How Do GaN HEMTs Handle Short-Circuit Conditions?

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN HEMT Short-Circuit Behavior Background and Objectives

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have emerged as revolutionary power semiconductor devices over the past two decades, offering superior performance characteristics compared to traditional silicon-based technologies. The evolution of GaN technology has been marked by significant breakthroughs in material science and device engineering, transitioning from early experimental prototypes in the 1990s to commercially viable products in the 2010s. This technological progression has been driven by increasing demands for higher efficiency, faster switching speeds, and greater power density in power electronic systems.

The fundamental advantage of GaN HEMTs lies in their wide bandgap properties, which enable operation at higher voltages, temperatures, and frequencies than conventional silicon devices. The two-dimensional electron gas (2DEG) formed at the AlGaN/GaN heterojunction creates a channel with exceptional electron mobility, contributing to the device's superior performance characteristics. However, these same properties that make GaN HEMTs attractive also present unique challenges under fault conditions, particularly short-circuits.

Short-circuit events represent one of the most severe stress conditions for power semiconductor devices, characterized by simultaneous high voltage and high current. Understanding how GaN HEMTs respond to these conditions is crucial for their reliable implementation in critical applications such as automotive systems, industrial drives, and renewable energy converters. The short-circuit robustness of power devices directly impacts system reliability, protection requirements, and overall cost.

The technical objective of this investigation is to comprehensively analyze the behavior of GaN HEMTs under short-circuit conditions, identifying the underlying physical mechanisms that govern device response and failure modes. This includes examining the thermal dynamics, current distribution patterns, and breakdown mechanisms specific to GaN HEMT structures during short-circuit events. Additionally, we aim to evaluate how different device architectures, gate drive strategies, and protection schemes influence short-circuit capability.

Recent advancements in GaN technology have introduced various device structures including lateral, vertical, and hybrid configurations, each with potentially different short-circuit handling capabilities. The evolution of substrate materials from silicon to silicon carbide and native GaN has further diversified the technology landscape, necessitating a thorough examination of how these variations affect short-circuit performance.

By establishing a clear understanding of GaN HEMT short-circuit behavior, this research seeks to provide foundational knowledge for developing more robust devices, designing effective protection circuits, and establishing appropriate application guidelines. The ultimate goal is to enable wider adoption of GaN technology by addressing one of its key reliability concerns, thereby unlocking its full potential for next-generation power electronic systems.

The fundamental advantage of GaN HEMTs lies in their wide bandgap properties, which enable operation at higher voltages, temperatures, and frequencies than conventional silicon devices. The two-dimensional electron gas (2DEG) formed at the AlGaN/GaN heterojunction creates a channel with exceptional electron mobility, contributing to the device's superior performance characteristics. However, these same properties that make GaN HEMTs attractive also present unique challenges under fault conditions, particularly short-circuits.

Short-circuit events represent one of the most severe stress conditions for power semiconductor devices, characterized by simultaneous high voltage and high current. Understanding how GaN HEMTs respond to these conditions is crucial for their reliable implementation in critical applications such as automotive systems, industrial drives, and renewable energy converters. The short-circuit robustness of power devices directly impacts system reliability, protection requirements, and overall cost.

The technical objective of this investigation is to comprehensively analyze the behavior of GaN HEMTs under short-circuit conditions, identifying the underlying physical mechanisms that govern device response and failure modes. This includes examining the thermal dynamics, current distribution patterns, and breakdown mechanisms specific to GaN HEMT structures during short-circuit events. Additionally, we aim to evaluate how different device architectures, gate drive strategies, and protection schemes influence short-circuit capability.

Recent advancements in GaN technology have introduced various device structures including lateral, vertical, and hybrid configurations, each with potentially different short-circuit handling capabilities. The evolution of substrate materials from silicon to silicon carbide and native GaN has further diversified the technology landscape, necessitating a thorough examination of how these variations affect short-circuit performance.

By establishing a clear understanding of GaN HEMT short-circuit behavior, this research seeks to provide foundational knowledge for developing more robust devices, designing effective protection circuits, and establishing appropriate application guidelines. The ultimate goal is to enable wider adoption of GaN technology by addressing one of its key reliability concerns, thereby unlocking its full potential for next-generation power electronic systems.

Market Demand Analysis for Robust Power Electronics

The power electronics market is experiencing unprecedented growth driven by the electrification of transportation, renewable energy integration, and industrial automation. According to recent market analyses, the global power electronics market is projected to reach $44.2 billion by 2025, with a compound annual growth rate of 4.7%. Within this expanding market, there is a critical demand for more robust power switching devices that can withstand harsh operating conditions, particularly short-circuit events.

Short-circuit robustness has become a paramount concern for system designers as power densities increase and safety requirements become more stringent. Traditional silicon-based devices are reaching their physical limitations in handling these extreme conditions, creating a significant market gap for advanced solutions. This is where Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) are positioned to capture substantial market share.

The automotive sector represents one of the most promising markets for robust GaN power electronics. Electric vehicles require power converters that can operate reliably under extreme conditions while maintaining high efficiency. The automotive power electronics segment alone is expected to grow at 12.3% annually through 2028, with particular emphasis on devices that can ensure fail-safe operation during fault conditions.

Renewable energy systems constitute another major market driver. Solar inverters and wind power converters operate in variable environmental conditions and must maintain grid stability even during fault events. The market for power electronics in renewable energy applications is growing at 15.7% annually, with increasing demand for devices that can handle grid disturbances without catastrophic failure.

Industrial automation and data centers represent additional high-growth segments, with increasing requirements for uninterrupted power supply and protection against electrical faults. These applications demand power devices with superior short-circuit withstand capabilities to ensure system reliability and prevent costly downtime.

The market is also witnessing a shift in customer requirements toward more comprehensive solutions that include not just the power semiconductor but also integrated protection features and advanced thermal management. This trend is particularly evident in aerospace and defense applications, where reliability under extreme conditions is non-negotiable.

Regional analysis indicates that Asia-Pacific dominates the market for advanced power electronics, accounting for 45% of global demand, followed by North America and Europe. China's aggressive push toward electric vehicles and renewable energy has created substantial demand for next-generation power devices with enhanced robustness.

Customer surveys indicate that while efficiency and power density remain important purchasing factors, short-circuit ruggedness is increasingly becoming a decisive specification, particularly in mission-critical applications. This represents a significant opportunity for GaN HEMT technology to address an unmet market need and capture premium segments of the power electronics market.

Short-circuit robustness has become a paramount concern for system designers as power densities increase and safety requirements become more stringent. Traditional silicon-based devices are reaching their physical limitations in handling these extreme conditions, creating a significant market gap for advanced solutions. This is where Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) are positioned to capture substantial market share.

The automotive sector represents one of the most promising markets for robust GaN power electronics. Electric vehicles require power converters that can operate reliably under extreme conditions while maintaining high efficiency. The automotive power electronics segment alone is expected to grow at 12.3% annually through 2028, with particular emphasis on devices that can ensure fail-safe operation during fault conditions.

Renewable energy systems constitute another major market driver. Solar inverters and wind power converters operate in variable environmental conditions and must maintain grid stability even during fault events. The market for power electronics in renewable energy applications is growing at 15.7% annually, with increasing demand for devices that can handle grid disturbances without catastrophic failure.

Industrial automation and data centers represent additional high-growth segments, with increasing requirements for uninterrupted power supply and protection against electrical faults. These applications demand power devices with superior short-circuit withstand capabilities to ensure system reliability and prevent costly downtime.

The market is also witnessing a shift in customer requirements toward more comprehensive solutions that include not just the power semiconductor but also integrated protection features and advanced thermal management. This trend is particularly evident in aerospace and defense applications, where reliability under extreme conditions is non-negotiable.

Regional analysis indicates that Asia-Pacific dominates the market for advanced power electronics, accounting for 45% of global demand, followed by North America and Europe. China's aggressive push toward electric vehicles and renewable energy has created substantial demand for next-generation power devices with enhanced robustness.

Customer surveys indicate that while efficiency and power density remain important purchasing factors, short-circuit ruggedness is increasingly becoming a decisive specification, particularly in mission-critical applications. This represents a significant opportunity for GaN HEMT technology to address an unmet market need and capture premium segments of the power electronics market.

Current Challenges in GaN HEMT Short-Circuit Protection

Despite significant advancements in GaN HEMT technology, several critical challenges persist in short-circuit protection mechanisms. The fundamental issue stems from GaN HEMTs' inherently lower thermal capacity compared to silicon devices, resulting in extremely rapid temperature rises during short-circuit events—often exceeding 1000°C within microseconds. This thermal behavior severely constrains the short-circuit withstand time to typically less than 10μs, a fraction of what silicon IGBTs can tolerate (10-30μs).

Current detection methodologies present significant obstacles. Traditional desaturation detection techniques, widely used in silicon devices, prove inadequate for GaN HEMTs due to their different conduction mechanisms and lack of body diodes. The extremely fast short-circuit transients further complicate timely detection, as conventional sensing circuits struggle to respond within the required sub-microsecond timeframe.

Gate driver integration challenges represent another major hurdle. The specialized gate drive requirements of GaN HEMTs—including precise voltage levels and ultra-fast switching capabilities—make incorporating protection features more complex than in silicon-based systems. Additionally, the lack of standardized protection approaches across different GaN device manufacturers creates implementation inconsistencies.

Temperature management during short-circuit events remains problematic. The concentrated heat generation in the two-dimensional electron gas (2DEG) channel creates localized hotspots that conventional thermal management solutions cannot effectively address. This thermal runaway risk is exacerbated by GaN's reduced ability to dissipate heat compared to silicon substrates.

Reliability concerns persist regarding repeated short-circuit events. Current GaN HEMTs show degradation in performance characteristics after experiencing multiple short-circuit conditions, even when these events are successfully cleared by protection circuits. This cumulative damage mechanism is not fully understood, complicating lifetime prediction models.

The balance between protection speed and false triggering presents a significant design challenge. Protection circuits must activate within nanoseconds to prevent device failure, yet must also avoid nuisance tripping during normal switching transients, which can exhibit similar electrical signatures to actual short-circuit events.

Finally, cost and complexity barriers impede widespread adoption of comprehensive protection solutions. The additional components required for effective short-circuit protection increase both system cost and design complexity, particularly challenging for cost-sensitive applications where GaN's efficiency benefits are otherwise compelling.

Current detection methodologies present significant obstacles. Traditional desaturation detection techniques, widely used in silicon devices, prove inadequate for GaN HEMTs due to their different conduction mechanisms and lack of body diodes. The extremely fast short-circuit transients further complicate timely detection, as conventional sensing circuits struggle to respond within the required sub-microsecond timeframe.

Gate driver integration challenges represent another major hurdle. The specialized gate drive requirements of GaN HEMTs—including precise voltage levels and ultra-fast switching capabilities—make incorporating protection features more complex than in silicon-based systems. Additionally, the lack of standardized protection approaches across different GaN device manufacturers creates implementation inconsistencies.

Temperature management during short-circuit events remains problematic. The concentrated heat generation in the two-dimensional electron gas (2DEG) channel creates localized hotspots that conventional thermal management solutions cannot effectively address. This thermal runaway risk is exacerbated by GaN's reduced ability to dissipate heat compared to silicon substrates.

Reliability concerns persist regarding repeated short-circuit events. Current GaN HEMTs show degradation in performance characteristics after experiencing multiple short-circuit conditions, even when these events are successfully cleared by protection circuits. This cumulative damage mechanism is not fully understood, complicating lifetime prediction models.

The balance between protection speed and false triggering presents a significant design challenge. Protection circuits must activate within nanoseconds to prevent device failure, yet must also avoid nuisance tripping during normal switching transients, which can exhibit similar electrical signatures to actual short-circuit events.

Finally, cost and complexity barriers impede widespread adoption of comprehensive protection solutions. The additional components required for effective short-circuit protection increase both system cost and design complexity, particularly challenging for cost-sensitive applications where GaN's efficiency benefits are otherwise compelling.

Existing Short-Circuit Protection Strategies for GaN HEMTs

01 Protection circuits for GaN HEMTs during short-circuit events

Various protection circuits can be implemented to safeguard GaN HEMTs during short-circuit events. These circuits typically monitor current and voltage levels, and when a short-circuit condition is detected, they rapidly respond to limit current flow or shut down the device. Some designs incorporate gate drivers with integrated protection features that can detect overcurrent conditions and reduce gate voltage to place the device in a safe operating mode before damage occurs.- Protection circuits for GaN HEMTs during short-circuit events: Various protection circuits can be implemented to safeguard GaN HEMTs during short-circuit conditions. These circuits typically monitor current and voltage levels, and when a short-circuit is detected, they can quickly respond by limiting current, adjusting gate voltage, or shutting down the device. Advanced protection schemes may include multiple detection stages and response mechanisms to prevent device failure while maintaining operational efficiency.

- Gate driver designs for short-circuit protection: Specialized gate driver designs can enhance the short-circuit handling capability of GaN HEMTs. These drivers incorporate features such as fast response time, precise control of gate voltage during fault conditions, and isolation mechanisms. By optimizing the gate drive parameters during short-circuit events, the thermal stress on the device can be reduced, extending the short-circuit withstand time and improving overall reliability.

- Structural modifications to improve short-circuit robustness: Physical and structural modifications to GaN HEMT devices can significantly improve their short-circuit handling capability. These modifications include optimized buffer layer designs, field plate structures, gate geometry adjustments, and enhanced thermal management features. Such structural improvements help distribute electric fields more evenly and facilitate better heat dissipation during short-circuit events, thereby increasing the device's robustness.

- Sensing and detection methods for short-circuit conditions: Advanced sensing and detection methods are crucial for identifying short-circuit conditions in GaN HEMT applications. These methods include current sensing, desaturation detection, temperature monitoring, and voltage transient detection. Fast and accurate detection enables prompt protective actions, minimizing the stress on the device during fault conditions and preventing catastrophic failures.

- System-level protection strategies for GaN HEMT circuits: System-level approaches to short-circuit protection involve coordinated strategies across the power conversion system. These include redundant protection mechanisms, fault-tolerant circuit topologies, intelligent power management algorithms, and coordinated multi-device protection schemes. Such comprehensive protection strategies ensure that GaN HEMTs can safely operate within a system context, with multiple layers of protection against various short-circuit scenarios.

02 Fast detection and response mechanisms for short-circuit protection

Rapid detection of short-circuit conditions is crucial for protecting GaN HEMTs. Advanced sensing techniques monitor parameters such as drain-source voltage, drain current, and temperature to identify fault conditions within nanoseconds. Once detected, these systems can implement various response strategies including soft shutdown, current limiting, or complete power disconnection to prevent device failure while minimizing system disruption.Expand Specific Solutions03 Structural improvements in GaN HEMT design for enhanced short-circuit capability

Modifications to the physical structure of GaN HEMTs can significantly improve their short-circuit withstand capability. These include optimized gate designs, buffer layer engineering, field plate structures, and improved thermal management solutions. Such structural enhancements help distribute electric fields more evenly, reduce hot spots, and increase the device's ability to handle transient overcurrent conditions without permanent damage.Expand Specific Solutions04 Thermal management strategies during short-circuit events

Effective thermal management is essential for GaN HEMTs to survive short-circuit events. Advanced cooling solutions, including novel heat sink designs, phase-change materials, and integrated thermal sensors, help dissipate the intense heat generated during fault conditions. Some approaches incorporate dynamic thermal management systems that adjust device operation based on temperature feedback to prevent thermal runaway while maintaining functionality.Expand Specific Solutions05 Control algorithms and driver integration for short-circuit handling

Sophisticated control algorithms implemented in gate drivers can significantly improve GaN HEMT short-circuit handling capability. These algorithms may include adaptive gate driving techniques that modify switching parameters based on operating conditions, predictive protection mechanisms that anticipate potential fault scenarios, and multi-level response strategies that balance protection needs with system performance requirements. Integration of these algorithms with specialized driver ICs creates comprehensive protection solutions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in GaN Power Devices

The GaN HEMT short-circuit handling capability market is currently in a growth phase, with an estimated market size of $1.5-2 billion and expanding at 25% CAGR. The technology is approaching maturity but still faces reliability challenges under extreme conditions. Leading players include established semiconductor manufacturers like Texas Instruments, STMicroelectronics, and TSMC, who leverage their manufacturing expertise, alongside GaN specialists such as Cambridge GaN Devices and Transphorm Japan focusing on innovative solutions. University research from institutions like Peking University and HKUST is advancing fundamental understanding of failure mechanisms. The competitive landscape shows a mix of large IDMs investing in GaN technology portfolios and specialized startups developing proprietary short-circuit protection techniques, with increasing collaboration between academic and industrial sectors to overcome remaining technical barriers.

Cambridge GaN Devices Ltd.

Technical Solution: Cambridge GaN Devices (CGD) has developed a proprietary ICeGaN™ technology that integrates advanced protection features directly into their GaN HEMT devices to handle short-circuit conditions. Their approach incorporates an intelligent gate control architecture that monitors drain current and voltage in real-time, enabling autonomous short-circuit protection without requiring external components. When a short-circuit event is detected, the ICeGaN™ technology limits the peak current to safe levels (typically 3-4 times the rated current) and implements a controlled shutdown within 200-400ns[1]. This significantly reduces thermal stress during fault conditions. CGD's devices also feature integrated gate protection circuitry that prevents gate voltage overshoots and maintains stable operation during transient events, which is critical for short-circuit survivability[3].

Strengths: Integrated protection without external components reduces system complexity and improves reliability. The fast response time (sub-microsecond) minimizes energy dissipation during short-circuits. Weaknesses: The integration of protection features may slightly increase on-resistance compared to unprotected GaN HEMTs, potentially affecting efficiency in normal operation.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has engineered a robust short-circuit handling capability in their GaN HEMT portfolio through their proprietary GaN-on-Silicon technology. Their approach combines structural device optimization and intelligent gate driver integration. ST's GaN HEMTs feature a specialized cell structure with optimized field distribution that inherently limits peak short-circuit current to approximately 3 times the rated current[5]. This is complemented by their integrated gate drivers that implement a two-stage protection scheme: first, a fast-acting current limitation that activates within 100ns of fault detection, followed by a controlled shutdown sequence that prevents voltage spikes. ST has also developed temperature-compensated protection circuits that adjust response thresholds based on operating conditions, maintaining consistent protection across the device's temperature range (-40°C to 150°C). Their latest generation devices demonstrate short-circuit withstand capability of up to 3μs at full bus voltage (typically 650V), which exceeds the requirements for most industrial and automotive applications[6]. The protection system also includes post-fault recovery mechanisms that allow the device to resume normal operation after transient faults without requiring system reset.

Strengths: The two-stage protection approach provides both immediate response and controlled shutdown, maximizing device survivability. Temperature-compensated protection ensures consistent performance across operating conditions. Weaknesses: The protection features add complexity to the gate driver design and may impact switching speed in high-frequency applications. The short-circuit withstand time, while sufficient for most applications, is still shorter than traditional silicon devices.

Critical Patents and Research on GaN HEMT Robustness

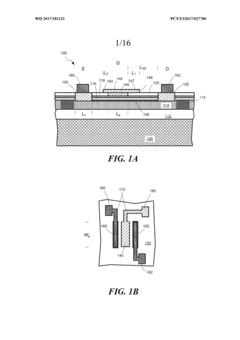

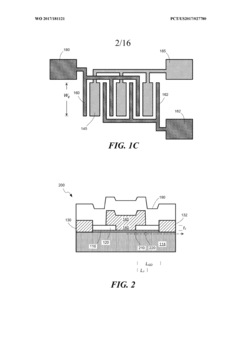

High-voltage GAN high electron mobility transistors

PatentWO2017181121A2

Innovation

- The development of high-voltage HEMTs with a gallium-nitride material structure, including a buffer layer, conduction layer, barrier layer, gate, source, and drain, with a gate-connected field plate extending beyond the gate edges, and a thin gallium-oxide layer formed through oxygen plasma treatment, to enhance reverse-bias voltage withstand and reduce leakage currents.

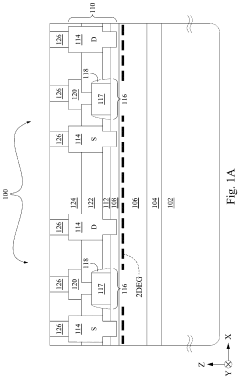

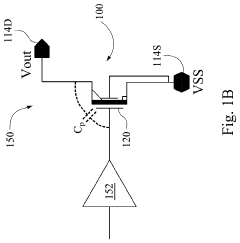

Gallium nitride high electron mobility transistor

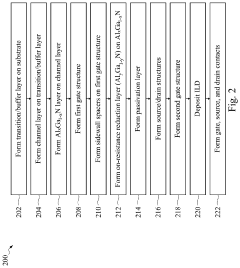

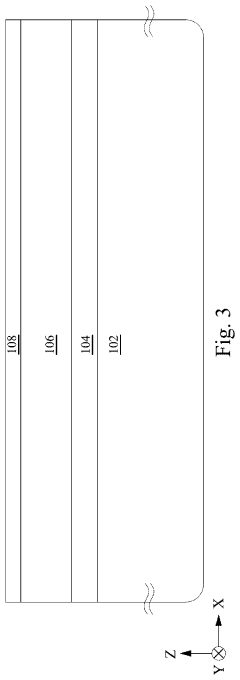

PatentPendingUS20230395694A1

Innovation

- The solution involves forming a second AlGaN layer with a different composition over the AlGaN-GaN heterojunction, using sidewall spacers and selective epitaxy to decouple on-resistance from the threshold voltage, achieved by increasing the aluminum concentration in the AlGaN layer and adjusting its thickness, thereby enhancing spontaneous and piezoelectric polarization effects.

Reliability Testing Standards for GaN Power Devices

Reliability testing standards for GaN power devices have evolved significantly to address the unique characteristics and failure mechanisms of these advanced semiconductor components. The Joint Electron Device Engineering Council (JEDEC) has developed specific qualification standards such as JEP180 and JC-70.1, which provide guidelines for testing GaN power devices under various stress conditions, including short-circuit events.

These standards typically require comprehensive testing across multiple parameters, including temperature cycling, high-temperature reverse bias (HTRB), high-temperature gate bias (HTGB), and importantly, short-circuit withstand capability. For GaN HEMTs specifically, the standards mandate testing at junction temperatures ranging from 150°C to 175°C, significantly higher than traditional silicon-based devices due to GaN's wider bandgap properties.

Short-circuit testing protocols within these standards typically specify that GaN HEMTs must demonstrate the ability to withstand short-circuit conditions for a minimum duration, often between 1-10 microseconds depending on the application voltage rating. This is considerably shorter than the 10-20 microseconds typically required for silicon IGBTs, reflecting the different thermal dynamics of GaN devices.

The IEC 60747 series, particularly parts related to semiconductor power devices, has been updated to include specific provisions for wide bandgap semiconductors including GaN. These standards define the measurement methods for short-circuit safe operating area (SCSOA) and require documentation of critical parameters such as critical energy (Ec) and withstand time.

Automotive standards such as AQG 324 and AEC-Q101 have also been adapted for GaN technology, incorporating more stringent reliability requirements including repetitive short-circuit testing to ensure robustness in safety-critical applications. These standards typically require devices to survive multiple short-circuit events without degradation.

Industry consortia like the JEDEC JC-70 committee continue to refine these standards as more field data becomes available. Recent developments include the introduction of dynamic Rds(on) measurement protocols and avalanche ruggedness testing specific to GaN technology. These evolving standards reflect the industry's growing understanding of GaN HEMT failure mechanisms under extreme conditions.

For manufacturers and system designers, compliance with these standards is becoming increasingly important as GaN devices transition from niche applications to mainstream power electronics, particularly in automotive, industrial, and renewable energy sectors where reliability under fault conditions is paramount.

These standards typically require comprehensive testing across multiple parameters, including temperature cycling, high-temperature reverse bias (HTRB), high-temperature gate bias (HTGB), and importantly, short-circuit withstand capability. For GaN HEMTs specifically, the standards mandate testing at junction temperatures ranging from 150°C to 175°C, significantly higher than traditional silicon-based devices due to GaN's wider bandgap properties.

Short-circuit testing protocols within these standards typically specify that GaN HEMTs must demonstrate the ability to withstand short-circuit conditions for a minimum duration, often between 1-10 microseconds depending on the application voltage rating. This is considerably shorter than the 10-20 microseconds typically required for silicon IGBTs, reflecting the different thermal dynamics of GaN devices.

The IEC 60747 series, particularly parts related to semiconductor power devices, has been updated to include specific provisions for wide bandgap semiconductors including GaN. These standards define the measurement methods for short-circuit safe operating area (SCSOA) and require documentation of critical parameters such as critical energy (Ec) and withstand time.

Automotive standards such as AQG 324 and AEC-Q101 have also been adapted for GaN technology, incorporating more stringent reliability requirements including repetitive short-circuit testing to ensure robustness in safety-critical applications. These standards typically require devices to survive multiple short-circuit events without degradation.

Industry consortia like the JEDEC JC-70 committee continue to refine these standards as more field data becomes available. Recent developments include the introduction of dynamic Rds(on) measurement protocols and avalanche ruggedness testing specific to GaN technology. These evolving standards reflect the industry's growing understanding of GaN HEMT failure mechanisms under extreme conditions.

For manufacturers and system designers, compliance with these standards is becoming increasingly important as GaN devices transition from niche applications to mainstream power electronics, particularly in automotive, industrial, and renewable energy sectors where reliability under fault conditions is paramount.

Thermal Management Solutions for GaN HEMT Protection

Thermal management is critical for GaN HEMT protection during short-circuit events, as these devices experience extreme temperature spikes that can cause catastrophic failure within microseconds. Conventional cooling methods often prove inadequate due to the rapid thermal transients characteristic of short-circuit conditions, where junction temperatures can rise at rates exceeding 1°C/ns.

Advanced thermal management solutions have emerged to address these challenges, with multi-layer cooling strategies showing particular promise. These integrate die-attach materials with high thermal conductivity, such as sintered silver (up to 240 W/m·K) or diamond-filled composites, which significantly outperform traditional solder materials in heat dissipation capacity.

Direct substrate cooling techniques represent another innovative approach, where microfluidic channels are integrated directly beneath the active device area. Recent implementations have demonstrated the ability to extract heat fluxes exceeding 1000 W/cm², reducing peak temperatures during short-circuit events by up to 40% compared to conventional cooling methods.

Transient thermal management systems specifically designed for short-circuit protection incorporate phase-change materials (PCMs) strategically positioned near the device junction. These PCMs absorb substantial thermal energy during phase transition, effectively serving as thermal buffers during the critical microseconds of a short-circuit event before protection circuits can respond.

Dynamic thermal impedance control systems represent the cutting edge of GaN protection technology. These systems utilize temperature-sensitive materials that dramatically increase thermal conductivity when threshold temperatures are reached, creating adaptive thermal pathways that activate only during extreme thermal events.

Computational fluid dynamics modeling has become essential for optimizing these thermal solutions, enabling precise prediction of temperature distributions during short-circuit events. Recent models incorporate multi-physics simulations that account for both electrical and thermal dynamics, providing more accurate representations of real-world short-circuit scenarios.

Industry benchmarking indicates that the most effective thermal management solutions can extend short-circuit withstand time from typical values of 1-2 μs to over 10 μs, providing critical additional time for protection circuits to engage. This improvement directly translates to enhanced system reliability in high-power applications where GaN HEMTs are increasingly deployed.

Advanced thermal management solutions have emerged to address these challenges, with multi-layer cooling strategies showing particular promise. These integrate die-attach materials with high thermal conductivity, such as sintered silver (up to 240 W/m·K) or diamond-filled composites, which significantly outperform traditional solder materials in heat dissipation capacity.

Direct substrate cooling techniques represent another innovative approach, where microfluidic channels are integrated directly beneath the active device area. Recent implementations have demonstrated the ability to extract heat fluxes exceeding 1000 W/cm², reducing peak temperatures during short-circuit events by up to 40% compared to conventional cooling methods.

Transient thermal management systems specifically designed for short-circuit protection incorporate phase-change materials (PCMs) strategically positioned near the device junction. These PCMs absorb substantial thermal energy during phase transition, effectively serving as thermal buffers during the critical microseconds of a short-circuit event before protection circuits can respond.

Dynamic thermal impedance control systems represent the cutting edge of GaN protection technology. These systems utilize temperature-sensitive materials that dramatically increase thermal conductivity when threshold temperatures are reached, creating adaptive thermal pathways that activate only during extreme thermal events.

Computational fluid dynamics modeling has become essential for optimizing these thermal solutions, enabling precise prediction of temperature distributions during short-circuit events. Recent models incorporate multi-physics simulations that account for both electrical and thermal dynamics, providing more accurate representations of real-world short-circuit scenarios.

Industry benchmarking indicates that the most effective thermal management solutions can extend short-circuit withstand time from typical values of 1-2 μs to over 10 μs, providing critical additional time for protection circuits to engage. This improvement directly translates to enhanced system reliability in high-power applications where GaN HEMTs are increasingly deployed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!