Ethyl Acetate’s Impact on Textile Processing Techniques

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Textiles: Background and Objectives

Ethyl acetate has emerged as a significant player in the textile industry, revolutionizing various processing techniques. This solvent, known for its versatility and effectiveness, has a rich history dating back to its first synthesis in the 19th century. Over the years, its applications in textiles have expanded, driven by the industry's quest for more efficient and environmentally friendly processes.

The evolution of ethyl acetate in textile processing is closely tied to the broader developments in chemical engineering and material science. Initially used primarily as a cleaning agent, its role has grown to encompass a wide range of applications, from fabric finishing to dyeing and printing. This expansion has been fueled by ongoing research into its properties and potential uses, as well as the textile industry's increasing focus on sustainability and performance enhancement.

In recent years, the textile sector has faced mounting pressure to adopt more sustainable practices. This shift has propelled ethyl acetate to the forefront of innovation, as it offers a more environmentally friendly alternative to many traditional solvents. Its low toxicity, high solvency power, and rapid evaporation rate make it an attractive option for various textile processes, aligning well with the industry's sustainability goals.

The current technological landscape surrounding ethyl acetate in textiles is characterized by a drive towards optimization and integration. Researchers and industry professionals are exploring ways to enhance its efficiency in existing applications while also identifying new areas where it can add value. This includes investigating its potential in advanced textile treatments, such as nanotechnology-based finishes and smart textiles.

Looking ahead, the objectives for ethyl acetate in textile processing are multifaceted. There is a strong focus on developing more sustainable production methods for the solvent itself, as well as optimizing its use to reduce overall environmental impact. Additionally, researchers are aiming to expand its applicability across different types of fibers and fabrics, potentially opening up new markets and applications.

Another key objective is to improve the integration of ethyl acetate-based processes with other emerging technologies in the textile industry. This includes exploring synergies with digital printing techniques, advanced dyeing methods, and innovative fabric treatments. By doing so, the industry hopes to create more efficient, flexible, and sustainable production processes that can meet the evolving demands of consumers and regulatory bodies alike.

The evolution of ethyl acetate in textile processing is closely tied to the broader developments in chemical engineering and material science. Initially used primarily as a cleaning agent, its role has grown to encompass a wide range of applications, from fabric finishing to dyeing and printing. This expansion has been fueled by ongoing research into its properties and potential uses, as well as the textile industry's increasing focus on sustainability and performance enhancement.

In recent years, the textile sector has faced mounting pressure to adopt more sustainable practices. This shift has propelled ethyl acetate to the forefront of innovation, as it offers a more environmentally friendly alternative to many traditional solvents. Its low toxicity, high solvency power, and rapid evaporation rate make it an attractive option for various textile processes, aligning well with the industry's sustainability goals.

The current technological landscape surrounding ethyl acetate in textiles is characterized by a drive towards optimization and integration. Researchers and industry professionals are exploring ways to enhance its efficiency in existing applications while also identifying new areas where it can add value. This includes investigating its potential in advanced textile treatments, such as nanotechnology-based finishes and smart textiles.

Looking ahead, the objectives for ethyl acetate in textile processing are multifaceted. There is a strong focus on developing more sustainable production methods for the solvent itself, as well as optimizing its use to reduce overall environmental impact. Additionally, researchers are aiming to expand its applicability across different types of fibers and fabrics, potentially opening up new markets and applications.

Another key objective is to improve the integration of ethyl acetate-based processes with other emerging technologies in the textile industry. This includes exploring synergies with digital printing techniques, advanced dyeing methods, and innovative fabric treatments. By doing so, the industry hopes to create more efficient, flexible, and sustainable production processes that can meet the evolving demands of consumers and regulatory bodies alike.

Market Analysis for Ethyl Acetate in Textile Industry

The global market for ethyl acetate in the textile industry has been experiencing steady growth, driven by the increasing demand for high-quality textiles and the adoption of advanced processing techniques. Ethyl acetate plays a crucial role in various textile processing applications, including dyeing, printing, and finishing, due to its excellent solvent properties and low toxicity.

The textile industry's shift towards more sustainable and eco-friendly practices has further boosted the demand for ethyl acetate. As a biodegradable solvent, it aligns well with the industry's growing focus on environmental responsibility and regulatory compliance. This trend is particularly evident in developed markets such as Europe and North America, where stringent environmental regulations are driving the adoption of greener chemicals in textile processing.

In terms of regional market dynamics, Asia-Pacific dominates the global ethyl acetate market in the textile industry. Countries like China, India, and Bangladesh, which are major textile manufacturing hubs, account for a significant share of the consumption. The rapid industrialization and growing textile exports from these countries are key factors contributing to the increased demand for ethyl acetate in the region.

The market is also witnessing a surge in demand from emerging economies in Latin America and Africa, where the textile industry is expanding rapidly. These regions present substantial growth opportunities for ethyl acetate manufacturers and suppliers, as local textile producers seek to enhance their production capabilities and product quality to compete in the global market.

One of the key trends shaping the market is the growing preference for water-based textile processing techniques. Ethyl acetate's compatibility with water-based systems makes it an attractive choice for manufacturers looking to reduce their environmental footprint while maintaining product quality. This trend is expected to drive further innovation in ethyl acetate formulations tailored specifically for water-based textile applications.

The market for ethyl acetate in the textile industry is characterized by intense competition among key players, including both global chemical companies and regional manufacturers. These companies are focusing on product innovation, strategic partnerships, and expansion of production capacities to gain a competitive edge in the market. Additionally, there is a growing emphasis on developing bio-based ethyl acetate to cater to the increasing demand for sustainable solutions in the textile industry.

The textile industry's shift towards more sustainable and eco-friendly practices has further boosted the demand for ethyl acetate. As a biodegradable solvent, it aligns well with the industry's growing focus on environmental responsibility and regulatory compliance. This trend is particularly evident in developed markets such as Europe and North America, where stringent environmental regulations are driving the adoption of greener chemicals in textile processing.

In terms of regional market dynamics, Asia-Pacific dominates the global ethyl acetate market in the textile industry. Countries like China, India, and Bangladesh, which are major textile manufacturing hubs, account for a significant share of the consumption. The rapid industrialization and growing textile exports from these countries are key factors contributing to the increased demand for ethyl acetate in the region.

The market is also witnessing a surge in demand from emerging economies in Latin America and Africa, where the textile industry is expanding rapidly. These regions present substantial growth opportunities for ethyl acetate manufacturers and suppliers, as local textile producers seek to enhance their production capabilities and product quality to compete in the global market.

One of the key trends shaping the market is the growing preference for water-based textile processing techniques. Ethyl acetate's compatibility with water-based systems makes it an attractive choice for manufacturers looking to reduce their environmental footprint while maintaining product quality. This trend is expected to drive further innovation in ethyl acetate formulations tailored specifically for water-based textile applications.

The market for ethyl acetate in the textile industry is characterized by intense competition among key players, including both global chemical companies and regional manufacturers. These companies are focusing on product innovation, strategic partnerships, and expansion of production capacities to gain a competitive edge in the market. Additionally, there is a growing emphasis on developing bio-based ethyl acetate to cater to the increasing demand for sustainable solutions in the textile industry.

Current Challenges in Ethyl Acetate Textile Processing

The textile industry's adoption of ethyl acetate in processing techniques has introduced several challenges that require careful consideration and innovative solutions. One of the primary concerns is the volatile nature of ethyl acetate, which poses safety risks in manufacturing environments. Its low flash point and high flammability necessitate stringent safety measures, including proper ventilation systems, fire suppression equipment, and specialized storage facilities. These requirements often lead to increased operational costs and potential regulatory hurdles for textile manufacturers.

Another significant challenge lies in the environmental impact of ethyl acetate usage. While it is considered less harmful than some alternative solvents, ethyl acetate still contributes to volatile organic compound (VOC) emissions. Textile processors must navigate increasingly strict environmental regulations, particularly in regions with advanced air quality standards. This necessitates investment in emission control technologies and the development of more sustainable processing methods to mitigate environmental concerns.

The chemical properties of ethyl acetate also present technical challenges in textile processing. Its rapid evaporation rate, while beneficial for quick drying, can lead to inconsistencies in fabric treatment, especially in large-scale operations. Maintaining uniform application and penetration of ethyl acetate-based solutions across textile surfaces requires precise control mechanisms and specialized equipment, which may not be readily available or cost-effective for smaller manufacturers.

Furthermore, the interaction between ethyl acetate and various textile fibers can be complex. Different fiber types react differently to ethyl acetate exposure, potentially affecting the fabric's physical properties, color fastness, and overall quality. This variability demands extensive research and testing to optimize processing parameters for each specific textile application, increasing development time and costs for new product lines.

The global supply chain for ethyl acetate introduces additional challenges. Price fluctuations and potential supply disruptions can impact production planning and cost management for textile manufacturers. The need for a stable and cost-effective supply of high-purity ethyl acetate suitable for textile applications adds another layer of complexity to procurement strategies.

Lastly, the textile industry faces challenges in workforce training and adaptation to ethyl acetate-based processes. Operators and technicians require specialized knowledge and skills to handle this solvent safely and effectively. Implementing comprehensive training programs and updating standard operating procedures to accommodate ethyl acetate usage can be time-consuming and resource-intensive for textile companies, particularly those transitioning from traditional processing methods.

Another significant challenge lies in the environmental impact of ethyl acetate usage. While it is considered less harmful than some alternative solvents, ethyl acetate still contributes to volatile organic compound (VOC) emissions. Textile processors must navigate increasingly strict environmental regulations, particularly in regions with advanced air quality standards. This necessitates investment in emission control technologies and the development of more sustainable processing methods to mitigate environmental concerns.

The chemical properties of ethyl acetate also present technical challenges in textile processing. Its rapid evaporation rate, while beneficial for quick drying, can lead to inconsistencies in fabric treatment, especially in large-scale operations. Maintaining uniform application and penetration of ethyl acetate-based solutions across textile surfaces requires precise control mechanisms and specialized equipment, which may not be readily available or cost-effective for smaller manufacturers.

Furthermore, the interaction between ethyl acetate and various textile fibers can be complex. Different fiber types react differently to ethyl acetate exposure, potentially affecting the fabric's physical properties, color fastness, and overall quality. This variability demands extensive research and testing to optimize processing parameters for each specific textile application, increasing development time and costs for new product lines.

The global supply chain for ethyl acetate introduces additional challenges. Price fluctuations and potential supply disruptions can impact production planning and cost management for textile manufacturers. The need for a stable and cost-effective supply of high-purity ethyl acetate suitable for textile applications adds another layer of complexity to procurement strategies.

Lastly, the textile industry faces challenges in workforce training and adaptation to ethyl acetate-based processes. Operators and technicians require specialized knowledge and skills to handle this solvent safely and effectively. Implementing comprehensive training programs and updating standard operating procedures to accommodate ethyl acetate usage can be time-consuming and resource-intensive for textile companies, particularly those transitioning from traditional processing methods.

Existing Ethyl Acetate Textile Processing Techniques

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The production methods aim to optimize the synthesis of ethyl acetate from its precursors, while purification steps focus on removing impurities and achieving high-quality product.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in diverse chemical processes, such as solvent extraction, as a reaction medium, and in the production of other chemicals. Its properties make it suitable for various industrial applications, including pharmaceuticals and polymer synthesis.

- Ethyl acetate in coating and adhesive formulations: Ethyl acetate is employed in the formulation of coatings, adhesives, and related products. Its solvent properties and compatibility with various resins make it valuable in these applications, contributing to improved product performance and characteristics.

- Recycling and recovery of ethyl acetate: Methods for recycling and recovering ethyl acetate from industrial processes are described. These techniques aim to reduce waste, improve efficiency, and minimize environmental impact in industries that use ethyl acetate as a solvent or reagent.

- Ethyl acetate in green chemistry and sustainable processes: The use of ethyl acetate in environmentally friendly chemical processes is explored. This includes its role as a less harmful solvent alternative, its production from renewable resources, and its application in sustainable manufacturing practices.

02 Applications of ethyl acetate in industrial processes

Ethyl acetate finds diverse applications in industrial processes. It is used as a solvent in various industries, including pharmaceuticals, coatings, and adhesives. The compound also serves as a raw material in the production of other chemicals and as an extraction medium in certain manufacturing processes.Expand Specific Solutions03 Ethyl acetate in green chemistry and sustainable processes

Research focuses on developing environmentally friendly methods for ethyl acetate production and utilization. This includes the use of renewable resources as feedstock, development of bio-based production routes, and the implementation of energy-efficient processes. The aim is to reduce the environmental impact of ethyl acetate production and use.Expand Specific Solutions04 Recovery and recycling of ethyl acetate

Methods for recovering and recycling ethyl acetate from industrial processes are described. These techniques aim to reduce waste and improve the overall efficiency of processes using ethyl acetate. Recovery methods include adsorption, membrane separation, and specialized distillation processes.Expand Specific Solutions05 Novel catalysts and reaction systems for ethyl acetate synthesis

Development of new catalysts and reaction systems to enhance the production of ethyl acetate. These innovations focus on improving reaction rates, selectivity, and yield while reducing energy consumption and side products. Novel reactor designs and process intensification techniques are also explored to optimize ethyl acetate synthesis.Expand Specific Solutions

Key Players in Ethyl Acetate Textile Processing

The textile processing industry is experiencing a transformative phase with the integration of ethyl acetate, showcasing a competitive landscape driven by technological advancements and market demands. The market is in a growth stage, with increasing adoption of eco-friendly and efficient processing techniques. Major players like Celanese International Corp., SABIC, and Eastman Chemical Co. are leading innovation in this space, leveraging their extensive R&D capabilities. The technology's maturity is progressing rapidly, with companies such as Henkel AG & Co. KGaA and Resonac Corp. developing specialized applications. Academic institutions like Tianjin University and National Taiwan University are contributing to fundamental research, fostering industry-academia collaborations and accelerating the technology's evolution in textile processing.

Celanese International Corp.

Technical Solution: Celanese International Corp. has made significant strides in leveraging ethyl acetate for innovative textile processing techniques. Their approach centers on using ethyl acetate as a primary component in advanced fiber spinning processes. Celanese has developed a method that utilizes ethyl acetate as a solvent in the production of high-performance fibers, resulting in improved tensile strength and thermal stability[10]. The company has also introduced a novel ethyl acetate-based surface treatment for synthetic fibers that enhances moisture wicking properties and improves dye uptake[11]. Furthermore, Celanese has implemented a green chemistry initiative that focuses on producing ethyl acetate from bioethanol, reducing the carbon footprint of their textile processing solutions[12].

Strengths: Enhanced fiber performance, improved moisture management in textiles, environmentally friendly production methods. Weaknesses: May require significant changes to existing fiber production processes, potential higher costs associated with bio-based ethyl acetate production.

Resonac Corp.

Technical Solution: Resonac Corp. has developed innovative textile processing techniques utilizing ethyl acetate. Their approach focuses on using ethyl acetate as a key component in advanced coating formulations for technical textiles. Resonac's ethyl acetate-based coatings provide enhanced chemical resistance and durability to fabrics used in extreme environments[13]. The company has also introduced a novel ethyl acetate recovery system that can be integrated into existing textile processing lines, allowing for efficient solvent recycling and reduced environmental impact[14]. Additionally, Resonac has developed a range of ethyl acetate-based auxiliaries that improve the softness and drape of synthetic fabrics without compromising their technical properties[15].

Strengths: Improved chemical resistance for technical textiles, efficient solvent recycling capabilities, enhanced fabric hand and drape. Weaknesses: May require specialized coating equipment, potential initial investment costs for recovery system implementation.

Innovations in Ethyl Acetate Textile Technology

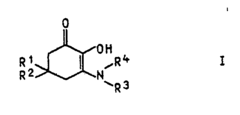

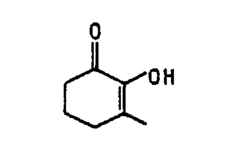

Process for discharge or reserve discharge printing with the use of amino reductones

PatentInactiveEP0342517A2

Innovation

- The use of 3-aminoreductones and their mineral acid salts as etchants in etching printing and etching reserve printing processes, which offer strong reducing power for the reductive removal of reducible disperse dyes on polyester, cellulose acetate, and polyamide textiles, avoiding fiber damage and heavy metal contamination while preventing formaldehyde development.

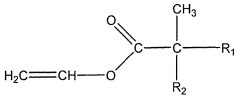

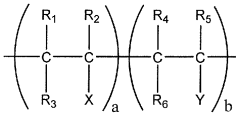

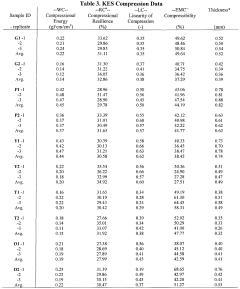

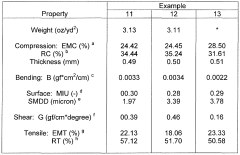

Vinyl acetate/ethylene (VAE) copolymers for fabric finishing

PatentWO2010121090A1

Innovation

- The use of vinyl acetate emulsions and polyvinyl alcohols, including copolymers like vinyl acetate/ethylene, acrylic emulsions, and polyvinyl alcohol resins, to impart comfort-related attributes such as compression recovery, hydrophobicity, and functional features like flame retardancy to textiles through a finishing process that involves preparing an aqueous liquor and processing the textiles at controlled temperatures to durably inter-associate the resins with the fibers.

Environmental Impact of Ethyl Acetate in Textiles

The environmental impact of ethyl acetate in textile processing is a critical consideration for the industry's sustainability efforts. Ethyl acetate, widely used as a solvent in various textile processes, has both positive and negative environmental implications that warrant careful examination.

One of the primary environmental advantages of ethyl acetate is its relatively low toxicity compared to other organic solvents. It is biodegradable and does not persist in the environment for extended periods, reducing long-term ecological risks. Additionally, ethyl acetate has a lower ozone depletion potential than many alternative solvents, contributing to the protection of the Earth's ozone layer.

However, the production and use of ethyl acetate in textile processing are not without environmental concerns. The manufacturing process of ethyl acetate involves petrochemical feedstocks, which contribute to carbon emissions and resource depletion. Furthermore, the volatile nature of ethyl acetate means that it can easily evaporate during textile processing, potentially contributing to air pollution and the formation of ground-level ozone if not properly controlled.

Water pollution is another significant environmental issue associated with ethyl acetate use in textiles. Effluents from textile processing containing ethyl acetate can contaminate water bodies if not adequately treated. This contamination can harm aquatic ecosystems and potentially affect human health through the food chain or direct exposure to polluted water sources.

To mitigate these environmental impacts, the textile industry has been exploring various strategies. Closed-loop systems that capture and recycle ethyl acetate vapors have been implemented in some facilities, reducing both air emissions and solvent consumption. Advanced wastewater treatment technologies, such as activated carbon filtration and biological treatment systems, are being employed to remove ethyl acetate from effluents before discharge.

The industry is also investigating alternative, more environmentally friendly solvents to replace or reduce ethyl acetate usage. Bio-based solvents derived from renewable resources are gaining attention as potential substitutes, offering similar performance with a lower environmental footprint. Additionally, waterborne processing techniques are being developed to minimize the use of organic solvents altogether.

Regulatory frameworks play a crucial role in managing the environmental impact of ethyl acetate in textile processing. Many countries have implemented strict emission standards and waste management regulations to control the release of volatile organic compounds, including ethyl acetate, into the environment. These regulations drive innovation in cleaner production technologies and encourage the adoption of more sustainable practices across the textile industry.

One of the primary environmental advantages of ethyl acetate is its relatively low toxicity compared to other organic solvents. It is biodegradable and does not persist in the environment for extended periods, reducing long-term ecological risks. Additionally, ethyl acetate has a lower ozone depletion potential than many alternative solvents, contributing to the protection of the Earth's ozone layer.

However, the production and use of ethyl acetate in textile processing are not without environmental concerns. The manufacturing process of ethyl acetate involves petrochemical feedstocks, which contribute to carbon emissions and resource depletion. Furthermore, the volatile nature of ethyl acetate means that it can easily evaporate during textile processing, potentially contributing to air pollution and the formation of ground-level ozone if not properly controlled.

Water pollution is another significant environmental issue associated with ethyl acetate use in textiles. Effluents from textile processing containing ethyl acetate can contaminate water bodies if not adequately treated. This contamination can harm aquatic ecosystems and potentially affect human health through the food chain or direct exposure to polluted water sources.

To mitigate these environmental impacts, the textile industry has been exploring various strategies. Closed-loop systems that capture and recycle ethyl acetate vapors have been implemented in some facilities, reducing both air emissions and solvent consumption. Advanced wastewater treatment technologies, such as activated carbon filtration and biological treatment systems, are being employed to remove ethyl acetate from effluents before discharge.

The industry is also investigating alternative, more environmentally friendly solvents to replace or reduce ethyl acetate usage. Bio-based solvents derived from renewable resources are gaining attention as potential substitutes, offering similar performance with a lower environmental footprint. Additionally, waterborne processing techniques are being developed to minimize the use of organic solvents altogether.

Regulatory frameworks play a crucial role in managing the environmental impact of ethyl acetate in textile processing. Many countries have implemented strict emission standards and waste management regulations to control the release of volatile organic compounds, including ethyl acetate, into the environment. These regulations drive innovation in cleaner production technologies and encourage the adoption of more sustainable practices across the textile industry.

Safety Regulations for Ethyl Acetate in Textile Industry

The use of ethyl acetate in textile processing necessitates strict adherence to safety regulations to protect workers, the environment, and the end consumers. In the textile industry, ethyl acetate is primarily used as a solvent in various processes, including dyeing, printing, and finishing. Its volatile nature and potential health hazards have led to the implementation of comprehensive safety measures across the industry.

Occupational safety standards for ethyl acetate exposure in textile facilities are typically set by national regulatory bodies. These standards often include permissible exposure limits (PELs) for both short-term and long-term exposure. For instance, the Occupational Safety and Health Administration (OSHA) in the United States has established a PEL of 400 parts per million (ppm) for an 8-hour time-weighted average.

To comply with these regulations, textile manufacturers are required to implement engineering controls such as proper ventilation systems and enclosed processing equipment. These measures help to minimize worker exposure to ethyl acetate vapors. Additionally, personal protective equipment (PPE) such as respirators, gloves, and protective eyewear must be provided and worn by workers handling ethyl acetate or working in areas where it is used.

Storage and handling regulations for ethyl acetate in textile facilities are equally stringent. The chemical must be stored in cool, well-ventilated areas away from sources of ignition due to its flammability. Proper labeling and safety data sheets (SDS) must be readily available, and workers must be trained in the safe handling and emergency procedures related to ethyl acetate.

Environmental regulations also play a crucial role in the use of ethyl acetate in textile processing. Many jurisdictions have implemented strict controls on volatile organic compound (VOC) emissions, of which ethyl acetate is a contributor. Textile manufacturers are often required to install emission control devices or adopt low-VOC alternatives to comply with air quality standards.

Waste management regulations govern the disposal of ethyl acetate and materials contaminated with it. Proper disposal methods must be employed to prevent environmental contamination. This may include treatment of wastewater containing ethyl acetate residues before discharge and appropriate disposal of solid waste through licensed hazardous waste management facilities.

Product safety regulations also extend to the finished textile products. Residual ethyl acetate in fabrics must be below specified limits to ensure consumer safety. This often requires rigorous quality control measures and testing protocols to be in place throughout the production process.

Compliance with these multifaceted safety regulations requires ongoing monitoring, documentation, and reporting. Regular audits and inspections by regulatory agencies are common in the textile industry to ensure adherence to safety standards. Manufacturers must maintain detailed records of chemical usage, exposure monitoring, and safety training to demonstrate compliance.

Occupational safety standards for ethyl acetate exposure in textile facilities are typically set by national regulatory bodies. These standards often include permissible exposure limits (PELs) for both short-term and long-term exposure. For instance, the Occupational Safety and Health Administration (OSHA) in the United States has established a PEL of 400 parts per million (ppm) for an 8-hour time-weighted average.

To comply with these regulations, textile manufacturers are required to implement engineering controls such as proper ventilation systems and enclosed processing equipment. These measures help to minimize worker exposure to ethyl acetate vapors. Additionally, personal protective equipment (PPE) such as respirators, gloves, and protective eyewear must be provided and worn by workers handling ethyl acetate or working in areas where it is used.

Storage and handling regulations for ethyl acetate in textile facilities are equally stringent. The chemical must be stored in cool, well-ventilated areas away from sources of ignition due to its flammability. Proper labeling and safety data sheets (SDS) must be readily available, and workers must be trained in the safe handling and emergency procedures related to ethyl acetate.

Environmental regulations also play a crucial role in the use of ethyl acetate in textile processing. Many jurisdictions have implemented strict controls on volatile organic compound (VOC) emissions, of which ethyl acetate is a contributor. Textile manufacturers are often required to install emission control devices or adopt low-VOC alternatives to comply with air quality standards.

Waste management regulations govern the disposal of ethyl acetate and materials contaminated with it. Proper disposal methods must be employed to prevent environmental contamination. This may include treatment of wastewater containing ethyl acetate residues before discharge and appropriate disposal of solid waste through licensed hazardous waste management facilities.

Product safety regulations also extend to the finished textile products. Residual ethyl acetate in fabrics must be below specified limits to ensure consumer safety. This often requires rigorous quality control measures and testing protocols to be in place throughout the production process.

Compliance with these multifaceted safety regulations requires ongoing monitoring, documentation, and reporting. Regular audits and inspections by regulatory agencies are common in the textile industry to ensure adherence to safety standards. Manufacturers must maintain detailed records of chemical usage, exposure monitoring, and safety training to demonstrate compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!