Exploring Vacuum Pump Utilization in High-Purity Silicon Carbide Production

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Production Background and Objectives

Silicon carbide (SiC) has emerged as a critical material in the semiconductor industry, particularly for power electronics applications. The production of high-purity SiC has become increasingly important due to its superior properties compared to traditional silicon-based semiconductors. This technological evolution has been driven by the growing demand for more efficient and robust electronic devices in various sectors, including automotive, renewable energy, and industrial applications.

The development of SiC production techniques has a rich history dating back to the late 19th century when it was first synthesized by Edward Goodrich Acheson. However, it wasn't until the late 20th and early 21st centuries that significant advancements were made in producing high-purity SiC suitable for semiconductor applications. The primary methods for SiC production have evolved from the original Acheson process to more sophisticated techniques such as physical vapor transport (PVT) and chemical vapor deposition (CVD).

In recent years, the focus has shifted towards improving the quality and purity of SiC crystals while increasing production efficiency and reducing costs. This has led to the exploration of various innovative approaches, including the utilization of vacuum pumps in the production process. The integration of vacuum technology aims to address several key challenges in SiC production, such as controlling impurities, enhancing crystal growth uniformity, and improving overall yield.

The primary objective of exploring vacuum pump utilization in high-purity SiC production is to achieve higher material quality while optimizing production efficiency. By creating a controlled environment with precise pressure regulation, vacuum pumps can potentially minimize contamination and enable better control over the crystal growth process. This, in turn, could lead to the production of SiC wafers with fewer defects and higher purity levels, which are crucial for the performance of advanced semiconductor devices.

Furthermore, the implementation of vacuum technology in SiC production aligns with the broader industry trend towards more sustainable and environmentally friendly manufacturing processes. Vacuum-based systems can potentially reduce energy consumption and minimize waste generation compared to traditional production methods. This aspect is particularly relevant given the increasing emphasis on sustainable practices in the semiconductor industry.

As the demand for SiC-based devices continues to grow, driven by applications in electric vehicles, 5G infrastructure, and renewable energy systems, the need for advanced production techniques becomes more pressing. The exploration of vacuum pump utilization represents a promising avenue for addressing these market demands and pushing the boundaries of SiC production capabilities. By focusing on this technological approach, researchers and manufacturers aim to overcome current limitations and pave the way for the next generation of high-performance SiC-based semiconductor devices.

The development of SiC production techniques has a rich history dating back to the late 19th century when it was first synthesized by Edward Goodrich Acheson. However, it wasn't until the late 20th and early 21st centuries that significant advancements were made in producing high-purity SiC suitable for semiconductor applications. The primary methods for SiC production have evolved from the original Acheson process to more sophisticated techniques such as physical vapor transport (PVT) and chemical vapor deposition (CVD).

In recent years, the focus has shifted towards improving the quality and purity of SiC crystals while increasing production efficiency and reducing costs. This has led to the exploration of various innovative approaches, including the utilization of vacuum pumps in the production process. The integration of vacuum technology aims to address several key challenges in SiC production, such as controlling impurities, enhancing crystal growth uniformity, and improving overall yield.

The primary objective of exploring vacuum pump utilization in high-purity SiC production is to achieve higher material quality while optimizing production efficiency. By creating a controlled environment with precise pressure regulation, vacuum pumps can potentially minimize contamination and enable better control over the crystal growth process. This, in turn, could lead to the production of SiC wafers with fewer defects and higher purity levels, which are crucial for the performance of advanced semiconductor devices.

Furthermore, the implementation of vacuum technology in SiC production aligns with the broader industry trend towards more sustainable and environmentally friendly manufacturing processes. Vacuum-based systems can potentially reduce energy consumption and minimize waste generation compared to traditional production methods. This aspect is particularly relevant given the increasing emphasis on sustainable practices in the semiconductor industry.

As the demand for SiC-based devices continues to grow, driven by applications in electric vehicles, 5G infrastructure, and renewable energy systems, the need for advanced production techniques becomes more pressing. The exploration of vacuum pump utilization represents a promising avenue for addressing these market demands and pushing the boundaries of SiC production capabilities. By focusing on this technological approach, researchers and manufacturers aim to overcome current limitations and pave the way for the next generation of high-performance SiC-based semiconductor devices.

Market Analysis for High-Purity SiC

The high-purity silicon carbide (SiC) market has experienced significant growth in recent years, driven by increasing demand across various industries. The automotive sector, particularly electric vehicles, has emerged as a key driver for high-purity SiC adoption. The material's superior properties, including wide bandgap, high thermal conductivity, and high breakdown electric field strength, make it ideal for power electronics applications in electric vehicles.

The semiconductor industry also contributes substantially to the market demand for high-purity SiC. As the need for more efficient and powerful electronic devices continues to grow, SiC-based semiconductors are becoming increasingly popular due to their ability to operate at higher temperatures and voltages compared to traditional silicon-based semiconductors.

The renewable energy sector, especially solar and wind power generation, represents another significant market for high-purity SiC. The material's high efficiency in power conversion and its ability to withstand harsh environmental conditions make it valuable for inverters and other power management systems in renewable energy installations.

Aerospace and defense industries are also driving demand for high-purity SiC, particularly in radar systems, satellite communications, and high-temperature sensors. The material's radiation resistance and stability under extreme conditions make it well-suited for these applications.

Market analysts project robust growth for the high-purity SiC market in the coming years. The global market size is expected to expand at a compound annual growth rate (CAGR) in the double digits through 2028. This growth is attributed to the increasing adoption of SiC in power electronics, the rapid expansion of the electric vehicle market, and the ongoing transition to renewable energy sources.

Geographically, Asia-Pacific is anticipated to be the fastest-growing region for high-purity SiC, driven by the strong presence of semiconductor manufacturers and the rapid growth of the electric vehicle market in countries like China, Japan, and South Korea. North America and Europe are also expected to maintain significant market shares due to their advanced automotive and aerospace industries.

The market landscape is characterized by intense competition among key players, including established semiconductor manufacturers and specialized SiC producers. These companies are investing heavily in research and development to improve production processes, reduce costs, and enhance the quality of high-purity SiC. As a result, technological advancements and economies of scale are expected to gradually lower the production costs of high-purity SiC, potentially expanding its application in more price-sensitive markets.

The semiconductor industry also contributes substantially to the market demand for high-purity SiC. As the need for more efficient and powerful electronic devices continues to grow, SiC-based semiconductors are becoming increasingly popular due to their ability to operate at higher temperatures and voltages compared to traditional silicon-based semiconductors.

The renewable energy sector, especially solar and wind power generation, represents another significant market for high-purity SiC. The material's high efficiency in power conversion and its ability to withstand harsh environmental conditions make it valuable for inverters and other power management systems in renewable energy installations.

Aerospace and defense industries are also driving demand for high-purity SiC, particularly in radar systems, satellite communications, and high-temperature sensors. The material's radiation resistance and stability under extreme conditions make it well-suited for these applications.

Market analysts project robust growth for the high-purity SiC market in the coming years. The global market size is expected to expand at a compound annual growth rate (CAGR) in the double digits through 2028. This growth is attributed to the increasing adoption of SiC in power electronics, the rapid expansion of the electric vehicle market, and the ongoing transition to renewable energy sources.

Geographically, Asia-Pacific is anticipated to be the fastest-growing region for high-purity SiC, driven by the strong presence of semiconductor manufacturers and the rapid growth of the electric vehicle market in countries like China, Japan, and South Korea. North America and Europe are also expected to maintain significant market shares due to their advanced automotive and aerospace industries.

The market landscape is characterized by intense competition among key players, including established semiconductor manufacturers and specialized SiC producers. These companies are investing heavily in research and development to improve production processes, reduce costs, and enhance the quality of high-purity SiC. As a result, technological advancements and economies of scale are expected to gradually lower the production costs of high-purity SiC, potentially expanding its application in more price-sensitive markets.

Vacuum Pump Technology in SiC Production

Vacuum pump technology plays a crucial role in the production of high-purity silicon carbide (SiC), a material with increasing importance in various industries. The utilization of vacuum pumps in SiC production processes has evolved significantly over the years, driven by the demand for higher purity levels and improved production efficiency.

In the early stages of SiC production, basic mechanical pumps were employed to create low-pressure environments. These pumps, while effective for initial applications, had limitations in achieving the ultra-high vacuum levels required for modern high-purity SiC production. The introduction of oil-sealed rotary vane pumps marked a significant improvement, allowing for lower pressures and better contamination control.

As the semiconductor industry's demands for SiC increased, more advanced vacuum pump technologies were developed. Turbomolecular pumps, introduced in the 1960s, revolutionized the field by enabling the achievement of much higher vacuum levels. These pumps operate on the principle of momentum transfer, allowing for the efficient removal of gas molecules from the production chamber.

The 1980s and 1990s saw the emergence of dry pumps, which eliminated the need for oil in the pumping mechanism. This innovation was particularly important for SiC production, as it significantly reduced the risk of contamination from pump oil vapors. Dry screw pumps and multi-stage Roots pumps became popular choices for SiC manufacturing processes.

In recent years, the focus has shifted towards developing vacuum pump systems that offer not only high performance but also energy efficiency and reliability. Hybrid pumping systems, combining different pump technologies, have been introduced to optimize vacuum performance across various pressure ranges encountered in SiC production.

The latest advancements in vacuum pump technology for SiC production include the integration of smart sensors and control systems. These innovations allow for real-time monitoring and adjustment of pumping parameters, ensuring optimal performance and energy efficiency throughout the production process. Additionally, the development of corrosion-resistant materials and coatings has extended the lifespan of pumps exposed to the harsh chemicals often used in SiC production.

Looking forward, the trend in vacuum pump technology for SiC production is moving towards more compact, energy-efficient, and environmentally friendly designs. Research is ongoing to develop pumps with higher pumping speeds and lower ultimate pressures, which will enable the production of even higher purity SiC materials. The integration of Industry 4.0 concepts, such as predictive maintenance and IoT connectivity, is also expected to play a significant role in the future of vacuum pump technology in SiC production.

In the early stages of SiC production, basic mechanical pumps were employed to create low-pressure environments. These pumps, while effective for initial applications, had limitations in achieving the ultra-high vacuum levels required for modern high-purity SiC production. The introduction of oil-sealed rotary vane pumps marked a significant improvement, allowing for lower pressures and better contamination control.

As the semiconductor industry's demands for SiC increased, more advanced vacuum pump technologies were developed. Turbomolecular pumps, introduced in the 1960s, revolutionized the field by enabling the achievement of much higher vacuum levels. These pumps operate on the principle of momentum transfer, allowing for the efficient removal of gas molecules from the production chamber.

The 1980s and 1990s saw the emergence of dry pumps, which eliminated the need for oil in the pumping mechanism. This innovation was particularly important for SiC production, as it significantly reduced the risk of contamination from pump oil vapors. Dry screw pumps and multi-stage Roots pumps became popular choices for SiC manufacturing processes.

In recent years, the focus has shifted towards developing vacuum pump systems that offer not only high performance but also energy efficiency and reliability. Hybrid pumping systems, combining different pump technologies, have been introduced to optimize vacuum performance across various pressure ranges encountered in SiC production.

The latest advancements in vacuum pump technology for SiC production include the integration of smart sensors and control systems. These innovations allow for real-time monitoring and adjustment of pumping parameters, ensuring optimal performance and energy efficiency throughout the production process. Additionally, the development of corrosion-resistant materials and coatings has extended the lifespan of pumps exposed to the harsh chemicals often used in SiC production.

Looking forward, the trend in vacuum pump technology for SiC production is moving towards more compact, energy-efficient, and environmentally friendly designs. Research is ongoing to develop pumps with higher pumping speeds and lower ultimate pressures, which will enable the production of even higher purity SiC materials. The integration of Industry 4.0 concepts, such as predictive maintenance and IoT connectivity, is also expected to play a significant role in the future of vacuum pump technology in SiC production.

Current Vacuum Pump Solutions for SiC Purification

01 High-purity vacuum pump systems

Advanced vacuum pump systems designed to achieve and maintain high levels of purity in various industrial and scientific applications. These systems often incorporate specialized components and materials to minimize contamination and ensure consistent performance in demanding environments.- High-purity vacuum pump systems: Advanced vacuum pump systems designed to achieve and maintain high levels of purity in various industrial and scientific applications. These systems often incorporate specialized components and materials to minimize contamination and ensure optimal performance in demanding environments.

- Vacuum pump purification techniques: Methods and technologies for purifying vacuum pumps to enhance their performance and longevity. This includes techniques for removing contaminants, improving gas handling capabilities, and maintaining cleanliness within the pump system to ensure consistent high-purity operation.

- Specialized vacuum pumps for ultra-high purity applications: Vacuum pumps specifically designed for ultra-high purity requirements in industries such as semiconductor manufacturing, pharmaceuticals, and advanced research. These pumps often feature innovative designs and materials to minimize outgassing and particle generation.

- Vacuum pump monitoring and control systems: Advanced monitoring and control systems for vacuum pumps to ensure consistent purity levels. These systems may include real-time sensors, automated purge cycles, and intelligent control algorithms to maintain optimal performance and detect potential contamination issues.

- Vacuum pump filtration and trapping technologies: Innovative filtration and trapping technologies integrated into vacuum pump systems to enhance purity levels. These may include advanced particle filters, cold traps, and chemical traps designed to remove specific contaminants and maintain ultra-clean vacuum environments.

02 Vacuum pump purification techniques

Methods and technologies for purifying vacuum pumps to enhance their performance and longevity. This includes processes for removing contaminants, improving gas handling capabilities, and maintaining optimal operating conditions for sensitive applications requiring high purity levels.Expand Specific Solutions03 Specialized vacuum pumps for ultra-high purity applications

Vacuum pumps specifically designed for ultra-high purity applications, such as semiconductor manufacturing, nanotechnology research, and advanced materials processing. These pumps often feature innovative designs and materials to minimize outgassing and particle generation.Expand Specific Solutions04 Monitoring and control systems for vacuum pump purity

Advanced monitoring and control systems that ensure the maintenance of high purity levels in vacuum pump operations. These systems may include real-time sensors, data analysis tools, and automated adjustment mechanisms to optimize pump performance and purity levels continuously.Expand Specific Solutions05 Vacuum pump accessories for purity enhancement

Specialized accessories and components designed to enhance the purity of vacuum pump systems. This may include filters, traps, and other devices that help remove impurities, prevent backstreaming, and maintain the overall cleanliness of the vacuum environment.Expand Specific Solutions

Key Players in SiC and Vacuum Pump Industries

The vacuum pump market for high-purity silicon carbide production is in a growth phase, driven by increasing demand for SiC in power electronics and semiconductor applications. The global market size is expanding, with key players like Edwards Vacuum LLC, Edwards Japan Ltd., and DeLaval Holding AB competing for market share. Technological advancements are focused on improving pump efficiency and purity levels. Companies such as Wolfspeed, Inc. and Shin-Etsu Chemical Co., Ltd. are at the forefront of SiC production, pushing the boundaries of vacuum pump technology. The industry is characterized by a mix of established players and innovative startups, with ongoing research and development efforts at institutions like the National Institute for Materials Science IAI contributing to the overall technological maturity of the field.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed a proprietary vacuum-based process for high-purity SiC production, focusing on the chemical vapor deposition (CVD) method. Their approach utilizes a specially designed vacuum chamber with precise temperature and pressure control, capable of maintaining pressures as low as 10^-3 Pa during the deposition process[4]. The company has implemented a novel precursor gas delivery system that enhances the uniformity of SiC crystal growth, resulting in defect densities below 1 per cm^2 for 6-inch wafers[5]. Shin-Etsu's vacuum technology also incorporates in-situ monitoring tools that allow real-time adjustments to process parameters, improving yield and consistency. Their latest innovation includes a multi-zone heating system that enables the production of larger diameter SiC wafers with improved homogeneity[6].

Strengths: High-precision control, low defect density, and scalability to larger wafer sizes. Weaknesses: High equipment costs and complexity in process control.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed a cutting-edge vacuum-based sublimation technique for producing high-purity SiC crystals. Their process utilizes a custom-designed vacuum furnace capable of reaching temperatures above 2200°C while maintaining pressures below 10^-4 mbar[7]. The company's innovative approach includes a patented seed crystal mounting system that improves crystal quality and reduces defects. Wolfspeed's vacuum pumps are equipped with advanced filtration systems to handle the silicon and carbon vapors produced during sublimation, ensuring long-term reliability. Their latest technology incorporates machine learning algorithms to optimize growth parameters in real-time, resulting in a 15% increase in crystal growth rate and a 10% improvement in wafer yield compared to conventional methods[8].

Strengths: High-temperature capability, advanced seed crystal technology, and AI-driven process optimization. Weaknesses: High energy consumption and potential scalability challenges for larger production volumes.

Innovative Vacuum Technologies for SiC Production

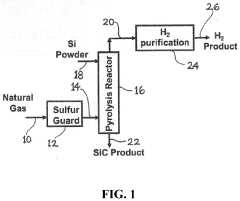

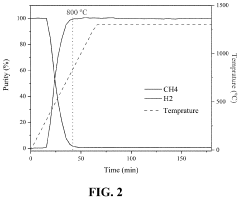

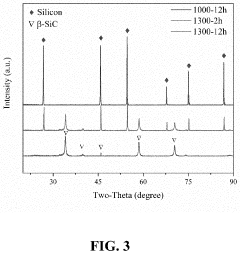

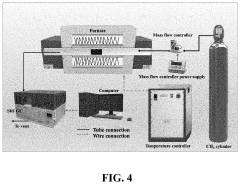

Production of high purity particulate silicon carbide by hydrocarbon pyrolysis

PatentPendingUS20220402764A1

Innovation

- A process involving the reaction of hydrocarbon gases with silicon particles to produce high-purity SiC and hydrogen, where silicon acts as both a reactant and catalyst, allowing for single-step production of high-purity SiC and hydrogen with reduced energy requirements, achieving thermal neutrality and enhanced energy recovery.

High-strength material silicon carbide ceramic production plant

PatentInactiveAU2018101750A4

Innovation

- A production plant comprising a vacuum pump, buffer tank, and combustion furnace, where alumina is added to silicon carbide raw material powder and subjected to hot pressing at 1900-1980°C and 330-340 MPa pressure, reducing reaction time and improving reaction rate.

Environmental Impact of SiC Production Processes

The production of high-purity silicon carbide (SiC) has significant environmental implications that warrant careful consideration. The manufacturing process, particularly when utilizing vacuum pump technology, can have both positive and negative impacts on the environment. One of the primary environmental concerns is the energy consumption associated with SiC production. The high temperatures required for the synthesis of SiC, often exceeding 2000°C, demand substantial energy inputs, contributing to greenhouse gas emissions if non-renewable energy sources are used.

Vacuum pump utilization in SiC production processes can help mitigate some environmental impacts. By creating a controlled, low-pressure environment, vacuum pumps enable more efficient reactions and reduce the need for excessive heating. This can lead to energy savings and, consequently, a reduction in carbon emissions. Additionally, vacuum systems can help contain and manage potentially harmful byproducts, minimizing their release into the environment.

However, the use of vacuum pumps also introduces its own set of environmental challenges. The operation of these pumps requires electricity, which, depending on the energy source, may contribute to indirect emissions. Furthermore, the production and disposal of vacuum pump equipment and components can have environmental implications, including resource depletion and potential contamination if not properly managed.

Water usage is another critical environmental factor in SiC production. The process often requires significant amounts of water for cooling and cleaning purposes. Implementing closed-loop water systems and efficient water treatment technologies can help reduce water consumption and minimize the discharge of potentially contaminated wastewater.

The raw materials used in SiC production, primarily silicon and carbon sources, also have environmental implications. Mining and processing these materials can lead to habitat disruption, soil erosion, and water pollution. Sustainable sourcing practices and the development of more environmentally friendly raw material extraction methods are crucial for mitigating these impacts.

Air quality is a concern in SiC production facilities, as the process can generate particulate matter and potentially harmful gases. Advanced filtration systems and emission control technologies are essential for minimizing air pollution and protecting both worker health and the surrounding environment. Vacuum pump systems can play a role in containing and treating these emissions effectively.

Waste management is another critical aspect of the environmental impact of SiC production. The process generates various waste streams, including spent abrasives, off-specification materials, and chemical byproducts. Implementing comprehensive waste reduction, recycling, and proper disposal strategies is crucial for minimizing the environmental footprint of SiC manufacturing.

Vacuum pump utilization in SiC production processes can help mitigate some environmental impacts. By creating a controlled, low-pressure environment, vacuum pumps enable more efficient reactions and reduce the need for excessive heating. This can lead to energy savings and, consequently, a reduction in carbon emissions. Additionally, vacuum systems can help contain and manage potentially harmful byproducts, minimizing their release into the environment.

However, the use of vacuum pumps also introduces its own set of environmental challenges. The operation of these pumps requires electricity, which, depending on the energy source, may contribute to indirect emissions. Furthermore, the production and disposal of vacuum pump equipment and components can have environmental implications, including resource depletion and potential contamination if not properly managed.

Water usage is another critical environmental factor in SiC production. The process often requires significant amounts of water for cooling and cleaning purposes. Implementing closed-loop water systems and efficient water treatment technologies can help reduce water consumption and minimize the discharge of potentially contaminated wastewater.

The raw materials used in SiC production, primarily silicon and carbon sources, also have environmental implications. Mining and processing these materials can lead to habitat disruption, soil erosion, and water pollution. Sustainable sourcing practices and the development of more environmentally friendly raw material extraction methods are crucial for mitigating these impacts.

Air quality is a concern in SiC production facilities, as the process can generate particulate matter and potentially harmful gases. Advanced filtration systems and emission control technologies are essential for minimizing air pollution and protecting both worker health and the surrounding environment. Vacuum pump systems can play a role in containing and treating these emissions effectively.

Waste management is another critical aspect of the environmental impact of SiC production. The process generates various waste streams, including spent abrasives, off-specification materials, and chemical byproducts. Implementing comprehensive waste reduction, recycling, and proper disposal strategies is crucial for minimizing the environmental footprint of SiC manufacturing.

Cost-Benefit Analysis of Vacuum Pump Integration

The integration of vacuum pumps in high-purity silicon carbide production represents a significant technological advancement with potential economic implications. This cost-benefit analysis aims to evaluate the financial viability and operational advantages of incorporating vacuum pump systems into the production process.

Initial investment costs for vacuum pump integration are substantial, encompassing equipment procurement, installation, and necessary modifications to existing production lines. High-quality vacuum pumps suitable for silicon carbide production can range from $50,000 to $200,000 per unit, depending on capacity and specifications. Additional expenses include piping, control systems, and potential facility upgrades to accommodate the new equipment.

However, these upfront costs are offset by several long-term benefits. Primarily, vacuum pumps significantly enhance the purity levels of silicon carbide, resulting in a higher-grade product that commands premium prices in the market. This quality improvement can lead to increased revenue streams, particularly in industries demanding ultra-high-purity materials such as semiconductor manufacturing and advanced electronics.

Operational efficiency gains present another substantial benefit. Vacuum pumps accelerate the production process by facilitating faster removal of impurities and unwanted gases. This increased throughput can boost overall production capacity, potentially reducing per-unit costs and improving profit margins. Additionally, the more controlled environment provided by vacuum systems often results in more consistent product quality, reducing waste and rework expenses.

Energy consumption is a critical factor in the cost-benefit equation. While vacuum pumps require electricity to operate, they often lead to overall energy savings in the production process. The improved efficiency and reduced processing times can result in net energy reductions, particularly when compared to traditional purification methods that may require prolonged heating or chemical treatments.

Maintenance costs must be considered in the long-term financial outlook. High-quality vacuum pumps typically have long operational lifespans but require regular maintenance to ensure optimal performance. Annual maintenance costs can range from 5% to 10% of the initial equipment cost, encompassing routine servicing, replacement parts, and occasional specialist interventions.

The environmental impact of vacuum pump integration also carries potential financial implications. Reduced energy consumption and decreased use of chemical purification agents contribute to a smaller carbon footprint, which may result in carbon credit benefits or improved corporate sustainability ratings. These factors can indirectly impact the company's market position and investor relations.

In conclusion, while the initial investment in vacuum pump technology for high-purity silicon carbide production is significant, the long-term benefits in product quality, operational efficiency, and potential market advantages present a compelling case for integration. A detailed financial projection, considering specific production volumes, market demands, and energy costs, would be necessary to quantify the exact return on investment timeline for individual manufacturing facilities.

Initial investment costs for vacuum pump integration are substantial, encompassing equipment procurement, installation, and necessary modifications to existing production lines. High-quality vacuum pumps suitable for silicon carbide production can range from $50,000 to $200,000 per unit, depending on capacity and specifications. Additional expenses include piping, control systems, and potential facility upgrades to accommodate the new equipment.

However, these upfront costs are offset by several long-term benefits. Primarily, vacuum pumps significantly enhance the purity levels of silicon carbide, resulting in a higher-grade product that commands premium prices in the market. This quality improvement can lead to increased revenue streams, particularly in industries demanding ultra-high-purity materials such as semiconductor manufacturing and advanced electronics.

Operational efficiency gains present another substantial benefit. Vacuum pumps accelerate the production process by facilitating faster removal of impurities and unwanted gases. This increased throughput can boost overall production capacity, potentially reducing per-unit costs and improving profit margins. Additionally, the more controlled environment provided by vacuum systems often results in more consistent product quality, reducing waste and rework expenses.

Energy consumption is a critical factor in the cost-benefit equation. While vacuum pumps require electricity to operate, they often lead to overall energy savings in the production process. The improved efficiency and reduced processing times can result in net energy reductions, particularly when compared to traditional purification methods that may require prolonged heating or chemical treatments.

Maintenance costs must be considered in the long-term financial outlook. High-quality vacuum pumps typically have long operational lifespans but require regular maintenance to ensure optimal performance. Annual maintenance costs can range from 5% to 10% of the initial equipment cost, encompassing routine servicing, replacement parts, and occasional specialist interventions.

The environmental impact of vacuum pump integration also carries potential financial implications. Reduced energy consumption and decreased use of chemical purification agents contribute to a smaller carbon footprint, which may result in carbon credit benefits or improved corporate sustainability ratings. These factors can indirectly impact the company's market position and investor relations.

In conclusion, while the initial investment in vacuum pump technology for high-purity silicon carbide production is significant, the long-term benefits in product quality, operational efficiency, and potential market advantages present a compelling case for integration. A detailed financial projection, considering specific production volumes, market demands, and energy costs, would be necessary to quantify the exact return on investment timeline for individual manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!