Functional Engineering of UHMWPE in Sound Isolation Panels

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Sound Isolation Background and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) has emerged as a promising material for sound isolation applications due to its unique properties and versatile nature. The development of UHMWPE-based sound isolation panels represents a significant advancement in acoustic engineering, addressing the growing demand for effective noise reduction solutions in various industries.

The evolution of UHMWPE in sound isolation technology can be traced back to the early 2000s when researchers began exploring its potential for acoustic applications. Initially, UHMWPE was primarily used in high-performance fibers and industrial components due to its exceptional strength and wear resistance. However, its low density and high impact resistance soon caught the attention of acoustic engineers seeking innovative materials for sound isolation.

Over the past two decades, the field of UHMWPE sound isolation has witnessed remarkable progress, driven by advancements in polymer science and acoustic engineering. Researchers have focused on enhancing the material's sound absorption properties through various techniques, including the incorporation of additives, structural modifications, and composite formulations.

The primary objective of UHMWPE sound isolation panel development is to create lightweight, durable, and highly effective acoustic barriers that can be easily integrated into diverse environments. These panels aim to provide superior noise reduction across a wide frequency range while maintaining the material's inherent advantages, such as chemical resistance and thermal stability.

Current research in this field is centered on optimizing the acoustic performance of UHMWPE panels through innovative engineering approaches. This includes exploring the potential of nanocomposites, developing multi-layered structures, and investigating the effects of surface treatments on sound absorption characteristics.

The growing emphasis on sustainable and eco-friendly materials has also influenced the direction of UHMWPE sound isolation research. Scientists are now exploring ways to incorporate recycled UHMWPE into acoustic panels, aligning with global efforts to reduce environmental impact and promote circular economy principles.

As urbanization and industrialization continue to accelerate, the demand for effective noise control solutions is expected to rise significantly. UHMWPE sound isolation panels are poised to play a crucial role in addressing this need, offering a balance between performance, durability, and cost-effectiveness.

The ongoing technological advancements and interdisciplinary collaborations in this field are expected to drive further innovations, potentially revolutionizing the acoustic insulation industry. The future of UHMWPE in sound isolation applications looks promising, with researchers aiming to develop next-generation panels that offer unprecedented levels of noise reduction while maintaining the material's unique properties.

The evolution of UHMWPE in sound isolation technology can be traced back to the early 2000s when researchers began exploring its potential for acoustic applications. Initially, UHMWPE was primarily used in high-performance fibers and industrial components due to its exceptional strength and wear resistance. However, its low density and high impact resistance soon caught the attention of acoustic engineers seeking innovative materials for sound isolation.

Over the past two decades, the field of UHMWPE sound isolation has witnessed remarkable progress, driven by advancements in polymer science and acoustic engineering. Researchers have focused on enhancing the material's sound absorption properties through various techniques, including the incorporation of additives, structural modifications, and composite formulations.

The primary objective of UHMWPE sound isolation panel development is to create lightweight, durable, and highly effective acoustic barriers that can be easily integrated into diverse environments. These panels aim to provide superior noise reduction across a wide frequency range while maintaining the material's inherent advantages, such as chemical resistance and thermal stability.

Current research in this field is centered on optimizing the acoustic performance of UHMWPE panels through innovative engineering approaches. This includes exploring the potential of nanocomposites, developing multi-layered structures, and investigating the effects of surface treatments on sound absorption characteristics.

The growing emphasis on sustainable and eco-friendly materials has also influenced the direction of UHMWPE sound isolation research. Scientists are now exploring ways to incorporate recycled UHMWPE into acoustic panels, aligning with global efforts to reduce environmental impact and promote circular economy principles.

As urbanization and industrialization continue to accelerate, the demand for effective noise control solutions is expected to rise significantly. UHMWPE sound isolation panels are poised to play a crucial role in addressing this need, offering a balance between performance, durability, and cost-effectiveness.

The ongoing technological advancements and interdisciplinary collaborations in this field are expected to drive further innovations, potentially revolutionizing the acoustic insulation industry. The future of UHMWPE in sound isolation applications looks promising, with researchers aiming to develop next-generation panels that offer unprecedented levels of noise reduction while maintaining the material's unique properties.

Acoustic Market Demand Analysis

The acoustic market has experienced significant growth in recent years, driven by increasing awareness of noise pollution and its detrimental effects on health and productivity. The global sound insulation market is projected to reach substantial value by 2028, with a compound annual growth rate (CAGR) exceeding 5% during the forecast period. This growth is primarily attributed to stringent noise regulations, rapid urbanization, and the rising demand for improved living and working environments.

In the construction sector, there is a growing emphasis on soundproofing in both residential and commercial buildings. Homeowners are increasingly seeking quieter living spaces, while businesses are recognizing the importance of noise reduction in enhancing employee productivity and customer satisfaction. This trend has led to a surge in demand for advanced sound isolation panels, particularly those incorporating innovative materials like Ultra-High Molecular Weight Polyethylene (UHMWPE).

The automotive industry represents another significant market for acoustic solutions. With the increasing focus on electric vehicles, which generate different noise profiles compared to traditional combustion engines, there is a renewed interest in developing effective sound isolation materials. UHMWPE-based panels are gaining attention in this sector due to their lightweight properties and excellent sound absorption capabilities.

The aerospace industry is also a key driver of acoustic market demand. Aircraft manufacturers are constantly seeking ways to reduce cabin noise levels to improve passenger comfort and comply with stringent noise regulations. The unique properties of UHMWPE make it an attractive option for developing next-generation sound isolation panels for aircraft interiors.

In the industrial sector, the need for noise control in manufacturing facilities, power plants, and other high-noise environments is fueling the demand for advanced acoustic solutions. UHMWPE-based panels offer potential advantages in terms of durability, chemical resistance, and performance in harsh industrial conditions.

The healthcare sector is emerging as a promising market for acoustic solutions. Hospitals and medical facilities are increasingly recognizing the importance of noise reduction in patient recovery and staff well-being. This has led to a growing demand for high-performance sound isolation materials in healthcare construction and renovation projects.

As environmental concerns continue to gain prominence, there is a rising demand for sustainable acoustic solutions. UHMWPE, being recyclable and having a long lifespan, aligns well with this trend. Manufacturers are exploring ways to incorporate recycled UHMWPE into sound isolation panels, further enhancing their eco-friendly appeal.

The market analysis indicates a shift towards multifunctional acoustic materials. Customers are seeking sound isolation panels that not only provide excellent noise reduction but also offer additional benefits such as fire resistance, thermal insulation, and ease of installation. This trend presents opportunities for innovative applications of UHMWPE in acoustic panel design.

In the construction sector, there is a growing emphasis on soundproofing in both residential and commercial buildings. Homeowners are increasingly seeking quieter living spaces, while businesses are recognizing the importance of noise reduction in enhancing employee productivity and customer satisfaction. This trend has led to a surge in demand for advanced sound isolation panels, particularly those incorporating innovative materials like Ultra-High Molecular Weight Polyethylene (UHMWPE).

The automotive industry represents another significant market for acoustic solutions. With the increasing focus on electric vehicles, which generate different noise profiles compared to traditional combustion engines, there is a renewed interest in developing effective sound isolation materials. UHMWPE-based panels are gaining attention in this sector due to their lightweight properties and excellent sound absorption capabilities.

The aerospace industry is also a key driver of acoustic market demand. Aircraft manufacturers are constantly seeking ways to reduce cabin noise levels to improve passenger comfort and comply with stringent noise regulations. The unique properties of UHMWPE make it an attractive option for developing next-generation sound isolation panels for aircraft interiors.

In the industrial sector, the need for noise control in manufacturing facilities, power plants, and other high-noise environments is fueling the demand for advanced acoustic solutions. UHMWPE-based panels offer potential advantages in terms of durability, chemical resistance, and performance in harsh industrial conditions.

The healthcare sector is emerging as a promising market for acoustic solutions. Hospitals and medical facilities are increasingly recognizing the importance of noise reduction in patient recovery and staff well-being. This has led to a growing demand for high-performance sound isolation materials in healthcare construction and renovation projects.

As environmental concerns continue to gain prominence, there is a rising demand for sustainable acoustic solutions. UHMWPE, being recyclable and having a long lifespan, aligns well with this trend. Manufacturers are exploring ways to incorporate recycled UHMWPE into sound isolation panels, further enhancing their eco-friendly appeal.

The market analysis indicates a shift towards multifunctional acoustic materials. Customers are seeking sound isolation panels that not only provide excellent noise reduction but also offer additional benefits such as fire resistance, thermal insulation, and ease of installation. This trend presents opportunities for innovative applications of UHMWPE in acoustic panel design.

UHMWPE Sound Isolation Challenges

Ultra-high molecular weight polyethylene (UHMWPE) has emerged as a promising material for sound isolation panels due to its unique properties. However, the application of UHMWPE in acoustic engineering faces several significant challenges that require innovative solutions and further research.

One of the primary challenges is optimizing the sound absorption capabilities of UHMWPE. While the material exhibits excellent impact resistance and durability, its inherent density and structure do not naturally lend themselves to efficient sound absorption across a wide frequency range. Engineers must develop novel methods to enhance the material's acoustic performance without compromising its mechanical properties.

Another critical challenge lies in the processing and manufacturing of UHMWPE for sound isolation applications. The material's high molecular weight and viscosity make it difficult to process using conventional methods. Developing specialized techniques for molding, shaping, and integrating UHMWPE into complex panel designs while maintaining its acoustic properties is a significant hurdle that researchers must overcome.

The integration of UHMWPE with other materials to create composite sound isolation panels presents another set of challenges. Achieving optimal bonding between UHMWPE and complementary materials, such as foams or fibrous layers, is crucial for enhancing overall acoustic performance. Engineers must develop effective joining techniques and explore compatible material combinations that synergize with UHMWPE's properties.

Thermal management is an additional concern when using UHMWPE in sound isolation panels. The material's low thermal conductivity can lead to heat buildup in certain applications, potentially affecting its acoustic properties and long-term performance. Developing strategies to dissipate heat effectively without compromising sound isolation capabilities is a key area of focus for researchers.

Cost-effectiveness remains a significant challenge in the widespread adoption of UHMWPE for sound isolation. The material's production process and specialized manufacturing requirements can result in higher costs compared to traditional acoustic materials. Finding ways to optimize production efficiency and reduce overall costs while maintaining performance standards is crucial for market viability.

Lastly, ensuring long-term durability and performance stability of UHMWPE sound isolation panels under various environmental conditions poses a challenge. Factors such as UV exposure, temperature fluctuations, and moisture can potentially affect the material's acoustic properties over time. Developing robust solutions to maintain consistent performance throughout the panel's lifecycle is essential for practical applications.

One of the primary challenges is optimizing the sound absorption capabilities of UHMWPE. While the material exhibits excellent impact resistance and durability, its inherent density and structure do not naturally lend themselves to efficient sound absorption across a wide frequency range. Engineers must develop novel methods to enhance the material's acoustic performance without compromising its mechanical properties.

Another critical challenge lies in the processing and manufacturing of UHMWPE for sound isolation applications. The material's high molecular weight and viscosity make it difficult to process using conventional methods. Developing specialized techniques for molding, shaping, and integrating UHMWPE into complex panel designs while maintaining its acoustic properties is a significant hurdle that researchers must overcome.

The integration of UHMWPE with other materials to create composite sound isolation panels presents another set of challenges. Achieving optimal bonding between UHMWPE and complementary materials, such as foams or fibrous layers, is crucial for enhancing overall acoustic performance. Engineers must develop effective joining techniques and explore compatible material combinations that synergize with UHMWPE's properties.

Thermal management is an additional concern when using UHMWPE in sound isolation panels. The material's low thermal conductivity can lead to heat buildup in certain applications, potentially affecting its acoustic properties and long-term performance. Developing strategies to dissipate heat effectively without compromising sound isolation capabilities is a key area of focus for researchers.

Cost-effectiveness remains a significant challenge in the widespread adoption of UHMWPE for sound isolation. The material's production process and specialized manufacturing requirements can result in higher costs compared to traditional acoustic materials. Finding ways to optimize production efficiency and reduce overall costs while maintaining performance standards is crucial for market viability.

Lastly, ensuring long-term durability and performance stability of UHMWPE sound isolation panels under various environmental conditions poses a challenge. Factors such as UV exposure, temperature fluctuations, and moisture can potentially affect the material's acoustic properties over time. Developing robust solutions to maintain consistent performance throughout the panel's lifecycle is essential for practical applications.

Current UHMWPE Sound Isolation Solutions

01 UHMWPE composites for sound isolation

Ultra-High Molecular Weight Polyethylene (UHMWPE) can be combined with other materials to create composites with enhanced sound isolation properties. These composites can be used in various applications where noise reduction is required, such as in construction, automotive, or industrial settings.- UHMWPE composites for sound isolation: Ultra-High Molecular Weight Polyethylene (UHMWPE) can be combined with other materials to create composites with enhanced sound isolation properties. These composites can be used in various applications where noise reduction is required, such as in construction, automotive, or industrial settings.

- UHMWPE fibers in acoustic panels: UHMWPE fibers can be incorporated into acoustic panels to improve sound absorption and isolation. The unique properties of UHMWPE fibers, such as high strength and low density, contribute to the overall performance of these panels in reducing noise transmission.

- UHMWPE-based foam for sound insulation: Foam materials made from or incorporating UHMWPE can be effective in sound insulation applications. The foam structure helps to absorb and dampen sound waves, making it suitable for use in various noise reduction scenarios.

- UHMWPE in multilayer sound isolation structures: UHMWPE can be used as a component in multilayer structures designed for sound isolation. These structures may combine different materials, including UHMWPE, to create an effective barrier against noise transmission across a wide range of frequencies.

- UHMWPE coatings for sound dampening: UHMWPE can be applied as a coating on various surfaces to enhance their sound dampening properties. This approach can be particularly useful in applications where a thin, durable layer is needed to reduce noise without significantly altering the dimensions or weight of the underlying structure.

02 UHMWPE fibers in acoustic panels

UHMWPE fibers can be incorporated into acoustic panels to improve sound absorption and isolation. The unique properties of UHMWPE fibers, such as high strength and low density, make them suitable for creating lightweight yet effective sound-isolating structures.Expand Specific Solutions03 UHMWPE foam for sound dampening

Foam materials made from UHMWPE can be used for sound dampening applications. The foam structure provides excellent sound absorption properties, making it suitable for use in various noise reduction scenarios, including automotive interiors and building insulation.Expand Specific Solutions04 UHMWPE in multi-layer sound isolation systems

UHMWPE can be used as a component in multi-layer sound isolation systems. These systems combine different materials, including UHMWPE, to create effective barriers against sound transmission. The layered approach allows for customization of sound isolation properties for specific applications.Expand Specific Solutions05 UHMWPE coatings for sound isolation

UHMWPE can be applied as a coating on various surfaces to enhance their sound isolation properties. This approach allows for the improvement of existing structures or materials without the need for complete replacement, making it a cost-effective solution for sound isolation in many applications.Expand Specific Solutions

Key Players in UHMWPE and Acoustics

The functional engineering of UHMWPE in sound isolation panels is an emerging field within the acoustic materials industry. The market is in its growth phase, with increasing demand for high-performance sound isolation solutions in various sectors, including aerospace, automotive, and construction. The global market size for advanced acoustic materials is projected to expand significantly in the coming years. Technologically, the field is rapidly evolving, with companies like Airbus Operations SAS, Zhuzhou Times New Materials Technology Co., Ltd., and Hutchinson SA leading innovation. These firms are investing in R&D to enhance UHMWPE's sound isolation properties, focusing on improving material composition, manufacturing processes, and integration techniques. The competitive landscape is characterized by a mix of established aerospace and materials science companies, alongside specialized acoustic solution providers, driving technological advancements and market growth.

Airbus Operations SAS

Technical Solution: Airbus has developed a novel approach to functional engineering of UHMWPE for sound isolation panels in aircraft. Their method involves creating a multi-layered composite structure, with UHMWPE as the core material. The UHMWPE is processed using a proprietary technique that enhances its sound-damping properties while maintaining its lightweight characteristics. This composite structure is designed to effectively attenuate a wide range of frequencies, particularly those common in aircraft cabins[1]. The panels are engineered to provide optimal acoustic performance while meeting stringent aviation safety standards, including fire resistance and durability requirements[3].

Strengths: Excellent sound isolation, lightweight, meets aviation safety standards. Weaknesses: Potentially higher production costs, limited to aerospace applications.

Teijin Twaron BV

Technical Solution: Teijin Twaron has developed a unique approach to UHMWPE functional engineering for sound isolation panels, leveraging their expertise in high-performance fibers. Their technology involves creating a non-woven fabric from UHMWPE fibers, which is then integrated into a multi-layer sound isolation panel. The UHMWPE fibers are processed to create a complex, three-dimensional structure that effectively traps and dissipates sound waves. Teijin's panels also incorporate their aramid fibers to enhance structural integrity and fire resistance. The company has developed a proprietary treatment process for the UHMWPE fibers to improve their acoustic properties and compatibility with other materials in the panel structure[9].

Strengths: High-performance sound isolation, excellent strength-to-weight ratio, fire-resistant properties. Weaknesses: Potentially higher cost, may require specialized manufacturing processes.

Core UHMWPE Acoustic Patents

Polypropylene composite material capable of blasting at low temperature, and preparation method therefor and application thereof

PatentPendingEP4324879A1

Innovation

- A polypropylene composite material is developed using ultrahigh molecular weight polyethylene and metallocene ethylene-propylene copolymer as a special toughening agent, combined with specific binary and ternary random co-polypropylenes, along with fillers and additives, to enhance both rigidity and low-temperature cracking performance.

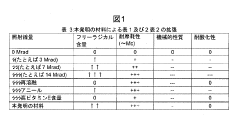

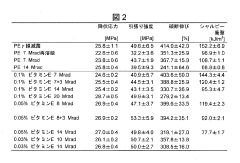

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

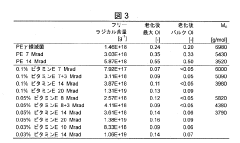

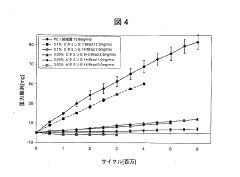

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Environmental Impact Assessment

The environmental impact assessment of Ultra-High Molecular Weight Polyethylene (UHMWPE) in sound isolation panels is a critical aspect of its functional engineering. UHMWPE, known for its exceptional strength and durability, presents both advantages and challenges in terms of environmental sustainability.

One of the primary environmental benefits of using UHMWPE in sound isolation panels is its longevity. The material's resistance to wear and tear significantly extends the lifespan of these panels, reducing the frequency of replacement and, consequently, the overall environmental footprint associated with manufacturing and disposal. This durability contributes to resource conservation and waste reduction in the long term.

However, the production process of UHMWPE raises some environmental concerns. The polymer is derived from petroleum, a non-renewable resource, and its manufacturing involves energy-intensive processes. This contributes to greenhouse gas emissions and potential environmental degradation associated with fossil fuel extraction. Efforts to mitigate these impacts include exploring bio-based alternatives and optimizing production efficiency to reduce energy consumption.

Recycling UHMWPE presents another environmental challenge. While the material is theoretically recyclable, its high molecular weight and cross-linked structure make conventional recycling methods less effective. Innovative recycling technologies are being developed to address this issue, including chemical recycling and mechanical downcycling, which could significantly improve the material's end-of-life environmental profile.

In the context of sound isolation panels, UHMWPE's performance characteristics offer indirect environmental benefits. Its superior sound insulation properties can lead to reduced noise pollution in urban environments, potentially improving quality of life and reducing stress-related health issues. Additionally, effective sound isolation can contribute to energy savings in buildings by reducing the need for additional heating or cooling to compensate for noise-related discomfort.

The use of UHMWPE in sound isolation panels also raises questions about indoor air quality. While the material is generally considered inert and non-toxic, further research is needed to assess any potential off-gassing or particulate release over time, especially in enclosed spaces.

From a lifecycle perspective, the environmental impact of UHMWPE in sound isolation panels must be evaluated against alternative materials. Comparative studies considering factors such as raw material sourcing, manufacturing energy requirements, use-phase performance, and end-of-life management are essential for a comprehensive environmental assessment.

In conclusion, while UHMWPE offers significant advantages in terms of durability and performance in sound isolation panels, its environmental impact is complex. Ongoing research and development efforts are focused on addressing the material's production and recycling challenges to enhance its overall environmental sustainability.

One of the primary environmental benefits of using UHMWPE in sound isolation panels is its longevity. The material's resistance to wear and tear significantly extends the lifespan of these panels, reducing the frequency of replacement and, consequently, the overall environmental footprint associated with manufacturing and disposal. This durability contributes to resource conservation and waste reduction in the long term.

However, the production process of UHMWPE raises some environmental concerns. The polymer is derived from petroleum, a non-renewable resource, and its manufacturing involves energy-intensive processes. This contributes to greenhouse gas emissions and potential environmental degradation associated with fossil fuel extraction. Efforts to mitigate these impacts include exploring bio-based alternatives and optimizing production efficiency to reduce energy consumption.

Recycling UHMWPE presents another environmental challenge. While the material is theoretically recyclable, its high molecular weight and cross-linked structure make conventional recycling methods less effective. Innovative recycling technologies are being developed to address this issue, including chemical recycling and mechanical downcycling, which could significantly improve the material's end-of-life environmental profile.

In the context of sound isolation panels, UHMWPE's performance characteristics offer indirect environmental benefits. Its superior sound insulation properties can lead to reduced noise pollution in urban environments, potentially improving quality of life and reducing stress-related health issues. Additionally, effective sound isolation can contribute to energy savings in buildings by reducing the need for additional heating or cooling to compensate for noise-related discomfort.

The use of UHMWPE in sound isolation panels also raises questions about indoor air quality. While the material is generally considered inert and non-toxic, further research is needed to assess any potential off-gassing or particulate release over time, especially in enclosed spaces.

From a lifecycle perspective, the environmental impact of UHMWPE in sound isolation panels must be evaluated against alternative materials. Comparative studies considering factors such as raw material sourcing, manufacturing energy requirements, use-phase performance, and end-of-life management are essential for a comprehensive environmental assessment.

In conclusion, while UHMWPE offers significant advantages in terms of durability and performance in sound isolation panels, its environmental impact is complex. Ongoing research and development efforts are focused on addressing the material's production and recycling challenges to enhance its overall environmental sustainability.

Cost-Benefit Analysis of UHMWPE Panels

The cost-benefit analysis of Ultra-High Molecular Weight Polyethylene (UHMWPE) panels in sound isolation applications reveals a complex interplay of economic factors. Initial production costs for UHMWPE panels are generally higher than traditional materials due to the specialized manufacturing processes required. However, these upfront expenses are often offset by the material's exceptional durability and longevity, which significantly reduce long-term replacement and maintenance costs.

UHMWPE panels demonstrate superior sound isolation properties, potentially allowing for thinner panel designs without compromising performance. This characteristic can lead to material savings and reduced transportation costs, particularly in large-scale applications. The lightweight nature of UHMWPE further contributes to easier installation and lower labor costs compared to heavier alternatives.

Energy efficiency is another crucial factor in the cost-benefit equation. UHMWPE panels' excellent insulation properties can result in substantial energy savings over time, especially in climate-controlled environments. This aspect becomes increasingly significant as energy prices rise and environmental regulations tighten.

From a lifecycle perspective, UHMWPE panels offer advantages in terms of recyclability and environmental impact. While the initial production may have a higher carbon footprint, the extended lifespan and potential for recycling at end-of-life can result in a lower overall environmental cost compared to materials with shorter lifespans or limited recyclability.

Market demand for high-performance sound isolation solutions in various sectors, including construction, automotive, and aerospace, may justify the higher initial investment in UHMWPE panels. The material's unique combination of properties can command premium pricing in specialized applications, potentially yielding higher profit margins for manufacturers and distributors.

However, the cost-benefit analysis must also consider potential drawbacks. The specialized nature of UHMWPE production may lead to supply chain vulnerabilities and price fluctuations. Additionally, the relatively new application of UHMWPE in sound isolation panels may require investment in education and marketing to overcome market inertia and establish trust among end-users.

In conclusion, while UHMWPE panels present higher upfront costs, their long-term benefits in durability, energy efficiency, and performance can provide a favorable return on investment in many applications. The specific cost-benefit ratio will vary depending on the scale of implementation, local energy costs, and the particular requirements of each project.

UHMWPE panels demonstrate superior sound isolation properties, potentially allowing for thinner panel designs without compromising performance. This characteristic can lead to material savings and reduced transportation costs, particularly in large-scale applications. The lightweight nature of UHMWPE further contributes to easier installation and lower labor costs compared to heavier alternatives.

Energy efficiency is another crucial factor in the cost-benefit equation. UHMWPE panels' excellent insulation properties can result in substantial energy savings over time, especially in climate-controlled environments. This aspect becomes increasingly significant as energy prices rise and environmental regulations tighten.

From a lifecycle perspective, UHMWPE panels offer advantages in terms of recyclability and environmental impact. While the initial production may have a higher carbon footprint, the extended lifespan and potential for recycling at end-of-life can result in a lower overall environmental cost compared to materials with shorter lifespans or limited recyclability.

Market demand for high-performance sound isolation solutions in various sectors, including construction, automotive, and aerospace, may justify the higher initial investment in UHMWPE panels. The material's unique combination of properties can command premium pricing in specialized applications, potentially yielding higher profit margins for manufacturers and distributors.

However, the cost-benefit analysis must also consider potential drawbacks. The specialized nature of UHMWPE production may lead to supply chain vulnerabilities and price fluctuations. Additionally, the relatively new application of UHMWPE in sound isolation panels may require investment in education and marketing to overcome market inertia and establish trust among end-users.

In conclusion, while UHMWPE panels present higher upfront costs, their long-term benefits in durability, energy efficiency, and performance can provide a favorable return on investment in many applications. The specific cost-benefit ratio will vary depending on the scale of implementation, local energy costs, and the particular requirements of each project.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!