Future Prospects of Ethyl Acetate in Renewable Energy

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Energy: Background and Objectives

Ethyl acetate, a versatile organic compound, has recently garnered attention in the renewable energy sector due to its potential applications and unique properties. Historically, ethyl acetate has been primarily used as a solvent in various industries, including pharmaceuticals, paints, and adhesives. However, the evolving landscape of renewable energy has opened new avenues for this compound's utilization.

The development trajectory of ethyl acetate in the energy sector is closely tied to the broader shift towards sustainable and environmentally friendly energy solutions. As global efforts to reduce carbon emissions intensify, researchers and industry professionals are exploring innovative ways to incorporate existing chemicals into renewable energy systems. Ethyl acetate's relatively low toxicity, high solvency, and biodegradability make it an attractive candidate for various energy-related applications.

One of the key areas where ethyl acetate shows promise is in the field of biofuels. As a potential additive or component in biofuel formulations, it could enhance the performance and efficiency of renewable fuel sources. Additionally, its role in the production and processing of biomass-derived fuels is being investigated, potentially streamlining the conversion of organic matter into usable energy.

The objectives of exploring ethyl acetate in the renewable energy context are multifaceted. Primarily, researchers aim to leverage its chemical properties to improve existing renewable energy technologies and develop new ones. This includes enhancing the efficiency of energy storage systems, optimizing fuel cell performance, and developing novel catalysts for energy conversion processes.

Furthermore, the integration of ethyl acetate into renewable energy solutions aligns with the broader goals of circular economy principles. By finding new applications for this widely produced compound in the energy sector, industries can potentially reduce waste and improve resource utilization. This approach not only contributes to sustainability efforts but also opens up new economic opportunities in the renewable energy market.

As we delve deeper into the potential of ethyl acetate in renewable energy, it is crucial to consider the technological challenges and market dynamics that will shape its future. The evolving regulatory landscape, particularly concerning environmental standards and energy policies, will play a significant role in determining the extent and speed of ethyl acetate's adoption in this sector. Understanding these factors is essential for predicting the compound's trajectory and its potential impact on the renewable energy industry.

The development trajectory of ethyl acetate in the energy sector is closely tied to the broader shift towards sustainable and environmentally friendly energy solutions. As global efforts to reduce carbon emissions intensify, researchers and industry professionals are exploring innovative ways to incorporate existing chemicals into renewable energy systems. Ethyl acetate's relatively low toxicity, high solvency, and biodegradability make it an attractive candidate for various energy-related applications.

One of the key areas where ethyl acetate shows promise is in the field of biofuels. As a potential additive or component in biofuel formulations, it could enhance the performance and efficiency of renewable fuel sources. Additionally, its role in the production and processing of biomass-derived fuels is being investigated, potentially streamlining the conversion of organic matter into usable energy.

The objectives of exploring ethyl acetate in the renewable energy context are multifaceted. Primarily, researchers aim to leverage its chemical properties to improve existing renewable energy technologies and develop new ones. This includes enhancing the efficiency of energy storage systems, optimizing fuel cell performance, and developing novel catalysts for energy conversion processes.

Furthermore, the integration of ethyl acetate into renewable energy solutions aligns with the broader goals of circular economy principles. By finding new applications for this widely produced compound in the energy sector, industries can potentially reduce waste and improve resource utilization. This approach not only contributes to sustainability efforts but also opens up new economic opportunities in the renewable energy market.

As we delve deeper into the potential of ethyl acetate in renewable energy, it is crucial to consider the technological challenges and market dynamics that will shape its future. The evolving regulatory landscape, particularly concerning environmental standards and energy policies, will play a significant role in determining the extent and speed of ethyl acetate's adoption in this sector. Understanding these factors is essential for predicting the compound's trajectory and its potential impact on the renewable energy industry.

Market Analysis for Renewable Energy Applications

The renewable energy sector has witnessed significant growth in recent years, driven by increasing environmental concerns and the need for sustainable alternatives to fossil fuels. Within this context, ethyl acetate, a versatile organic compound, is emerging as a potential player in the renewable energy landscape. The market for ethyl acetate in renewable energy applications is showing promising signs of expansion, with several key factors contributing to its growth potential.

One of the primary drivers for the adoption of ethyl acetate in renewable energy is its potential use as a biofuel additive. As governments worldwide implement stricter regulations on emissions and push for cleaner fuel alternatives, the demand for bio-based additives is expected to rise. Ethyl acetate, when blended with conventional fuels, can improve combustion efficiency and reduce harmful emissions, making it an attractive option for the automotive and transportation sectors.

The chemical industry is another significant market for ethyl acetate in renewable energy applications. As companies seek to reduce their carbon footprint and transition towards more sustainable production processes, bio-based ethyl acetate is gaining traction as a green solvent. Its use in the production of coatings, adhesives, and other chemical products aligns with the growing trend of eco-friendly manufacturing practices.

In the energy storage sector, ethyl acetate shows promise as a component in next-generation battery technologies. Research is ongoing to develop electrolytes and electrode materials that incorporate ethyl acetate, potentially enhancing the performance and sustainability of energy storage systems. This application could open up new market opportunities in the rapidly expanding renewable energy storage industry.

The agricultural sector presents another avenue for ethyl acetate in renewable energy applications. As a byproduct of fermentation processes, ethyl acetate can be produced from agricultural waste, creating a circular economy model. This not only provides a sustainable source of the compound but also offers farmers an additional revenue stream, potentially driving adoption in rural and agricultural communities.

Market analysis indicates that the Asia-Pacific region is expected to be a key growth area for ethyl acetate in renewable energy applications. Countries like China and India, with their rapidly expanding renewable energy sectors and growing chemical industries, are likely to be significant consumers. Additionally, European markets, driven by stringent environmental regulations and a strong focus on sustainability, are anticipated to contribute substantially to market growth.

However, challenges remain in fully realizing the market potential of ethyl acetate in renewable energy applications. These include the need for further technological advancements to improve production efficiency and reduce costs, as well as the development of standardized regulations for its use in various applications. Overcoming these hurdles will be crucial in determining the extent of ethyl acetate's market penetration in the renewable energy sector.

One of the primary drivers for the adoption of ethyl acetate in renewable energy is its potential use as a biofuel additive. As governments worldwide implement stricter regulations on emissions and push for cleaner fuel alternatives, the demand for bio-based additives is expected to rise. Ethyl acetate, when blended with conventional fuels, can improve combustion efficiency and reduce harmful emissions, making it an attractive option for the automotive and transportation sectors.

The chemical industry is another significant market for ethyl acetate in renewable energy applications. As companies seek to reduce their carbon footprint and transition towards more sustainable production processes, bio-based ethyl acetate is gaining traction as a green solvent. Its use in the production of coatings, adhesives, and other chemical products aligns with the growing trend of eco-friendly manufacturing practices.

In the energy storage sector, ethyl acetate shows promise as a component in next-generation battery technologies. Research is ongoing to develop electrolytes and electrode materials that incorporate ethyl acetate, potentially enhancing the performance and sustainability of energy storage systems. This application could open up new market opportunities in the rapidly expanding renewable energy storage industry.

The agricultural sector presents another avenue for ethyl acetate in renewable energy applications. As a byproduct of fermentation processes, ethyl acetate can be produced from agricultural waste, creating a circular economy model. This not only provides a sustainable source of the compound but also offers farmers an additional revenue stream, potentially driving adoption in rural and agricultural communities.

Market analysis indicates that the Asia-Pacific region is expected to be a key growth area for ethyl acetate in renewable energy applications. Countries like China and India, with their rapidly expanding renewable energy sectors and growing chemical industries, are likely to be significant consumers. Additionally, European markets, driven by stringent environmental regulations and a strong focus on sustainability, are anticipated to contribute substantially to market growth.

However, challenges remain in fully realizing the market potential of ethyl acetate in renewable energy applications. These include the need for further technological advancements to improve production efficiency and reduce costs, as well as the development of standardized regulations for its use in various applications. Overcoming these hurdles will be crucial in determining the extent of ethyl acetate's market penetration in the renewable energy sector.

Current Status and Challenges in Ethyl Acetate Utilization

The current status of ethyl acetate utilization in renewable energy is characterized by both promising advancements and significant challenges. Ethyl acetate, traditionally used as a solvent in various industries, has gained attention for its potential applications in the renewable energy sector. Its biodegradability and relatively low toxicity make it an attractive option for environmentally conscious energy solutions.

In recent years, researchers have explored the use of ethyl acetate as a biofuel additive, demonstrating its ability to enhance the performance of conventional fuels when blended in appropriate proportions. Studies have shown that ethyl acetate can improve the octane rating of gasoline, potentially leading to more efficient combustion and reduced emissions. However, the widespread adoption of ethyl acetate in this capacity faces challenges related to production costs and scalability.

Another promising area of development is the use of ethyl acetate in energy storage systems. Preliminary research suggests that ethyl acetate-based electrolytes could enhance the performance of certain types of batteries, particularly in terms of charge-discharge efficiency and cycle life. Despite these potential benefits, the technology is still in its early stages and requires further optimization to compete with existing solutions.

The production of ethyl acetate from renewable sources has also seen progress, with bio-based methods gaining traction. Fermentation processes using agricultural waste and other biomass feedstocks have demonstrated the feasibility of sustainable ethyl acetate production. However, these methods currently struggle to match the efficiency and cost-effectiveness of traditional petrochemical routes, presenting a significant hurdle for large-scale implementation.

One of the primary challenges in ethyl acetate utilization is the need for infrastructure adaptation. Existing fuel distribution systems and engine technologies may require modifications to accommodate ethyl acetate-based fuels or additives, necessitating substantial investments and regulatory changes. Additionally, concerns about long-term material compatibility and potential corrosive effects on engine components need to be thoroughly addressed.

The regulatory landscape surrounding ethyl acetate in renewable energy applications remains complex and varies significantly across different regions. While some countries have implemented policies to encourage the use of bio-based solvents and additives, others lack clear guidelines, creating uncertainty for potential investors and developers. Harmonizing regulations and establishing international standards for ethyl acetate use in energy applications could accelerate its adoption and market penetration.

In conclusion, while ethyl acetate shows promise in various renewable energy applications, significant technical, economic, and regulatory challenges must be overcome to realize its full potential. Continued research and development efforts, coupled with supportive policies and industry collaboration, will be crucial in addressing these challenges and advancing the role of ethyl acetate in the renewable energy sector.

In recent years, researchers have explored the use of ethyl acetate as a biofuel additive, demonstrating its ability to enhance the performance of conventional fuels when blended in appropriate proportions. Studies have shown that ethyl acetate can improve the octane rating of gasoline, potentially leading to more efficient combustion and reduced emissions. However, the widespread adoption of ethyl acetate in this capacity faces challenges related to production costs and scalability.

Another promising area of development is the use of ethyl acetate in energy storage systems. Preliminary research suggests that ethyl acetate-based electrolytes could enhance the performance of certain types of batteries, particularly in terms of charge-discharge efficiency and cycle life. Despite these potential benefits, the technology is still in its early stages and requires further optimization to compete with existing solutions.

The production of ethyl acetate from renewable sources has also seen progress, with bio-based methods gaining traction. Fermentation processes using agricultural waste and other biomass feedstocks have demonstrated the feasibility of sustainable ethyl acetate production. However, these methods currently struggle to match the efficiency and cost-effectiveness of traditional petrochemical routes, presenting a significant hurdle for large-scale implementation.

One of the primary challenges in ethyl acetate utilization is the need for infrastructure adaptation. Existing fuel distribution systems and engine technologies may require modifications to accommodate ethyl acetate-based fuels or additives, necessitating substantial investments and regulatory changes. Additionally, concerns about long-term material compatibility and potential corrosive effects on engine components need to be thoroughly addressed.

The regulatory landscape surrounding ethyl acetate in renewable energy applications remains complex and varies significantly across different regions. While some countries have implemented policies to encourage the use of bio-based solvents and additives, others lack clear guidelines, creating uncertainty for potential investors and developers. Harmonizing regulations and establishing international standards for ethyl acetate use in energy applications could accelerate its adoption and market penetration.

In conclusion, while ethyl acetate shows promise in various renewable energy applications, significant technical, economic, and regulatory challenges must be overcome to realize its full potential. Continued research and development efforts, coupled with supportive policies and industry collaboration, will be crucial in addressing these challenges and advancing the role of ethyl acetate in the renewable energy sector.

Existing Ethyl Acetate-based Energy Solutions

01 Production and purification of ethyl acetate

Various methods are employed for the production and purification of ethyl acetate, including esterification, distillation, and extraction processes. These techniques aim to improve yield, purity, and efficiency in the manufacturing of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods are employed for the production and purification of ethyl acetate, including esterification reactions, distillation processes, and separation techniques. These methods aim to improve yield, purity, and efficiency in the manufacturing of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is widely used as a solvent and reagent in various chemical processes. It finds applications in organic synthesis, extraction procedures, and as a component in formulations for different industries such as pharmaceuticals, coatings, and adhesives.

- Ethyl acetate in polymer and material science: Ethyl acetate plays a role in polymer and material science applications. It is used in the preparation of polymers, as a solvent for resins, and in the development of advanced materials with specific properties for various industrial uses.

- Environmental and safety considerations for ethyl acetate: Research and development efforts focus on addressing environmental and safety concerns related to ethyl acetate use. This includes developing greener production methods, improving handling and storage practices, and exploring alternatives to reduce environmental impact and enhance worker safety.

- Novel applications and derivatives of ethyl acetate: Ongoing research explores novel applications and derivatives of ethyl acetate. This includes its use in emerging technologies, development of new compounds based on ethyl acetate, and innovative formulations for specialized industrial applications.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is widely used as a solvent and reagent in various chemical processes. It plays a crucial role in reactions, extractions, and as a medium for synthesizing other compounds. Its versatility makes it valuable in industries such as pharmaceuticals, polymers, and fine chemicals.Expand Specific Solutions03 Ethyl acetate in sustainable and green chemistry

Research focuses on developing environmentally friendly methods for producing and using ethyl acetate. This includes exploring bio-based sources, improving energy efficiency in production processes, and finding ways to recycle or reuse ethyl acetate in industrial applications.Expand Specific Solutions04 Separation and recovery of ethyl acetate

Various techniques are employed for the separation and recovery of ethyl acetate from mixtures or waste streams. These methods aim to improve the efficiency of ethyl acetate recycling in industrial processes, reducing waste and environmental impact while increasing cost-effectiveness.Expand Specific Solutions05 Ethyl acetate in material science and engineering

Ethyl acetate finds applications in material science and engineering, particularly in the development of coatings, adhesives, and polymer materials. Its properties make it suitable for use in various manufacturing processes and as a component in specialized materials for different industries.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The future prospects of ethyl acetate in renewable energy are characterized by a dynamic competitive landscape in an emerging market. The industry is in its early growth stage, with increasing interest from both established chemical companies and innovative startups. Market size is expected to expand significantly as renewable energy solutions gain traction globally. Technological maturity varies among players, with companies like Celanese International Corp., Evonik Operations GmbH, and China Petroleum & Chemical Corp. leveraging their extensive chemical expertise to advance ethyl acetate applications. Research institutions such as Nanjing Normal University and the Dalian Institute of Chemical Physics are contributing to technological advancements, while specialized firms like Nantong Baichuan New Material Co., Ltd. are focusing on niche applications within the renewable energy sector.

Celanese International Corp.

Technical Solution: Celanese International Corp. has been at the forefront of developing innovative applications for ethyl acetate in the renewable energy sector. Their research focuses on utilizing ethyl acetate as a key component in advanced energy storage solutions. The company has developed a proprietary process for synthesizing high-purity ethyl acetate from renewable feedstocks, primarily using bioethanol derived from agricultural waste[1]. This bio-based ethyl acetate is being explored as a sustainable solvent in the production of next-generation lithium-ion battery electrolytes, potentially enhancing battery performance and reducing environmental impact[2]. Celanese is also investigating the use of ethyl acetate-based composites in the manufacturing of lightweight, high-strength materials for wind turbine blades, aiming to improve energy efficiency in wind power generation[3]. Furthermore, the company is exploring the potential of ethyl acetate as a platform chemical for producing other renewable energy materials, such as advanced biofuels and solar panel components[4].

Strengths: Strong expertise in chemical engineering and material science; established global presence in specialty chemicals market. Weaknesses: Potential competition from other renewable solvents; dependency on availability and price fluctuations of bioethanol feedstock.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has been actively researching the potential of ethyl acetate in renewable energy applications. The company has developed a novel process for producing bio-based ethyl acetate using renewable resources, primarily focusing on lignocellulosic biomass as a feedstock[1]. This approach not only reduces reliance on fossil fuels but also contributes to a circular economy model. Evonik is exploring the use of this sustainable ethyl acetate in the production of advanced biofuels, particularly as a solvent in the extraction and purification processes of next-generation biofuels[2]. Additionally, the company is investigating the application of ethyl acetate-derived materials in the manufacturing of high-efficiency solar cells, aiming to improve their durability and performance[3]. Evonik is also researching the potential of ethyl acetate as a precursor for producing bio-based polymers that could be used in energy-efficient building materials and lightweight components for electric vehicles[4].

Strengths: Strong R&D capabilities in specialty chemicals; extensive experience in developing sustainable solutions. Weaknesses: Potential challenges in scaling up bio-based production processes; competition from established petrochemical-based ethyl acetate producers.

Innovative Patents in Ethyl Acetate Energy Applications

Ethyl Acetate As Fuel Or Fuel Additive

PatentInactiveUS20110296744A1

Innovation

- Using ethyl acetate as a fuel additive or blending agent in hydrocarbon-containing fuels, which is non-hygroscopic and offers desirable fuel characteristics, including higher heat of combustion and improved winter performance, thereby avoiding ethanol's drawbacks.

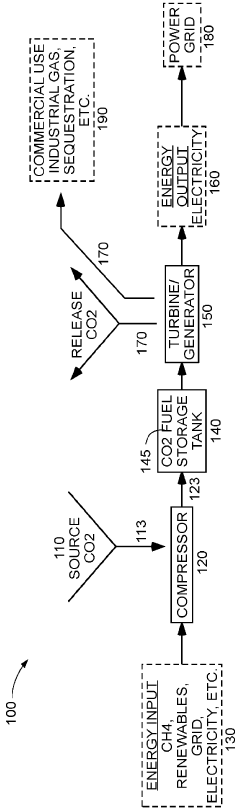

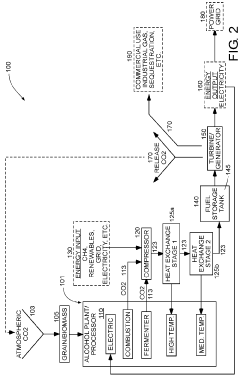

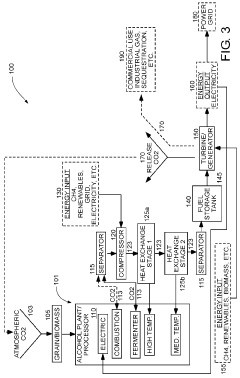

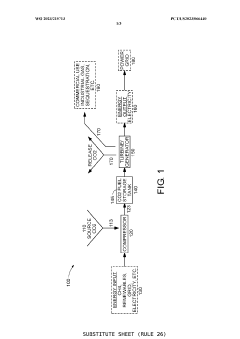

Utilization of carbon dioxide emissions as a fuel source and related systems and methods

PatentWO2023215713A1

Innovation

- The system captures carbon dioxide emissions and transforms them into a higher energy state fluid, which is stored for later use as a fuel source, enabling energy production during peak demand periods through devices like turbines, while also considering recapture and purification processes.

Environmental Impact Assessment

The environmental impact assessment of ethyl acetate in renewable energy applications reveals both potential benefits and challenges. As a renewable resource derived from biomass, ethyl acetate offers a promising alternative to fossil fuel-based solvents and energy carriers. Its production from sustainable feedstocks can contribute to reducing greenhouse gas emissions and dependence on non-renewable resources.

When used as a biofuel or fuel additive, ethyl acetate can potentially lower overall carbon emissions compared to conventional petroleum-based fuels. Its high oxygen content may lead to more complete combustion, resulting in reduced particulate matter and carbon monoxide emissions. However, the full life cycle analysis of ethyl acetate production and use must be considered to accurately assess its net environmental impact.

The production process of ethyl acetate from renewable sources, such as agricultural waste or dedicated energy crops, presents its own set of environmental considerations. While it can utilize waste materials and reduce landfill burden, large-scale production may compete with food crops for land use, potentially leading to indirect land-use changes and associated environmental impacts.

Water consumption and quality are critical factors in the environmental assessment of ethyl acetate production. The fermentation and distillation processes required for bio-based ethyl acetate can be water-intensive, necessitating careful water management strategies, especially in water-stressed regions. Additionally, proper treatment of wastewater from production facilities is essential to prevent water pollution and ecosystem disruption.

Air quality impacts of ethyl acetate production and use must also be evaluated. While it may reduce certain emissions when used as a fuel, the volatile nature of ethyl acetate can contribute to the formation of ground-level ozone and photochemical smog if released into the atmosphere during production or storage. Implementing robust emission control technologies and best practices in handling and storage is crucial to mitigate these potential air quality issues.

Biodegradability is a significant advantage of ethyl acetate over many synthetic solvents. Its relatively rapid breakdown in the environment reduces the risk of long-term contamination and bioaccumulation. However, the ecological effects of increased ethyl acetate concentrations in soil and water systems due to large-scale use and potential spills should be thoroughly investigated to ensure ecosystem health is not compromised.

In conclusion, while ethyl acetate shows promise as a renewable energy component with potential environmental benefits, a comprehensive and ongoing assessment of its impacts across the entire life cycle is necessary. This includes evaluating production methods, land use changes, water and air quality effects, and ecosystem interactions to ensure its sustainable integration into renewable energy systems.

When used as a biofuel or fuel additive, ethyl acetate can potentially lower overall carbon emissions compared to conventional petroleum-based fuels. Its high oxygen content may lead to more complete combustion, resulting in reduced particulate matter and carbon monoxide emissions. However, the full life cycle analysis of ethyl acetate production and use must be considered to accurately assess its net environmental impact.

The production process of ethyl acetate from renewable sources, such as agricultural waste or dedicated energy crops, presents its own set of environmental considerations. While it can utilize waste materials and reduce landfill burden, large-scale production may compete with food crops for land use, potentially leading to indirect land-use changes and associated environmental impacts.

Water consumption and quality are critical factors in the environmental assessment of ethyl acetate production. The fermentation and distillation processes required for bio-based ethyl acetate can be water-intensive, necessitating careful water management strategies, especially in water-stressed regions. Additionally, proper treatment of wastewater from production facilities is essential to prevent water pollution and ecosystem disruption.

Air quality impacts of ethyl acetate production and use must also be evaluated. While it may reduce certain emissions when used as a fuel, the volatile nature of ethyl acetate can contribute to the formation of ground-level ozone and photochemical smog if released into the atmosphere during production or storage. Implementing robust emission control technologies and best practices in handling and storage is crucial to mitigate these potential air quality issues.

Biodegradability is a significant advantage of ethyl acetate over many synthetic solvents. Its relatively rapid breakdown in the environment reduces the risk of long-term contamination and bioaccumulation. However, the ecological effects of increased ethyl acetate concentrations in soil and water systems due to large-scale use and potential spills should be thoroughly investigated to ensure ecosystem health is not compromised.

In conclusion, while ethyl acetate shows promise as a renewable energy component with potential environmental benefits, a comprehensive and ongoing assessment of its impacts across the entire life cycle is necessary. This includes evaluating production methods, land use changes, water and air quality effects, and ecosystem interactions to ensure its sustainable integration into renewable energy systems.

Economic Feasibility and Cost Analysis

The economic feasibility and cost analysis of ethyl acetate in renewable energy applications is a critical factor in determining its future prospects. The production of ethyl acetate from renewable sources, such as biomass-derived ethanol and acetic acid, presents both opportunities and challenges in terms of economic viability.

Currently, the production cost of bio-based ethyl acetate is generally higher than its petroleum-based counterpart. This is primarily due to the higher costs associated with renewable feedstocks and the additional processing steps required for their conversion. However, as technology advances and economies of scale are achieved, the cost gap is expected to narrow.

The economic feasibility of ethyl acetate in renewable energy applications is closely tied to the volatility of oil prices. When oil prices are high, bio-based ethyl acetate becomes more competitive. Conversely, low oil prices can make it challenging for renewable alternatives to compete on a cost basis alone. This dynamic underscores the importance of policy support and incentives to promote the adoption of bio-based chemicals in the renewable energy sector.

One of the key factors influencing the cost-effectiveness of ethyl acetate in renewable energy is the efficiency of production processes. Ongoing research and development efforts are focused on improving catalysts, optimizing reaction conditions, and developing more efficient separation techniques. These advancements have the potential to significantly reduce production costs and enhance the economic viability of bio-based ethyl acetate.

The cost analysis of ethyl acetate in renewable energy applications must also consider the entire value chain, from feedstock production to end-use applications. This includes factors such as transportation costs, storage requirements, and potential modifications needed in existing infrastructure to accommodate bio-based ethyl acetate. Additionally, the potential for co-product valorization, such as the utilization of by-products or waste streams, can contribute to improved overall economics.

Market demand and scale of production play crucial roles in determining the economic feasibility of ethyl acetate in renewable energy. As demand for sustainable and renewable chemicals grows, increased production volumes can lead to economies of scale, potentially reducing costs and improving competitiveness. Furthermore, the development of integrated biorefineries, where multiple bio-based products are produced from a single feedstock, can enhance the overall economic viability of ethyl acetate production.

In conclusion, while challenges remain, the economic feasibility of ethyl acetate in renewable energy applications shows promise for improvement. Continued technological advancements, supportive policies, and growing market demand for sustainable alternatives are expected to drive down costs and enhance the competitiveness of bio-based ethyl acetate in the coming years.

Currently, the production cost of bio-based ethyl acetate is generally higher than its petroleum-based counterpart. This is primarily due to the higher costs associated with renewable feedstocks and the additional processing steps required for their conversion. However, as technology advances and economies of scale are achieved, the cost gap is expected to narrow.

The economic feasibility of ethyl acetate in renewable energy applications is closely tied to the volatility of oil prices. When oil prices are high, bio-based ethyl acetate becomes more competitive. Conversely, low oil prices can make it challenging for renewable alternatives to compete on a cost basis alone. This dynamic underscores the importance of policy support and incentives to promote the adoption of bio-based chemicals in the renewable energy sector.

One of the key factors influencing the cost-effectiveness of ethyl acetate in renewable energy is the efficiency of production processes. Ongoing research and development efforts are focused on improving catalysts, optimizing reaction conditions, and developing more efficient separation techniques. These advancements have the potential to significantly reduce production costs and enhance the economic viability of bio-based ethyl acetate.

The cost analysis of ethyl acetate in renewable energy applications must also consider the entire value chain, from feedstock production to end-use applications. This includes factors such as transportation costs, storage requirements, and potential modifications needed in existing infrastructure to accommodate bio-based ethyl acetate. Additionally, the potential for co-product valorization, such as the utilization of by-products or waste streams, can contribute to improved overall economics.

Market demand and scale of production play crucial roles in determining the economic feasibility of ethyl acetate in renewable energy. As demand for sustainable and renewable chemicals grows, increased production volumes can lead to economies of scale, potentially reducing costs and improving competitiveness. Furthermore, the development of integrated biorefineries, where multiple bio-based products are produced from a single feedstock, can enhance the overall economic viability of ethyl acetate production.

In conclusion, while challenges remain, the economic feasibility of ethyl acetate in renewable energy applications shows promise for improvement. Continued technological advancements, supportive policies, and growing market demand for sustainable alternatives are expected to drive down costs and enhance the competitiveness of bio-based ethyl acetate in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!