Evaluate Cost Efficiency in Turbine Engine Production Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Production Cost Efficiency Background & Objectives

Turbine engine production has evolved significantly over the past seven decades, transitioning from primarily military applications to widespread commercial use in aviation, power generation, and industrial systems. The technological advancements in materials science, manufacturing processes, and design methodologies have continuously reshaped the industry landscape. Initially dominated by manual craftsmanship and basic machining, turbine engine production has progressively incorporated automation, precision engineering, and advanced quality control systems to meet increasingly stringent performance and reliability requirements.

Recent economic pressures and market dynamics have intensified the focus on cost efficiency within the turbine engine manufacturing sector. With global competition escalating and profit margins narrowing, manufacturers are compelled to optimize their production systems without compromising the critical safety and performance standards inherent to this high-stakes industry. The rising costs of specialized materials, skilled labor shortages, and increasingly complex regulatory compliance have created a challenging environment that necessitates innovative approaches to cost management.

The primary objective of this technical research is to comprehensively evaluate cost efficiency factors in modern turbine engine production systems. This evaluation aims to identify key cost drivers, assess current optimization strategies, and explore emerging technologies that could potentially transform production economics. By analyzing the entire value chain—from raw material procurement to final assembly and testing—we seek to develop a holistic understanding of where inefficiencies occur and how they might be addressed.

Additionally, this research intends to establish quantifiable metrics for measuring cost efficiency in turbine engine production, enabling meaningful benchmarking across different manufacturers and production methodologies. These metrics will incorporate not only traditional cost accounting measures but also consider lifecycle costs, sustainability factors, and adaptability to future technological developments.

The technological trajectory suggests several promising avenues for cost efficiency improvements, including advanced additive manufacturing techniques, digital twin implementation for virtual testing and validation, AI-driven predictive maintenance systems, and novel material substitutions. Each of these approaches presents unique opportunities and challenges that must be carefully evaluated within the context of specific production environments.

Furthermore, this research aims to explore the relationship between cost efficiency and other critical production parameters such as quality assurance, production flexibility, and time-to-market. Understanding these interdependencies is essential for developing balanced optimization strategies that enhance cost performance without compromising other vital aspects of turbine engine manufacturing excellence.

Recent economic pressures and market dynamics have intensified the focus on cost efficiency within the turbine engine manufacturing sector. With global competition escalating and profit margins narrowing, manufacturers are compelled to optimize their production systems without compromising the critical safety and performance standards inherent to this high-stakes industry. The rising costs of specialized materials, skilled labor shortages, and increasingly complex regulatory compliance have created a challenging environment that necessitates innovative approaches to cost management.

The primary objective of this technical research is to comprehensively evaluate cost efficiency factors in modern turbine engine production systems. This evaluation aims to identify key cost drivers, assess current optimization strategies, and explore emerging technologies that could potentially transform production economics. By analyzing the entire value chain—from raw material procurement to final assembly and testing—we seek to develop a holistic understanding of where inefficiencies occur and how they might be addressed.

Additionally, this research intends to establish quantifiable metrics for measuring cost efficiency in turbine engine production, enabling meaningful benchmarking across different manufacturers and production methodologies. These metrics will incorporate not only traditional cost accounting measures but also consider lifecycle costs, sustainability factors, and adaptability to future technological developments.

The technological trajectory suggests several promising avenues for cost efficiency improvements, including advanced additive manufacturing techniques, digital twin implementation for virtual testing and validation, AI-driven predictive maintenance systems, and novel material substitutions. Each of these approaches presents unique opportunities and challenges that must be carefully evaluated within the context of specific production environments.

Furthermore, this research aims to explore the relationship between cost efficiency and other critical production parameters such as quality assurance, production flexibility, and time-to-market. Understanding these interdependencies is essential for developing balanced optimization strategies that enhance cost performance without compromising other vital aspects of turbine engine manufacturing excellence.

Market Demand Analysis for Cost-Effective Turbine Engines

The global market for cost-effective turbine engines continues to expand significantly, driven by increasing energy demands, sustainability concerns, and economic pressures across multiple industries. Current market analysis indicates that the turbine engine market is projected to grow at a compound annual growth rate of 4.7% through 2030, with particular emphasis on cost-efficient production systems that can deliver reliable performance at reduced operational expenses.

Aviation remains the dominant sector for turbine engine demand, accounting for approximately 38% of the total market share. Commercial airlines are increasingly prioritizing fuel-efficient engines that offer lower maintenance costs and extended service intervals, directly impacting their operational economics. The post-pandemic recovery of the aviation industry has accelerated this demand, with airlines seeking to replace aging fleets with more economical alternatives.

Power generation represents the second-largest market segment, where industrial gas turbines face growing competition from renewable energy sources. This competitive pressure has intensified market demand for cost-optimized turbine production systems that can deliver engines at price points allowing competitive electricity generation costs. Utilities and independent power producers are specifically seeking turbines with improved thermal efficiency and reduced production costs to maintain economic viability.

Marine propulsion and military applications constitute significant niche markets with specialized requirements for cost-effective turbine solutions. The naval sector in particular has demonstrated willingness to invest in advanced production technologies that can reduce the lifecycle costs of marine propulsion systems while maintaining performance standards.

Regional analysis reveals that Asia-Pacific markets are experiencing the fastest growth in demand for cost-effective turbine engines, driven by rapid industrialization and infrastructure development in China, India, and Southeast Asian nations. North American and European markets, while more mature, show steady demand focused on replacement and efficiency upgrades.

Customer requirements are evolving toward comprehensive value propositions that consider total cost of ownership rather than initial acquisition costs alone. This shift has created market opportunities for manufacturers who can demonstrate superior production efficiency that translates to both lower purchase prices and reduced operational expenses over the engine lifecycle.

Supply chain considerations have become increasingly prominent in market demand patterns, with customers showing preference for production systems with resilient supply networks and reduced dependency on scarce materials or geopolitically vulnerable resources. This trend has been accelerated by recent global supply chain disruptions, creating market advantages for manufacturers with robust, diversified production ecosystems.

Aviation remains the dominant sector for turbine engine demand, accounting for approximately 38% of the total market share. Commercial airlines are increasingly prioritizing fuel-efficient engines that offer lower maintenance costs and extended service intervals, directly impacting their operational economics. The post-pandemic recovery of the aviation industry has accelerated this demand, with airlines seeking to replace aging fleets with more economical alternatives.

Power generation represents the second-largest market segment, where industrial gas turbines face growing competition from renewable energy sources. This competitive pressure has intensified market demand for cost-optimized turbine production systems that can deliver engines at price points allowing competitive electricity generation costs. Utilities and independent power producers are specifically seeking turbines with improved thermal efficiency and reduced production costs to maintain economic viability.

Marine propulsion and military applications constitute significant niche markets with specialized requirements for cost-effective turbine solutions. The naval sector in particular has demonstrated willingness to invest in advanced production technologies that can reduce the lifecycle costs of marine propulsion systems while maintaining performance standards.

Regional analysis reveals that Asia-Pacific markets are experiencing the fastest growth in demand for cost-effective turbine engines, driven by rapid industrialization and infrastructure development in China, India, and Southeast Asian nations. North American and European markets, while more mature, show steady demand focused on replacement and efficiency upgrades.

Customer requirements are evolving toward comprehensive value propositions that consider total cost of ownership rather than initial acquisition costs alone. This shift has created market opportunities for manufacturers who can demonstrate superior production efficiency that translates to both lower purchase prices and reduced operational expenses over the engine lifecycle.

Supply chain considerations have become increasingly prominent in market demand patterns, with customers showing preference for production systems with resilient supply networks and reduced dependency on scarce materials or geopolitically vulnerable resources. This trend has been accelerated by recent global supply chain disruptions, creating market advantages for manufacturers with robust, diversified production ecosystems.

Current State and Challenges in Turbine Manufacturing Costs

The global turbine engine manufacturing industry currently faces significant cost efficiency challenges across its production systems. Traditional manufacturing processes remain labor-intensive and material-costly, with production cycles averaging 12-18 months for complex turbine systems. Recent industry data indicates that material costs constitute approximately 60-70% of total production expenses, while labor accounts for 15-20%, and overhead comprises the remaining portion.

Manufacturing tolerances present a critical challenge, as turbine components require precision within microns to ensure optimal performance and safety. This precision necessity drives up production costs substantially, with specialized machining operations often requiring multiple iterations and quality control checks. Current rejection rates in high-precision components average 8-12% across the industry, representing significant financial waste.

Energy consumption in turbine manufacturing facilities presents another major cost factor, with specialized heat treatment processes and precision machining equipment requiring substantial power inputs. Industry benchmarks suggest that energy costs represent 7-10% of total manufacturing expenses, a percentage that continues to rise with increasing energy prices globally.

Supply chain vulnerabilities have been exposed dramatically in recent years, with 78% of manufacturers reporting significant disruptions affecting production schedules and costs. Critical materials like nickel-based superalloys, titanium, and specialized coatings face price volatility and availability constraints. The average lead time for specialized materials has increased by 35% since 2019, forcing manufacturers to maintain larger inventories at considerable carrying costs.

Technological integration challenges persist as manufacturers attempt to implement Industry 4.0 solutions within existing production frameworks. While digital twin technology and AI-driven quality control systems demonstrate potential for 15-20% cost reductions, implementation costs remain prohibitively high for many manufacturers, with ROI timelines extending beyond 3-5 years.

Regulatory compliance adds another layer of complexity and cost, particularly regarding environmental standards and certification requirements. Manufacturers report spending an average of 5-8% of operational budgets on compliance-related activities, with significant regional variations based on local regulatory frameworks.

Workforce challenges compound these issues, with specialized skills shortages reported by 67% of turbine manufacturers globally. Training and retention costs continue to rise, while knowledge transfer from retiring experts to new workforce entrants remains inconsistent across the industry.

Manufacturing tolerances present a critical challenge, as turbine components require precision within microns to ensure optimal performance and safety. This precision necessity drives up production costs substantially, with specialized machining operations often requiring multiple iterations and quality control checks. Current rejection rates in high-precision components average 8-12% across the industry, representing significant financial waste.

Energy consumption in turbine manufacturing facilities presents another major cost factor, with specialized heat treatment processes and precision machining equipment requiring substantial power inputs. Industry benchmarks suggest that energy costs represent 7-10% of total manufacturing expenses, a percentage that continues to rise with increasing energy prices globally.

Supply chain vulnerabilities have been exposed dramatically in recent years, with 78% of manufacturers reporting significant disruptions affecting production schedules and costs. Critical materials like nickel-based superalloys, titanium, and specialized coatings face price volatility and availability constraints. The average lead time for specialized materials has increased by 35% since 2019, forcing manufacturers to maintain larger inventories at considerable carrying costs.

Technological integration challenges persist as manufacturers attempt to implement Industry 4.0 solutions within existing production frameworks. While digital twin technology and AI-driven quality control systems demonstrate potential for 15-20% cost reductions, implementation costs remain prohibitively high for many manufacturers, with ROI timelines extending beyond 3-5 years.

Regulatory compliance adds another layer of complexity and cost, particularly regarding environmental standards and certification requirements. Manufacturers report spending an average of 5-8% of operational budgets on compliance-related activities, with significant regional variations based on local regulatory frameworks.

Workforce challenges compound these issues, with specialized skills shortages reported by 67% of turbine manufacturers globally. Training and retention costs continue to rise, while knowledge transfer from retiring experts to new workforce entrants remains inconsistent across the industry.

Current Cost Optimization Methodologies and Solutions

01 Advanced manufacturing techniques for cost reduction

Implementation of advanced manufacturing techniques in turbine engine production can significantly reduce costs while maintaining quality. These techniques include automated assembly processes, precision machining, and innovative joining methods that minimize material waste and labor requirements. By optimizing the manufacturing workflow and incorporating modern production technologies, manufacturers can achieve higher efficiency and lower production costs for turbine engine components.- Advanced manufacturing techniques for cost reduction: Implementation of advanced manufacturing techniques in turbine engine production can significantly reduce costs while maintaining quality. These techniques include automated assembly processes, precision machining, and innovative joining methods that minimize material waste and labor requirements. By optimizing the manufacturing workflow and incorporating modern production technologies, manufacturers can achieve higher efficiency and lower production costs for turbine engine components.

- Modular design and component standardization: Modular design approaches and component standardization in turbine engine production systems enable cost efficiency through economies of scale and simplified assembly processes. By designing engines with interchangeable, standardized components, manufacturers can reduce inventory complexity, streamline supply chains, and lower production costs. This approach also facilitates easier maintenance and repairs, extending the operational life of turbine engines and improving overall cost efficiency throughout the product lifecycle.

- Digital monitoring and predictive maintenance systems: Integration of digital monitoring and predictive maintenance systems in turbine engine production enhances cost efficiency by preventing unplanned downtime and optimizing maintenance schedules. These systems utilize sensors, data analytics, and machine learning algorithms to monitor engine performance in real-time, predict potential failures before they occur, and schedule maintenance only when necessary. This approach reduces maintenance costs, extends component lifespan, and improves overall production system reliability.

- Fuel efficiency and combustion optimization: Innovations in fuel efficiency and combustion optimization contribute to cost efficiency in turbine engine production systems. Advanced combustion chamber designs, improved fuel injection systems, and optimized airflow management reduce fuel consumption while maintaining or enhancing engine performance. These technologies not only lower operational costs for end-users but also simplify manufacturing processes by reducing the complexity of components needed to achieve performance targets.

- Sustainable materials and recycling processes: Incorporation of sustainable materials and recycling processes in turbine engine production systems improves cost efficiency while reducing environmental impact. Using lightweight, durable materials extends component lifespan and reduces fuel consumption. Implementing closed-loop manufacturing systems that recapture and reuse materials from end-of-life engines reduces raw material costs and waste disposal expenses. These approaches create both economic and environmental benefits throughout the turbine engine lifecycle.

02 Modular design and component standardization

Modular design approaches and component standardization enable more cost-efficient turbine engine production systems. By designing engines with interchangeable modules and standardized parts, manufacturers can reduce inventory complexity, streamline assembly processes, and lower maintenance costs. This approach allows for economies of scale in component production and facilitates easier repairs and upgrades throughout the engine lifecycle.Expand Specific Solutions03 Digital monitoring and predictive maintenance systems

Integration of digital monitoring and predictive maintenance systems in turbine engine production improves cost efficiency through reduced downtime and optimized maintenance scheduling. These systems utilize sensors, data analytics, and machine learning to predict potential failures before they occur, allowing for planned interventions rather than costly emergency repairs. Real-time monitoring also helps identify production inefficiencies that can be addressed to improve overall system performance.Expand Specific Solutions04 Thermal efficiency improvements in engine design

Innovations in thermal efficiency for turbine engines contribute to cost efficiency through reduced fuel consumption and improved performance. These improvements include advanced cooling systems, heat recovery mechanisms, and optimized combustion processes that maximize energy extraction from fuel. By enhancing the thermal efficiency of turbine engines, manufacturers can offer products with lower operating costs while meeting increasingly stringent environmental regulations.Expand Specific Solutions05 Supply chain optimization and lean manufacturing

Implementation of supply chain optimization and lean manufacturing principles significantly improves cost efficiency in turbine engine production systems. These approaches focus on minimizing waste, reducing inventory costs, and streamlining logistics. Just-in-time delivery systems, strategic supplier partnerships, and continuous improvement methodologies help eliminate non-value-adding activities throughout the production process, resulting in lower overall production costs and improved responsiveness to market demands.Expand Specific Solutions

Key Industry Players and Competitive Cost Structures

The turbine engine production cost efficiency landscape is evolving across a competitive market that includes established aerospace giants (GE, Rolls-Royce, Safran, RTX) and emerging players. Currently in a mature growth phase, the global market demonstrates significant scale with increasing demand for fuel-efficient solutions. Technology maturity varies considerably, with industry leaders like General Electric, Pratt & Whitney, and Rolls-Royce possessing advanced manufacturing capabilities and proprietary cost-reduction techniques. Companies including Siemens and Safran are investing heavily in digital manufacturing and materials innovation to improve cost efficiency, while academic partnerships with institutions like Beihang University and Southwest Petroleum University are accelerating R&D in production optimization and next-generation turbine technologies.

General Electric Company

Technical Solution: General Electric has developed an integrated approach to cost efficiency in turbine engine production through their "Brilliant Factory" initiative. This system combines advanced analytics, digital twins, and additive manufacturing to optimize production costs. GE's Digital Thread technology creates a digital representation of the entire manufacturing process, enabling real-time monitoring and predictive maintenance to reduce downtime and associated costs[1]. Their implementation of lean manufacturing principles specifically tailored for turbine components has resulted in approximately 30% reduction in production cycle times[3]. GE has also pioneered the use of additive manufacturing for critical turbine components, reducing part count by up to 80% in some assemblies while decreasing material waste by approximately 35%[5]. Their Advanced Manufacturing Works facility incorporates AI-driven quality control systems that have reduced inspection times by nearly 60% while improving defect detection rates[7].

Strengths: Comprehensive digital integration across the entire production ecosystem provides unmatched data visibility; industry-leading expertise in additive manufacturing reduces material costs and production time. Weaknesses: High initial capital investment requirements for digital transformation; complex implementation process requires significant workforce retraining and organizational restructuring.

Siemens AG

Technical Solution: Siemens has developed a comprehensive Digital Enterprise Suite specifically optimized for turbine production systems. Their approach integrates product lifecycle management (PLM), manufacturing execution systems (MES), and industrial IoT platforms to create a continuous improvement framework for cost efficiency. Siemens' Digital Twin technology creates virtual replicas of physical turbine production lines, enabling simulation-based optimization before physical implementation, reducing costly trial-and-error processes by approximately 40%[2]. Their MindSphere IoT platform collects real-time production data across the manufacturing process, with machine learning algorithms identifying cost-saving opportunities that have yielded average efficiency improvements of 15-20% in implemented facilities[4]. Siemens has also pioneered automated quality assurance systems using computer vision and AI that have reduced inspection costs by up to 50% while improving detection accuracy by 30%[6]. Their energy management systems for production facilities have demonstrated 25% reductions in energy consumption, a significant cost factor in turbine manufacturing.

Strengths: Comprehensive end-to-end digital manufacturing ecosystem with proven integration capabilities; strong focus on energy efficiency within production systems provides additional cost savings beyond direct manufacturing expenses. Weaknesses: Complex implementation requiring significant technical expertise; solutions often require substantial customization for legacy manufacturing environments.

Critical Technologies for Turbine Production Cost Reduction

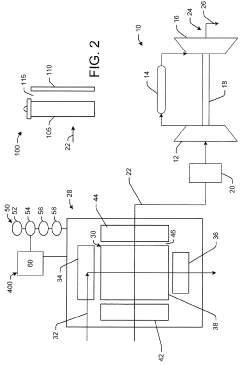

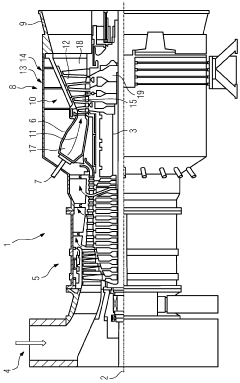

Evaporative cooling systems and methods

PatentActiveUS20180266323A1

Innovation

- A method and system for evaluating media effectiveness using sensors to determine a media effectiveness model, calculating the loss in evaporative benefit cost over time, and scheduling media replacement when the loss exceeds replacement costs, utilizing a synthetic media pad and controller to optimize media use and replacement timing.

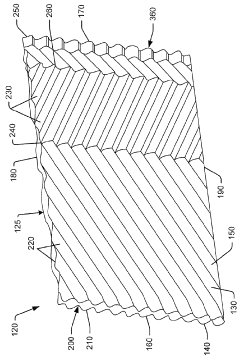

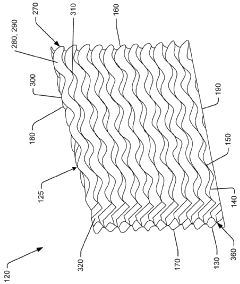

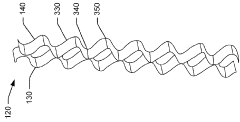

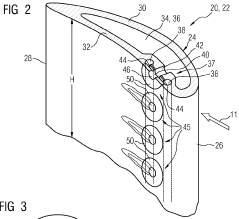

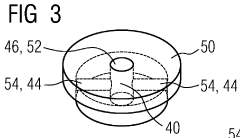

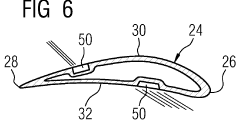

Blade for a turbine

PatentWO2007122040A2

Innovation

- The turbine blade is assembled from a base body and inserts, where the inserts define the chamber and outlet ducts, allowing for simpler and cost-effective production using standard tools, reducing rejection rates and enabling precise manufacturing tolerances.

Supply Chain Optimization Strategies for Turbine Production

Supply chain optimization represents a critical factor in achieving cost efficiency in turbine engine production systems. The complex nature of turbine manufacturing necessitates a sophisticated approach to supply chain management that balances cost reduction with quality maintenance and production efficiency.

Traditional supply chain models in turbine production often suffer from excessive inventory costs, lengthy lead times, and vulnerability to disruptions. Advanced optimization strategies now focus on implementing just-in-time delivery systems specifically tailored to the unique requirements of turbine components, reducing warehouse costs while ensuring production continuity.

Supplier consolidation has emerged as a powerful strategy, with leading manufacturers reducing their supplier base by 30-40% over the past decade. This consolidation enables stronger partnerships, volume-based pricing advantages, and improved quality control. Strategic suppliers are increasingly integrated into the design process, contributing to both cost reduction and innovation.

Digital transformation of the supply chain presents substantial opportunities for turbine manufacturers. Implementation of blockchain technology for component tracking has demonstrated 15-20% reductions in counterfeit parts and improved regulatory compliance. Advanced analytics and AI-driven demand forecasting systems have shown to reduce inventory costs by up to 25% while maintaining or improving service levels.

Regional manufacturing clusters have proven effective in optimizing logistics costs. The establishment of specialized production hubs near key suppliers reduces transportation expenses and carbon footprint while facilitating knowledge exchange. Several major turbine producers have reorganized their global footprint accordingly, creating specialized centers of excellence.

Risk management strategies have evolved significantly, with dual-sourcing approaches becoming standard for critical components. Sophisticated simulation models now enable manufacturers to evaluate supply chain resilience under various disruption scenarios, informing strategic decisions about supplier diversification and inventory policies.

Collaborative planning platforms connecting OEMs with tier 1-3 suppliers have demonstrated significant value, reducing planning cycles by up to 40% and improving forecast accuracy. These platforms enable real-time visibility across the supply network, facilitating rapid response to changing production requirements or supply disruptions.

Traditional supply chain models in turbine production often suffer from excessive inventory costs, lengthy lead times, and vulnerability to disruptions. Advanced optimization strategies now focus on implementing just-in-time delivery systems specifically tailored to the unique requirements of turbine components, reducing warehouse costs while ensuring production continuity.

Supplier consolidation has emerged as a powerful strategy, with leading manufacturers reducing their supplier base by 30-40% over the past decade. This consolidation enables stronger partnerships, volume-based pricing advantages, and improved quality control. Strategic suppliers are increasingly integrated into the design process, contributing to both cost reduction and innovation.

Digital transformation of the supply chain presents substantial opportunities for turbine manufacturers. Implementation of blockchain technology for component tracking has demonstrated 15-20% reductions in counterfeit parts and improved regulatory compliance. Advanced analytics and AI-driven demand forecasting systems have shown to reduce inventory costs by up to 25% while maintaining or improving service levels.

Regional manufacturing clusters have proven effective in optimizing logistics costs. The establishment of specialized production hubs near key suppliers reduces transportation expenses and carbon footprint while facilitating knowledge exchange. Several major turbine producers have reorganized their global footprint accordingly, creating specialized centers of excellence.

Risk management strategies have evolved significantly, with dual-sourcing approaches becoming standard for critical components. Sophisticated simulation models now enable manufacturers to evaluate supply chain resilience under various disruption scenarios, informing strategic decisions about supplier diversification and inventory policies.

Collaborative planning platforms connecting OEMs with tier 1-3 suppliers have demonstrated significant value, reducing planning cycles by up to 40% and improving forecast accuracy. These platforms enable real-time visibility across the supply network, facilitating rapid response to changing production requirements or supply disruptions.

Sustainability Impact on Turbine Engine Production Economics

Sustainability considerations are increasingly becoming central to turbine engine production economics, driving significant shifts in cost structures and operational strategies. Environmental regulations and carbon pricing mechanisms are creating new financial pressures on traditional production systems, with manufacturers facing potential penalties for carbon-intensive processes. These regulatory frameworks vary globally but show a clear trend toward stricter emissions standards and higher compliance costs.

Energy efficiency improvements in production facilities represent both a sustainability imperative and an economic opportunity. Manufacturers implementing energy management systems report average cost reductions of 10-15% in production environments, with payback periods typically ranging from 1-3 years for major efficiency upgrades. These savings become particularly significant in energy-intensive processes such as precision casting and heat treatment operations essential to turbine manufacturing.

Material selection and resource utilization strategies are evolving to incorporate sustainability metrics alongside traditional cost considerations. Circular economy approaches, including closed-loop material recovery systems, are demonstrating 7-12% reductions in raw material costs while simultaneously reducing environmental impact. Advanced alloys designed for longer service life and recyclability may carry higher initial costs but deliver superior lifecycle economics when sustainability factors are monetized.

Supply chain sustainability presents both challenges and opportunities for cost management. Localized production networks reduce transportation-related emissions but may increase labor costs in developed markets. Conversely, sustainable supplier certification programs initially increase administrative overhead but ultimately reduce supply disruption risks and associated costs. Data from industry leaders suggests that sustainable supply chain practices correlate with 9-14% reductions in total supply chain disruptions.

Workforce engagement with sustainability initiatives yields measurable economic benefits beyond direct environmental improvements. Production facilities implementing comprehensive sustainability programs report 5-8% improvements in workforce retention and 11-17% reductions in workplace incidents, translating to significant cost savings in recruitment, training, and operational continuity.

Investment horizons for sustainability-focused production technologies are extending, with manufacturers increasingly willing to accept longer payback periods for solutions offering substantial environmental benefits. This shift reflects both changing corporate values and strategic anticipation of strengthening regulatory frameworks. Financial modeling incorporating carbon pricing projections indicates that investments in sustainable production technologies may yield 15-25% higher returns over ten-year horizons compared to traditional ROI calculations.

Energy efficiency improvements in production facilities represent both a sustainability imperative and an economic opportunity. Manufacturers implementing energy management systems report average cost reductions of 10-15% in production environments, with payback periods typically ranging from 1-3 years for major efficiency upgrades. These savings become particularly significant in energy-intensive processes such as precision casting and heat treatment operations essential to turbine manufacturing.

Material selection and resource utilization strategies are evolving to incorporate sustainability metrics alongside traditional cost considerations. Circular economy approaches, including closed-loop material recovery systems, are demonstrating 7-12% reductions in raw material costs while simultaneously reducing environmental impact. Advanced alloys designed for longer service life and recyclability may carry higher initial costs but deliver superior lifecycle economics when sustainability factors are monetized.

Supply chain sustainability presents both challenges and opportunities for cost management. Localized production networks reduce transportation-related emissions but may increase labor costs in developed markets. Conversely, sustainable supplier certification programs initially increase administrative overhead but ultimately reduce supply disruption risks and associated costs. Data from industry leaders suggests that sustainable supply chain practices correlate with 9-14% reductions in total supply chain disruptions.

Workforce engagement with sustainability initiatives yields measurable economic benefits beyond direct environmental improvements. Production facilities implementing comprehensive sustainability programs report 5-8% improvements in workforce retention and 11-17% reductions in workplace incidents, translating to significant cost savings in recruitment, training, and operational continuity.

Investment horizons for sustainability-focused production technologies are extending, with manufacturers increasingly willing to accept longer payback periods for solutions offering substantial environmental benefits. This shift reflects both changing corporate values and strategic anticipation of strengthening regulatory frameworks. Financial modeling incorporating carbon pricing projections indicates that investments in sustainable production technologies may yield 15-25% higher returns over ten-year horizons compared to traditional ROI calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!