Exploring Tungsten’s Role In Space Exploration

Tungsten in Space: Background and Objectives

Tungsten, a metal with exceptional properties, has played a crucial role in space exploration since the dawn of the space age. Its high melting point, excellent thermal conductivity, and remarkable strength-to-weight ratio make it an invaluable material for various space applications. The history of tungsten in space technology can be traced back to the early days of rocket development, where it was used in nozzles and heat shields due to its ability to withstand extreme temperatures.

As space exploration has evolved, so has the utilization of tungsten in spacecraft and related technologies. From its initial applications in thermal protection systems, tungsten has found its way into numerous components critical for space missions. These include radiation shielding, thruster components, and electrical systems, among others. The metal's unique characteristics have enabled engineers to overcome many challenges posed by the harsh environment of space, such as intense radiation, extreme temperature fluctuations, and the need for lightweight yet durable materials.

The objectives of exploring tungsten's role in space exploration are multifaceted. Primarily, researchers aim to maximize the potential of this versatile metal to enhance the performance, durability, and efficiency of space vehicles and equipment. This includes developing new alloys and composites that leverage tungsten's properties to create materials tailored for specific space applications. Additionally, there is a focus on improving manufacturing techniques to produce complex tungsten components more efficiently and cost-effectively.

Another key objective is to investigate tungsten's potential in advanced propulsion systems. As space agencies and private companies set their sights on deep space exploration and long-duration missions, the development of more powerful and efficient propulsion technologies becomes crucial. Tungsten's high temperature resistance and durability make it a promising candidate for use in next-generation ion engines and nuclear thermal propulsion systems.

Furthermore, the exploration of tungsten's role extends to its potential applications in space-based energy systems. With the growing interest in establishing permanent bases on the Moon and Mars, there is a need for reliable and long-lasting power sources. Tungsten's properties make it an attractive option for thermoelectric generators and nuclear power systems designed for extraterrestrial environments.

As we continue to push the boundaries of space exploration, the importance of materials science cannot be overstated. Tungsten, with its unique set of properties, stands at the forefront of this field, promising to enable new capabilities and overcome existing limitations in space technology. The ongoing research and development in tungsten applications for space exploration aim not only to improve current space systems but also to pave the way for future missions that were once thought impossible.

Space Industry Demand for Tungsten

The space industry's demand for tungsten has been steadily increasing as space exploration missions become more ambitious and technologically advanced. Tungsten's unique properties make it an invaluable material for various space applications, driving its demand across multiple sectors of the space industry.

In spacecraft construction, tungsten's high melting point and excellent thermal conductivity make it ideal for heat shields and thermal protection systems. These components are crucial for protecting spacecraft during atmospheric re-entry, where temperatures can reach extreme levels. As space agencies and private companies plan more ambitious missions, including potential human missions to Mars, the demand for advanced heat shield materials like tungsten is expected to grow significantly.

Propulsion systems also rely heavily on tungsten components. The material's high density and resistance to wear make it suitable for rocket nozzles and thruster components. As the space industry moves towards more efficient and powerful propulsion technologies, such as ion engines and nuclear thermal propulsion, the demand for tungsten in these applications is likely to increase.

Tungsten's radiation-shielding properties are particularly valuable in space environments. It is used in radiation shielding for sensitive electronic components and in habitation modules for crewed missions. With plans for long-duration missions and potential lunar or Martian bases, the need for effective radiation shielding materials like tungsten is becoming more critical.

The growing commercial space sector, including satellite manufacturing and launch services, is another significant driver of tungsten demand. Tungsten alloys are used in satellite components, such as balance weights and vibration dampers, due to their high density and stability. As the number of satellite launches continues to rise, driven by the expansion of global communication networks and Earth observation systems, the demand for tungsten in this sector is expected to grow proportionally.

Space-based scientific instruments and telescopes also utilize tungsten in various components. Its properties make it suitable for precision instruments that must withstand the harsh conditions of space while maintaining accuracy. As space agencies plan more ambitious scientific missions, such as next-generation space telescopes and planetary exploration probes, the demand for tungsten in specialized scientific instruments is likely to increase.

The emerging field of space mining and resource utilization presents another potential area of growth for tungsten demand. As technologies for in-situ resource utilization (ISRU) develop, tungsten's properties could make it valuable for manufacturing tools and equipment directly in space environments.

Current Challenges in Space-Grade Tungsten

Despite tungsten's remarkable properties that make it an attractive material for space applications, several significant challenges persist in developing and utilizing space-grade tungsten. One of the primary obstacles is the material's high melting point, which, while advantageous in many aspects, poses difficulties in manufacturing and processing. The extreme temperatures required for shaping and forming tungsten components often lead to increased production costs and limited manufacturing capabilities.

Another critical challenge lies in tungsten's inherent brittleness at room temperature. This characteristic makes it susceptible to cracking and fracturing during launch and deployment, where spacecraft components are subjected to intense vibrations and mechanical stresses. Researchers are actively exploring ways to enhance tungsten's ductility without compromising its other desirable properties, but achieving the right balance remains a complex task.

The high density of tungsten, while beneficial for radiation shielding, presents weight-related challenges in space applications where every gram matters. Engineers must carefully consider the trade-offs between the material's protective capabilities and the overall mass constraints of space missions. This often necessitates innovative design solutions to optimize the use of tungsten in spacecraft components.

Tungsten's susceptibility to oxidation at elevated temperatures is another concern in space environments. Although space is predominantly a vacuum, trace amounts of atomic oxygen in low Earth orbit can react with tungsten surfaces, potentially degrading their performance over time. Developing effective protective coatings or alloying strategies to mitigate this issue remains an active area of research.

The limited availability and high cost of high-purity tungsten suitable for space applications also pose challenges. Ensuring a consistent supply chain for space-grade tungsten, free from impurities that could compromise its performance in the harsh space environment, is crucial for long-term space exploration initiatives.

Furthermore, the space industry faces challenges in standardizing testing and qualification procedures for tungsten components. The unique conditions of space, including extreme temperature fluctuations, radiation exposure, and vacuum environments, require specialized testing protocols that are not always readily available or universally accepted.

Lastly, the integration of tungsten components with other materials in spacecraft systems presents ongoing challenges. Issues such as thermal expansion mismatches, galvanic corrosion, and joining techniques need to be carefully addressed to ensure the long-term reliability and performance of tungsten-based space technologies.

Existing Tungsten Applications in Space

01 Tungsten deposition and film formation

Various methods for depositing tungsten and forming tungsten films on substrates. This includes techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and atomic layer deposition (ALD). These processes are crucial in semiconductor manufacturing for creating interconnects and other conductive structures.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten-based alloys and composites: Development of tungsten-based alloys and composite materials with enhanced properties, such as improved strength, hardness, and thermal stability. These materials find applications in aerospace, defense, and high-temperature industrial processes.

- Tungsten etching and patterning: Techniques for etching and patterning tungsten layers in microelectronics fabrication, including plasma etching and chemical mechanical polishing (CMP). These processes are crucial for creating intricate circuit patterns and interconnects in semiconductor devices.

- Tungsten-based lighting technologies: Innovations in tungsten-based lighting technologies, including improvements in filament design, gas mixtures, and bulb construction. These advancements aim to enhance the efficiency, longevity, and performance of tungsten-based lighting solutions.

- Tungsten recycling and recovery: Methods for recycling and recovering tungsten from various sources, including industrial waste and end-of-life products. These processes aim to reduce environmental impact and conserve valuable tungsten resources through efficient extraction and purification techniques.

02 Tungsten etching and patterning

Techniques for etching and patterning tungsten layers in semiconductor devices. This includes dry etching methods, wet etching processes, and selective removal of tungsten. These processes are essential for creating precise structures and patterns in integrated circuits and other microelectronic devices.Expand Specific Solutions03 Tungsten alloys and composites

Development and production of tungsten alloys and composite materials. This includes combining tungsten with other metals or materials to enhance properties such as strength, conductivity, or thermal resistance. These materials find applications in various industries, including aerospace, electronics, and energy.Expand Specific Solutions04 Tungsten in lighting and electron emission

Use of tungsten in lighting applications and electron emission devices. This includes the development of tungsten filaments for incandescent lamps, cathodes for electron tubes, and field emission devices. The high melting point and good electron emission properties of tungsten make it suitable for these applications.Expand Specific Solutions05 Tungsten in nuclear applications

Applications of tungsten in nuclear technology, including its use as a shielding material, neutron reflector, and in nuclear fuel assemblies. The high density and radiation resistance of tungsten make it valuable in various nuclear-related applications, from power generation to research reactors.Expand Specific Solutions

Key Players in Space Tungsten Industry

The exploration of tungsten's role in space exploration is currently in a growth phase, with increasing market size and technological advancements. The global space industry, valued at over $400 billion, is driving demand for high-performance materials like tungsten. Technological maturity varies across applications, with companies like Raytheon Co., Lockheed Martin Corp., and Aerojet Rocketdyne, Inc. leading in propulsion systems and thermal protection. The European Space Agency and Japan Aerospace Exploration Agency are advancing tungsten's use in spacecraft components. Emerging players such as Space Micro, Inc. and Beijing Institute of Spacecraft System Engineering are focusing on innovative tungsten applications, while established materials companies like Kennametal, Inc. and Advanced Technology & Materials Co., Ltd. are developing specialized tungsten alloys for space environments.

Raytheon Co.

European Space Agency

Innovations in Space-Grade Tungsten

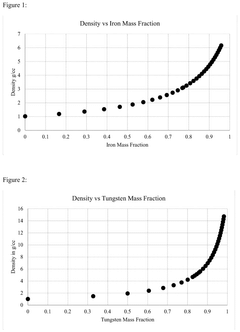

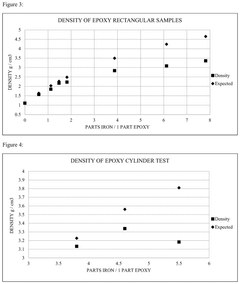

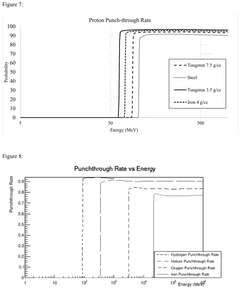

- A spacecraft material comprising a polymer and a shielding material, such as tungsten or iron, is developed. This material exhibits a less than 90% electron or proton punch-through rate under specific energy bombardments and is designed to fully destroy upon re-entry, ensuring impact energies below 15 J.

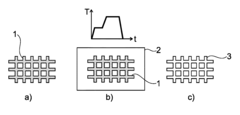

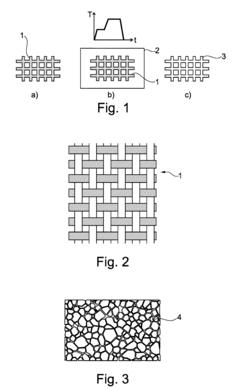

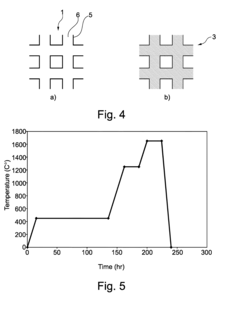

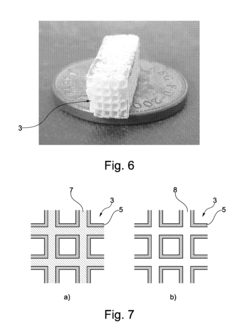

- A method involving 3D-printing or 3D-weaving of metal or metal matrix composite preforms, followed by a controlled heat treatment in a gas atmosphere to induce a metal-gas reaction, allowing for the transformation of the preform into a ceramic with precise control over structure and porosity, and the incorporation of additives to enhance the solid-gas reaction.

Environmental Impact of Tungsten in Space

The environmental impact of tungsten in space exploration is a critical consideration as humanity expands its presence beyond Earth. Tungsten, with its unique properties, plays a significant role in various space applications, but its use also raises concerns about potential environmental consequences.

In spacecraft construction, tungsten is utilized for radiation shielding, heat-resistant components, and thruster nozzles. While these applications enhance mission capabilities, they also introduce tungsten into the space environment. The primary concern is the potential release of tungsten particles during spacecraft operations or in the event of accidents or collisions.

Tungsten's high density and durability mean that particles released in space could remain in orbit for extended periods. These particles contribute to the growing problem of space debris, potentially posing risks to other spacecraft and satellites. The accumulation of tungsten debris in Earth's orbit could exacerbate the already challenging issue of space junk management.

Furthermore, the use of tungsten in spacecraft propulsion systems raises questions about the environmental impact of tungsten-based exhaust products. While the space environment is vast, the cumulative effect of multiple missions using tungsten components could lead to localized concentrations of tungsten particles in certain orbital regions.

On celestial bodies such as the Moon or Mars, where future human activities are planned, the introduction of tungsten through exploration activities could have unforeseen consequences. The interaction between tungsten and the local environment, including potential chemical reactions with regolith or atmospheric components, requires careful study to prevent unintended alterations to these pristine environments.

The recycling and disposal of tungsten-containing space components also present challenges. As space missions become more frequent and ambitious, the need for responsible management of materials used in space, including tungsten, becomes increasingly important. Developing strategies for the safe deorbiting or repurposing of tungsten-rich spacecraft parts is crucial to mitigate long-term environmental impacts.

Research into the behavior of tungsten in the space environment is ongoing. Scientists are studying the potential for tungsten to interact with solar radiation, cosmic rays, and other space phenomena, which could lead to changes in its physical or chemical properties over time. Understanding these processes is essential for predicting long-term environmental effects and developing mitigation strategies.

As space exploration advances, the space industry must balance the benefits of tungsten's unique properties with the need for environmental stewardship. This includes exploring alternative materials, improving spacecraft design to minimize tungsten release, and developing technologies for the active removal of tungsten debris from orbit. Collaborative efforts between space agencies, researchers, and environmental scientists are crucial to address these challenges and ensure sustainable space exploration practices.

International Cooperation in Space Tungsten Research

International cooperation in space tungsten research has become increasingly vital as nations recognize the potential of this refractory metal in advancing space exploration technologies. The unique properties of tungsten, including its high melting point, excellent thermal conductivity, and radiation shielding capabilities, make it an invaluable resource for various space applications. Collaborative efforts among space agencies, research institutions, and private companies from different countries have led to significant advancements in tungsten-based technologies for space exploration.

One of the most prominent examples of international cooperation in this field is the joint research initiative between NASA and the European Space Agency (ESA) on tungsten-based heat shields for spacecraft re-entry. This collaboration has resulted in the development of advanced thermal protection systems that can withstand extreme temperatures during atmospheric re-entry, significantly improving the safety and reliability of space missions.

In addition to bilateral partnerships, multilateral research consortia have been established to tackle complex challenges in space tungsten applications. The International Space Tungsten Consortium (ISTC), comprising members from the United States, Russia, China, Japan, and several European countries, focuses on developing innovative tungsten alloys and composites for use in space propulsion systems and structural components of spacecraft.

The sharing of research facilities and resources has been a key aspect of international cooperation in this field. For instance, the High-Temperature Materials Testing Facility in Germany, which specializes in evaluating the performance of tungsten-based materials under extreme conditions, has been made available to researchers from various countries through collaborative agreements.

Knowledge exchange and technology transfer have been facilitated through international conferences, workshops, and joint publications. The biennial International Conference on Space Tungsten Applications (ICSTA) serves as a platform for researchers and engineers from around the world to share their latest findings and discuss future directions in the field.

Emerging space nations have also benefited from international cooperation in tungsten research. Through technology transfer programs and joint research projects, countries like India and Brazil have been able to develop their capabilities in manufacturing tungsten components for space applications, contributing to the diversification of the global space industry supply chain.

As space exploration ventures become more ambitious, international cooperation in tungsten research is expected to intensify. Future collaborative efforts are likely to focus on developing advanced manufacturing techniques for complex tungsten components, exploring new tungsten-based composites for radiation shielding in deep space missions, and optimizing tungsten alloys for use in next-generation space nuclear propulsion systems.