Exploring UHMWPE's Environmental Stress Cracking Resistance

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE ESCR Background

Ultra-high molecular weight polyethylene (UHMWPE) has been a subject of extensive research and development due to its exceptional mechanical properties and wide-ranging applications. The focus on UHMWPE's environmental stress cracking resistance (ESCR) has gained significant attention in recent years, as this property is crucial for its performance in various demanding environments.

ESCR refers to the ability of a material to withstand the combined effects of mechanical stress and exposure to aggressive chemicals or environmental conditions without premature failure. In the case of UHMWPE, this property is particularly important for applications in industries such as oil and gas, chemical processing, and medical implants, where the material is subjected to harsh conditions and prolonged stress.

The development of UHMWPE's ESCR can be traced back to the 1950s when the polymer was first synthesized. Initially, the focus was primarily on improving its wear resistance and mechanical strength. However, as the material found its way into more diverse applications, the need for enhanced ESCR became apparent.

Throughout the 1970s and 1980s, researchers began to investigate the mechanisms of environmental stress cracking in UHMWPE. They discovered that the polymer's susceptibility to stress cracking was closely related to its molecular structure, particularly its crystallinity and molecular weight distribution. This understanding led to the development of new grades of UHMWPE with improved ESCR properties.

In the 1990s and early 2000s, advancements in polymer science and processing techniques allowed for further improvements in UHMWPE's ESCR. Cross-linking techniques, such as electron beam irradiation and chemical cross-linking, were introduced to enhance the material's resistance to environmental stress cracking while maintaining its other desirable properties.

The ongoing research in UHMWPE's ESCR has been driven by the increasing demands of various industries. For instance, in the oil and gas sector, UHMWPE components are required to withstand exposure to hydrocarbons, high pressures, and extreme temperatures for extended periods. Similarly, in medical applications, UHMWPE implants must resist degradation in the presence of body fluids and maintain their integrity over many years.

Recent technological advancements have focused on developing novel additives and processing methods to further enhance UHMWPE's ESCR. These include the incorporation of nanoparticles, the use of advanced stabilizers, and the optimization of molding and extrusion processes. Additionally, there has been a growing interest in understanding the long-term behavior of UHMWPE under various environmental conditions, leading to the development of accelerated testing methods and predictive models for ESCR performance.

ESCR refers to the ability of a material to withstand the combined effects of mechanical stress and exposure to aggressive chemicals or environmental conditions without premature failure. In the case of UHMWPE, this property is particularly important for applications in industries such as oil and gas, chemical processing, and medical implants, where the material is subjected to harsh conditions and prolonged stress.

The development of UHMWPE's ESCR can be traced back to the 1950s when the polymer was first synthesized. Initially, the focus was primarily on improving its wear resistance and mechanical strength. However, as the material found its way into more diverse applications, the need for enhanced ESCR became apparent.

Throughout the 1970s and 1980s, researchers began to investigate the mechanisms of environmental stress cracking in UHMWPE. They discovered that the polymer's susceptibility to stress cracking was closely related to its molecular structure, particularly its crystallinity and molecular weight distribution. This understanding led to the development of new grades of UHMWPE with improved ESCR properties.

In the 1990s and early 2000s, advancements in polymer science and processing techniques allowed for further improvements in UHMWPE's ESCR. Cross-linking techniques, such as electron beam irradiation and chemical cross-linking, were introduced to enhance the material's resistance to environmental stress cracking while maintaining its other desirable properties.

The ongoing research in UHMWPE's ESCR has been driven by the increasing demands of various industries. For instance, in the oil and gas sector, UHMWPE components are required to withstand exposure to hydrocarbons, high pressures, and extreme temperatures for extended periods. Similarly, in medical applications, UHMWPE implants must resist degradation in the presence of body fluids and maintain their integrity over many years.

Recent technological advancements have focused on developing novel additives and processing methods to further enhance UHMWPE's ESCR. These include the incorporation of nanoparticles, the use of advanced stabilizers, and the optimization of molding and extrusion processes. Additionally, there has been a growing interest in understanding the long-term behavior of UHMWPE under various environmental conditions, leading to the development of accelerated testing methods and predictive models for ESCR performance.

Market Demand Analysis

The market demand for Ultra-High Molecular Weight Polyethylene (UHMWPE) with enhanced Environmental Stress Cracking Resistance (ESCR) has been steadily growing across various industries. This demand is primarily driven by the material's exceptional properties, including high impact strength, low friction coefficient, and excellent chemical resistance, which make it ideal for applications in harsh environments.

In the oil and gas sector, UHMWPE with improved ESCR is increasingly sought after for pipeline linings, offshore equipment, and downhole tools. The material's ability to withstand aggressive chemicals and high pressures while maintaining its structural integrity is crucial in these applications. As the industry continues to explore more challenging environments, the demand for UHMWPE with superior ESCR is expected to rise further.

The medical industry represents another significant market for UHMWPE with enhanced ESCR. Orthopedic implants, particularly joint replacements, benefit greatly from the material's wear resistance and biocompatibility. As the global population ages and the prevalence of joint-related disorders increases, the demand for long-lasting, high-performance implants is projected to grow substantially.

In the automotive sector, UHMWPE with improved ESCR is gaining traction for use in lightweight components, fuel systems, and electrical insulation. The material's resistance to environmental stress cracking is particularly valuable in these applications, where exposure to various chemicals and temperature fluctuations is common. With the automotive industry's focus on fuel efficiency and electrification, the demand for lightweight, durable materials like UHMWPE is expected to expand.

The packaging industry is another area where UHMWPE with enhanced ESCR is seeing increased adoption. The material's excellent barrier properties and resistance to environmental stress cracking make it suitable for food packaging, industrial containers, and protective coatings. As sustainability concerns grow, the demand for recyclable and durable packaging solutions using UHMWPE is likely to increase.

Market analysts project that the global UHMWPE market will continue to grow at a compound annual growth rate (CAGR) of around 9% over the next five years. This growth is largely attributed to the increasing demand for materials with superior mechanical properties and environmental stress cracking resistance across various end-use industries.

However, challenges remain in fully realizing the market potential of UHMWPE with enhanced ESCR. These include the relatively high production costs compared to conventional polymers and the need for specialized processing techniques. Addressing these challenges through ongoing research and development efforts is crucial to meeting the growing market demand and expanding the material's applications across industries.

In the oil and gas sector, UHMWPE with improved ESCR is increasingly sought after for pipeline linings, offshore equipment, and downhole tools. The material's ability to withstand aggressive chemicals and high pressures while maintaining its structural integrity is crucial in these applications. As the industry continues to explore more challenging environments, the demand for UHMWPE with superior ESCR is expected to rise further.

The medical industry represents another significant market for UHMWPE with enhanced ESCR. Orthopedic implants, particularly joint replacements, benefit greatly from the material's wear resistance and biocompatibility. As the global population ages and the prevalence of joint-related disorders increases, the demand for long-lasting, high-performance implants is projected to grow substantially.

In the automotive sector, UHMWPE with improved ESCR is gaining traction for use in lightweight components, fuel systems, and electrical insulation. The material's resistance to environmental stress cracking is particularly valuable in these applications, where exposure to various chemicals and temperature fluctuations is common. With the automotive industry's focus on fuel efficiency and electrification, the demand for lightweight, durable materials like UHMWPE is expected to expand.

The packaging industry is another area where UHMWPE with enhanced ESCR is seeing increased adoption. The material's excellent barrier properties and resistance to environmental stress cracking make it suitable for food packaging, industrial containers, and protective coatings. As sustainability concerns grow, the demand for recyclable and durable packaging solutions using UHMWPE is likely to increase.

Market analysts project that the global UHMWPE market will continue to grow at a compound annual growth rate (CAGR) of around 9% over the next five years. This growth is largely attributed to the increasing demand for materials with superior mechanical properties and environmental stress cracking resistance across various end-use industries.

However, challenges remain in fully realizing the market potential of UHMWPE with enhanced ESCR. These include the relatively high production costs compared to conventional polymers and the need for specialized processing techniques. Addressing these challenges through ongoing research and development efforts is crucial to meeting the growing market demand and expanding the material's applications across industries.

ESCR Challenges

Environmental Stress Cracking Resistance (ESCR) is a critical property for Ultra-High Molecular Weight Polyethylene (UHMWPE), particularly in demanding applications such as industrial components, medical implants, and high-performance fibers. However, UHMWPE faces several significant challenges in maintaining its ESCR under various environmental conditions.

One of the primary challenges is the susceptibility of UHMWPE to oxidative degradation. When exposed to oxygen, especially at elevated temperatures or in the presence of UV radiation, the polymer chains can undergo scission and cross-linking, leading to embrittlement and reduced ESCR. This oxidation process can be accelerated in aggressive chemical environments, further compromising the material's long-term performance.

Another major challenge is the impact of mechanical stress on UHMWPE's ESCR. Under constant or cyclic loading, especially in the presence of environmental factors like moisture or chemicals, UHMWPE can experience slow crack growth. This phenomenon, known as slow crack propagation, can lead to premature failure of components, particularly in applications where long-term reliability is crucial.

The processing and manufacturing of UHMWPE also present challenges to its ESCR. The high molecular weight that gives UHMWPE its unique properties also makes it difficult to process. Inadequate consolidation during molding or extrusion can lead to the formation of weak interfaces between polymer particles, creating potential initiation sites for environmental stress cracking.

Furthermore, the addition of additives and fillers, while often necessary to enhance certain properties, can sometimes have detrimental effects on ESCR. For instance, some antioxidants may leach out over time, leaving the material more vulnerable to oxidative degradation and stress cracking.

The crystallinity of UHMWPE plays a crucial role in its ESCR, but achieving the optimal balance is challenging. Higher crystallinity generally improves mechanical properties but can also increase brittleness, potentially reducing ESCR in certain environments. Conversely, lower crystallinity may enhance flexibility but at the cost of reduced strength and wear resistance.

In medical applications, particularly in orthopedic implants, UHMWPE faces unique ESCR challenges. The combination of cyclic loading, body fluids, and potential oxidative stress can lead to material degradation over time. This is especially critical in joint replacements, where maintaining long-term integrity is essential for patient safety and implant longevity.

Addressing these ESCR challenges requires a multifaceted approach, involving advancements in polymer science, processing technologies, and application-specific engineering solutions. Ongoing research focuses on developing new grades of UHMWPE with enhanced ESCR, optimizing processing conditions, and exploring novel additives and surface treatments to mitigate environmental stress cracking.

One of the primary challenges is the susceptibility of UHMWPE to oxidative degradation. When exposed to oxygen, especially at elevated temperatures or in the presence of UV radiation, the polymer chains can undergo scission and cross-linking, leading to embrittlement and reduced ESCR. This oxidation process can be accelerated in aggressive chemical environments, further compromising the material's long-term performance.

Another major challenge is the impact of mechanical stress on UHMWPE's ESCR. Under constant or cyclic loading, especially in the presence of environmental factors like moisture or chemicals, UHMWPE can experience slow crack growth. This phenomenon, known as slow crack propagation, can lead to premature failure of components, particularly in applications where long-term reliability is crucial.

The processing and manufacturing of UHMWPE also present challenges to its ESCR. The high molecular weight that gives UHMWPE its unique properties also makes it difficult to process. Inadequate consolidation during molding or extrusion can lead to the formation of weak interfaces between polymer particles, creating potential initiation sites for environmental stress cracking.

Furthermore, the addition of additives and fillers, while often necessary to enhance certain properties, can sometimes have detrimental effects on ESCR. For instance, some antioxidants may leach out over time, leaving the material more vulnerable to oxidative degradation and stress cracking.

The crystallinity of UHMWPE plays a crucial role in its ESCR, but achieving the optimal balance is challenging. Higher crystallinity generally improves mechanical properties but can also increase brittleness, potentially reducing ESCR in certain environments. Conversely, lower crystallinity may enhance flexibility but at the cost of reduced strength and wear resistance.

In medical applications, particularly in orthopedic implants, UHMWPE faces unique ESCR challenges. The combination of cyclic loading, body fluids, and potential oxidative stress can lead to material degradation over time. This is especially critical in joint replacements, where maintaining long-term integrity is essential for patient safety and implant longevity.

Addressing these ESCR challenges requires a multifaceted approach, involving advancements in polymer science, processing technologies, and application-specific engineering solutions. Ongoing research focuses on developing new grades of UHMWPE with enhanced ESCR, optimizing processing conditions, and exploring novel additives and surface treatments to mitigate environmental stress cracking.

Current ESCR Solutions

01 Composition modifications for improved ESCR

Enhancing the environmental stress cracking resistance (ESCR) of UHMWPE through composition modifications. This includes blending with other polymers, incorporating additives, or adjusting the molecular weight distribution to improve the material's resistance to environmental stress cracking.- Composition modifications to improve ESCR: Enhancing the environmental stress cracking resistance (ESCR) of UHMWPE can be achieved through composition modifications. This includes blending UHMWPE with other polymers, incorporating additives, or using specific catalysts during polymerization. These modifications can alter the molecular structure and improve the material's resistance to environmental stress cracking.

- Processing techniques for improved ESCR: Various processing techniques can be employed to enhance the ESCR of UHMWPE. These may include specific molding methods, heat treatments, or compression techniques. By optimizing the processing conditions, the molecular orientation and crystallinity of UHMWPE can be controlled, leading to improved resistance to environmental stress cracking.

- Surface treatments to enhance ESCR: Surface treatments can be applied to UHMWPE to improve its ESCR. These treatments may include plasma treatment, chemical etching, or the application of protective coatings. By modifying the surface properties, the material's resistance to environmental stress cracking can be significantly enhanced.

- Crosslinking methods for ESCR improvement: Crosslinking techniques can be used to improve the ESCR of UHMWPE. This may involve radiation-induced crosslinking, chemical crosslinking, or the use of specific crosslinking agents. By creating a network of interconnected polymer chains, the material's resistance to environmental stress cracking can be enhanced.

- Testing and evaluation methods for ESCR: Developing and implementing effective testing and evaluation methods is crucial for assessing the ESCR of UHMWPE. This includes standardized test procedures, accelerated aging techniques, and advanced analytical methods to characterize the material's performance under various environmental conditions. These methods help in quantifying and comparing the ESCR of different UHMWPE formulations and treatments.

02 Processing techniques to enhance ESCR

Utilizing specific processing techniques during the manufacturing of UHMWPE to improve its environmental stress cracking resistance. This may involve optimizing extrusion parameters, employing specialized heat treatments, or using novel molding processes to enhance the material's performance under environmental stress.Expand Specific Solutions03 Surface treatments for improved ESCR

Applying surface treatments or modifications to UHMWPE to enhance its resistance to environmental stress cracking. This can include chemical treatments, plasma treatments, or the application of protective coatings to improve the material's surface properties and overall ESCR performance.Expand Specific Solutions04 Testing and evaluation methods for ESCR

Developing and implementing specialized testing and evaluation methods to assess the environmental stress cracking resistance of UHMWPE. This includes creating standardized test procedures, designing new testing equipment, and establishing performance criteria to accurately measure and compare ESCR properties.Expand Specific Solutions05 ESCR improvement for specific applications

Tailoring UHMWPE formulations and processing methods to enhance environmental stress cracking resistance for specific end-use applications. This involves optimizing material properties to meet the unique requirements of industries such as medical devices, automotive components, or industrial equipment, where ESCR is critical for long-term performance and safety.Expand Specific Solutions

Key Industry Players

The environmental stress cracking resistance of UHMWPE is a critical area of research in the advanced materials industry, currently in a growth phase. The market for UHMWPE applications is expanding, driven by increasing demand in sectors like medical devices, aerospace, and industrial equipment. While the technology is relatively mature, ongoing research by companies such as China Petroleum & Chemical Corp., Shanghai Research Institute of Chemical Industry, and LG Chem Ltd. focuses on enhancing UHMWPE's performance under environmental stress. Universities like South China University of Technology and Politecnico di Milano are also contributing to advancements in this field, indicating a collaborative effort between industry and academia to improve UHMWPE's properties and applications.

Basell Polyolefine GmbH

Technical Solution: Basell Polyolefine GmbH has developed a proprietary technology for enhancing UHMWPE's environmental stress cracking resistance (ESCR). Their approach involves a multi-stage polymerization process that creates a unique molecular structure with improved tie-molecule density[1]. This results in a more uniform distribution of stress throughout the polymer matrix, significantly increasing its resistance to environmental stress cracking. The company has also implemented a novel crosslinking technique that further enhances the material's ESCR without compromising its other mechanical properties[3]. Additionally, Basell has developed specialized additives that act as stabilizers against oxidative degradation, which is often a precursor to stress cracking in harsh environments[5].

Strengths: Superior ESCR performance, maintained mechanical properties, and improved oxidative stability. Weaknesses: Potentially higher production costs and limited applicability to certain grades of UHMWPE.

SABIC Global Technologies BV

Technical Solution: SABIC Global Technologies BV has pioneered an advanced UHMWPE formulation with enhanced ESCR properties. Their technology involves a proprietary blend of UHMWPE with carefully selected co-monomers that improve chain entanglement and crystalline structure[2]. This results in a material with superior resistance to environmental stress cracking while maintaining the high molecular weight characteristics of UHMWPE. SABIC has also developed a specialized processing technique that optimizes the orientation of polymer chains during fabrication, further enhancing the material's ESCR[4]. Additionally, the company has implemented a surface modification technology that creates a protective layer on UHMWPE products, providing an extra barrier against environmental stressors[6].

Strengths: Excellent ESCR performance, versatile application range, and improved processing characteristics. Weaknesses: Potential increase in material costs and possible limitations in extreme temperature applications.

ESCR Innovations

Ultra-High Molecular Weight Polyethylene

PatentActiveUS20120289667A1

Innovation

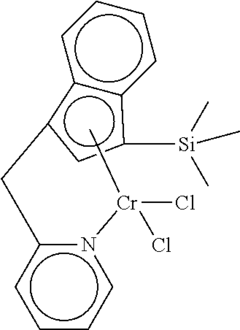

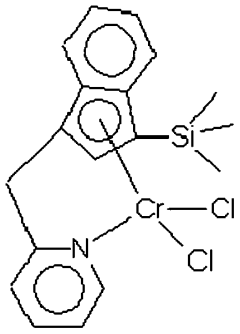

- A novel UHMW-PE is produced using a blend of metallocene-type catalysts, with a bimetallic catalyst residue comprising Hf and Cr, which are present as ionic compounds or complexes, to achieve superior abrasion and Charpy impact resistance, along with a medium density and suitable grain size, utilizing specific polymerization conditions and analytical methods to quantify the catalyst residues.

Ultra-high molecular weight polyethylene

PatentWO2011089017A1

Innovation

- The use of a blend of two metallocene-type catalysts, with Hafnium (Hf) and Chromium (Cr) as catalyst residues, to produce UHMW-PE with medium density and enhanced Charpy impact resistance, achieving a synergistic effect that improves both abrasion and impact resistance, and maintaining a suitable average grain size.

Environmental Factors

Environmental factors play a crucial role in determining the environmental stress cracking resistance (ESCR) of Ultra-High Molecular Weight Polyethylene (UHMWPE). These factors can significantly impact the material's performance and longevity in various applications. Temperature is one of the primary environmental factors affecting UHMWPE's ESCR. Higher temperatures generally accelerate the stress cracking process, as they increase molecular mobility and enhance the diffusion of environmental agents into the polymer matrix.

Exposure to ultraviolet (UV) radiation is another critical environmental factor. UV radiation can cause photo-oxidation of UHMWPE, leading to chain scission and crosslinking, which may alter the material's mechanical properties and ESCR. The intensity and duration of UV exposure are key parameters in determining the extent of degradation.

Chemical exposure is a significant concern for UHMWPE's ESCR. Certain chemicals, particularly organic solvents and surfactants, can act as stress cracking agents. These substances may penetrate the polymer structure, causing localized swelling and reducing intermolecular forces, ultimately leading to crack initiation and propagation.

Humidity and moisture levels in the environment can also influence UHMWPE's ESCR. While UHMWPE is generally hydrophobic, prolonged exposure to high humidity or direct contact with water can affect its surface properties and potentially impact its resistance to environmental stress cracking.

Mechanical stress is an environmental factor that works in conjunction with other factors to induce stress cracking. The type, magnitude, and duration of applied stress can significantly influence the material's susceptibility to environmental stress cracking. Cyclic loading, for instance, may accelerate the stress cracking process compared to static loading conditions.

Atmospheric pollutants and contaminants can also contribute to the degradation of UHMWPE's ESCR. Ozone, for example, is known to cause oxidative degradation in polymers, potentially leading to surface embrittlement and reduced stress cracking resistance.

The synergistic effects of multiple environmental factors must be considered when evaluating UHMWPE's ESCR. For instance, the combination of elevated temperatures, UV radiation, and chemical exposure may result in more severe degradation than any single factor alone. Understanding these complex interactions is crucial for predicting and improving the long-term performance of UHMWPE in various applications and environments.

Exposure to ultraviolet (UV) radiation is another critical environmental factor. UV radiation can cause photo-oxidation of UHMWPE, leading to chain scission and crosslinking, which may alter the material's mechanical properties and ESCR. The intensity and duration of UV exposure are key parameters in determining the extent of degradation.

Chemical exposure is a significant concern for UHMWPE's ESCR. Certain chemicals, particularly organic solvents and surfactants, can act as stress cracking agents. These substances may penetrate the polymer structure, causing localized swelling and reducing intermolecular forces, ultimately leading to crack initiation and propagation.

Humidity and moisture levels in the environment can also influence UHMWPE's ESCR. While UHMWPE is generally hydrophobic, prolonged exposure to high humidity or direct contact with water can affect its surface properties and potentially impact its resistance to environmental stress cracking.

Mechanical stress is an environmental factor that works in conjunction with other factors to induce stress cracking. The type, magnitude, and duration of applied stress can significantly influence the material's susceptibility to environmental stress cracking. Cyclic loading, for instance, may accelerate the stress cracking process compared to static loading conditions.

Atmospheric pollutants and contaminants can also contribute to the degradation of UHMWPE's ESCR. Ozone, for example, is known to cause oxidative degradation in polymers, potentially leading to surface embrittlement and reduced stress cracking resistance.

The synergistic effects of multiple environmental factors must be considered when evaluating UHMWPE's ESCR. For instance, the combination of elevated temperatures, UV radiation, and chemical exposure may result in more severe degradation than any single factor alone. Understanding these complex interactions is crucial for predicting and improving the long-term performance of UHMWPE in various applications and environments.

Regulatory Landscape

The regulatory landscape surrounding Ultra-High Molecular Weight Polyethylene (UHMWPE) and its environmental stress cracking resistance (ESCR) is complex and multifaceted. Various international and national regulatory bodies have established guidelines and standards to ensure the safety and quality of UHMWPE products, particularly in critical applications such as medical devices and industrial equipment.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating UHMWPE used in medical implants. The FDA has issued guidance documents outlining the testing requirements for UHMWPE materials, including ESCR evaluations. These guidelines emphasize the importance of long-term performance and durability, which are directly related to the material's resistance to environmental stress cracking.

The European Union has implemented the Medical Device Regulation (MDR), which came into full effect in May 2021. This regulation includes stringent requirements for the evaluation and monitoring of medical devices, including those made from UHMWPE. Manufacturers must demonstrate compliance with essential safety and performance requirements, which encompass ESCR properties.

International standards organizations, such as ASTM International and ISO, have developed specific test methods and specifications for assessing the ESCR of UHMWPE. ASTM F2183 and ISO 16428 are examples of standards that provide guidelines for evaluating the resistance of polyethylene materials to environmental stress cracking.

In the industrial sector, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have established guidelines for the safe use of materials in various applications. These guidelines often reference the importance of material properties like ESCR in ensuring the longevity and safety of equipment and components.

Environmental regulations also impact the development and use of UHMWPE. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to assess and manage the risks associated with chemicals used in their products, including those that may affect ESCR properties.

As sustainability becomes an increasingly important focus, regulations are evolving to address the environmental impact of materials throughout their lifecycle. This includes considerations for recycling and disposal of UHMWPE products, which may influence future material development and ESCR requirements.

The regulatory landscape continues to evolve, with a trend towards more stringent requirements and a greater emphasis on long-term performance and safety. Manufacturers and researchers working with UHMWPE must stay abreast of these regulatory changes and adapt their development and testing processes accordingly to ensure compliance and market access.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating UHMWPE used in medical implants. The FDA has issued guidance documents outlining the testing requirements for UHMWPE materials, including ESCR evaluations. These guidelines emphasize the importance of long-term performance and durability, which are directly related to the material's resistance to environmental stress cracking.

The European Union has implemented the Medical Device Regulation (MDR), which came into full effect in May 2021. This regulation includes stringent requirements for the evaluation and monitoring of medical devices, including those made from UHMWPE. Manufacturers must demonstrate compliance with essential safety and performance requirements, which encompass ESCR properties.

International standards organizations, such as ASTM International and ISO, have developed specific test methods and specifications for assessing the ESCR of UHMWPE. ASTM F2183 and ISO 16428 are examples of standards that provide guidelines for evaluating the resistance of polyethylene materials to environmental stress cracking.

In the industrial sector, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have established guidelines for the safe use of materials in various applications. These guidelines often reference the importance of material properties like ESCR in ensuring the longevity and safety of equipment and components.

Environmental regulations also impact the development and use of UHMWPE. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to assess and manage the risks associated with chemicals used in their products, including those that may affect ESCR properties.

As sustainability becomes an increasingly important focus, regulations are evolving to address the environmental impact of materials throughout their lifecycle. This includes considerations for recycling and disposal of UHMWPE products, which may influence future material development and ESCR requirements.

The regulatory landscape continues to evolve, with a trend towards more stringent requirements and a greater emphasis on long-term performance and safety. Manufacturers and researchers working with UHMWPE must stay abreast of these regulatory changes and adapt their development and testing processes accordingly to ensure compliance and market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!