How Are GaN HEMTs Applied In Wind Turbine Power Electronics?

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN HEMT Technology Evolution and Wind Energy Goals

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have undergone remarkable evolution since their inception in the early 1990s. Initially developed for military and aerospace applications due to their superior high-frequency performance, these wide-bandgap semiconductor devices have progressively transitioned into commercial power electronics over the past two decades. The technology evolution has been characterized by significant improvements in material quality, device architecture, and manufacturing processes, enabling GaN HEMTs to achieve higher breakdown voltages, lower on-resistance, and enhanced thermal management capabilities.

The evolution trajectory of GaN HEMT technology has been marked by several key milestones. Early developments focused on epitaxial growth techniques to reduce defect densities in GaN layers. Subsequently, innovations in device structures, such as the introduction of field plates and advanced gate designs, substantially improved voltage handling capabilities and switching performance. Recent advancements have centered on enhancing reliability through passivation techniques and developing normally-off (enhancement-mode) configurations that are more compatible with existing power electronic systems.

In parallel with GaN HEMT technology evolution, the wind energy sector has established increasingly ambitious goals driven by global renewable energy targets. Modern wind turbines have grown from kilowatt-scale generators to multi-megawatt systems, necessitating more efficient and reliable power conversion solutions. The industry aims to reduce the levelized cost of energy (LCOE) while improving grid integration capabilities and operational reliability under harsh environmental conditions.

Wind energy goals specifically relevant to power electronics include achieving higher power densities to reduce nacelle weight and size, improving conversion efficiency to maximize energy harvest, enhancing reliability to minimize maintenance requirements, and enabling advanced grid support functions such as low-voltage ride-through and reactive power control. Additionally, there is growing emphasis on extending operational lifetimes beyond 25 years while maintaining performance in offshore and remote installations where maintenance access is challenging and costly.

The convergence of GaN HEMT technology evolution and wind energy goals presents a compelling opportunity. As GaN HEMTs mature toward higher voltage ratings (>650V), lower specific on-resistance, and improved reliability metrics, they increasingly align with the power handling requirements of wind turbine converters. The technology's inherent advantages—faster switching speeds, lower switching losses, and higher temperature operation—directly address the wind industry's efficiency and power density objectives.

Looking forward, the continued co-evolution of these technologies is expected to enable more compact, efficient, and reliable wind power systems. Research efforts are increasingly focused on optimizing GaN HEMT designs specifically for renewable energy applications, with particular attention to cost reduction strategies that will facilitate broader commercial adoption in utility-scale wind installations.

The evolution trajectory of GaN HEMT technology has been marked by several key milestones. Early developments focused on epitaxial growth techniques to reduce defect densities in GaN layers. Subsequently, innovations in device structures, such as the introduction of field plates and advanced gate designs, substantially improved voltage handling capabilities and switching performance. Recent advancements have centered on enhancing reliability through passivation techniques and developing normally-off (enhancement-mode) configurations that are more compatible with existing power electronic systems.

In parallel with GaN HEMT technology evolution, the wind energy sector has established increasingly ambitious goals driven by global renewable energy targets. Modern wind turbines have grown from kilowatt-scale generators to multi-megawatt systems, necessitating more efficient and reliable power conversion solutions. The industry aims to reduce the levelized cost of energy (LCOE) while improving grid integration capabilities and operational reliability under harsh environmental conditions.

Wind energy goals specifically relevant to power electronics include achieving higher power densities to reduce nacelle weight and size, improving conversion efficiency to maximize energy harvest, enhancing reliability to minimize maintenance requirements, and enabling advanced grid support functions such as low-voltage ride-through and reactive power control. Additionally, there is growing emphasis on extending operational lifetimes beyond 25 years while maintaining performance in offshore and remote installations where maintenance access is challenging and costly.

The convergence of GaN HEMT technology evolution and wind energy goals presents a compelling opportunity. As GaN HEMTs mature toward higher voltage ratings (>650V), lower specific on-resistance, and improved reliability metrics, they increasingly align with the power handling requirements of wind turbine converters. The technology's inherent advantages—faster switching speeds, lower switching losses, and higher temperature operation—directly address the wind industry's efficiency and power density objectives.

Looking forward, the continued co-evolution of these technologies is expected to enable more compact, efficient, and reliable wind power systems. Research efforts are increasingly focused on optimizing GaN HEMT designs specifically for renewable energy applications, with particular attention to cost reduction strategies that will facilitate broader commercial adoption in utility-scale wind installations.

Market Analysis for GaN-Based Wind Turbine Power Electronics

The global market for GaN-based power electronics in wind turbine applications is experiencing significant growth, driven by the increasing demand for more efficient and reliable renewable energy solutions. The market size for GaN power devices in wind energy was valued at approximately $89 million in 2022 and is projected to reach $412 million by 2028, representing a compound annual growth rate (CAGR) of 29.1% during the forecast period.

Wind energy has emerged as one of the fastest-growing renewable energy sources globally, with installed capacity exceeding 837 GW by the end of 2022. This rapid expansion creates substantial demand for advanced power electronic solutions that can enhance energy conversion efficiency and system reliability. GaN HEMTs are particularly well-positioned to address these market needs due to their superior performance characteristics compared to traditional silicon-based devices.

Regional analysis reveals that Europe currently leads the market for GaN-based wind turbine power electronics, accounting for approximately 38% of the global market share. This dominance is attributed to Europe's aggressive renewable energy targets and substantial investments in offshore wind farms. Asia-Pacific follows closely with 34% market share, driven primarily by China's massive wind energy installations and Japan's growing focus on renewable energy following the Fukushima incident.

North America represents about 22% of the market, with increasing adoption expected as the region accelerates its transition to renewable energy sources. The remaining 6% is distributed across other regions, including the Middle East and Africa, where wind energy projects are gradually gaining momentum.

Market segmentation by application shows that power converters represent the largest application segment (43%), followed by inverters (31%), and other power management systems (26%). The offshore wind segment is growing particularly fast, with a CAGR of 32.7%, outpacing the onshore segment's growth rate of 27.3%.

Key market drivers include the increasing size of wind turbines, which necessitates more efficient power electronics; growing focus on grid stability and power quality; and the push for higher energy conversion efficiency to reduce levelized cost of energy (LCOE). Additionally, government regulations promoting renewable energy and carbon emission reduction targets are creating favorable market conditions for advanced power electronic solutions.

Market challenges include the relatively higher initial cost of GaN-based systems compared to silicon alternatives, limited manufacturing capacity for GaN devices, and the need for redesigning existing power electronic architectures to fully leverage GaN's capabilities. Despite these challenges, the long-term economic benefits and performance advantages of GaN HEMTs are expected to drive continued market expansion in the wind energy sector.

Wind energy has emerged as one of the fastest-growing renewable energy sources globally, with installed capacity exceeding 837 GW by the end of 2022. This rapid expansion creates substantial demand for advanced power electronic solutions that can enhance energy conversion efficiency and system reliability. GaN HEMTs are particularly well-positioned to address these market needs due to their superior performance characteristics compared to traditional silicon-based devices.

Regional analysis reveals that Europe currently leads the market for GaN-based wind turbine power electronics, accounting for approximately 38% of the global market share. This dominance is attributed to Europe's aggressive renewable energy targets and substantial investments in offshore wind farms. Asia-Pacific follows closely with 34% market share, driven primarily by China's massive wind energy installations and Japan's growing focus on renewable energy following the Fukushima incident.

North America represents about 22% of the market, with increasing adoption expected as the region accelerates its transition to renewable energy sources. The remaining 6% is distributed across other regions, including the Middle East and Africa, where wind energy projects are gradually gaining momentum.

Market segmentation by application shows that power converters represent the largest application segment (43%), followed by inverters (31%), and other power management systems (26%). The offshore wind segment is growing particularly fast, with a CAGR of 32.7%, outpacing the onshore segment's growth rate of 27.3%.

Key market drivers include the increasing size of wind turbines, which necessitates more efficient power electronics; growing focus on grid stability and power quality; and the push for higher energy conversion efficiency to reduce levelized cost of energy (LCOE). Additionally, government regulations promoting renewable energy and carbon emission reduction targets are creating favorable market conditions for advanced power electronic solutions.

Market challenges include the relatively higher initial cost of GaN-based systems compared to silicon alternatives, limited manufacturing capacity for GaN devices, and the need for redesigning existing power electronic architectures to fully leverage GaN's capabilities. Despite these challenges, the long-term economic benefits and performance advantages of GaN HEMTs are expected to drive continued market expansion in the wind energy sector.

Technical Challenges in GaN HEMT Wind Power Applications

Despite the promising advantages of GaN HEMTs in wind turbine power electronics, several significant technical challenges impede their widespread adoption. The high-frequency switching capability of GaN devices introduces electromagnetic interference (EMI) issues that require sophisticated shielding and filtering solutions. This is particularly problematic in wind turbine environments where equipment must operate reliably under harsh conditions while meeting strict electromagnetic compatibility standards.

Thermal management represents another critical challenge. While GaN HEMTs offer superior thermal conductivity compared to silicon, the high power density and switching frequencies generate substantial heat that must be efficiently dissipated. The confined spaces within wind turbine nacelles exacerbate this issue, necessitating advanced cooling systems that can maintain optimal operating temperatures without significantly increasing system size or weight.

Reliability concerns persist as GaN technology matures. The dynamic stress conditions in wind turbines—including voltage surges, temperature fluctuations, and mechanical vibrations—can accelerate device degradation. Current-collapse phenomena and gate degradation mechanisms remain particularly problematic for long-term operation, requiring robust device designs and packaging solutions to ensure the 20+ year lifespan expected of wind turbine components.

Gate driving presents unique challenges for GaN HEMTs in wind power applications. The devices require precise voltage control with minimal ringing and overshoot, yet must switch rapidly to maximize efficiency benefits. Conventional silicon-based gate drivers often prove inadequate, necessitating specialized driving circuits that can handle the unique characteristics of GaN devices while maintaining isolation in high-voltage environments.

System integration issues arise when incorporating GaN HEMTs into existing wind power converter architectures. The faster switching speeds require careful consideration of circuit layout to minimize parasitic inductances and capacitances. Additionally, the interaction between GaN devices and other system components can create unforeseen resonances and instabilities that compromise overall system performance.

Cost factors remain a significant barrier to widespread adoption. Though GaN manufacturing has advanced considerably, production volumes remain relatively low compared to silicon technologies, resulting in higher component costs. The economic justification for GaN implementation in wind power systems requires careful consideration of the total cost of ownership, including potential efficiency gains, reliability improvements, and reduced maintenance requirements over the system lifetime.

Standardization and qualification challenges further complicate GaN adoption in wind power applications. The industry lacks comprehensive standards specifically addressing GaN device qualification for wind turbine environments, creating uncertainty for manufacturers and system integrators. Developing appropriate testing protocols and reliability models tailored to the unique stress conditions of wind power applications represents an ongoing challenge for the industry.

Thermal management represents another critical challenge. While GaN HEMTs offer superior thermal conductivity compared to silicon, the high power density and switching frequencies generate substantial heat that must be efficiently dissipated. The confined spaces within wind turbine nacelles exacerbate this issue, necessitating advanced cooling systems that can maintain optimal operating temperatures without significantly increasing system size or weight.

Reliability concerns persist as GaN technology matures. The dynamic stress conditions in wind turbines—including voltage surges, temperature fluctuations, and mechanical vibrations—can accelerate device degradation. Current-collapse phenomena and gate degradation mechanisms remain particularly problematic for long-term operation, requiring robust device designs and packaging solutions to ensure the 20+ year lifespan expected of wind turbine components.

Gate driving presents unique challenges for GaN HEMTs in wind power applications. The devices require precise voltage control with minimal ringing and overshoot, yet must switch rapidly to maximize efficiency benefits. Conventional silicon-based gate drivers often prove inadequate, necessitating specialized driving circuits that can handle the unique characteristics of GaN devices while maintaining isolation in high-voltage environments.

System integration issues arise when incorporating GaN HEMTs into existing wind power converter architectures. The faster switching speeds require careful consideration of circuit layout to minimize parasitic inductances and capacitances. Additionally, the interaction between GaN devices and other system components can create unforeseen resonances and instabilities that compromise overall system performance.

Cost factors remain a significant barrier to widespread adoption. Though GaN manufacturing has advanced considerably, production volumes remain relatively low compared to silicon technologies, resulting in higher component costs. The economic justification for GaN implementation in wind power systems requires careful consideration of the total cost of ownership, including potential efficiency gains, reliability improvements, and reduced maintenance requirements over the system lifetime.

Standardization and qualification challenges further complicate GaN adoption in wind power applications. The industry lacks comprehensive standards specifically addressing GaN device qualification for wind turbine environments, creating uncertainty for manufacturers and system integrators. Developing appropriate testing protocols and reliability models tailored to the unique stress conditions of wind power applications represents an ongoing challenge for the industry.

Current GaN HEMT Implementation Strategies

01 GaN HEMT device structures and fabrication methods

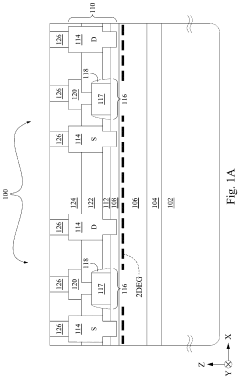

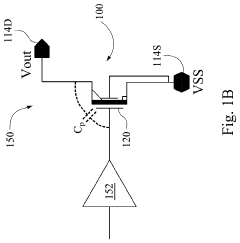

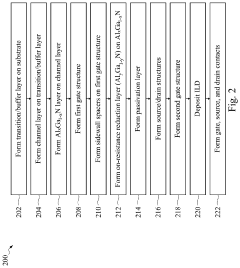

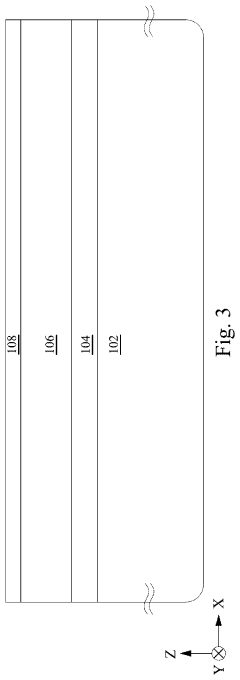

Various structural designs and fabrication techniques for GaN HEMTs are disclosed, including layer compositions, gate configurations, and manufacturing processes. These innovations focus on optimizing the device architecture to enhance performance characteristics such as power handling, switching speed, and reliability. Key structural elements include buffer layers, barrier layers, gate structures, and surface passivation techniques that collectively determine the device's electrical properties.- GaN HEMT device structures and fabrication: Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have specific device structures that enhance their performance. These structures include specialized gate configurations, buffer layers, and channel designs that improve electron mobility and power handling capabilities. Various fabrication techniques are employed to create these structures, including epitaxial growth methods, etching processes, and metallization techniques that optimize device performance and reliability.

- Power management and efficiency improvements: GaN HEMTs offer significant advantages in power management applications due to their high breakdown voltage and low on-resistance. Innovations in this area focus on improving power conversion efficiency, reducing switching losses, and enhancing thermal management. These improvements enable GaN HEMTs to operate at higher frequencies and power densities compared to traditional silicon-based transistors, making them ideal for power electronics applications.

- Reliability and performance enhancement techniques: Various techniques are employed to enhance the reliability and performance of GaN HEMTs. These include surface passivation methods, gate engineering, field plate designs, and stress management approaches. These techniques address common failure mechanisms such as current collapse, gate leakage, and thermal degradation, thereby extending device lifetime and improving operational stability under high-voltage and high-temperature conditions.

- Integration and packaging solutions: Integration and packaging solutions for GaN HEMTs focus on optimizing thermal management, reducing parasitic elements, and enabling high-frequency operation. Advanced packaging techniques include flip-chip bonding, embedded die technology, and integrated passive components. These solutions address the challenges of heat dissipation and electromagnetic interference while maximizing the performance benefits of GaN technology in compact form factors.

- Novel materials and heterostructures: Research in GaN HEMTs includes the development of novel materials and heterostructures to further enhance device performance. These innovations include alternative barrier layers, novel substrate materials, and advanced polarization engineering. The incorporation of materials such as AlGaN, InAlN, and diamond heat spreaders enables improvements in electron mobility, thermal conductivity, and breakdown voltage, pushing the performance boundaries of GaN HEMT technology.

02 Power electronics applications of GaN HEMTs

GaN HEMTs are implemented in various power electronic applications, leveraging their high breakdown voltage, low on-resistance, and fast switching capabilities. These devices are utilized in power conversion systems, amplifiers, and high-frequency circuits where efficiency and power density are critical. The implementations include specialized circuit topologies and driving methods designed to maximize the advantages of GaN technology in power management applications.Expand Specific Solutions03 Thermal management and reliability enhancement

Techniques for improving the thermal performance and reliability of GaN HEMTs are presented, addressing key challenges in high-power operation. These approaches include advanced heat dissipation structures, thermal interface materials, and packaging solutions designed to manage the high power density of GaN devices. Additionally, methods for mitigating degradation mechanisms such as current collapse and electron trapping are implemented to extend device lifetime and maintain stable performance under stress conditions.Expand Specific Solutions04 Integration and packaging technologies

Innovative integration and packaging solutions for GaN HEMTs are developed to optimize their performance in system-level applications. These include advanced interconnect technologies, multi-chip module approaches, and heterogeneous integration with other semiconductor technologies. The packaging techniques address challenges related to parasitic inductances, thermal resistance, and electromagnetic interference, enabling GaN HEMTs to achieve their full potential in compact, high-performance electronic systems.Expand Specific Solutions05 Novel materials and heterostructures

Research on advanced materials and heterostructures for next-generation GaN HEMTs focuses on enhancing electron mobility, increasing carrier density, and improving breakdown characteristics. These innovations include alternative barrier materials, novel channel designs, and composite substrate approaches. The material systems are engineered to reduce defect densities, minimize lattice mismatch, and optimize band alignments, resulting in devices with superior performance metrics for high-frequency and high-power applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GaN HEMT market in wind turbine power electronics is in a growth phase, with increasing adoption driven by demands for higher efficiency and power density in renewable energy systems. The market is expanding as wind energy installations grow globally, projected to reach significant value by 2030. Technologically, GaN HEMTs are maturing rapidly with companies like Transphorm, Fujitsu, and Power Integrations leading commercial applications, while Texas Instruments, STMicroelectronics, and Infineon advance device reliability and performance. Research institutions including MIT and UESTC collaborate with industry players like Toshiba and Sumitomo Electric to overcome thermal management challenges and improve integration with existing systems, accelerating the transition from silicon-based power electronics to GaN solutions in wind energy applications.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed a comprehensive GaN HEMT portfolio targeting renewable energy applications, with specific optimizations for wind turbine power electronics. Their technology utilizes a proprietary normally-off GaN-on-Silicon platform that enables direct integration with their advanced silicon driver and control ICs. ST's GaN devices feature breakdown voltages up to 650V with RDS(on) values below 50mΩ, making them suitable for multi-MW wind turbine power converters. Their technology incorporates advanced field plate structures and optimized buffer layers that minimize dynamic RDS(on) effects - a critical factor for maintaining efficiency in the variable load conditions typical of wind power generation. ST has demonstrated GaN-based power converters achieving efficiency improvements of 2-3% compared to silicon IGBT solutions in wind turbine applications, which translates to significant energy yield improvements over the 20+ year operational life of wind installations. Their GaN solutions include specialized protection features addressing grid fault conditions and lightning surge protection requirements specific to wind turbine environments.

Strengths: Vertical integration from wafer to system solution; extensive power electronics ecosystem supporting GaN implementation; proven high-volume manufacturing capability ensuring supply chain stability. Weaknesses: Relatively conservative voltage ratings compared to some SiC alternatives for very high-power wind applications; thermal management solutions still evolving for highest power density applications.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed an integrated GaN HEMT solution specifically targeting renewable energy applications including wind turbine power electronics. Their approach combines GaN power devices with specialized gate drivers and protection circuitry optimized for the demanding requirements of wind power systems. TI's GaN technology features a unique enhancement-mode design that eliminates the need for negative gate voltage, simplifying driver requirements in wind converter applications. Their GaN portfolio includes 600V and 650V devices with integrated drivers that achieve switching frequencies up to 2MHz while maintaining robust short-circuit protection essential for wind turbine reliability. TI has demonstrated that their GaN-based power converters can achieve power densities 3-4 times higher than silicon-based designs in wind power applications, enabling more compact nacelle installations. Their technology incorporates advanced thermal management techniques that address the challenging environmental conditions faced by wind turbine electronics, including wide temperature variations and high humidity environments.

Strengths: Comprehensive ecosystem including drivers, controllers and protection circuits specifically designed for GaN; extensive application support and design tools; proven reliability in harsh environments. Weaknesses: Limited high-current single-device options compared to some competitors; relatively newer entrant to high-power GaN applications compared to power semiconductor specialists.

Key Patents and Breakthroughs in GaN Wind Power Integration

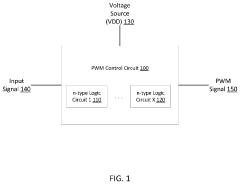

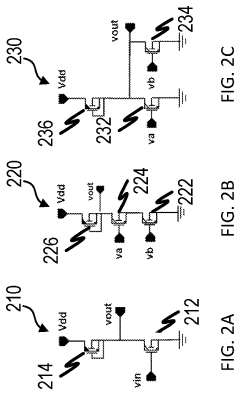

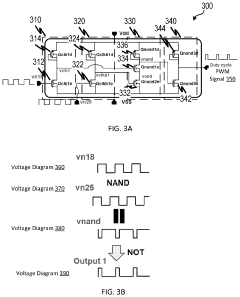

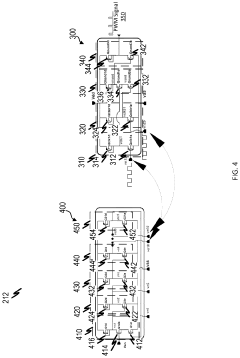

Pulse Width Control Apparatus and Method

PatentActiveUS20230396238A1

Innovation

- Implementing logic circuitry using only n-type HEMTs to generate PWM signals with minimal to no power loss, utilizing a combination of enhancement mode (E-HEMTs) and depletion mode (D-HEMTs) in series to control duty cycles without the need for additional components like sawtooth generators, level shifters, or comparators.

Gallium nitride high electron mobility transistor

PatentPendingUS20230395694A1

Innovation

- The solution involves forming a second AlGaN layer with a different composition over the AlGaN-GaN heterojunction, using sidewall spacers and selective epitaxy to decouple on-resistance from the threshold voltage, achieved by increasing the aluminum concentration in the AlGaN layer and adjusting its thickness, thereby enhancing spontaneous and piezoelectric polarization effects.

Reliability and Lifetime Assessment of GaN HEMTs

The reliability and lifetime assessment of GaN HEMTs is critical for their successful implementation in wind turbine power electronics, where operational conditions are harsh and maintenance is costly. These devices must withstand extreme temperature fluctuations, high humidity, and mechanical stresses while maintaining consistent performance over decades of operation.

Current reliability testing methodologies for GaN HEMTs in wind turbine applications include accelerated life testing, thermal cycling, power cycling, and humidity tests. These tests aim to simulate the stressors encountered in real-world wind turbine environments, which often exceed those in other power electronics applications due to the remote installation locations and exposure to environmental elements.

Key reliability concerns specific to GaN HEMTs in wind turbine power electronics include dynamic Ron degradation under high-voltage switching conditions, gate degradation mechanisms, and thermal management challenges. The high switching frequencies enabled by GaN technology create unique reliability challenges not present in traditional silicon-based systems, requiring specialized assessment protocols.

Industry data suggests that properly designed GaN HEMT power converters can achieve a mean time between failures (MTBF) exceeding 100,000 hours, which aligns with the 20-25 year expected lifetime of modern wind turbines. However, this requires careful system design with appropriate derating factors and robust thermal management solutions.

Lifetime prediction models for GaN HEMTs have evolved significantly, incorporating physics-of-failure approaches that consider multiple degradation mechanisms simultaneously. These models typically account for thermal cycling, power cycling, humidity effects, and mechanical vibration—all prevalent in wind turbine environments.

Recent advancements in reliability engineering for GaN HEMTs include the development of specialized packaging solutions that better withstand the thermal expansion stresses encountered during operation. Additionally, improved passivation techniques have enhanced resistance to moisture ingress, addressing a critical failure mechanism in humid offshore environments.

Field data from early GaN HEMT implementations in wind turbine power electronics demonstrates promising reliability metrics, with failure rates comparable to or better than silicon-based alternatives when properly designed. However, the relatively limited deployment history necessitates continued monitoring and data collection to validate long-term reliability projections.

Standardization efforts for reliability assessment are ongoing, with organizations like JEDEC and IEC developing specific test protocols for wide bandgap semiconductors in renewable energy applications. These standards will be crucial for ensuring consistent reliability evaluation across the industry and facilitating broader adoption of GaN technology in wind power systems.

Current reliability testing methodologies for GaN HEMTs in wind turbine applications include accelerated life testing, thermal cycling, power cycling, and humidity tests. These tests aim to simulate the stressors encountered in real-world wind turbine environments, which often exceed those in other power electronics applications due to the remote installation locations and exposure to environmental elements.

Key reliability concerns specific to GaN HEMTs in wind turbine power electronics include dynamic Ron degradation under high-voltage switching conditions, gate degradation mechanisms, and thermal management challenges. The high switching frequencies enabled by GaN technology create unique reliability challenges not present in traditional silicon-based systems, requiring specialized assessment protocols.

Industry data suggests that properly designed GaN HEMT power converters can achieve a mean time between failures (MTBF) exceeding 100,000 hours, which aligns with the 20-25 year expected lifetime of modern wind turbines. However, this requires careful system design with appropriate derating factors and robust thermal management solutions.

Lifetime prediction models for GaN HEMTs have evolved significantly, incorporating physics-of-failure approaches that consider multiple degradation mechanisms simultaneously. These models typically account for thermal cycling, power cycling, humidity effects, and mechanical vibration—all prevalent in wind turbine environments.

Recent advancements in reliability engineering for GaN HEMTs include the development of specialized packaging solutions that better withstand the thermal expansion stresses encountered during operation. Additionally, improved passivation techniques have enhanced resistance to moisture ingress, addressing a critical failure mechanism in humid offshore environments.

Field data from early GaN HEMT implementations in wind turbine power electronics demonstrates promising reliability metrics, with failure rates comparable to or better than silicon-based alternatives when properly designed. However, the relatively limited deployment history necessitates continued monitoring and data collection to validate long-term reliability projections.

Standardization efforts for reliability assessment are ongoing, with organizations like JEDEC and IEC developing specific test protocols for wide bandgap semiconductors in renewable energy applications. These standards will be crucial for ensuring consistent reliability evaluation across the industry and facilitating broader adoption of GaN technology in wind power systems.

Grid Integration Standards and Compliance Requirements

The integration of GaN HEMT-based power electronics in wind turbine systems must comply with stringent grid integration standards to ensure reliable and stable operation within the broader electrical grid infrastructure. These standards vary by region but generally focus on power quality, grid stability, and fault response capabilities.

In Europe, the EN 50438 and IEC 61400-21 standards specifically address the grid connection requirements for wind turbines, including harmonic distortion limits, voltage fluctuation parameters, and reactive power control capabilities. GaN HEMT-based converters must demonstrate compliance with these standards through rigorous testing and certification processes before deployment in commercial wind energy systems.

The IEEE 1547 standard, widely adopted in North America, establishes criteria for interconnection of distributed energy resources with electric power systems. For GaN HEMT applications in wind turbines, this requires advanced control algorithms to manage voltage regulation, frequency response, and islanding detection. The faster switching capabilities of GaN devices actually provide advantages in meeting these requirements, as they enable more precise power flow control and faster response to grid disturbances.

Grid codes in various countries have evolved to require Low Voltage Ride Through (LVRT) and High Voltage Ride Through (HVRT) capabilities, ensuring wind turbines remain connected during temporary grid voltage anomalies. GaN HEMT-based power converters must demonstrate robust performance under these conditions, maintaining stability during voltage sags as low as 0.2 per unit for specified durations.

Harmonic emission limits represent another critical compliance area. The IEC 61000-3-12 standard limits harmonic current emissions for equipment connected to public low-voltage systems. GaN HEMT converters, despite their high switching frequencies, must incorporate appropriate filtering solutions to maintain harmonic distortion below prescribed thresholds, typically with Total Harmonic Distortion (THD) below 5%.

Electromagnetic Compatibility (EMC) requirements, governed by standards such as IEC 61000-6-4 for emissions and IEC 61000-6-2 for immunity, present unique challenges for GaN-based systems due to their high dv/dt and di/dt characteristics. Manufacturers must implement effective EMI mitigation strategies, including optimized PCB layouts, appropriate shielding, and filtering components.

Reactive power management capabilities are increasingly mandated by grid codes worldwide. Modern requirements specify that wind turbines must be capable of operating across a defined range of power factors, typically from 0.95 leading to 0.95 lagging. GaN HEMT-based converters must incorporate control algorithms that enable precise and dynamic reactive power adjustment to support grid voltage stability under varying load conditions.

In Europe, the EN 50438 and IEC 61400-21 standards specifically address the grid connection requirements for wind turbines, including harmonic distortion limits, voltage fluctuation parameters, and reactive power control capabilities. GaN HEMT-based converters must demonstrate compliance with these standards through rigorous testing and certification processes before deployment in commercial wind energy systems.

The IEEE 1547 standard, widely adopted in North America, establishes criteria for interconnection of distributed energy resources with electric power systems. For GaN HEMT applications in wind turbines, this requires advanced control algorithms to manage voltage regulation, frequency response, and islanding detection. The faster switching capabilities of GaN devices actually provide advantages in meeting these requirements, as they enable more precise power flow control and faster response to grid disturbances.

Grid codes in various countries have evolved to require Low Voltage Ride Through (LVRT) and High Voltage Ride Through (HVRT) capabilities, ensuring wind turbines remain connected during temporary grid voltage anomalies. GaN HEMT-based power converters must demonstrate robust performance under these conditions, maintaining stability during voltage sags as low as 0.2 per unit for specified durations.

Harmonic emission limits represent another critical compliance area. The IEC 61000-3-12 standard limits harmonic current emissions for equipment connected to public low-voltage systems. GaN HEMT converters, despite their high switching frequencies, must incorporate appropriate filtering solutions to maintain harmonic distortion below prescribed thresholds, typically with Total Harmonic Distortion (THD) below 5%.

Electromagnetic Compatibility (EMC) requirements, governed by standards such as IEC 61000-6-4 for emissions and IEC 61000-6-2 for immunity, present unique challenges for GaN-based systems due to their high dv/dt and di/dt characteristics. Manufacturers must implement effective EMI mitigation strategies, including optimized PCB layouts, appropriate shielding, and filtering components.

Reactive power management capabilities are increasingly mandated by grid codes worldwide. Modern requirements specify that wind turbines must be capable of operating across a defined range of power factors, typically from 0.95 leading to 0.95 lagging. GaN HEMT-based converters must incorporate control algorithms that enable precise and dynamic reactive power adjustment to support grid voltage stability under varying load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!