GaN HEMT Applications In Renewable Energy Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN HEMT Evolution and Objectives

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have emerged as revolutionary semiconductor devices that are transforming renewable energy systems. The evolution of GaN technology began in the early 1990s with fundamental research into wide bandgap semiconductors. By the early 2000s, researchers had developed the first practical GaN HEMTs, primarily targeting RF applications for telecommunications and defense sectors.

The technological trajectory shifted significantly around 2010 when researchers and industry began exploring GaN's potential for power electronics applications. This pivot was driven by GaN's inherent material advantages: a wide bandgap (3.4 eV compared to silicon's 1.1 eV), high electron mobility, and superior thermal conductivity. These properties enable GaN HEMTs to operate at higher voltages, frequencies, and temperatures than traditional silicon-based devices.

Between 2010 and 2020, GaN HEMT technology matured considerably, with significant improvements in device reliability, performance, and manufacturing scalability. The introduction of enhancement-mode GaN HEMTs (e-mode) represented a critical milestone, enabling simpler gate drive requirements and facilitating broader adoption in power conversion applications.

In renewable energy systems specifically, GaN HEMTs have evolved from experimental components to commercial products that are reshaping solar inverters, wind power converters, and energy storage systems. The technology's trajectory has been characterized by continuous improvements in power density, efficiency, and cost-effectiveness, making renewable energy systems more competitive against fossil fuel alternatives.

The primary technical objectives for GaN HEMTs in renewable energy applications center on several key parameters. First is the enhancement of power conversion efficiency, with targets exceeding 99% for next-generation systems. This would significantly reduce energy losses in renewable power generation and storage. Second is increasing power density to enable more compact and lightweight renewable energy equipment, particularly important for distributed generation systems.

Additional objectives include improving thermal management capabilities to ensure reliable operation under variable environmental conditions typical in renewable energy installations. Researchers are also focused on extending device lifetime to match or exceed the 20-25 year operational expectancy of renewable energy infrastructure. Cost reduction remains a critical goal, with the aim of achieving price parity with silicon-based solutions while delivering superior performance.

Looking forward, the technology roadmap for GaN HEMTs in renewable energy systems aims to enable higher voltage ratings (beyond 1200V), enhance integration capabilities for more sophisticated power management solutions, and develop application-specific optimizations for different renewable energy technologies. These advancements will be crucial for supporting the global transition to renewable energy and achieving carbon neutrality targets.

The technological trajectory shifted significantly around 2010 when researchers and industry began exploring GaN's potential for power electronics applications. This pivot was driven by GaN's inherent material advantages: a wide bandgap (3.4 eV compared to silicon's 1.1 eV), high electron mobility, and superior thermal conductivity. These properties enable GaN HEMTs to operate at higher voltages, frequencies, and temperatures than traditional silicon-based devices.

Between 2010 and 2020, GaN HEMT technology matured considerably, with significant improvements in device reliability, performance, and manufacturing scalability. The introduction of enhancement-mode GaN HEMTs (e-mode) represented a critical milestone, enabling simpler gate drive requirements and facilitating broader adoption in power conversion applications.

In renewable energy systems specifically, GaN HEMTs have evolved from experimental components to commercial products that are reshaping solar inverters, wind power converters, and energy storage systems. The technology's trajectory has been characterized by continuous improvements in power density, efficiency, and cost-effectiveness, making renewable energy systems more competitive against fossil fuel alternatives.

The primary technical objectives for GaN HEMTs in renewable energy applications center on several key parameters. First is the enhancement of power conversion efficiency, with targets exceeding 99% for next-generation systems. This would significantly reduce energy losses in renewable power generation and storage. Second is increasing power density to enable more compact and lightweight renewable energy equipment, particularly important for distributed generation systems.

Additional objectives include improving thermal management capabilities to ensure reliable operation under variable environmental conditions typical in renewable energy installations. Researchers are also focused on extending device lifetime to match or exceed the 20-25 year operational expectancy of renewable energy infrastructure. Cost reduction remains a critical goal, with the aim of achieving price parity with silicon-based solutions while delivering superior performance.

Looking forward, the technology roadmap for GaN HEMTs in renewable energy systems aims to enable higher voltage ratings (beyond 1200V), enhance integration capabilities for more sophisticated power management solutions, and develop application-specific optimizations for different renewable energy technologies. These advancements will be crucial for supporting the global transition to renewable energy and achieving carbon neutrality targets.

Renewable Energy Market Demand Analysis

The renewable energy market has experienced unprecedented growth over the past decade, with global investments reaching $282.2 billion in 2019 and projected to exceed $1.5 trillion annually by 2030. This exponential growth is primarily driven by increasing environmental concerns, government policies promoting clean energy adoption, and significant cost reductions in renewable technologies. Within this expanding market, power electronics components play a crucial role in energy conversion efficiency, with GaN HEMT technology emerging as a transformative solution.

Solar energy represents the largest segment for potential GaN HEMT applications, with global capacity additions of 115 GW in 2019 and expected to reach 270 GW annually by 2030. The demand for higher efficiency inverters with reduced size and weight creates a substantial opportunity for GaN-based power devices, which can operate at higher frequencies and temperatures than traditional silicon solutions.

Wind energy systems, particularly offshore installations, require robust power conversion solutions capable of handling high voltages and harsh environmental conditions. With global wind capacity projected to grow at 10% CAGR through 2025, the need for advanced power electronics that can improve energy harvest efficiency while reducing maintenance costs presents another significant market for GaN HEMT technology.

Energy storage systems represent the fastest-growing segment in renewable energy, with annual deployments expected to triple by 2025. Bi-directional converters utilizing GaN technology can achieve higher power density and efficiency in battery management systems, addressing the critical need for improved grid integration of intermittent renewable sources.

Electric vehicle charging infrastructure, though peripheral to energy generation, forms an integral part of the renewable energy ecosystem. The global EV charging station market is expanding at 46% CAGR, creating demand for ultra-fast charging solutions where GaN HEMTs' high-frequency operation capabilities provide substantial advantages.

Market analysis indicates that efficiency improvements of just 1-2% in power conversion systems can translate to billions in additional revenue across the renewable energy value chain. GaN HEMT technology, offering potential efficiency gains of 3-5% over silicon-based solutions, presents compelling economic value beyond the initial component cost considerations.

Regional analysis shows Asia-Pacific leading market demand, accounting for 54% of global renewable energy investments, followed by Europe (22%) and North America (18%). China dominates manufacturing capacity for both renewable energy systems and semiconductor components, creating strategic supply chain considerations for global technology deployment.

Solar energy represents the largest segment for potential GaN HEMT applications, with global capacity additions of 115 GW in 2019 and expected to reach 270 GW annually by 2030. The demand for higher efficiency inverters with reduced size and weight creates a substantial opportunity for GaN-based power devices, which can operate at higher frequencies and temperatures than traditional silicon solutions.

Wind energy systems, particularly offshore installations, require robust power conversion solutions capable of handling high voltages and harsh environmental conditions. With global wind capacity projected to grow at 10% CAGR through 2025, the need for advanced power electronics that can improve energy harvest efficiency while reducing maintenance costs presents another significant market for GaN HEMT technology.

Energy storage systems represent the fastest-growing segment in renewable energy, with annual deployments expected to triple by 2025. Bi-directional converters utilizing GaN technology can achieve higher power density and efficiency in battery management systems, addressing the critical need for improved grid integration of intermittent renewable sources.

Electric vehicle charging infrastructure, though peripheral to energy generation, forms an integral part of the renewable energy ecosystem. The global EV charging station market is expanding at 46% CAGR, creating demand for ultra-fast charging solutions where GaN HEMTs' high-frequency operation capabilities provide substantial advantages.

Market analysis indicates that efficiency improvements of just 1-2% in power conversion systems can translate to billions in additional revenue across the renewable energy value chain. GaN HEMT technology, offering potential efficiency gains of 3-5% over silicon-based solutions, presents compelling economic value beyond the initial component cost considerations.

Regional analysis shows Asia-Pacific leading market demand, accounting for 54% of global renewable energy investments, followed by Europe (22%) and North America (18%). China dominates manufacturing capacity for both renewable energy systems and semiconductor components, creating strategic supply chain considerations for global technology deployment.

GaN HEMT Technology Status and Barriers

GaN HEMT technology has made significant strides in renewable energy applications, yet faces several technological barriers that limit its widespread adoption. Currently, GaN HEMT devices demonstrate superior performance characteristics compared to traditional silicon-based semiconductors, including higher breakdown voltage, faster switching speeds, and better thermal conductivity. These properties make them ideal for power conversion systems in solar inverters, wind turbine converters, and energy storage systems where efficiency is paramount.

Despite these advantages, manufacturing challenges persist in producing high-quality GaN epitaxial layers on large-diameter substrates. The lattice mismatch between GaN and common substrates like silicon or sapphire creates defects that compromise device performance and reliability. Industry leaders have developed various buffer layer technologies to mitigate these issues, but defect densities remain higher than optimal for critical renewable energy applications.

Another significant barrier is the current-collapse phenomenon, where dynamic on-resistance increases during switching operations, reducing efficiency in high-frequency applications. This effect, attributed to surface states and buffer traps, has been partially addressed through surface passivation techniques and field plate structures, but complete elimination remains elusive, particularly in high-voltage devices exceeding 650V.

Thermal management represents another critical challenge. While GaN's thermal conductivity exceeds silicon's, the high power density in GaN HEMTs creates localized hotspots that can accelerate device degradation. Advanced packaging solutions incorporating diamond heat spreaders show promise but remain cost-prohibitive for mass-market renewable energy systems.

Reliability concerns also hinder widespread adoption. GaN HEMTs in renewable energy systems must withstand harsh environmental conditions and operate reliably for decades. Current accelerated lifetime testing protocols may not adequately predict long-term performance in these applications, creating uncertainty for system designers and investors.

From a geographical perspective, GaN HEMT technology development shows concentration in specific regions. Japan, the United States, and Germany lead in fundamental research and intellectual property, while Taiwan and China have emerged as manufacturing powerhouses. This distribution creates potential supply chain vulnerabilities for renewable energy system manufacturers seeking stable component sourcing.

Cost remains perhaps the most significant barrier to widespread adoption. Despite progress in manufacturing techniques, GaN HEMTs still command a premium over silicon alternatives. The renewable energy sector, with its focus on levelized cost of energy, remains particularly price-sensitive. Industry analysts project that economies of scale will gradually reduce this gap, but silicon-based solutions will likely maintain cost advantages in lower-power applications for the foreseeable future.

Despite these advantages, manufacturing challenges persist in producing high-quality GaN epitaxial layers on large-diameter substrates. The lattice mismatch between GaN and common substrates like silicon or sapphire creates defects that compromise device performance and reliability. Industry leaders have developed various buffer layer technologies to mitigate these issues, but defect densities remain higher than optimal for critical renewable energy applications.

Another significant barrier is the current-collapse phenomenon, where dynamic on-resistance increases during switching operations, reducing efficiency in high-frequency applications. This effect, attributed to surface states and buffer traps, has been partially addressed through surface passivation techniques and field plate structures, but complete elimination remains elusive, particularly in high-voltage devices exceeding 650V.

Thermal management represents another critical challenge. While GaN's thermal conductivity exceeds silicon's, the high power density in GaN HEMTs creates localized hotspots that can accelerate device degradation. Advanced packaging solutions incorporating diamond heat spreaders show promise but remain cost-prohibitive for mass-market renewable energy systems.

Reliability concerns also hinder widespread adoption. GaN HEMTs in renewable energy systems must withstand harsh environmental conditions and operate reliably for decades. Current accelerated lifetime testing protocols may not adequately predict long-term performance in these applications, creating uncertainty for system designers and investors.

From a geographical perspective, GaN HEMT technology development shows concentration in specific regions. Japan, the United States, and Germany lead in fundamental research and intellectual property, while Taiwan and China have emerged as manufacturing powerhouses. This distribution creates potential supply chain vulnerabilities for renewable energy system manufacturers seeking stable component sourcing.

Cost remains perhaps the most significant barrier to widespread adoption. Despite progress in manufacturing techniques, GaN HEMTs still command a premium over silicon alternatives. The renewable energy sector, with its focus on levelized cost of energy, remains particularly price-sensitive. Industry analysts project that economies of scale will gradually reduce this gap, but silicon-based solutions will likely maintain cost advantages in lower-power applications for the foreseeable future.

Current GaN HEMT Implementation Solutions

01 GaN HEMT device structure and fabrication

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have a specific device structure that enables their high-performance characteristics. The fabrication process typically involves growing epitaxial layers on substrates like silicon carbide or silicon, followed by gate formation and contact metallization. Key structural elements include the AlGaN barrier layer, GaN channel layer, and various buffer layers that help manage strain and improve device performance. Advanced fabrication techniques focus on optimizing the 2DEG (two-dimensional electron gas) formation at the AlGaN/GaN interface, which is critical for the high electron mobility that gives these devices their name.- GaN HEMT device structure and fabrication: Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have specific structural designs that enhance their performance. These devices typically include a GaN layer, an AlGaN barrier layer, and specialized gate structures. The fabrication process involves epitaxial growth techniques, gate formation, and passivation layers to minimize surface states. Various structural innovations such as field plates, recessed gates, and buffer layer designs are implemented to improve breakdown voltage and reduce leakage current.

- Power applications and high-frequency performance: GaN HEMTs are widely used in power electronics and high-frequency applications due to their superior properties. These devices offer high breakdown voltage, low on-resistance, and excellent switching characteristics, making them ideal for power conversion systems. In RF applications, GaN HEMTs provide high power density, high efficiency, and operation at frequencies ranging from MHz to GHz. Their thermal management capabilities and reliability under high-power conditions make them suitable for telecommunications, radar systems, and power amplifiers.

- Reliability and thermal management solutions: Ensuring reliability and effective thermal management are critical aspects of GaN HEMT technology. Various approaches are employed to address issues such as current collapse, gate leakage, and thermal degradation. These include specialized passivation techniques, buffer layer optimization, and innovative heat dissipation structures. Advanced packaging solutions with improved thermal interfaces help manage the high power density of these devices. Reliability testing methodologies and lifetime prediction models are developed to ensure long-term stable operation under various stress conditions.

- Integration and packaging technologies: Integration of GaN HEMTs with other semiconductor technologies and advanced packaging solutions enhance their functionality and performance. Monolithic integration approaches combine GaN HEMTs with control circuits, protection features, and other functional blocks on the same chip. Novel packaging technologies address thermal, electrical, and mechanical challenges specific to GaN devices. These include flip-chip bonding, embedded die technologies, and specialized substrate materials that optimize heat dissipation while maintaining electrical performance. Such integration enables compact power modules and highly efficient RF systems.

- Novel materials and heterostructures: Research on novel materials and heterostructures aims to enhance GaN HEMT performance beyond conventional designs. This includes exploration of alternative barrier layers, such as InAlN or AlN, to improve carrier concentration and mobility. Advanced polarization engineering techniques modify the two-dimensional electron gas properties. Incorporation of novel materials in the gate stack, passivation layers, and ohmic contacts reduces parasitic resistances and improves reliability. These material innovations address current limitations in power handling, frequency response, and long-term stability of GaN HEMTs.

02 Power electronics applications of GaN HEMTs

GaN HEMTs are increasingly being utilized in power electronics applications due to their superior performance characteristics compared to silicon-based devices. These transistors offer higher breakdown voltage, faster switching speeds, and lower on-resistance, making them ideal for high-frequency power conversion systems. Applications include power supplies, motor drives, renewable energy inverters, and electric vehicle charging systems. The wide bandgap properties of GaN allow these devices to operate at higher temperatures and voltages while maintaining efficiency, resulting in smaller, more efficient power electronic systems with reduced cooling requirements.Expand Specific Solutions03 RF and microwave applications of GaN HEMTs

GaN HEMTs excel in radio frequency (RF) and microwave applications due to their high electron mobility, high power density, and ability to operate at high frequencies. These devices are widely used in telecommunications infrastructure, radar systems, satellite communications, and military applications. The high breakdown field of GaN allows these transistors to deliver higher output power at microwave frequencies compared to traditional semiconductor technologies. Recent developments focus on improving linearity, efficiency, and reliability for next-generation wireless communication systems including 5G and beyond.Expand Specific Solutions04 Reliability and thermal management of GaN HEMTs

Reliability and thermal management are critical aspects of GaN HEMT technology. These devices operate at high power densities, which can lead to significant self-heating and potential degradation mechanisms. Research focuses on understanding and mitigating various failure modes, including gate leakage, current collapse, and thermal degradation. Advanced packaging solutions, improved heat dissipation techniques, and novel substrate materials are being developed to enhance thermal performance. Reliability testing methodologies specific to GaN technology have been established to ensure long-term stability under various operating conditions, particularly for mission-critical applications.Expand Specific Solutions05 Novel GaN HEMT architectures and enhancements

Innovative GaN HEMT architectures are being developed to overcome limitations of conventional designs. These include enhancement-mode (normally-off) structures, which are preferred for power switching applications due to their fail-safe operation. Various gate technologies such as p-GaN gates, recessed gates, and hybrid structures are being explored to achieve normally-off operation while maintaining high performance. Other enhancements include field plates for improved breakdown voltage, passivation techniques to reduce surface-related effects, and novel buffer layer designs to minimize leakage currents. Integration with other semiconductor technologies and advanced packaging approaches are also being pursued to create more versatile and higher-performing devices.Expand Specific Solutions

Key Industry Players and Competitive Landscape

GaN HEMT technology in renewable energy systems is currently in a growth phase, with the market expected to expand significantly due to increasing demand for high-efficiency power conversion solutions. The global market for GaN power devices is projected to reach several billion dollars by 2026, driven by applications in solar inverters, wind power systems, and energy storage. Technologically, companies like Wolfspeed, MACOM, and Fujitsu are leading innovation with commercial GaN HEMT products, while Huawei and QUALCOMM are integrating these devices into renewable energy solutions. Academic institutions including Xidian University and UESTC are advancing fundamental research. Taiwan Semiconductor and UMC are scaling manufacturing capabilities, though challenges in cost reduction and reliability remain before widespread adoption can occur.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has pioneered GaN HEMT technology specifically optimized for renewable energy applications. Their solutions feature high-frequency switching capabilities (up to 100 kHz) that enable more compact and efficient power conversion systems. Wolfspeed's GaN HEMTs demonstrate superior performance in solar inverters, achieving efficiency ratings exceeding 98.5% in grid-tie applications. Their proprietary GaN-on-SiC technology offers breakdown voltages of 650V and 1200V, making them suitable for both residential and utility-scale renewable energy systems. The company has developed specialized packaging techniques to enhance thermal management, allowing their GaN devices to operate reliably at junction temperatures up to 175°C, which is critical for solar installations in harsh environments. Wolfspeed's renewable energy portfolio includes optimized gate driver solutions that address the unique switching characteristics of GaN, reducing parasitic inductances and enabling faster transition times.

Strengths: Industry-leading efficiency ratings, superior thermal performance, and specialized packaging for renewable applications. Weaknesses: Higher cost compared to silicon alternatives, requires specialized gate driver designs, and has more complex thermal management requirements in high-power applications.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced GaN HEMT technology for renewable energy systems, focusing on high-efficiency power conversion. Their FusionSolar smart PV solution incorporates GaN-based inverters that achieve peak efficiency of 99%, representing a significant improvement over traditional silicon-based systems. Huawei's GaN devices feature breakdown voltages of 650V with current ratings suitable for both residential and commercial solar installations. The company has implemented multi-level topologies in their inverter designs that leverage GaN's fast switching capabilities (>1 MHz) to reduce passive component sizes by approximately 40%. Their patented thermal management system allows for higher power density, resulting in inverters that are 30% smaller than conventional designs. Huawei has also developed specialized digital control algorithms that compensate for GaN's unique characteristics, optimizing switching patterns to minimize losses and electromagnetic interference in renewable energy applications.

Strengths: Comprehensive system-level integration, advanced digital control algorithms, and high power density solutions. Weaknesses: Proprietary ecosystem that may limit interoperability with third-party components, and relatively higher initial investment costs compared to traditional solutions.

Critical Patents and Technical Innovations

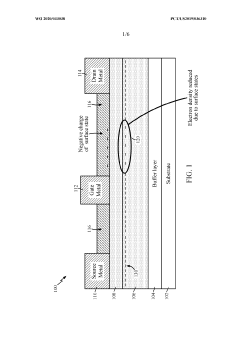

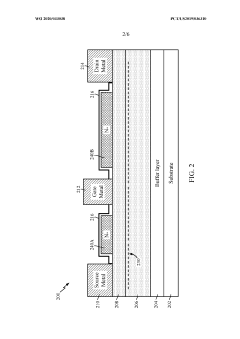

Gallium nitride high electron mobility transistor with ledges and field plates

PatentWO2020033038A1

Innovation

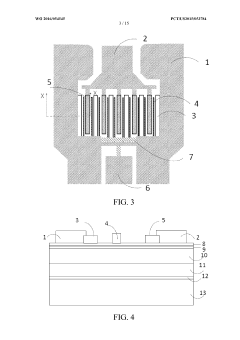

- Incorporating n-doped protuberances, or ledges, between the gate and source/drain electrodes, and optionally using field plates, to reduce surface states and increase channel electron density, thereby enhancing breakdown voltage and switching efficiency.

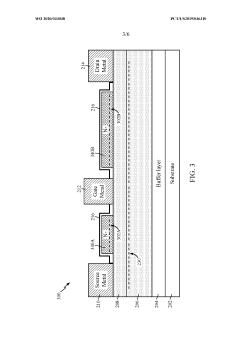

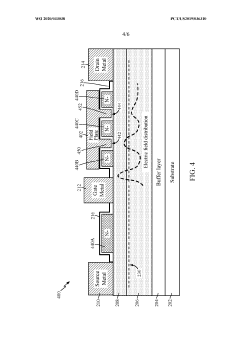

High electron mobility transistors with improved heat dissipation

PatentWO2016054545A1

Innovation

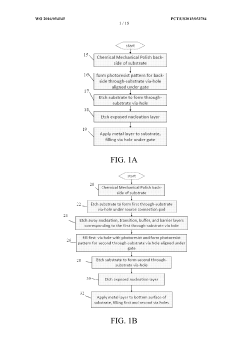

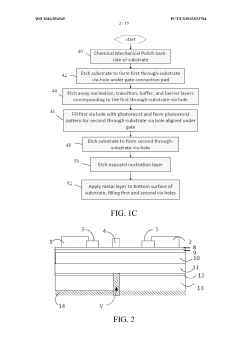

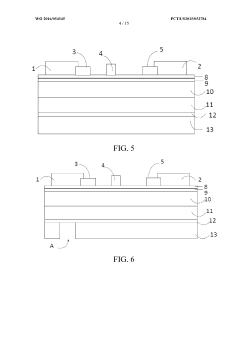

- The method involves etching a via hole through the substrate under the gate or active region of the HEMT to expose and remove the thermally resistive nucleation layer, followed by filling the via hole with metal to enhance heat dissipation, which can be connected to the source, drain, or gate electrodes, and includes forming additional via-holes under the source or gate to act as a field plate and heat sink.

Thermal Management Challenges

Thermal management represents one of the most critical challenges in the widespread adoption of GaN HEMT technology for renewable energy systems. As power density increases in these high-frequency, high-power applications, heat dissipation becomes a limiting factor that directly impacts device reliability, efficiency, and lifespan. GaN HEMTs operating in renewable energy inverters and power conversion systems can experience junction temperatures exceeding 200°C under high-load conditions, significantly accelerating device degradation mechanisms.

The thermal conductivity limitation of GaN substrates (approximately 130 W/m·K) compared to silicon carbide (490 W/m·K) creates inherent thermal bottlenecks. This challenge is further exacerbated in renewable energy applications where devices must operate reliably in variable environmental conditions, from sub-zero temperatures in wind turbines to extreme heat in solar installations.

Current thermal management approaches include advanced packaging technologies such as flip-chip configurations that reduce thermal resistance paths. Direct liquid cooling systems have demonstrated up to 40% improvement in heat dissipation compared to traditional air cooling but introduce complexity and reliability concerns in field deployments. Diamond heat spreaders, with thermal conductivity exceeding 1500 W/m·K, show promise but remain prohibitively expensive for mass-market renewable energy applications.

Thermal interface materials (TIMs) represent another critical component, with recent developments in graphene-enhanced composites showing thermal conductivity improvements of 60-80% over conventional materials. However, long-term reliability of these interfaces under thermal cycling conditions typical in renewable energy systems remains inadequately characterized.

Computational fluid dynamics (CFD) modeling has become essential for optimizing thermal designs, with recent advances in multi-physics simulation enabling more accurate prediction of hotspot formation and thermal transients during variable renewable energy generation. These tools have reduced design iterations by approximately 30% but require extensive validation in field conditions.

The industry faces a significant challenge in standardizing thermal characterization methodologies specific to renewable energy applications. Current testing protocols often fail to capture the unique thermal cycling and long-duration reliability requirements of solar inverters and wind power converters, leading to potential underestimation of thermal management needs in real-world deployments.

Emerging approaches include phase-change cooling systems and embedded microchannel cooling, which have demonstrated junction temperature reductions of up to 30°C in laboratory settings but face integration and manufacturing challenges when scaled to production volumes required for renewable energy markets.

The thermal conductivity limitation of GaN substrates (approximately 130 W/m·K) compared to silicon carbide (490 W/m·K) creates inherent thermal bottlenecks. This challenge is further exacerbated in renewable energy applications where devices must operate reliably in variable environmental conditions, from sub-zero temperatures in wind turbines to extreme heat in solar installations.

Current thermal management approaches include advanced packaging technologies such as flip-chip configurations that reduce thermal resistance paths. Direct liquid cooling systems have demonstrated up to 40% improvement in heat dissipation compared to traditional air cooling but introduce complexity and reliability concerns in field deployments. Diamond heat spreaders, with thermal conductivity exceeding 1500 W/m·K, show promise but remain prohibitively expensive for mass-market renewable energy applications.

Thermal interface materials (TIMs) represent another critical component, with recent developments in graphene-enhanced composites showing thermal conductivity improvements of 60-80% over conventional materials. However, long-term reliability of these interfaces under thermal cycling conditions typical in renewable energy systems remains inadequately characterized.

Computational fluid dynamics (CFD) modeling has become essential for optimizing thermal designs, with recent advances in multi-physics simulation enabling more accurate prediction of hotspot formation and thermal transients during variable renewable energy generation. These tools have reduced design iterations by approximately 30% but require extensive validation in field conditions.

The industry faces a significant challenge in standardizing thermal characterization methodologies specific to renewable energy applications. Current testing protocols often fail to capture the unique thermal cycling and long-duration reliability requirements of solar inverters and wind power converters, leading to potential underestimation of thermal management needs in real-world deployments.

Emerging approaches include phase-change cooling systems and embedded microchannel cooling, which have demonstrated junction temperature reductions of up to 30°C in laboratory settings but face integration and manufacturing challenges when scaled to production volumes required for renewable energy markets.

Cost-Performance Analysis

The economic viability of GaN HEMT technology in renewable energy systems hinges on a delicate balance between initial investment costs and long-term performance benefits. Currently, GaN HEMT devices command a premium price point compared to traditional silicon-based alternatives, with manufacturing costs approximately 3-5 times higher per unit area. This cost differential stems primarily from substrate materials, epitaxial growth processes, and lower production volumes that prevent economies of scale.

Despite higher upfront costs, GaN HEMT implementations demonstrate compelling performance advantages that translate to economic benefits over system lifetimes. In solar inverter applications, GaN-based systems achieve efficiency improvements of 1-3% compared to silicon alternatives, resulting in increased energy harvest that can generate an additional 2-5% revenue over the installation lifetime. The higher switching frequencies (typically 100-500 kHz versus 10-50 kHz for silicon) enable smaller passive components, reducing overall system size by up to 40% and decreasing material costs for supporting infrastructure.

Reliability metrics further strengthen the cost-performance proposition. GaN HEMTs exhibit lower failure rates in field deployments, with mean time between failures (MTBF) extending 1.5-2 times beyond silicon equivalents in similar operating conditions. This translates to reduced maintenance costs and system downtime, particularly valuable in remote renewable installations where service access presents logistical challenges.

The total cost of ownership (TCO) analysis reveals that GaN HEMT systems typically reach cost parity with silicon alternatives within 3-5 years of operation in utility-scale installations. For residential systems, this breakeven point extends to 5-7 years due to lower utilization rates and energy throughput. As manufacturing volumes increase, industry projections suggest GaN device costs will decrease by approximately 15% annually over the next five years, potentially accelerating adoption across renewable energy applications.

Energy density metrics further illustrate the cost-performance advantage, with GaN-based power conversion systems achieving 2.5-4 kW/L compared to 1-2 kW/L for silicon equivalents. This higher power density reduces installation footprint requirements by 30-50%, creating substantial savings for space-constrained applications and decreasing structural support costs in large-scale deployments.

Market sensitivity analysis indicates that GaN HEMT technology becomes increasingly economically favorable as energy prices rise and as carbon pricing mechanisms are implemented in more jurisdictions. With a carbon price of $30-50 per ton, the economic case for GaN technology strengthens by an additional 10-15% compared to baseline scenarios, highlighting the technology's alignment with broader decarbonization economic incentives.

Despite higher upfront costs, GaN HEMT implementations demonstrate compelling performance advantages that translate to economic benefits over system lifetimes. In solar inverter applications, GaN-based systems achieve efficiency improvements of 1-3% compared to silicon alternatives, resulting in increased energy harvest that can generate an additional 2-5% revenue over the installation lifetime. The higher switching frequencies (typically 100-500 kHz versus 10-50 kHz for silicon) enable smaller passive components, reducing overall system size by up to 40% and decreasing material costs for supporting infrastructure.

Reliability metrics further strengthen the cost-performance proposition. GaN HEMTs exhibit lower failure rates in field deployments, with mean time between failures (MTBF) extending 1.5-2 times beyond silicon equivalents in similar operating conditions. This translates to reduced maintenance costs and system downtime, particularly valuable in remote renewable installations where service access presents logistical challenges.

The total cost of ownership (TCO) analysis reveals that GaN HEMT systems typically reach cost parity with silicon alternatives within 3-5 years of operation in utility-scale installations. For residential systems, this breakeven point extends to 5-7 years due to lower utilization rates and energy throughput. As manufacturing volumes increase, industry projections suggest GaN device costs will decrease by approximately 15% annually over the next five years, potentially accelerating adoption across renewable energy applications.

Energy density metrics further illustrate the cost-performance advantage, with GaN-based power conversion systems achieving 2.5-4 kW/L compared to 1-2 kW/L for silicon equivalents. This higher power density reduces installation footprint requirements by 30-50%, creating substantial savings for space-constrained applications and decreasing structural support costs in large-scale deployments.

Market sensitivity analysis indicates that GaN HEMT technology becomes increasingly economically favorable as energy prices rise and as carbon pricing mechanisms are implemented in more jurisdictions. With a carbon price of $30-50 per ton, the economic case for GaN technology strengthens by an additional 10-15% compared to baseline scenarios, highlighting the technology's alignment with broader decarbonization economic incentives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!