced in regions with strict environmental policies, such as Europe and North America.

In the printing industry, where ethyl acetate is used in flexographic and rotogravure printing processes, there is a growing awareness of the economic and environmental benefits of solvent recycling. Printers are increasingly investing in on-site recycling systems to reduce their reliance on fresh solvents and minimize waste disposal costs.

Geographically, Asia-Pacific is emerging as a lucrative market for ethyl acetate recycling technologies. The rapid industrialization in countries like China and India, coupled with growing environmental consciousness, is driving the adoption of recycling solutions. North America and Europe, with their well-established regulatory frameworks, continue to be significant markets for advanced recycling technologies.

The market demand for ethyl acetate recycling is also influenced by the broader trend towards circular economy principles. As businesses across various sectors seek to close the loop on their production processes, the recovery and reuse of solvents like ethyl acetate have become integral to their sustainability strategies.

In the pharmaceutical sector, the push for sustainable practices and cost reduction has led to a surge in demand for ethyl acetate recycling solutions. As drug manufacturers strive to minimize waste and reduce their environmental footprint, the adoption of recycling technologies has become a priority. This trend is expected to continue, with the pharmaceutical industry projected to be a major driver of market growth in the coming years.

The paints and coatings industry, another significant consumer of ethyl acetate, has also shown a strong inclination towards recycling. With volatile organic compound (VOC) emissions becoming increasingly regulated, manufacturers are seeking ways to recover and reuse solvents like ethyl acetate. This not only helps in compliance with environmental regulations but also offers substantial cost savings in raw material procurement.

The adhesives and sealants market, which relies heavily on ethyl acetate as a solvent, is another key contributor to the growing demand for recycling technologies. As sustainability becomes a core focus for many adhesive manufacturers, the implementation of solvent recovery systems has gained traction. This trend is particularly pronounced in regions with strict environmental policies, such as Europe and North America.

In the printing industry, where ethyl acetate is used in flexographic and rotogravure printing processes, there is a growing awareness of the economic and environmental benefits of solvent recycling. Printers are increasingly investing in on-site recycling systems to reduce their reliance on fresh solvents and minimize waste disposal costs.

Geographically, Asia-Pacific is emerging as a lucrative market for ethyl acetate recycling technologies. The rapid industrialization in countries like China and India, coupled with growing environmental consciousness, is driving the adoption of recycling solutions. North America and Europe, with their well-established regulatory frameworks, continue to be significant markets for advanced recycling technologies.

The market demand for ethyl acetate recycling is also influenced by the broader trend towards circular economy principles. As businesses across various sectors seek to close the loop on their production processes, the recovery and reuse of solvents like ethyl acetate have become integral to their sustainability strategies.

Current Challenges in Ethyl Acetate Recovery

The recovery of ethyl acetate presents several significant challenges in industrial processes, primarily due to its physical and chemical properties. One of the main difficulties lies in the formation of azeotropes with water, which complicates traditional distillation methods. The ethyl acetate-water azeotrope forms at 70.4% ethyl acetate by weight, making it impossible to achieve complete separation through simple distillation.

Energy consumption is another major concern in ethyl acetate recovery. Conventional distillation processes require substantial thermal energy input, contributing to high operational costs and environmental impact. This energy-intensive nature of recovery processes poses a significant challenge for industries striving to reduce their carbon footprint and operational expenses.

The presence of impurities in the recovered ethyl acetate stream further complicates the recycling process. These impurities may include other organic solvents, reaction by-products, or contaminants introduced during the manufacturing process. Removing these impurities to meet the required purity standards for reuse or sale often necessitates additional purification steps, increasing process complexity and cost.

Corrosion of equipment is an ongoing issue in ethyl acetate recovery systems. The acidic nature of ethyl acetate, especially in the presence of water, can lead to accelerated corrosion of metal components in processing equipment. This necessitates the use of corrosion-resistant materials or protective coatings, adding to capital and maintenance costs.

Volatile organic compound (VOC) emissions during the recovery process pose environmental and health concerns. Ethyl acetate is classified as a VOC, and its release into the atmosphere contributes to air pollution and potential health hazards. Stringent environmental regulations require effective containment and treatment of these emissions, adding another layer of complexity to the recovery process.

The efficiency of current recovery technologies is a persistent challenge. Many existing methods struggle to achieve high recovery rates while maintaining product quality. This inefficiency results in material losses and increased waste generation, impacting both economic viability and environmental sustainability of the process.

Scalability of recovery technologies presents difficulties, especially for smaller or medium-sized operations. Many advanced separation techniques that offer improved efficiency are often not economically viable or technically feasible at smaller scales, limiting their adoption across the industry.

Energy consumption is another major concern in ethyl acetate recovery. Conventional distillation processes require substantial thermal energy input, contributing to high operational costs and environmental impact. This energy-intensive nature of recovery processes poses a significant challenge for industries striving to reduce their carbon footprint and operational expenses.

The presence of impurities in the recovered ethyl acetate stream further complicates the recycling process. These impurities may include other organic solvents, reaction by-products, or contaminants introduced during the manufacturing process. Removing these impurities to meet the required purity standards for reuse or sale often necessitates additional purification steps, increasing process complexity and cost.

Corrosion of equipment is an ongoing issue in ethyl acetate recovery systems. The acidic nature of ethyl acetate, especially in the presence of water, can lead to accelerated corrosion of metal components in processing equipment. This necessitates the use of corrosion-resistant materials or protective coatings, adding to capital and maintenance costs.

Volatile organic compound (VOC) emissions during the recovery process pose environmental and health concerns. Ethyl acetate is classified as a VOC, and its release into the atmosphere contributes to air pollution and potential health hazards. Stringent environmental regulations require effective containment and treatment of these emissions, adding another layer of complexity to the recovery process.

The efficiency of current recovery technologies is a persistent challenge. Many existing methods struggle to achieve high recovery rates while maintaining product quality. This inefficiency results in material losses and increased waste generation, impacting both economic viability and environmental sustainability of the process.

Scalability of recovery technologies presents difficulties, especially for smaller or medium-sized operations. Many advanced separation techniques that offer improved efficiency are often not economically viable or technically feasible at smaller scales, limiting their adoption across the industry.

Existing Ethyl Acetate Recovery Methods

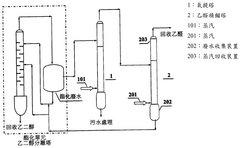

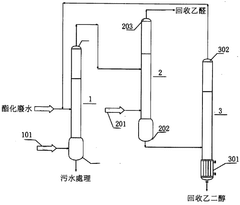

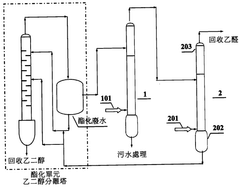

01 Distillation and condensation methods

Ethyl acetate recycling can be achieved through distillation and condensation processes. These methods involve separating ethyl acetate from other components in a mixture by heating and cooling. The vapor is collected and condensed back into liquid form, allowing for the recovery and reuse of ethyl acetate in various industrial applications.- Distillation and purification methods: Various distillation and purification techniques are employed to recycle ethyl acetate. These methods often involve separating ethyl acetate from other components in the mixture, such as water or impurities. The process may include fractional distillation, azeotropic distillation, or the use of specialized distillation columns to achieve high purity recycled ethyl acetate.

- Membrane separation technology: Membrane separation techniques are utilized for ethyl acetate recycling. This approach involves the use of selective membranes to separate ethyl acetate from other components in the mixture. The process can be more energy-efficient compared to traditional distillation methods and may be particularly useful for separating ethyl acetate from azeotropic mixtures.

- Adsorption and desorption processes: Adsorption-based methods are employed for ethyl acetate recovery. These processes typically use adsorbents such as activated carbon or zeolites to selectively adsorb ethyl acetate from a mixture. The adsorbed ethyl acetate is then recovered through desorption, often using temperature or pressure swing techniques. This method can be effective for recovering ethyl acetate from dilute streams.

- Integrated recycling systems: Integrated systems combining multiple recycling techniques are developed for efficient ethyl acetate recovery. These systems may incorporate a combination of distillation, membrane separation, and adsorption processes to achieve high recovery rates and purity. Such integrated approaches can be tailored to specific industrial applications and can offer improved energy efficiency and reduced environmental impact.

- Solvent extraction and recovery: Solvent extraction methods are used to recover ethyl acetate from various mixtures. This approach involves using a suitable extracting solvent to selectively remove ethyl acetate from the original mixture. The ethyl acetate is then separated from the extracting solvent, often through distillation or other separation techniques. This method can be particularly useful for recovering ethyl acetate from aqueous solutions or complex mixtures.

02 Membrane separation technology

Membrane separation technology is utilized for ethyl acetate recycling. This method employs selective membranes to separate ethyl acetate from other substances based on molecular size or chemical properties. The process allows for efficient recovery of ethyl acetate while minimizing energy consumption and reducing waste.Expand Specific Solutions03 Adsorption and desorption techniques

Adsorption and desorption techniques are employed in ethyl acetate recycling. These methods use adsorbent materials to capture ethyl acetate molecules from a mixture. The adsorbed ethyl acetate is then recovered through desorption processes, such as temperature or pressure changes, allowing for its reuse in various applications.Expand Specific Solutions04 Continuous recycling systems

Continuous recycling systems are designed for efficient and uninterrupted ethyl acetate recovery. These systems integrate various recycling methods and often include automated control mechanisms to optimize the recycling process. They are particularly useful in industrial settings where large volumes of ethyl acetate are used and need to be recycled continuously.Expand Specific Solutions05 Purification and quality control

Purification and quality control processes are crucial in ethyl acetate recycling to ensure the recovered solvent meets the required standards for reuse. These processes may include additional filtration steps, chemical treatments, or analytical techniques to remove impurities and verify the purity of the recycled ethyl acetate.Expand Specific Solutions

Key Players in Solvent Recycling Industry

The ethyl acetate recycling technology market is in a growth phase, driven by increasing environmental regulations and sustainability initiatives. The market size is expanding as industries seek cost-effective and eco-friendly solutions for solvent recovery. While the technology is relatively mature, ongoing research and development efforts by key players are focused on improving efficiency and reducing energy consumption. Companies like Celanese International Corp., Nantong Acetic Acid Chemical Co., Ltd., and LOTTE Chemical Corp. are at the forefront of developing advanced recycling technologies. Academic institutions such as National Taiwan University and Washington State University are contributing to fundamental research in this field, potentially leading to breakthrough innovations in ethyl acetate recycling processes.

Celanese International Corp.

Technical Solution: Celanese has developed an advanced membrane separation technology for ethyl acetate recycling. This process utilizes selective permeable membranes to separate ethyl acetate from other components in waste streams. The technology employs a multi-stage membrane system that achieves high purity recovery (>99%) of ethyl acetate[1]. The process operates at lower temperatures and pressures compared to traditional distillation, resulting in significant energy savings. Celanese has also integrated this membrane technology with their acetic acid production process, allowing for efficient recycling of ethyl acetate byproducts[2].

Strengths: High recovery rate, energy-efficient, integration with existing processes. Weaknesses: High initial capital cost, potential for membrane fouling over time.

BP Corporation North America, Inc.

Technical Solution: BP has developed a novel catalytic process for ethyl acetate recycling using their proprietary BP-CATIVA™ technology. This process involves the catalytic conversion of ethyl acetate to acetic acid and ethanol, which can then be recombined to form fresh ethyl acetate. The catalyst used is a highly selective iridium-based system that operates at milder conditions compared to traditional processes[3]. BP's technology achieves conversion rates of up to 95% and selectivity exceeding 99%[4]. The process is designed to handle a wide range of ethyl acetate concentrations, making it suitable for various industrial waste streams.

Strengths: High conversion and selectivity, versatile feedstock handling. Weaknesses: Reliance on precious metal catalysts, potential catalyst deactivation issues.

Innovative Ethyl Acetate Recycling Patents

Method of recycling ethylene glycol and acetaldehyde from polyester waste water

PatentActiveTW201434758A

Innovation

- Direct utilization of existing ethylene glycol separation tower from the esterification unit for recycling, eliminating the need for a standalone device.

- Combination of ethylene glycol separation with an acetaldehyde recycling system for simultaneous recovery of both compounds.

- Continuous and uninterrupted recycling process achieving high purity of recovered ethylene glycol (≥95%) and acetaldehyde (≥98%).

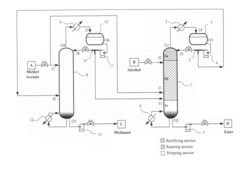

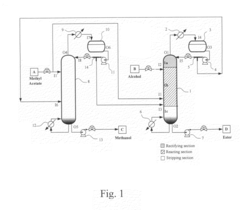

Transesterification process of methyl acetate

PatentActiveUS7399881B1

Innovation

- A cost-effective transesterification process involving a reactive distillation system with a plurality of reactive, stripping, and rectifying trays, using ion exchange resins as catalysts, where methyl acetate is reacted with a limiting alcohol reagent to produce high-purity esters and methanol, optimizing temperature and pressure conditions to minimize steam usage and enhance conversion rates.

Environmental Impact of Ethyl Acetate Recycling

The environmental impact of ethyl acetate recycling is a critical consideration in the adoption and implementation of new technologies and approaches in this field. Recycling ethyl acetate offers significant environmental benefits compared to traditional disposal methods, primarily by reducing waste and minimizing the need for fresh solvent production.

One of the key environmental advantages of ethyl acetate recycling is the reduction in volatile organic compound (VOC) emissions. By recovering and reusing ethyl acetate, industries can substantially decrease the amount of this solvent released into the atmosphere. This reduction in VOC emissions contributes to improved air quality and helps mitigate the formation of ground-level ozone, a major component of smog.

Water pollution is another environmental concern addressed by ethyl acetate recycling. When not properly managed, ethyl acetate can contaminate water sources, posing risks to aquatic ecosystems and human health. Recycling technologies help prevent this contamination by capturing and reprocessing the solvent, rather than allowing it to enter wastewater streams or natural water bodies.

The recycling process itself, however, requires energy input, which can have its own environmental implications. Modern recycling technologies are focusing on improving energy efficiency to minimize the carbon footprint associated with the recycling process. Innovations in distillation techniques, membrane separation, and other recovery methods are continually reducing the energy requirements and, consequently, the greenhouse gas emissions linked to ethyl acetate recycling.

Land use and waste management are also positively impacted by ethyl acetate recycling. By reducing the volume of waste that needs to be disposed of in landfills or through incineration, recycling helps conserve landfill space and reduces the environmental burdens associated with waste transportation and disposal.

Furthermore, the lifecycle analysis of ethyl acetate recycling demonstrates significant reductions in overall environmental impact compared to the production of new solvent. Recycling reduces the demand for raw materials, energy, and water required in the manufacturing of fresh ethyl acetate. This conservation of resources translates to lower carbon emissions, reduced water consumption, and decreased pressure on natural resource extraction.

As recycling technologies advance, there is an increasing focus on developing closed-loop systems that maximize resource efficiency and minimize environmental impact. These systems aim to integrate recycling processes directly into production lines, further reducing transportation needs and associated emissions.

In conclusion, while ethyl acetate recycling does have some environmental costs associated with the recycling process itself, the overall environmental benefits far outweigh these considerations. The continued development of more efficient and environmentally friendly recycling technologies promises to further enhance the positive environmental impact of ethyl acetate recycling in the future.

One of the key environmental advantages of ethyl acetate recycling is the reduction in volatile organic compound (VOC) emissions. By recovering and reusing ethyl acetate, industries can substantially decrease the amount of this solvent released into the atmosphere. This reduction in VOC emissions contributes to improved air quality and helps mitigate the formation of ground-level ozone, a major component of smog.

Water pollution is another environmental concern addressed by ethyl acetate recycling. When not properly managed, ethyl acetate can contaminate water sources, posing risks to aquatic ecosystems and human health. Recycling technologies help prevent this contamination by capturing and reprocessing the solvent, rather than allowing it to enter wastewater streams or natural water bodies.

The recycling process itself, however, requires energy input, which can have its own environmental implications. Modern recycling technologies are focusing on improving energy efficiency to minimize the carbon footprint associated with the recycling process. Innovations in distillation techniques, membrane separation, and other recovery methods are continually reducing the energy requirements and, consequently, the greenhouse gas emissions linked to ethyl acetate recycling.

Land use and waste management are also positively impacted by ethyl acetate recycling. By reducing the volume of waste that needs to be disposed of in landfills or through incineration, recycling helps conserve landfill space and reduces the environmental burdens associated with waste transportation and disposal.

Furthermore, the lifecycle analysis of ethyl acetate recycling demonstrates significant reductions in overall environmental impact compared to the production of new solvent. Recycling reduces the demand for raw materials, energy, and water required in the manufacturing of fresh ethyl acetate. This conservation of resources translates to lower carbon emissions, reduced water consumption, and decreased pressure on natural resource extraction.

As recycling technologies advance, there is an increasing focus on developing closed-loop systems that maximize resource efficiency and minimize environmental impact. These systems aim to integrate recycling processes directly into production lines, further reducing transportation needs and associated emissions.

In conclusion, while ethyl acetate recycling does have some environmental costs associated with the recycling process itself, the overall environmental benefits far outweigh these considerations. The continued development of more efficient and environmentally friendly recycling technologies promises to further enhance the positive environmental impact of ethyl acetate recycling in the future.

Economic Feasibility of Recycling Technologies

The economic feasibility of ethyl acetate recycling technologies is a critical factor in determining their adoption and implementation in industrial processes. The cost-effectiveness of these technologies depends on several key factors, including the initial investment required, operational costs, and potential savings from reduced raw material consumption and waste disposal.

One of the primary considerations is the capital expenditure necessary for installing recycling equipment. This includes the cost of distillation columns, membrane separation units, or other specialized apparatus. While the upfront costs can be substantial, they must be weighed against the long-term benefits of reduced material costs and environmental compliance expenses.

Operational costs are another significant factor in the economic equation. Energy consumption is often a major component, particularly for distillation-based recycling methods. However, advancements in heat integration and energy-efficient designs have helped to mitigate these costs. Maintenance requirements and the lifespan of equipment also play a role in determining the overall economic viability of recycling systems.

The potential for cost savings through recycling is considerable. By recovering and reusing ethyl acetate, companies can significantly reduce their raw material purchases. This is especially impactful given the volatility of ethyl acetate prices in the global market. Additionally, recycling reduces the volume of waste that needs to be treated or disposed of, leading to further cost savings in waste management.

Market dynamics also influence the economic feasibility of recycling technologies. As environmental regulations become more stringent, the cost of waste disposal is likely to increase, making recycling more attractive. Furthermore, consumer demand for sustainable products may drive companies to adopt recycling practices as a means of improving their environmental credentials and market positioning.

The scale of operation is a crucial determinant of economic viability. Larger facilities with higher ethyl acetate consumption are more likely to achieve economies of scale that justify the investment in recycling technologies. For smaller operations, the break-even point may be more challenging to reach, potentially necessitating alternative approaches such as shared recycling facilities or outsourced recycling services.

Technological advancements continue to improve the economic prospects of ethyl acetate recycling. Innovations in membrane technology, for instance, are reducing energy requirements and improving separation efficiency. These developments are gradually lowering the economic barriers to adoption, making recycling more feasible for a broader range of industries and operational scales.

In conclusion, while the economic feasibility of ethyl acetate recycling technologies varies depending on specific circumstances, the overall trend points towards increasing viability. As technology improves and environmental considerations gain prominence, the economic case for implementing these recycling solutions is likely to strengthen across diverse industrial applications.

One of the primary considerations is the capital expenditure necessary for installing recycling equipment. This includes the cost of distillation columns, membrane separation units, or other specialized apparatus. While the upfront costs can be substantial, they must be weighed against the long-term benefits of reduced material costs and environmental compliance expenses.

Operational costs are another significant factor in the economic equation. Energy consumption is often a major component, particularly for distillation-based recycling methods. However, advancements in heat integration and energy-efficient designs have helped to mitigate these costs. Maintenance requirements and the lifespan of equipment also play a role in determining the overall economic viability of recycling systems.

The potential for cost savings through recycling is considerable. By recovering and reusing ethyl acetate, companies can significantly reduce their raw material purchases. This is especially impactful given the volatility of ethyl acetate prices in the global market. Additionally, recycling reduces the volume of waste that needs to be treated or disposed of, leading to further cost savings in waste management.

Market dynamics also influence the economic feasibility of recycling technologies. As environmental regulations become more stringent, the cost of waste disposal is likely to increase, making recycling more attractive. Furthermore, consumer demand for sustainable products may drive companies to adopt recycling practices as a means of improving their environmental credentials and market positioning.

The scale of operation is a crucial determinant of economic viability. Larger facilities with higher ethyl acetate consumption are more likely to achieve economies of scale that justify the investment in recycling technologies. For smaller operations, the break-even point may be more challenging to reach, potentially necessitating alternative approaches such as shared recycling facilities or outsourced recycling services.

Technological advancements continue to improve the economic prospects of ethyl acetate recycling. Innovations in membrane technology, for instance, are reducing energy requirements and improving separation efficiency. These developments are gradually lowering the economic barriers to adoption, making recycling more feasible for a broader range of industries and operational scales.

In conclusion, while the economic feasibility of ethyl acetate recycling technologies varies depending on specific circumstances, the overall trend points towards increasing viability. As technology improves and environmental considerations gain prominence, the economic case for implementing these recycling solutions is likely to strengthen across diverse industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!