Exploring the Material Science of Lipid Nanoparticles in Gene Therapy

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LNP Technology Evolution and Objectives

Lipid nanoparticles (LNPs) have emerged as revolutionary delivery vehicles for genetic material, marking a significant milestone in the evolution of gene therapy. The journey of LNP technology began in the 1960s with the discovery of liposomes, which laid the foundation for more sophisticated lipid-based delivery systems. By the 1990s, researchers had developed the first generation of lipid-based carriers for nucleic acid delivery, though these early systems faced challenges related to stability, efficacy, and toxicity.

The field experienced a transformative breakthrough in the early 2000s with the development of ionizable lipids, which significantly enhanced transfection efficiency while reducing toxicity. This innovation catalyzed rapid advancement in LNP technology, culminating in the approval of Patisiran in 2018, the first siRNA therapy utilizing LNP delivery systems for treating hereditary transthyretin amyloidosis.

The COVID-19 pandemic further accelerated LNP technology development, as these particles became the delivery platform of choice for mRNA vaccines. This unprecedented global application demonstrated the scalability and efficacy of LNP technology, while simultaneously highlighting areas requiring further optimization.

Current technological objectives in LNP development focus on several critical aspects. Enhancing tissue-specific targeting represents a primary goal, as most current LNPs predominantly accumulate in the liver. Researchers aim to develop LNPs capable of efficiently targeting diverse tissues including the central nervous system, lungs, and immune cells, which would significantly expand therapeutic applications.

Improving the stability profile of LNPs constitutes another key objective. Current formulations often require stringent cold-chain storage conditions, limiting accessibility in resource-constrained settings. Developing thermostable LNPs would dramatically improve global distribution capabilities for gene therapies and vaccines.

Researchers are also focused on optimizing the cargo capacity and release kinetics of LNPs. The ability to deliver larger genetic payloads or multiple therapeutic agents simultaneously would enable more complex genetic interventions. Additionally, controlling the precise timing and location of cargo release would enhance therapeutic efficacy while minimizing off-target effects.

The long-term vision for LNP technology encompasses the development of programmable delivery systems with tunable properties that can be tailored to specific therapeutic applications. This includes creating LNPs with environmentally responsive elements that can adapt to physiological conditions, as well as systems capable of crossing biological barriers that currently limit gene therapy applications, such as the blood-brain barrier.

The field experienced a transformative breakthrough in the early 2000s with the development of ionizable lipids, which significantly enhanced transfection efficiency while reducing toxicity. This innovation catalyzed rapid advancement in LNP technology, culminating in the approval of Patisiran in 2018, the first siRNA therapy utilizing LNP delivery systems for treating hereditary transthyretin amyloidosis.

The COVID-19 pandemic further accelerated LNP technology development, as these particles became the delivery platform of choice for mRNA vaccines. This unprecedented global application demonstrated the scalability and efficacy of LNP technology, while simultaneously highlighting areas requiring further optimization.

Current technological objectives in LNP development focus on several critical aspects. Enhancing tissue-specific targeting represents a primary goal, as most current LNPs predominantly accumulate in the liver. Researchers aim to develop LNPs capable of efficiently targeting diverse tissues including the central nervous system, lungs, and immune cells, which would significantly expand therapeutic applications.

Improving the stability profile of LNPs constitutes another key objective. Current formulations often require stringent cold-chain storage conditions, limiting accessibility in resource-constrained settings. Developing thermostable LNPs would dramatically improve global distribution capabilities for gene therapies and vaccines.

Researchers are also focused on optimizing the cargo capacity and release kinetics of LNPs. The ability to deliver larger genetic payloads or multiple therapeutic agents simultaneously would enable more complex genetic interventions. Additionally, controlling the precise timing and location of cargo release would enhance therapeutic efficacy while minimizing off-target effects.

The long-term vision for LNP technology encompasses the development of programmable delivery systems with tunable properties that can be tailored to specific therapeutic applications. This includes creating LNPs with environmentally responsive elements that can adapt to physiological conditions, as well as systems capable of crossing biological barriers that currently limit gene therapy applications, such as the blood-brain barrier.

Gene Therapy Market Analysis

The gene therapy market has experienced remarkable growth in recent years, driven by significant advancements in delivery technologies, particularly lipid nanoparticles (LNPs). As of 2023, the global gene therapy market is valued at approximately $7.8 billion and is projected to reach $35.1 billion by 2030, representing a compound annual growth rate (CAGR) of 27.3% during the forecast period.

North America currently dominates the market with about 48% share, followed by Europe at 28% and Asia-Pacific at 18%. This regional distribution reflects the concentration of research institutions, pharmaceutical companies, and regulatory frameworks that support gene therapy development and commercialization.

The market segmentation reveals interesting patterns when analyzed by therapeutic areas. Oncology applications lead with 32% market share, followed by rare genetic disorders (27%), cardiovascular diseases (15%), neurological disorders (12%), and other applications (14%). The prevalence of these conditions and the potential for gene therapy to offer curative rather than symptomatic treatments drive this distribution.

LNP-based delivery systems specifically have captured approximately 41% of the gene therapy delivery market, outpacing viral vectors (38%) and other non-viral methods (21%). This dominance stems from LNPs' demonstrated success in mRNA vaccine development during the COVID-19 pandemic, which has accelerated their adoption in therapeutic applications.

Key market drivers include increasing prevalence of genetic disorders, growing investment in research and development, favorable regulatory frameworks, and rising demand for personalized medicine. The success of approved gene therapies like Luxturna and Zolgensma has bolstered investor confidence, with venture capital funding for gene therapy startups reaching $4.5 billion in 2022 alone.

However, several factors constrain market growth. High treatment costs remain a significant barrier, with some gene therapies priced between $850,000 and $2.1 million per treatment. Manufacturing challenges, regulatory hurdles, and safety concerns also limit market expansion. Additionally, limited healthcare infrastructure in developing regions restricts global market penetration.

Consumer trends indicate growing acceptance of gene therapy treatments, particularly among patients with limited therapeutic options. Payers and healthcare systems are increasingly exploring innovative payment models, including outcomes-based agreements and installment plans, to manage the high upfront costs of these treatments.

Looking forward, the market is expected to benefit from technological advancements in LNP formulations that enhance targeting specificity, reduce immunogenicity, and improve manufacturing scalability. These improvements will likely expand the application scope of gene therapies and drive further market growth.

North America currently dominates the market with about 48% share, followed by Europe at 28% and Asia-Pacific at 18%. This regional distribution reflects the concentration of research institutions, pharmaceutical companies, and regulatory frameworks that support gene therapy development and commercialization.

The market segmentation reveals interesting patterns when analyzed by therapeutic areas. Oncology applications lead with 32% market share, followed by rare genetic disorders (27%), cardiovascular diseases (15%), neurological disorders (12%), and other applications (14%). The prevalence of these conditions and the potential for gene therapy to offer curative rather than symptomatic treatments drive this distribution.

LNP-based delivery systems specifically have captured approximately 41% of the gene therapy delivery market, outpacing viral vectors (38%) and other non-viral methods (21%). This dominance stems from LNPs' demonstrated success in mRNA vaccine development during the COVID-19 pandemic, which has accelerated their adoption in therapeutic applications.

Key market drivers include increasing prevalence of genetic disorders, growing investment in research and development, favorable regulatory frameworks, and rising demand for personalized medicine. The success of approved gene therapies like Luxturna and Zolgensma has bolstered investor confidence, with venture capital funding for gene therapy startups reaching $4.5 billion in 2022 alone.

However, several factors constrain market growth. High treatment costs remain a significant barrier, with some gene therapies priced between $850,000 and $2.1 million per treatment. Manufacturing challenges, regulatory hurdles, and safety concerns also limit market expansion. Additionally, limited healthcare infrastructure in developing regions restricts global market penetration.

Consumer trends indicate growing acceptance of gene therapy treatments, particularly among patients with limited therapeutic options. Payers and healthcare systems are increasingly exploring innovative payment models, including outcomes-based agreements and installment plans, to manage the high upfront costs of these treatments.

Looking forward, the market is expected to benefit from technological advancements in LNP formulations that enhance targeting specificity, reduce immunogenicity, and improve manufacturing scalability. These improvements will likely expand the application scope of gene therapies and drive further market growth.

LNP Material Science Status and Barriers

Lipid nanoparticles (LNPs) have emerged as the leading delivery system for nucleic acid therapeutics, with their breakthrough application in mRNA COVID-19 vaccines highlighting their potential. However, the current state of LNP material science reveals significant barriers that limit their broader application in gene therapy.

The composition of LNPs typically includes four key components: ionizable lipids, helper phospholipids, cholesterol, and PEG-lipids. While this basic structure has proven effective for liver-targeted delivery, achieving targeted delivery to other tissues remains challenging. Current LNPs predominantly accumulate in the liver due to interactions with apolipoprotein E (ApoE), limiting their therapeutic application to hepatic diseases.

Stability issues present another major barrier in LNP development. These nanoparticles are susceptible to aggregation, lipid oxidation, and hydrolysis, necessitating stringent cold chain requirements that increase costs and complicate global distribution. The mRNA COVID-19 vaccines, for instance, require storage at ultra-low temperatures, highlighting this limitation.

Manufacturing scalability poses significant challenges for widespread LNP adoption. Current production methods, primarily based on microfluidic mixing, face difficulties in consistent scale-up while maintaining critical quality attributes such as size distribution, encapsulation efficiency, and morphology. This manufacturing bottleneck restricts the availability of LNP-based therapeutics and increases production costs.

Immunogenicity remains a persistent concern with LNP formulations. The lipid components, particularly ionizable lipids, can trigger immune responses that lead to adverse effects and reduced efficacy in repeat dosing scenarios. This immune activation, while beneficial in vaccine applications, becomes problematic for chronic disease treatments requiring multiple administrations.

The characterization of LNPs presents technical challenges that impede development. Current analytical methods struggle to provide comprehensive data on LNP structure, lipid distribution, and in vivo behavior. Advanced techniques like cryo-electron microscopy have revealed heterogeneity in LNP structures, but more sophisticated analytical tools are needed to guide rational design.

Regulatory frameworks for LNP-based therapeutics are still evolving, creating uncertainty in development pathways. The novelty of these delivery systems means that regulatory agencies are continuously updating guidelines, which can delay approval processes and increase development costs.

Intellectual property landscapes surrounding LNP technology are complex and fragmented, with key patents held by a limited number of companies. This concentration of IP rights creates barriers to entry for new players and potentially limits innovation in the field.

The composition of LNPs typically includes four key components: ionizable lipids, helper phospholipids, cholesterol, and PEG-lipids. While this basic structure has proven effective for liver-targeted delivery, achieving targeted delivery to other tissues remains challenging. Current LNPs predominantly accumulate in the liver due to interactions with apolipoprotein E (ApoE), limiting their therapeutic application to hepatic diseases.

Stability issues present another major barrier in LNP development. These nanoparticles are susceptible to aggregation, lipid oxidation, and hydrolysis, necessitating stringent cold chain requirements that increase costs and complicate global distribution. The mRNA COVID-19 vaccines, for instance, require storage at ultra-low temperatures, highlighting this limitation.

Manufacturing scalability poses significant challenges for widespread LNP adoption. Current production methods, primarily based on microfluidic mixing, face difficulties in consistent scale-up while maintaining critical quality attributes such as size distribution, encapsulation efficiency, and morphology. This manufacturing bottleneck restricts the availability of LNP-based therapeutics and increases production costs.

Immunogenicity remains a persistent concern with LNP formulations. The lipid components, particularly ionizable lipids, can trigger immune responses that lead to adverse effects and reduced efficacy in repeat dosing scenarios. This immune activation, while beneficial in vaccine applications, becomes problematic for chronic disease treatments requiring multiple administrations.

The characterization of LNPs presents technical challenges that impede development. Current analytical methods struggle to provide comprehensive data on LNP structure, lipid distribution, and in vivo behavior. Advanced techniques like cryo-electron microscopy have revealed heterogeneity in LNP structures, but more sophisticated analytical tools are needed to guide rational design.

Regulatory frameworks for LNP-based therapeutics are still evolving, creating uncertainty in development pathways. The novelty of these delivery systems means that regulatory agencies are continuously updating guidelines, which can delay approval processes and increase development costs.

Intellectual property landscapes surrounding LNP technology are complex and fragmented, with key patents held by a limited number of companies. This concentration of IP rights creates barriers to entry for new players and potentially limits innovation in the field.

Current LNP Formulation Approaches

01 Lipid nanoparticle composition and structure

Lipid nanoparticles are composed of various lipid components including ionizable lipids, helper lipids, cholesterol, and PEG-lipids. The specific composition and ratio of these components significantly affect the physical properties, stability, and functionality of the nanoparticles. The structural design of lipid nanoparticles can be optimized to enhance encapsulation efficiency, control release kinetics, and improve overall performance in drug delivery applications.- Lipid nanoparticle composition and structure: Lipid nanoparticles are composed of various lipid components including ionizable lipids, helper lipids, cholesterol, and PEG-lipids. The specific composition and structural arrangement of these components significantly impact the stability, encapsulation efficiency, and delivery capabilities of the nanoparticles. Advanced material science approaches are used to optimize the lipid ratios and structural configurations to enhance functionality for specific applications.

- Manufacturing processes for lipid nanoparticles: Various manufacturing techniques are employed to produce lipid nanoparticles with controlled size, morphology, and polydispersity. These include microfluidic mixing, ethanol injection, high-pressure homogenization, and solvent evaporation methods. The material science aspects of these processes focus on optimizing production parameters to ensure reproducibility, scalability, and maintenance of critical quality attributes that influence the nanoparticles' performance in biological systems.

- Surface modification and functionalization: Surface engineering of lipid nanoparticles involves modification with targeting ligands, stealth polymers, or charge-altering moieties to enhance their biological interactions. Material science approaches focus on developing novel surface chemistries that improve cellular uptake, reduce immunogenicity, and enable tissue-specific targeting. These modifications can significantly alter the biodistribution and pharmacokinetic profiles of the nanoparticles, making them more effective for therapeutic applications.

- Characterization techniques for lipid nanoparticles: Advanced analytical methods are essential for characterizing the physicochemical properties of lipid nanoparticles. These include dynamic light scattering for size determination, zeta potential measurements for surface charge analysis, electron microscopy for morphological assessment, and various spectroscopic techniques for compositional analysis. Material science approaches focus on developing and refining these characterization methods to better understand structure-function relationships and ensure batch-to-batch consistency.

- Stability and storage considerations: The stability of lipid nanoparticles under various storage conditions is a critical material science consideration. Factors affecting stability include temperature, pH, ionic strength, and freeze-thaw cycles. Research focuses on developing formulation strategies such as lyophilization, cryoprotectants, and specialized packaging materials to enhance long-term stability. Understanding the molecular mechanisms of degradation and developing predictive stability models are key areas of material science research in this field.

02 Manufacturing processes for lipid nanoparticles

Various manufacturing techniques are employed to produce lipid nanoparticles with controlled size distribution and morphology. These include microfluidic mixing, ethanol injection, high-pressure homogenization, and solvent evaporation methods. The processing parameters such as temperature, pressure, flow rate, and solvent composition significantly impact the physicochemical properties of the resulting nanoparticles. Advanced manufacturing approaches focus on scalability, reproducibility, and maintaining the integrity of encapsulated materials.Expand Specific Solutions03 Characterization and stability of lipid nanoparticles

Comprehensive characterization of lipid nanoparticles involves analyzing particle size, polydispersity index, zeta potential, morphology, and encapsulation efficiency. Advanced analytical techniques such as dynamic light scattering, electron microscopy, and spectroscopic methods are employed to evaluate these parameters. Stability studies assess the physical and chemical integrity of lipid nanoparticles under various storage conditions, including temperature fluctuations, freeze-thaw cycles, and exposure to different pH environments. Formulation strategies to enhance long-term stability include lyophilization, cryoprotectants, and surface modification.Expand Specific Solutions04 Functionalization and targeting capabilities

Lipid nanoparticles can be functionalized with various ligands, antibodies, peptides, or other targeting moieties to enhance their specificity for particular tissues or cell types. Surface modification strategies include covalent conjugation, adsorption, or incorporation of functionalized lipids during formulation. These modifications can improve cellular uptake, reduce off-target effects, and enhance therapeutic efficacy. Smart responsive lipid nanoparticles can be designed to release their cargo in response to specific stimuli such as pH, temperature, enzymes, or redox conditions.Expand Specific Solutions05 Applications in drug and nucleic acid delivery

Lipid nanoparticles serve as versatile delivery systems for various therapeutic payloads, including small molecule drugs, proteins, and nucleic acids such as mRNA, siRNA, and DNA. For nucleic acid delivery, lipid nanoparticles protect the cargo from enzymatic degradation, facilitate cellular uptake, and enable endosomal escape. The design of lipid nanoparticles for mRNA vaccines requires specific considerations regarding lipid composition, particle size, and surface properties to optimize immunogenicity and stability. Recent advances focus on improving transfection efficiency, reducing immunogenicity, and enhancing the therapeutic index of lipid nanoparticle-based formulations.Expand Specific Solutions

Key Industry Players in LNP Technology

The lipid nanoparticle (LNP) gene therapy field is currently in a growth phase, with an estimated market size exceeding $5 billion and projected to expand at a CAGR of 15-20% through 2030. The competitive landscape features established academic institutions (MIT, Yale, Cornell) conducting foundational research alongside specialized biotech companies developing commercial applications. Companies like Generation Bio, Tessera Therapeutics, and Verve Therapeutics are advancing proprietary LNP delivery platforms, while Abogen Biosciences and EnhancedBio are making significant progress in clinical applications. The technology is approaching maturity for liver-targeted therapies but remains in early development stages for other tissue targets. Recent innovations from Massachusetts Institute of Technology and Fudan University are improving LNP stability and tissue-specific targeting, accelerating the field's evolution toward broader therapeutic applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced lipid nanoparticle (LNP) delivery systems for gene therapy applications with their patented ionizable lipid formulations. Their technology focuses on optimizing the lipid composition to enhance cellular uptake and endosomal escape, critical factors for effective gene delivery. MIT researchers have developed specialized lipidoid nanoparticles with customizable surface properties that improve tissue targeting specificity while reducing off-target effects. Their LNP platform incorporates biodegradable lipids with tunable degradation rates to minimize toxicity concerns associated with traditional delivery systems. MIT has also implemented microfluidic-based manufacturing processes that ensure consistent nanoparticle size distribution (typically 70-100 nm) and high encapsulation efficiency (>90%) of nucleic acid payloads, resulting in more predictable pharmacokinetic profiles.

Strengths: Superior endosomal escape mechanisms, highly customizable lipid compositions, and advanced manufacturing techniques ensuring consistent quality. Weaknesses: Complex formulation processes may present scalability challenges, and some proprietary lipids may have higher production costs compared to conventional alternatives.

The Regents of the University of California

Technical Solution: The University of California system has developed a comprehensive LNP platform for gene therapy delivery that addresses several key challenges in the field. Their technology incorporates novel ionizable lipids with optimized pKa values (6.2-6.5) that enhance endosomal escape while maintaining serum stability. UC researchers have engineered LNPs with tissue-specific targeting capabilities through the incorporation of ligand-modified lipids that recognize receptors on target cells. Their formulations include proprietary helper lipids that improve membrane fusion efficiency and intracellular release of genetic payloads. The UC system has also pioneered methods for freeze-drying LNPs while maintaining structural integrity, significantly extending shelf-life from weeks to over a year at standard refrigeration temperatures. Their platform demonstrates versatility across multiple nucleic acid cargo types including mRNA, siRNA, and CRISPR components.

Strengths: Exceptional targeting capabilities, extended product stability through advanced preservation techniques, and versatility across different genetic payloads. Weaknesses: Some formulations show limited penetration of certain tissue barriers (particularly the blood-brain barrier) and may require specialized manufacturing equipment.

Critical Patents in LNP Material Science

Lipid nanoparticles

PatentWO2023188830A1

Innovation

- Development of lipid nanoparticles containing pH-sensitive cationic lipids with branched hydrocarbon chains, combined with sterol and polyalkylene glycol-modified lipids, to enhance gene delivery efficiency to liver and spleen cells.

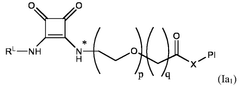

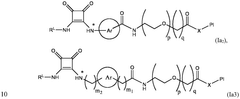

Ionizable lipid nanoparticles

PatentWO2025051994A1

Innovation

- The development of ionizable lipid nanoparticles that incorporate a squaramide modified lipid, specifically a squaramide modified phospholipid, which is covalently linked to a functional moiety containing a steric shielding agent, labelling agent, cell-type targeting ligand, or receptor targeting ligand, via a squaramide moiety.

Regulatory Framework for LNP-based Therapeutics

The regulatory landscape for Lipid Nanoparticle (LNP) therapeutics represents a complex and evolving framework that significantly impacts the development and commercialization of gene therapy products. Currently, regulatory agencies worldwide, including the FDA, EMA, and PMDA, are actively developing specific guidelines for LNP-based gene therapies, recognizing their unique characteristics compared to traditional pharmaceutical products.

In the United States, the FDA evaluates LNP-based therapeutics through a combination of existing frameworks for biologics, gene therapies, and nanomedicines. The Center for Biologics Evaluation and Research (CBER) typically takes the lead in reviewing these products, with particular emphasis on characterization of the lipid components, encapsulation efficiency, and stability profiles. The FDA's 2019 guidance on drug products containing nanomaterials provides some direction, though specific LNP considerations continue to evolve.

European regulatory approaches through the EMA have established the Advanced Therapy Medicinal Products (ATMP) classification, under which many LNP-based gene therapies fall. The EMA requires comprehensive physicochemical characterization of LNPs, including size distribution, surface charge, and morphology, alongside traditional safety and efficacy data. The Scientific Advice procedure offers developers early regulatory guidance specific to their LNP formulations.

Quality control represents a critical regulatory challenge for LNP therapeutics. Regulatory bodies require robust analytical methods to ensure batch-to-batch consistency, stability throughout the product lifecycle, and absence of potentially harmful impurities. The establishment of reference standards for LNP characterization remains an ongoing challenge that industry consortia and regulatory agencies are actively addressing.

Safety assessment frameworks for LNP-based therapeutics focus on potential immunogenicity, cytotoxicity, and biodistribution profiles. Regulatory agencies increasingly request comprehensive non-clinical studies that evaluate both the lipid components and the genetic payload. The recent approval of mRNA-LNP COVID-19 vaccines has accelerated regulatory understanding in this area, though long-term safety monitoring requirements remain stringent.

International harmonization efforts through the International Council for Harmonisation (ICH) are working to standardize regulatory approaches to LNP therapeutics globally. The ICH Q3D guideline on elemental impurities and ongoing discussions about nanomedicine-specific guidelines demonstrate progress toward consistent global standards, though significant regional differences in regulatory requirements persist.

Accelerated approval pathways, including the FDA's Breakthrough Therapy designation and the EMA's PRIME scheme, have become increasingly important for novel LNP-based gene therapies addressing serious unmet medical needs. These pathways offer enhanced regulatory support and potentially expedited review timelines, though they do not circumvent the need for robust safety and efficacy data.

In the United States, the FDA evaluates LNP-based therapeutics through a combination of existing frameworks for biologics, gene therapies, and nanomedicines. The Center for Biologics Evaluation and Research (CBER) typically takes the lead in reviewing these products, with particular emphasis on characterization of the lipid components, encapsulation efficiency, and stability profiles. The FDA's 2019 guidance on drug products containing nanomaterials provides some direction, though specific LNP considerations continue to evolve.

European regulatory approaches through the EMA have established the Advanced Therapy Medicinal Products (ATMP) classification, under which many LNP-based gene therapies fall. The EMA requires comprehensive physicochemical characterization of LNPs, including size distribution, surface charge, and morphology, alongside traditional safety and efficacy data. The Scientific Advice procedure offers developers early regulatory guidance specific to their LNP formulations.

Quality control represents a critical regulatory challenge for LNP therapeutics. Regulatory bodies require robust analytical methods to ensure batch-to-batch consistency, stability throughout the product lifecycle, and absence of potentially harmful impurities. The establishment of reference standards for LNP characterization remains an ongoing challenge that industry consortia and regulatory agencies are actively addressing.

Safety assessment frameworks for LNP-based therapeutics focus on potential immunogenicity, cytotoxicity, and biodistribution profiles. Regulatory agencies increasingly request comprehensive non-clinical studies that evaluate both the lipid components and the genetic payload. The recent approval of mRNA-LNP COVID-19 vaccines has accelerated regulatory understanding in this area, though long-term safety monitoring requirements remain stringent.

International harmonization efforts through the International Council for Harmonisation (ICH) are working to standardize regulatory approaches to LNP therapeutics globally. The ICH Q3D guideline on elemental impurities and ongoing discussions about nanomedicine-specific guidelines demonstrate progress toward consistent global standards, though significant regional differences in regulatory requirements persist.

Accelerated approval pathways, including the FDA's Breakthrough Therapy designation and the EMA's PRIME scheme, have become increasingly important for novel LNP-based gene therapies addressing serious unmet medical needs. These pathways offer enhanced regulatory support and potentially expedited review timelines, though they do not circumvent the need for robust safety and efficacy data.

Manufacturing Scalability Challenges

The scaling of lipid nanoparticle (LNP) production from laboratory to industrial scale presents significant challenges that must be addressed to meet the growing demand for gene therapy applications. Current manufacturing processes often rely on batch methods using microfluidic mixing devices, which face limitations when production volumes increase. These limitations include maintaining consistent particle size distribution, encapsulation efficiency, and stability across larger production batches.

One critical challenge is the precise control of mixing parameters during scale-up. Laboratory-scale production typically achieves excellent reproducibility through microfluidic devices with well-defined mixing geometries. However, when scaling to industrial production, maintaining the same level of mixing efficiency becomes problematic, often resulting in heterogeneous particle populations with variable therapeutic efficacy.

Raw material consistency represents another significant hurdle. Industrial-scale production requires large quantities of lipids with consistent quality profiles. Variations in lipid purity, chain length distribution, or oxidation status can dramatically affect LNP formation and stability. The supply chain for specialized lipids remains relatively immature compared to traditional pharmaceutical excipients, creating bottlenecks in manufacturing scale-up.

Sterility assurance during large-scale production presents unique challenges for LNP manufacturing. Unlike small molecule drugs, LNPs are sensitive to terminal sterilization methods such as heat or radiation. Aseptic processing becomes necessary but introduces complexity and cost to manufacturing operations. Implementing closed-system processing technologies while maintaining product quality attributes requires significant engineering solutions.

Analytical characterization at production scale also poses difficulties. Methods that work well for small-batch analysis may become impractical or insufficiently sensitive when applied to industrial-scale production. Real-time monitoring of critical quality attributes during manufacturing remains limited, complicating process control strategies and quality assurance.

Regulatory frameworks for LNP manufacturing are still evolving, creating uncertainty for manufacturers scaling production. Defining critical quality attributes and acceptable ranges becomes more complex at industrial scale, where process variations may have subtle but important effects on product performance. Regulatory agencies are working to develop appropriate guidelines, but the rapidly evolving nature of the technology creates a challenging environment for standardization.

Cost considerations significantly impact scalability decisions. Current manufacturing approaches for clinical-grade LNPs remain expensive, with estimates suggesting production costs of $1,000-$10,000 per gram of formulated product. Developing economically viable large-scale production methods will require innovations in continuous manufacturing, automation, and process intensification to reduce costs while maintaining product quality.

One critical challenge is the precise control of mixing parameters during scale-up. Laboratory-scale production typically achieves excellent reproducibility through microfluidic devices with well-defined mixing geometries. However, when scaling to industrial production, maintaining the same level of mixing efficiency becomes problematic, often resulting in heterogeneous particle populations with variable therapeutic efficacy.

Raw material consistency represents another significant hurdle. Industrial-scale production requires large quantities of lipids with consistent quality profiles. Variations in lipid purity, chain length distribution, or oxidation status can dramatically affect LNP formation and stability. The supply chain for specialized lipids remains relatively immature compared to traditional pharmaceutical excipients, creating bottlenecks in manufacturing scale-up.

Sterility assurance during large-scale production presents unique challenges for LNP manufacturing. Unlike small molecule drugs, LNPs are sensitive to terminal sterilization methods such as heat or radiation. Aseptic processing becomes necessary but introduces complexity and cost to manufacturing operations. Implementing closed-system processing technologies while maintaining product quality attributes requires significant engineering solutions.

Analytical characterization at production scale also poses difficulties. Methods that work well for small-batch analysis may become impractical or insufficiently sensitive when applied to industrial-scale production. Real-time monitoring of critical quality attributes during manufacturing remains limited, complicating process control strategies and quality assurance.

Regulatory frameworks for LNP manufacturing are still evolving, creating uncertainty for manufacturers scaling production. Defining critical quality attributes and acceptable ranges becomes more complex at industrial scale, where process variations may have subtle but important effects on product performance. Regulatory agencies are working to develop appropriate guidelines, but the rapidly evolving nature of the technology creates a challenging environment for standardization.

Cost considerations significantly impact scalability decisions. Current manufacturing approaches for clinical-grade LNPs remain expensive, with estimates suggesting production costs of $1,000-$10,000 per gram of formulated product. Developing economically viable large-scale production methods will require innovations in continuous manufacturing, automation, and process intensification to reduce costs while maintaining product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!