Exploring Vacuum Pump Efficiency in Hybrid Energy Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pumps have been an integral part of industrial processes for over a century, with their evolution closely tied to advancements in manufacturing, research, and energy systems. The journey of vacuum pump technology began in the early 20th century with the development of mechanical pumps, which laid the foundation for more sophisticated designs in subsequent decades.

As industries evolved, so did the demands on vacuum pump technology. The mid-20th century saw the introduction of diffusion pumps and turbomolecular pumps, which significantly improved the achievable vacuum levels and expanded the applications of vacuum technology. These advancements were crucial in supporting the growth of semiconductor manufacturing, aerospace research, and scientific instrumentation.

In recent years, the focus has shifted towards improving energy efficiency and reducing environmental impact. This shift has led to the development of dry vacuum pumps, which eliminate the need for oil and minimize contamination risks. Additionally, the integration of smart technologies and IoT capabilities has enabled better monitoring and control of vacuum systems, further enhancing their efficiency and reliability.

The current technological landscape presents both challenges and opportunities for vacuum pump technology in hybrid energy systems. The primary objective is to optimize energy consumption while maintaining high performance across various operating conditions. This goal necessitates a multifaceted approach, addressing not only the pump design but also its integration within the broader energy ecosystem.

One key objective is to enhance the adaptability of vacuum pumps to fluctuating energy sources, a common characteristic of hybrid systems. This involves developing intelligent control systems that can dynamically adjust pump operation based on available energy and system demands. Another critical aim is to improve the overall system efficiency by minimizing energy losses and maximizing heat recovery from pump operations.

Furthermore, there is a growing emphasis on developing vacuum pumps that can operate effectively with renewable energy sources. This objective aligns with the global push towards sustainable energy solutions and presents an opportunity to reduce the carbon footprint of industrial processes that rely on vacuum technology.

The exploration of novel materials and manufacturing techniques also plays a crucial role in advancing vacuum pump technology. Objectives in this area include reducing pump weight, improving durability, and enhancing thermal management capabilities. These advancements are essential for creating more compact and efficient pumps suitable for integration into complex hybrid energy systems.

As we look towards the future, the evolution of vacuum pump technology in hybrid energy systems will likely focus on achieving higher levels of integration, intelligence, and sustainability. The objectives will continue to revolve around maximizing energy efficiency, minimizing environmental impact, and enhancing overall system performance to meet the growing demands of various industries relying on vacuum technology.

As industries evolved, so did the demands on vacuum pump technology. The mid-20th century saw the introduction of diffusion pumps and turbomolecular pumps, which significantly improved the achievable vacuum levels and expanded the applications of vacuum technology. These advancements were crucial in supporting the growth of semiconductor manufacturing, aerospace research, and scientific instrumentation.

In recent years, the focus has shifted towards improving energy efficiency and reducing environmental impact. This shift has led to the development of dry vacuum pumps, which eliminate the need for oil and minimize contamination risks. Additionally, the integration of smart technologies and IoT capabilities has enabled better monitoring and control of vacuum systems, further enhancing their efficiency and reliability.

The current technological landscape presents both challenges and opportunities for vacuum pump technology in hybrid energy systems. The primary objective is to optimize energy consumption while maintaining high performance across various operating conditions. This goal necessitates a multifaceted approach, addressing not only the pump design but also its integration within the broader energy ecosystem.

One key objective is to enhance the adaptability of vacuum pumps to fluctuating energy sources, a common characteristic of hybrid systems. This involves developing intelligent control systems that can dynamically adjust pump operation based on available energy and system demands. Another critical aim is to improve the overall system efficiency by minimizing energy losses and maximizing heat recovery from pump operations.

Furthermore, there is a growing emphasis on developing vacuum pumps that can operate effectively with renewable energy sources. This objective aligns with the global push towards sustainable energy solutions and presents an opportunity to reduce the carbon footprint of industrial processes that rely on vacuum technology.

The exploration of novel materials and manufacturing techniques also plays a crucial role in advancing vacuum pump technology. Objectives in this area include reducing pump weight, improving durability, and enhancing thermal management capabilities. These advancements are essential for creating more compact and efficient pumps suitable for integration into complex hybrid energy systems.

As we look towards the future, the evolution of vacuum pump technology in hybrid energy systems will likely focus on achieving higher levels of integration, intelligence, and sustainability. The objectives will continue to revolve around maximizing energy efficiency, minimizing environmental impact, and enhancing overall system performance to meet the growing demands of various industries relying on vacuum technology.

Hybrid Energy Market Analysis

The hybrid energy market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for sustainable and efficient energy solutions. This market encompasses a wide range of technologies that combine multiple energy sources, such as solar, wind, and conventional fossil fuels, to create more reliable and cost-effective power systems. The integration of vacuum pump technology in these hybrid systems has emerged as a crucial factor in enhancing overall efficiency and performance.

Market demand for hybrid energy systems has been steadily rising, with a particular focus on applications in remote areas, industrial facilities, and grid-connected installations. The global hybrid energy market size was valued at approximately $26 billion in 2020 and is projected to reach $57 billion by 2026, growing at a CAGR of 14% during the forecast period. This growth is primarily attributed to the increasing need for reliable power supply, rising environmental concerns, and government initiatives promoting clean energy adoption.

The vacuum pump segment within the hybrid energy market is expected to witness substantial growth, driven by its critical role in improving system efficiency and reducing energy consumption. Vacuum pumps are essential components in various hybrid energy applications, including energy storage systems, power generation, and industrial processes. The market for vacuum pumps in hybrid energy systems is estimated to grow at a CAGR of 8% from 2021 to 2026, reaching a value of $3.5 billion by the end of the forecast period.

Key factors driving the demand for efficient vacuum pumps in hybrid energy systems include the need for improved energy conversion efficiency, reduced maintenance costs, and enhanced system reliability. Industries such as power generation, oil and gas, and manufacturing are increasingly adopting hybrid energy solutions that incorporate advanced vacuum pump technologies to optimize their operations and reduce environmental impact.

The market landscape for hybrid energy systems is characterized by intense competition and rapid technological advancements. Major players in this sector are investing heavily in research and development to improve the efficiency and performance of their products, with a particular focus on integrating smart technologies and IoT capabilities. The vacuum pump segment within this market is witnessing a trend towards the development of more compact, energy-efficient, and environmentally friendly solutions.

Geographically, North America and Europe currently dominate the hybrid energy market, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and government initiatives promoting clean energy adoption. Emerging economies such as China and India are expected to be key growth drivers for the hybrid energy market, including the vacuum pump segment.

Market demand for hybrid energy systems has been steadily rising, with a particular focus on applications in remote areas, industrial facilities, and grid-connected installations. The global hybrid energy market size was valued at approximately $26 billion in 2020 and is projected to reach $57 billion by 2026, growing at a CAGR of 14% during the forecast period. This growth is primarily attributed to the increasing need for reliable power supply, rising environmental concerns, and government initiatives promoting clean energy adoption.

The vacuum pump segment within the hybrid energy market is expected to witness substantial growth, driven by its critical role in improving system efficiency and reducing energy consumption. Vacuum pumps are essential components in various hybrid energy applications, including energy storage systems, power generation, and industrial processes. The market for vacuum pumps in hybrid energy systems is estimated to grow at a CAGR of 8% from 2021 to 2026, reaching a value of $3.5 billion by the end of the forecast period.

Key factors driving the demand for efficient vacuum pumps in hybrid energy systems include the need for improved energy conversion efficiency, reduced maintenance costs, and enhanced system reliability. Industries such as power generation, oil and gas, and manufacturing are increasingly adopting hybrid energy solutions that incorporate advanced vacuum pump technologies to optimize their operations and reduce environmental impact.

The market landscape for hybrid energy systems is characterized by intense competition and rapid technological advancements. Major players in this sector are investing heavily in research and development to improve the efficiency and performance of their products, with a particular focus on integrating smart technologies and IoT capabilities. The vacuum pump segment within this market is witnessing a trend towards the development of more compact, energy-efficient, and environmentally friendly solutions.

Geographically, North America and Europe currently dominate the hybrid energy market, accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and government initiatives promoting clean energy adoption. Emerging economies such as China and India are expected to be key growth drivers for the hybrid energy market, including the vacuum pump segment.

Vacuum Pump Challenges in Hybrid Systems

Vacuum pumps play a crucial role in hybrid energy systems, but their integration presents several significant challenges. One of the primary issues is maintaining optimal efficiency across varying operational conditions. Hybrid systems often experience fluctuating energy demands and supply, which can lead to inconsistent vacuum levels and reduced pump performance.

The complexity of hybrid energy systems also poses a challenge for vacuum pump integration. These systems typically combine multiple energy sources, such as solar, wind, and conventional fuels, each with its own operational characteristics. Coordinating vacuum pump operation with these diverse energy inputs requires sophisticated control systems and algorithms, which can be difficult to design and implement effectively.

Energy efficiency is another major concern in hybrid systems. Vacuum pumps are energy-intensive components, and their power consumption can significantly impact the overall system efficiency. Balancing the energy requirements of vacuum pumps with the available renewable energy sources is a delicate task that requires careful optimization and management.

Reliability and durability of vacuum pumps in hybrid environments present additional challenges. The intermittent nature of renewable energy sources can lead to frequent start-stop cycles for vacuum pumps, potentially increasing wear and tear on components. This can result in higher maintenance requirements and reduced equipment lifespan, impacting the long-term viability of the hybrid system.

Furthermore, the diverse operating conditions in hybrid systems can expose vacuum pumps to a wide range of temperatures, pressures, and contaminants. Designing pumps that can maintain performance and reliability across these varied conditions is a significant engineering challenge. This often necessitates the development of specialized materials, coatings, and sealing technologies to ensure pump longevity and efficiency.

Scalability is another critical challenge for vacuum pumps in hybrid systems. As these systems grow in size and complexity, scaling up vacuum pump capacity while maintaining efficiency and reliability becomes increasingly difficult. This is particularly true when attempting to integrate larger vacuum systems with renewable energy sources that may have inherent limitations in terms of power output and consistency.

Lastly, the cost-effectiveness of vacuum pump integration in hybrid systems remains a significant hurdle. While hybrid energy systems offer potential long-term benefits, the initial capital costs for high-efficiency, durable vacuum pumps can be substantial. Balancing these upfront investments against the expected energy savings and system performance improvements is a complex economic challenge that requires careful analysis and planning.

The complexity of hybrid energy systems also poses a challenge for vacuum pump integration. These systems typically combine multiple energy sources, such as solar, wind, and conventional fuels, each with its own operational characteristics. Coordinating vacuum pump operation with these diverse energy inputs requires sophisticated control systems and algorithms, which can be difficult to design and implement effectively.

Energy efficiency is another major concern in hybrid systems. Vacuum pumps are energy-intensive components, and their power consumption can significantly impact the overall system efficiency. Balancing the energy requirements of vacuum pumps with the available renewable energy sources is a delicate task that requires careful optimization and management.

Reliability and durability of vacuum pumps in hybrid environments present additional challenges. The intermittent nature of renewable energy sources can lead to frequent start-stop cycles for vacuum pumps, potentially increasing wear and tear on components. This can result in higher maintenance requirements and reduced equipment lifespan, impacting the long-term viability of the hybrid system.

Furthermore, the diverse operating conditions in hybrid systems can expose vacuum pumps to a wide range of temperatures, pressures, and contaminants. Designing pumps that can maintain performance and reliability across these varied conditions is a significant engineering challenge. This often necessitates the development of specialized materials, coatings, and sealing technologies to ensure pump longevity and efficiency.

Scalability is another critical challenge for vacuum pumps in hybrid systems. As these systems grow in size and complexity, scaling up vacuum pump capacity while maintaining efficiency and reliability becomes increasingly difficult. This is particularly true when attempting to integrate larger vacuum systems with renewable energy sources that may have inherent limitations in terms of power output and consistency.

Lastly, the cost-effectiveness of vacuum pump integration in hybrid systems remains a significant hurdle. While hybrid energy systems offer potential long-term benefits, the initial capital costs for high-efficiency, durable vacuum pumps can be substantial. Balancing these upfront investments against the expected energy savings and system performance improvements is a complex economic challenge that requires careful analysis and planning.

Current Vacuum Pump Solutions

01 Improved rotor design for vacuum pumps

Enhancing the rotor design in vacuum pumps can significantly increase efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, improve sealing, and maximize pumping capacity. Advanced rotor designs can lead to better performance and energy efficiency in vacuum systems.- Improved rotor design for vacuum pumps: Enhancing the rotor design in vacuum pumps can significantly improve efficiency. This includes optimizing the shape, material, and configuration of the rotor to reduce friction, minimize energy loss, and increase pumping capacity. Advanced rotor designs can also help in reducing wear and extending the pump's lifespan.

- Innovative sealing mechanisms: Developing new sealing mechanisms or improving existing ones can greatly enhance vacuum pump efficiency. These innovations focus on reducing leakage, minimizing friction between moving parts, and maintaining optimal pressure differentials. Advanced sealing technologies can contribute to better vacuum quality and reduced power consumption.

- Integration of smart control systems: Incorporating smart control systems and sensors into vacuum pumps can optimize their operation in real-time. These systems can adjust pump parameters based on load conditions, monitor performance, and predict maintenance needs. This results in improved energy efficiency, reduced downtime, and extended equipment life.

- Advanced cooling and lubrication techniques: Implementing innovative cooling and lubrication methods can significantly enhance vacuum pump efficiency. This includes developing new coolant formulations, optimizing lubrication systems, and designing better heat dissipation mechanisms. These advancements help reduce friction, prevent overheating, and maintain optimal operating conditions.

- Multi-stage and hybrid pump designs: Developing multi-stage or hybrid vacuum pump designs can improve overall system efficiency. These configurations combine different pumping mechanisms or stages to achieve higher vacuum levels and better performance across a wide range of operating conditions. Such designs can offer improved energy efficiency and versatility in various applications.

02 Multi-stage vacuum pump systems

Implementing multi-stage vacuum pump systems can improve overall efficiency. By combining different types of pumps or multiple pumping stages, these systems can achieve higher vacuum levels and better performance across a wider range of operating conditions. This approach allows for optimized energy consumption and improved pumping speed.Expand Specific Solutions03 Advanced sealing technologies

Incorporating advanced sealing technologies in vacuum pumps can significantly enhance their efficiency. This includes the use of innovative materials and designs for gaskets, O-rings, and other sealing components to minimize leakage and maintain high vacuum levels. Improved sealing can lead to better pump performance and reduced energy consumption.Expand Specific Solutions04 Intelligent control systems for vacuum pumps

Implementing intelligent control systems can optimize vacuum pump operation and efficiency. These systems use sensors, algorithms, and adaptive controls to adjust pump parameters based on real-time conditions. This results in improved energy efficiency, reduced wear, and enhanced overall performance of the vacuum system.Expand Specific Solutions05 Heat management and energy recovery in vacuum pumps

Improving heat management and implementing energy recovery systems can boost vacuum pump efficiency. This includes designing better cooling mechanisms, using heat-resistant materials, and incorporating systems to capture and reuse waste heat. These approaches can lead to reduced energy consumption and improved pump longevity.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump efficiency market in hybrid energy systems is in a growth phase, driven by increasing demand for energy-efficient solutions. The market size is expanding, with major players like LEYBOLD AG, Edwards Ltd., and Robert Bosch GmbH leading technological advancements. These companies are investing heavily in R&D to improve pump efficiency and reduce energy consumption. The technology is maturing rapidly, with innovations in materials and design enhancing performance. Emerging players such as HYDAC Technology GmbH and BDR Thermea Group BV are also contributing to market competitiveness, focusing on specialized applications and niche markets. As sustainability becomes a key focus, the industry is seeing a shift towards more environmentally friendly and energy-efficient vacuum pump solutions.

LEYBOLD AG

Technical Solution: LEYBOLD AG has developed advanced vacuum pump technologies for hybrid energy systems, focusing on improving efficiency and reducing energy consumption. Their DRYVAC series of dry screw vacuum pumps incorporates intelligent control systems and optimized rotor designs to achieve high pumping speeds with minimal power input[1]. The company has also introduced the VARODRY series, which utilizes a variable frequency drive to adjust pump speed based on process demands, resulting in energy savings of up to 50% compared to conventional pumps[2]. LEYBOLD's innovative sealing technology and bearing designs contribute to extended maintenance intervals and reduced lifecycle costs[3].

Strengths: High energy efficiency, intelligent control systems, and extended maintenance intervals. Weaknesses: Higher initial investment costs compared to traditional vacuum pumps.

Edwards Ltd.

Technical Solution: Edwards Ltd. has made significant strides in vacuum pump efficiency for hybrid energy systems. Their GXS dry screw pump series utilizes advanced screw technology and optimized motor control to achieve high pumping speeds with reduced power consumption[4]. The company's nEXT turbomolecular pumps incorporate a unique bearing design and advanced rotor materials, enabling higher speeds and improved pumping performance in compact sizes[5]. Edwards has also developed the iXH series of dry pumps, which feature a novel tapered screw design and intelligent control system, resulting in up to 30% energy savings compared to previous generations[6].

Strengths: Advanced screw technology, compact designs, and significant energy savings. Weaknesses: May require specialized maintenance and higher upfront costs.

Innovative Vacuum Pump Designs

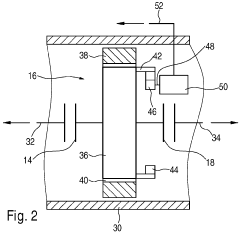

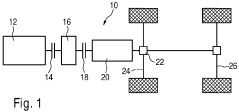

Vacuum generation in hybrid-drive vehicles

PatentWO2008015048A1

Innovation

- A variable volume flow vacuum pump, such as an adjustable axial piston pump, is driven by the electric machine, ensuring a consistent vacuum supply to the brake booster while avoiding permanent energy consumption, and an additional electrically operated vacuum pump can be used for low-speed driving to maintain basic vacuum levels.

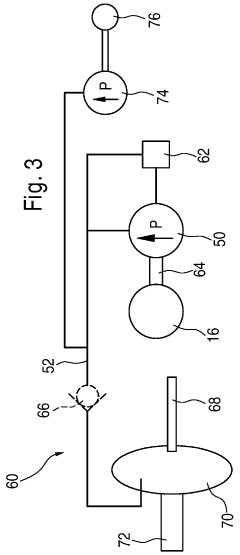

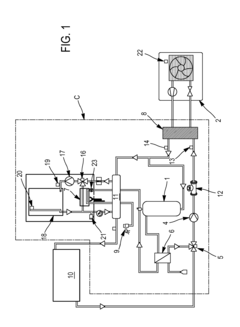

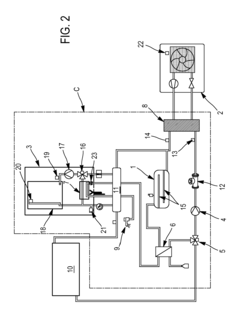

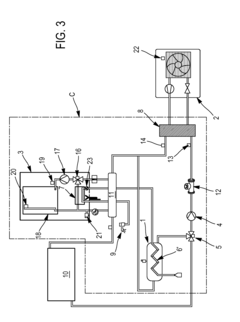

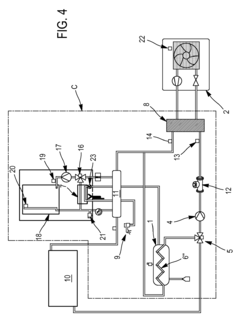

Hybrid system for producing domestic hot water with a heat pump and a boiler

PatentActiveEP2700883A1

Innovation

- A hybrid system combining a boiler and a heat pump, with a bypass branch and additional exchanger that integrates the heat pump into the domestic hot water production circuit, allowing for efficient energy use and compact installation by utilizing the heat pump's energy for both heating and domestic hot water production.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the development and implementation of vacuum pump technologies in hybrid energy systems. These regulations are designed to promote energy conservation, reduce greenhouse gas emissions, and drive innovation in the energy sector. In the context of vacuum pump efficiency, several key regulatory frameworks have been established globally to address energy consumption and performance standards.

The European Union's Ecodesign Directive (2009/125/EC) has been particularly influential in setting energy efficiency requirements for vacuum pumps. This directive mandates minimum efficiency standards for various industrial equipment, including vacuum pumps used in hybrid energy systems. Manufacturers are required to meet specific energy efficiency index (EEI) values, which are calculated based on the pump's power consumption and performance characteristics.

In the United States, the Department of Energy (DOE) has implemented energy conservation standards for certain types of pumps under the Energy Policy and Conservation Act (EPCA). While these standards do not explicitly cover all vacuum pumps used in hybrid energy systems, they have set a precedent for energy efficiency regulations in the pump industry. The DOE continues to evaluate the potential for expanding these standards to include a broader range of pump technologies.

China, as a major player in the global energy market, has also introduced energy efficiency regulations that impact vacuum pump technologies. The China Energy Label program, established under the Energy Conservation Law, requires manufacturers to disclose energy consumption information for various products, including certain types of pumps. This initiative aims to promote energy-efficient technologies and inform consumers about the energy performance of different products.

International standards, such as ISO 50001 for energy management systems, have further influenced the development of energy-efficient vacuum pump technologies. While not specific to vacuum pumps, these standards provide a framework for organizations to continuously improve their energy performance, which often leads to the adoption of more efficient pump technologies in hybrid energy systems.

The impact of these regulations on vacuum pump efficiency in hybrid energy systems has been significant. Manufacturers have been driven to invest in research and development to create more energy-efficient pump designs, incorporating advanced materials, improved sealing technologies, and optimized control systems. This has resulted in a new generation of vacuum pumps that consume less energy while maintaining or improving performance characteristics.

As energy efficiency regulations continue to evolve, it is expected that vacuum pump technologies will face increasingly stringent requirements. Future regulations may focus on lifecycle energy consumption, including manufacturing processes and end-of-life recycling. Additionally, there is a growing trend towards harmonizing energy efficiency standards across different regions, which could lead to more consistent global requirements for vacuum pump efficiency in hybrid energy systems.

The European Union's Ecodesign Directive (2009/125/EC) has been particularly influential in setting energy efficiency requirements for vacuum pumps. This directive mandates minimum efficiency standards for various industrial equipment, including vacuum pumps used in hybrid energy systems. Manufacturers are required to meet specific energy efficiency index (EEI) values, which are calculated based on the pump's power consumption and performance characteristics.

In the United States, the Department of Energy (DOE) has implemented energy conservation standards for certain types of pumps under the Energy Policy and Conservation Act (EPCA). While these standards do not explicitly cover all vacuum pumps used in hybrid energy systems, they have set a precedent for energy efficiency regulations in the pump industry. The DOE continues to evaluate the potential for expanding these standards to include a broader range of pump technologies.

China, as a major player in the global energy market, has also introduced energy efficiency regulations that impact vacuum pump technologies. The China Energy Label program, established under the Energy Conservation Law, requires manufacturers to disclose energy consumption information for various products, including certain types of pumps. This initiative aims to promote energy-efficient technologies and inform consumers about the energy performance of different products.

International standards, such as ISO 50001 for energy management systems, have further influenced the development of energy-efficient vacuum pump technologies. While not specific to vacuum pumps, these standards provide a framework for organizations to continuously improve their energy performance, which often leads to the adoption of more efficient pump technologies in hybrid energy systems.

The impact of these regulations on vacuum pump efficiency in hybrid energy systems has been significant. Manufacturers have been driven to invest in research and development to create more energy-efficient pump designs, incorporating advanced materials, improved sealing technologies, and optimized control systems. This has resulted in a new generation of vacuum pumps that consume less energy while maintaining or improving performance characteristics.

As energy efficiency regulations continue to evolve, it is expected that vacuum pump technologies will face increasingly stringent requirements. Future regulations may focus on lifecycle energy consumption, including manufacturing processes and end-of-life recycling. Additionally, there is a growing trend towards harmonizing energy efficiency standards across different regions, which could lead to more consistent global requirements for vacuum pump efficiency in hybrid energy systems.

Environmental Impact Assessment

The environmental impact assessment of vacuum pump efficiency in hybrid energy systems is a critical aspect of evaluating the overall sustainability and ecological footprint of these advanced energy solutions. Vacuum pumps play a crucial role in various components of hybrid energy systems, particularly in maintaining optimal pressure conditions for efficient energy conversion and storage processes.

One of the primary environmental considerations is the energy consumption of vacuum pumps themselves. Improved efficiency in vacuum pump operation directly translates to reduced energy demand, which in turn lowers the overall carbon footprint of the hybrid energy system. This reduction in energy consumption contributes to decreased greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

The use of more efficient vacuum pumps also leads to a reduction in waste heat generation. This not only improves the overall system efficiency but also minimizes the thermal impact on the surrounding environment. Lower heat emissions can help mitigate local temperature increases and reduce the need for additional cooling systems, further conserving energy and resources.

Another significant environmental aspect is the potential for reduced material usage and extended equipment lifespan. Higher efficiency vacuum pumps often require less frequent maintenance and replacement, resulting in decreased consumption of raw materials and reduced waste generation over the system's lifecycle. This contributes to resource conservation and minimizes the environmental impact associated with manufacturing and disposal processes.

The noise pollution generated by vacuum pumps is an often-overlooked environmental concern. More efficient pumps typically operate with lower noise levels, reducing the acoustic impact on both human operators and local ecosystems. This is particularly important in urban or sensitive environmental settings where noise regulations may be stringent.

Furthermore, the improved efficiency of vacuum pumps can lead to enhanced overall performance of hybrid energy systems. This increased efficiency allows for better utilization of renewable energy sources, potentially reducing reliance on fossil fuels and further decreasing the system's environmental footprint. The ability to operate more effectively with intermittent renewable energy sources contributes to the broader goal of transitioning to cleaner energy production methods.

Lastly, the environmental impact assessment should consider the potential for reduced chemical usage in vacuum pump systems. More efficient pumps may require less lubricant or coolant, minimizing the risk of chemical leaks and reducing the environmental hazards associated with the handling and disposal of these substances. This aspect is particularly relevant in sensitive environments or applications where contamination risks must be carefully managed.

One of the primary environmental considerations is the energy consumption of vacuum pumps themselves. Improved efficiency in vacuum pump operation directly translates to reduced energy demand, which in turn lowers the overall carbon footprint of the hybrid energy system. This reduction in energy consumption contributes to decreased greenhouse gas emissions associated with power generation, aligning with global efforts to combat climate change.

The use of more efficient vacuum pumps also leads to a reduction in waste heat generation. This not only improves the overall system efficiency but also minimizes the thermal impact on the surrounding environment. Lower heat emissions can help mitigate local temperature increases and reduce the need for additional cooling systems, further conserving energy and resources.

Another significant environmental aspect is the potential for reduced material usage and extended equipment lifespan. Higher efficiency vacuum pumps often require less frequent maintenance and replacement, resulting in decreased consumption of raw materials and reduced waste generation over the system's lifecycle. This contributes to resource conservation and minimizes the environmental impact associated with manufacturing and disposal processes.

The noise pollution generated by vacuum pumps is an often-overlooked environmental concern. More efficient pumps typically operate with lower noise levels, reducing the acoustic impact on both human operators and local ecosystems. This is particularly important in urban or sensitive environmental settings where noise regulations may be stringent.

Furthermore, the improved efficiency of vacuum pumps can lead to enhanced overall performance of hybrid energy systems. This increased efficiency allows for better utilization of renewable energy sources, potentially reducing reliance on fossil fuels and further decreasing the system's environmental footprint. The ability to operate more effectively with intermittent renewable energy sources contributes to the broader goal of transitioning to cleaner energy production methods.

Lastly, the environmental impact assessment should consider the potential for reduced chemical usage in vacuum pump systems. More efficient pumps may require less lubricant or coolant, minimizing the risk of chemical leaks and reducing the environmental hazards associated with the handling and disposal of these substances. This aspect is particularly relevant in sensitive environments or applications where contamination risks must be carefully managed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!