Evaluation of induction motor lifespan under extreme conditions

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Lifespan Challenges

Induction motors face significant challenges when operating under extreme conditions, which can severely impact their lifespan and performance. These conditions include high temperatures, excessive vibrations, corrosive environments, and frequent start-stop cycles. The primary challenge lies in maintaining the motor's integrity and efficiency while subjected to these harsh operating parameters.

High temperatures pose a particularly severe threat to induction motor longevity. Excessive heat accelerates the degradation of insulation materials, leading to premature failure of windings and bearings. This thermal stress can cause expansion and contraction cycles, potentially resulting in mechanical misalignments and increased wear on components. Moreover, elevated temperatures can alter the properties of lubricants, reducing their effectiveness and accelerating bearing wear.

Vibration-related challenges are another critical factor affecting induction motor lifespan. Extreme vibrations, often encountered in industrial settings or due to imbalances in the motor itself, can cause fatigue in structural components, loosen connections, and accelerate wear on bearings and other moving parts. Over time, these vibrations may lead to misalignment of the rotor and stator, further exacerbating the problem and potentially causing catastrophic failure.

Corrosive environments present a unique set of challenges for induction motors. Exposure to chemicals, moisture, or salt-laden air can lead to rapid deterioration of motor components, particularly those made of susceptible materials. This corrosion can affect electrical connections, compromise insulation, and weaken structural integrity, all of which contribute to reduced motor lifespan and increased maintenance requirements.

The challenge of frequent start-stop cycles is often underestimated but can significantly impact motor longevity. Each start-up subjects the motor to high inrush currents and mechanical stresses, which can cause thermal cycling, accelerated wear on bearings, and potential damage to the rotor and stator. Over time, these repeated stresses can lead to fatigue failure of various components and reduce overall motor efficiency.

Another significant challenge is the cumulative effect of these extreme conditions. While a motor might be designed to withstand one or two of these factors individually, the combination of high temperatures, vibrations, corrosive environments, and frequent cycling can create a synergistic effect that dramatically reduces lifespan. This complexity makes it difficult to accurately predict motor performance and longevity under real-world extreme conditions.

Addressing these challenges requires a multifaceted approach, including advanced materials science, innovative cooling techniques, improved sealing technologies, and sophisticated control systems. The development of more resilient insulation materials, better bearing designs, and more effective protection against environmental factors are crucial areas of focus. Additionally, the implementation of advanced monitoring and predictive maintenance strategies is essential to detect and mitigate potential issues before they lead to catastrophic failure.

High temperatures pose a particularly severe threat to induction motor longevity. Excessive heat accelerates the degradation of insulation materials, leading to premature failure of windings and bearings. This thermal stress can cause expansion and contraction cycles, potentially resulting in mechanical misalignments and increased wear on components. Moreover, elevated temperatures can alter the properties of lubricants, reducing their effectiveness and accelerating bearing wear.

Vibration-related challenges are another critical factor affecting induction motor lifespan. Extreme vibrations, often encountered in industrial settings or due to imbalances in the motor itself, can cause fatigue in structural components, loosen connections, and accelerate wear on bearings and other moving parts. Over time, these vibrations may lead to misalignment of the rotor and stator, further exacerbating the problem and potentially causing catastrophic failure.

Corrosive environments present a unique set of challenges for induction motors. Exposure to chemicals, moisture, or salt-laden air can lead to rapid deterioration of motor components, particularly those made of susceptible materials. This corrosion can affect electrical connections, compromise insulation, and weaken structural integrity, all of which contribute to reduced motor lifespan and increased maintenance requirements.

The challenge of frequent start-stop cycles is often underestimated but can significantly impact motor longevity. Each start-up subjects the motor to high inrush currents and mechanical stresses, which can cause thermal cycling, accelerated wear on bearings, and potential damage to the rotor and stator. Over time, these repeated stresses can lead to fatigue failure of various components and reduce overall motor efficiency.

Another significant challenge is the cumulative effect of these extreme conditions. While a motor might be designed to withstand one or two of these factors individually, the combination of high temperatures, vibrations, corrosive environments, and frequent cycling can create a synergistic effect that dramatically reduces lifespan. This complexity makes it difficult to accurately predict motor performance and longevity under real-world extreme conditions.

Addressing these challenges requires a multifaceted approach, including advanced materials science, innovative cooling techniques, improved sealing technologies, and sophisticated control systems. The development of more resilient insulation materials, better bearing designs, and more effective protection against environmental factors are crucial areas of focus. Additionally, the implementation of advanced monitoring and predictive maintenance strategies is essential to detect and mitigate potential issues before they lead to catastrophic failure.

Market Demand Analysis

The market demand for induction motors capable of operating under extreme conditions has been steadily increasing across various industries. This growth is primarily driven by the need for robust and reliable motor systems in challenging environments such as oil and gas exploration, mining, aerospace, and heavy manufacturing.

In the oil and gas sector, the demand for induction motors that can withstand high temperatures, corrosive atmospheres, and explosive environments has seen significant growth. As exploration moves into deeper waters and more hostile terrains, the need for motors that can operate reliably in these conditions becomes paramount. The offshore drilling market, in particular, has shown a strong appetite for motors with extended lifespans under extreme conditions.

The mining industry presents another substantial market for durable induction motors. Underground mining operations require motors that can function in dusty, humid, and potentially explosive atmospheres. The ability of these motors to maintain performance and longevity in such harsh conditions directly impacts operational efficiency and safety, driving demand for advanced motor technologies.

In the aerospace sector, the push for more electric aircraft has led to increased demand for high-performance induction motors that can operate at extreme altitudes and temperatures. These motors need to maintain reliability and efficiency while being subjected to rapid temperature changes and low-pressure environments.

Heavy manufacturing industries, such as steel production and chemical processing, also contribute significantly to the market demand. These sectors require motors that can withstand high temperatures, chemical exposure, and continuous operation. The focus on energy efficiency and reduced downtime in these industries further fuels the need for motors with extended lifespans under challenging conditions.

The global trend towards automation and Industry 4.0 is another factor driving market demand. As more industrial processes become automated, the reliance on robust motor systems increases. This trend is particularly evident in emerging economies where rapid industrialization is taking place.

Market analysis indicates that the Asia-Pacific region is expected to see the highest growth in demand for these specialized induction motors. This is largely due to the rapid industrialization in countries like China and India, coupled with increasing investments in infrastructure and manufacturing.

From a technological standpoint, there is a growing demand for smart induction motors equipped with sensors and diagnostic capabilities. These advanced features allow for predictive maintenance and real-time monitoring, which is crucial for motors operating in extreme conditions. This trend aligns with the broader movement towards the Industrial Internet of Things (IIoT) and smart manufacturing.

In the oil and gas sector, the demand for induction motors that can withstand high temperatures, corrosive atmospheres, and explosive environments has seen significant growth. As exploration moves into deeper waters and more hostile terrains, the need for motors that can operate reliably in these conditions becomes paramount. The offshore drilling market, in particular, has shown a strong appetite for motors with extended lifespans under extreme conditions.

The mining industry presents another substantial market for durable induction motors. Underground mining operations require motors that can function in dusty, humid, and potentially explosive atmospheres. The ability of these motors to maintain performance and longevity in such harsh conditions directly impacts operational efficiency and safety, driving demand for advanced motor technologies.

In the aerospace sector, the push for more electric aircraft has led to increased demand for high-performance induction motors that can operate at extreme altitudes and temperatures. These motors need to maintain reliability and efficiency while being subjected to rapid temperature changes and low-pressure environments.

Heavy manufacturing industries, such as steel production and chemical processing, also contribute significantly to the market demand. These sectors require motors that can withstand high temperatures, chemical exposure, and continuous operation. The focus on energy efficiency and reduced downtime in these industries further fuels the need for motors with extended lifespans under challenging conditions.

The global trend towards automation and Industry 4.0 is another factor driving market demand. As more industrial processes become automated, the reliance on robust motor systems increases. This trend is particularly evident in emerging economies where rapid industrialization is taking place.

Market analysis indicates that the Asia-Pacific region is expected to see the highest growth in demand for these specialized induction motors. This is largely due to the rapid industrialization in countries like China and India, coupled with increasing investments in infrastructure and manufacturing.

From a technological standpoint, there is a growing demand for smart induction motors equipped with sensors and diagnostic capabilities. These advanced features allow for predictive maintenance and real-time monitoring, which is crucial for motors operating in extreme conditions. This trend aligns with the broader movement towards the Industrial Internet of Things (IIoT) and smart manufacturing.

Current Limitations

The evaluation of induction motor lifespan under extreme conditions faces several significant limitations that hinder comprehensive and accurate assessments. One primary constraint is the difficulty in replicating real-world extreme conditions in laboratory settings. Factors such as extreme temperatures, high humidity, corrosive environments, and intense vibrations often coexist in industrial applications, making it challenging to simulate these complex interactions accurately.

Another limitation lies in the accelerated aging techniques commonly used to estimate long-term performance. While these methods provide valuable insights, they may not fully capture the cumulative effects of prolonged exposure to extreme conditions. The extrapolation of short-term test results to predict long-term behavior introduces uncertainties that can affect the reliability of lifespan estimations.

The variability in manufacturing processes and material quality also poses a challenge in standardizing lifespan evaluations. Slight differences in component materials, assembly techniques, or quality control measures can lead to significant variations in motor performance and durability under extreme conditions. This variability makes it difficult to establish universally applicable lifespan models or prediction methods.

Furthermore, the interdependence of various motor components complicates the assessment process. The degradation of one component, such as insulation, can accelerate the wear of others, creating a complex web of failure modes that are challenging to predict and model accurately. This interdependence often leads to oversimplified assumptions in current evaluation methods, potentially overlooking critical failure mechanisms.

The lack of comprehensive historical data on motor performance under specific extreme conditions is another significant limitation. While some industries have accumulated valuable data over the years, many extreme scenarios remain underrepresented in existing databases. This data scarcity hampers the development and validation of robust predictive models and limits the ability to draw meaningful statistical conclusions about motor lifespan in these conditions.

Additionally, the evolving nature of motor designs and materials introduces uncertainties in applying historical data to newer motor generations. Improvements in insulation materials, bearing technologies, and cooling systems may alter the motor's response to extreme conditions, necessitating continuous updates to evaluation methodologies and predictive models.

Lastly, the economic and practical constraints of conducting long-term tests under extreme conditions often lead to compromises in test duration and sample size. These limitations can result in incomplete understanding of long-term degradation mechanisms and reduce the statistical significance of the findings, potentially leading to overly conservative or optimistic lifespan estimates.

Another limitation lies in the accelerated aging techniques commonly used to estimate long-term performance. While these methods provide valuable insights, they may not fully capture the cumulative effects of prolonged exposure to extreme conditions. The extrapolation of short-term test results to predict long-term behavior introduces uncertainties that can affect the reliability of lifespan estimations.

The variability in manufacturing processes and material quality also poses a challenge in standardizing lifespan evaluations. Slight differences in component materials, assembly techniques, or quality control measures can lead to significant variations in motor performance and durability under extreme conditions. This variability makes it difficult to establish universally applicable lifespan models or prediction methods.

Furthermore, the interdependence of various motor components complicates the assessment process. The degradation of one component, such as insulation, can accelerate the wear of others, creating a complex web of failure modes that are challenging to predict and model accurately. This interdependence often leads to oversimplified assumptions in current evaluation methods, potentially overlooking critical failure mechanisms.

The lack of comprehensive historical data on motor performance under specific extreme conditions is another significant limitation. While some industries have accumulated valuable data over the years, many extreme scenarios remain underrepresented in existing databases. This data scarcity hampers the development and validation of robust predictive models and limits the ability to draw meaningful statistical conclusions about motor lifespan in these conditions.

Additionally, the evolving nature of motor designs and materials introduces uncertainties in applying historical data to newer motor generations. Improvements in insulation materials, bearing technologies, and cooling systems may alter the motor's response to extreme conditions, necessitating continuous updates to evaluation methodologies and predictive models.

Lastly, the economic and practical constraints of conducting long-term tests under extreme conditions often lead to compromises in test duration and sample size. These limitations can result in incomplete understanding of long-term degradation mechanisms and reduce the statistical significance of the findings, potentially leading to overly conservative or optimistic lifespan estimates.

Existing Evaluation Methods

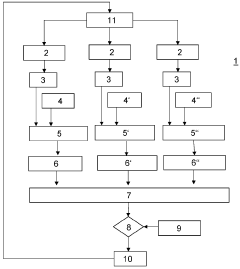

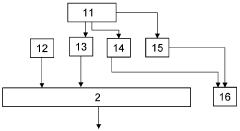

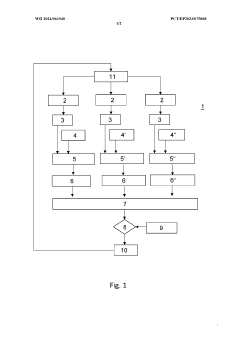

01 Monitoring and predicting induction motor lifespan

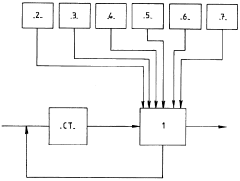

Advanced monitoring systems and predictive algorithms are used to assess the condition of induction motors and estimate their remaining useful life. These systems analyze various parameters such as temperature, vibration, and electrical characteristics to detect early signs of degradation and predict potential failures.- Monitoring and predicting induction motor lifespan: Advanced monitoring systems and predictive algorithms are used to assess the health and estimate the remaining lifespan of induction motors. These systems analyze various parameters such as temperature, vibration, and electrical characteristics to detect early signs of degradation and predict potential failures, allowing for timely maintenance and optimization of motor lifespan.

- Thermal management for extended motor life: Effective thermal management techniques are employed to regulate the operating temperature of induction motors, thereby extending their lifespan. This includes advanced cooling systems, temperature monitoring, and thermal protection mechanisms to prevent overheating and reduce thermal stress on motor components.

- Optimizing motor design for longevity: Induction motor designs are optimized to enhance durability and extend operational life. This involves using high-quality materials, improving insulation systems, and implementing advanced manufacturing techniques to create more robust and reliable motor components that can withstand long-term operational stress.

- Maintenance strategies for prolonging motor lifespan: Comprehensive maintenance strategies are developed to maximize the lifespan of induction motors. These include regular inspections, condition-based maintenance, and predictive maintenance techniques that utilize data analytics and machine learning to optimize maintenance schedules and prevent premature failures.

- Load management and operational optimization: Techniques for managing motor loads and optimizing operational parameters are implemented to extend induction motor lifespan. This includes intelligent control systems that adjust motor operation based on load requirements, power quality management, and strategies to minimize stress during start-up and shutdown procedures.

02 Improving motor efficiency and longevity

Techniques for enhancing the efficiency and lifespan of induction motors include optimizing motor design, using advanced materials, and implementing intelligent control strategies. These improvements can reduce energy consumption, minimize wear and tear, and extend the overall operational life of the motor.Expand Specific Solutions03 Maintenance strategies for prolonging motor life

Effective maintenance practices play a crucial role in extending the lifespan of induction motors. This includes regular inspections, preventive maintenance schedules, condition-based maintenance, and timely repairs or replacements of worn components to prevent catastrophic failures and maximize motor longevity.Expand Specific Solutions04 Environmental and operational factors affecting motor lifespan

Various environmental and operational factors can impact the lifespan of induction motors. These include ambient temperature, humidity, dust, vibration, load variations, and power quality. Understanding and mitigating these factors can help in designing more resilient motors and implementing appropriate protection measures.Expand Specific Solutions05 Innovative technologies for lifespan extension

Emerging technologies are being developed to extend the lifespan of induction motors. These include advanced cooling systems, smart lubrication techniques, novel insulation materials, and the integration of IoT and AI-based monitoring and control systems for real-time health management and adaptive operation.Expand Specific Solutions

Key Industry Players

The evaluation of induction motor lifespan under extreme conditions is a critical area of research in the mature electric motor industry. The market for this technology is substantial, driven by the widespread use of induction motors in various sectors. Key players like Toyota Motor Corp., Mitsubishi Electric Corp., and Robert Bosch GmbH are at the forefront of this field, leveraging their extensive experience in motor manufacturing and automotive applications. Companies such as FANUC Corp. and Hitachi Industrial Products Ltd. are also making significant contributions, particularly in industrial automation and process equipment. The technology's maturity is evident, with ongoing research focusing on improving motor durability and efficiency in challenging environments.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced thermal management systems for induction motors operating in extreme conditions. Their approach includes innovative cooling techniques, such as integrated heat pipes and phase-change materials, to efficiently dissipate heat from motor windings[1]. They have also implemented advanced insulation materials with improved thermal conductivity and resistance to degradation at high temperatures[2]. Mitsubishi's motor design incorporates sophisticated sensors and real-time monitoring systems to track critical parameters like temperature, vibration, and electrical characteristics, enabling predictive maintenance and early fault detection[3]. Additionally, they have developed specialized lubricants and bearing designs to withstand extreme temperatures and harsh environments, significantly extending motor lifespan[4].

Strengths: Comprehensive thermal management, advanced materials, and predictive maintenance capabilities. Weaknesses: Potentially higher initial costs and complexity in implementation.

Robert Bosch GmbH

Technical Solution: Bosch has developed a holistic approach to evaluating and extending induction motor lifespan under extreme conditions. Their method combines advanced materials science with intelligent control systems. Bosch utilizes high-performance insulation materials and coatings that can withstand extreme temperatures and corrosive environments[1]. They have also implemented adaptive control algorithms that optimize motor performance based on real-time environmental conditions, reducing stress on critical components[2]. Bosch's approach includes a comprehensive sensor network that monitors various parameters such as temperature, vibration, and electrical characteristics, feeding data into advanced diagnostic and prognostic models[3]. These models use machine learning algorithms to predict potential failures and optimize maintenance schedules, significantly extending motor lifespan[4].

Strengths: Integration of advanced materials with intelligent control systems, predictive maintenance capabilities. Weaknesses: May require significant initial investment and specialized expertise for implementation.

Core Research Innovations

Method for calculating and influencing the remaining service life of components of an electrically driven vehicle

PatentWO2024061940A1

Innovation

- A method that combines measured sensor data and calculated parameters to form a damage model, activating a life extension mode when the remaining lifespan falls below a threshold, which implements measures such as load distribution, route optimization, and driver assistance to extend the service life by influencing thermal and mechanical damage distribution within drive components.

Method for optimising the performance of the internal combustion engine of a vehicle, such as an automotive vehicle

PatentWO2008037913A1

Innovation

- A method that monitors and adjusts engine settings based on exhaust gas temperature, using sensors to define a critical operating zone and increment a time counter to modify fuel injection and air flow settings, reducing exhaust gas temperature and engine performance only when the engine operates above 800°C for an extended duration, thereby extending the lifespan of engine components.

Environmental Impact Factors

The environmental factors play a crucial role in determining the lifespan of induction motors operating under extreme conditions. These factors can significantly impact the motor's performance, efficiency, and overall durability. Temperature is one of the most critical environmental factors affecting induction motor lifespan. Extreme heat or cold can lead to thermal stress, causing insulation breakdown, bearing failures, and reduced lubricant effectiveness. High temperatures accelerate the degradation of insulation materials, potentially leading to short circuits and motor failure.

Humidity is another significant factor that can impact induction motor longevity. Excessive moisture in the environment can lead to corrosion of motor components, particularly in coastal or tropical regions. This corrosion can affect the motor's electrical and mechanical integrity, potentially causing premature failure. Additionally, high humidity can lead to condensation inside the motor, which may result in electrical shorts or insulation breakdown.

Dust and particulate matter present in the operating environment can also have detrimental effects on induction motor lifespan. Accumulation of dust on motor windings can impede heat dissipation, leading to increased operating temperatures and accelerated insulation degradation. Particulates can also infiltrate bearings, causing increased friction and wear, ultimately reducing the motor's operational life.

Vibration, whether from external sources or inherent in the motor's operation, is another environmental factor that can significantly impact motor lifespan. Excessive vibration can lead to mechanical stress on bearings, shaft misalignment, and loosening of components. Over time, this can result in increased wear, reduced efficiency, and potential motor failure.

Chemical exposure is a critical consideration in certain industrial environments. Corrosive gases, vapors, or liquids can attack motor components, leading to accelerated degradation of materials. This is particularly relevant in industries such as chemical processing, where motors may be exposed to harsh chemical environments.

Altitude is an often-overlooked environmental factor that can affect induction motor performance and lifespan. At higher altitudes, the reduced air density can impact motor cooling efficiency, potentially leading to overheating issues if not properly addressed in the motor design or application.

Lastly, the presence of electromagnetic interference (EMI) in the operating environment can impact the motor's electrical performance and control systems. Strong electromagnetic fields can induce currents in motor windings, potentially leading to increased heating and reduced efficiency.

Understanding these environmental impact factors is crucial for accurately evaluating induction motor lifespan under extreme conditions. Proper consideration of these factors in motor selection, design, and maintenance strategies can significantly enhance motor reliability and longevity in challenging operational environments.

Humidity is another significant factor that can impact induction motor longevity. Excessive moisture in the environment can lead to corrosion of motor components, particularly in coastal or tropical regions. This corrosion can affect the motor's electrical and mechanical integrity, potentially causing premature failure. Additionally, high humidity can lead to condensation inside the motor, which may result in electrical shorts or insulation breakdown.

Dust and particulate matter present in the operating environment can also have detrimental effects on induction motor lifespan. Accumulation of dust on motor windings can impede heat dissipation, leading to increased operating temperatures and accelerated insulation degradation. Particulates can also infiltrate bearings, causing increased friction and wear, ultimately reducing the motor's operational life.

Vibration, whether from external sources or inherent in the motor's operation, is another environmental factor that can significantly impact motor lifespan. Excessive vibration can lead to mechanical stress on bearings, shaft misalignment, and loosening of components. Over time, this can result in increased wear, reduced efficiency, and potential motor failure.

Chemical exposure is a critical consideration in certain industrial environments. Corrosive gases, vapors, or liquids can attack motor components, leading to accelerated degradation of materials. This is particularly relevant in industries such as chemical processing, where motors may be exposed to harsh chemical environments.

Altitude is an often-overlooked environmental factor that can affect induction motor performance and lifespan. At higher altitudes, the reduced air density can impact motor cooling efficiency, potentially leading to overheating issues if not properly addressed in the motor design or application.

Lastly, the presence of electromagnetic interference (EMI) in the operating environment can impact the motor's electrical performance and control systems. Strong electromagnetic fields can induce currents in motor windings, potentially leading to increased heating and reduced efficiency.

Understanding these environmental impact factors is crucial for accurately evaluating induction motor lifespan under extreme conditions. Proper consideration of these factors in motor selection, design, and maintenance strategies can significantly enhance motor reliability and longevity in challenging operational environments.

Reliability Testing Standards

Reliability testing standards play a crucial role in evaluating the lifespan of induction motors under extreme conditions. These standards provide a systematic approach to assess the durability and performance of motors in challenging environments, ensuring their longevity and reliability.

The International Electrotechnical Commission (IEC) has established several standards specifically for induction motor testing. IEC 60034-1 outlines the general requirements for rotating electrical machines, including induction motors. This standard defines the operating conditions, performance characteristics, and testing procedures for various motor types.

For extreme conditions, IEC 60034-14 is particularly relevant. It focuses on mechanical vibration measurements and limits for rotating electrical machines. This standard is essential when evaluating induction motors in high-vibration environments, which can significantly impact motor lifespan.

NEMA MG 1 (Motors and Generators) is another widely recognized standard in the industry. It provides comprehensive guidelines for the manufacturing and testing of electric motors, including specific sections on extreme environmental conditions such as high temperatures, humidity, and corrosive atmospheres.

IEEE 112 is a standard test procedure for polyphase induction motors and generators. It outlines methods for determining efficiency, which is crucial when assessing motor performance under extreme conditions. The standard includes procedures for testing at various load points and temperatures, providing valuable data for lifespan evaluation.

For thermal evaluation, IEC 60034-11 specifies thermal protection systems for rotating electrical machines. This standard is particularly important when assessing motor lifespan in high-temperature environments or applications with frequent start-stop cycles.

The Ingress Protection (IP) rating system, defined by IEC 60529, is essential for evaluating motor protection against solid objects and liquids. When assessing induction motor lifespan in dusty or wet environments, the appropriate IP rating must be considered and tested accordingly.

Accelerated life testing methods, such as those outlined in IEC 61124, provide valuable insights into long-term motor reliability. These methods involve subjecting motors to intensified stress conditions to predict their lifespan in a shorter timeframe.

Reliability testing standards also encompass specific tests for extreme conditions. For instance, salt spray tests (ASTM B117) evaluate corrosion resistance, while thermal shock tests (IEC 60068-2-14) assess the motor's ability to withstand rapid temperature changes.

Implementing these standards in reliability testing ensures a comprehensive evaluation of induction motor lifespan under extreme conditions. By adhering to these guidelines, manufacturers and end-users can make informed decisions about motor selection, maintenance schedules, and expected service life in challenging operational environments.

The International Electrotechnical Commission (IEC) has established several standards specifically for induction motor testing. IEC 60034-1 outlines the general requirements for rotating electrical machines, including induction motors. This standard defines the operating conditions, performance characteristics, and testing procedures for various motor types.

For extreme conditions, IEC 60034-14 is particularly relevant. It focuses on mechanical vibration measurements and limits for rotating electrical machines. This standard is essential when evaluating induction motors in high-vibration environments, which can significantly impact motor lifespan.

NEMA MG 1 (Motors and Generators) is another widely recognized standard in the industry. It provides comprehensive guidelines for the manufacturing and testing of electric motors, including specific sections on extreme environmental conditions such as high temperatures, humidity, and corrosive atmospheres.

IEEE 112 is a standard test procedure for polyphase induction motors and generators. It outlines methods for determining efficiency, which is crucial when assessing motor performance under extreme conditions. The standard includes procedures for testing at various load points and temperatures, providing valuable data for lifespan evaluation.

For thermal evaluation, IEC 60034-11 specifies thermal protection systems for rotating electrical machines. This standard is particularly important when assessing motor lifespan in high-temperature environments or applications with frequent start-stop cycles.

The Ingress Protection (IP) rating system, defined by IEC 60529, is essential for evaluating motor protection against solid objects and liquids. When assessing induction motor lifespan in dusty or wet environments, the appropriate IP rating must be considered and tested accordingly.

Accelerated life testing methods, such as those outlined in IEC 61124, provide valuable insights into long-term motor reliability. These methods involve subjecting motors to intensified stress conditions to predict their lifespan in a shorter timeframe.

Reliability testing standards also encompass specific tests for extreme conditions. For instance, salt spray tests (ASTM B117) evaluate corrosion resistance, while thermal shock tests (IEC 60068-2-14) assess the motor's ability to withstand rapid temperature changes.

Implementing these standards in reliability testing ensures a comprehensive evaluation of induction motor lifespan under extreme conditions. By adhering to these guidelines, manufacturers and end-users can make informed decisions about motor selection, maintenance schedules, and expected service life in challenging operational environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!