High-altitude Performance Optimization for Turbine Engines

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-altitude Turbine Engine Development History and Objectives

The evolution of turbine engines for high-altitude operations traces back to the mid-20th century, with significant advancements occurring during the Cold War era when military aircraft required enhanced performance at extreme altitudes. Initial designs faced substantial challenges related to air density reduction, oxygen scarcity, and temperature fluctuations that severely impacted combustion efficiency and overall engine performance. These early limitations restricted operational ceilings and reduced thrust capabilities when aircraft needed them most.

The 1960s and 1970s marked a pivotal transition with the introduction of variable geometry components and advanced compressor designs that could maintain pressure ratios despite thinner air. This period established the fundamental understanding that high-altitude engine optimization requires specialized approaches beyond standard sea-level performance parameters. The development of altitude test chambers during this era enabled more accurate simulation of stratospheric conditions, accelerating innovation cycles.

By the 1990s, computational fluid dynamics (CFD) revolutionized high-altitude engine design by allowing engineers to model complex airflow behaviors at various altitudes without costly physical testing. This technological leap coincided with growing commercial interest in more efficient high-altitude cruise performance for long-haul passenger aircraft, expanding research beyond purely military applications.

The 21st century has witnessed an intensified focus on high-altitude performance optimization driven by several factors: increasing demand for ultra-long-haul commercial flights, the emergence of high-altitude long-endurance (HALE) unmanned aerial vehicles, and renewed interest in supersonic and hypersonic flight. These applications have pushed engineers to develop engines capable of maintaining optimal combustion efficiency across dramatically varying atmospheric conditions.

Current technical objectives in this field center around several key areas: developing advanced materials capable of withstanding extreme temperature differentials encountered during rapid altitude changes; creating more sophisticated variable geometry systems that can continuously optimize airflow parameters; improving fuel injection systems for consistent atomization regardless of ambient pressure; and implementing adaptive control algorithms that can predict and compensate for altitude-related performance variations in real-time.

The ultimate goal of contemporary high-altitude turbine engine research is to develop propulsion systems with "altitude-agnostic" performance—engines that can maintain near-optimal efficiency, thrust, and fuel consumption regardless of operating altitude. This represents a significant departure from traditional design philosophies that accepted inevitable performance degradation at altitude in favor of optimizing for specific flight envelopes.

The 1960s and 1970s marked a pivotal transition with the introduction of variable geometry components and advanced compressor designs that could maintain pressure ratios despite thinner air. This period established the fundamental understanding that high-altitude engine optimization requires specialized approaches beyond standard sea-level performance parameters. The development of altitude test chambers during this era enabled more accurate simulation of stratospheric conditions, accelerating innovation cycles.

By the 1990s, computational fluid dynamics (CFD) revolutionized high-altitude engine design by allowing engineers to model complex airflow behaviors at various altitudes without costly physical testing. This technological leap coincided with growing commercial interest in more efficient high-altitude cruise performance for long-haul passenger aircraft, expanding research beyond purely military applications.

The 21st century has witnessed an intensified focus on high-altitude performance optimization driven by several factors: increasing demand for ultra-long-haul commercial flights, the emergence of high-altitude long-endurance (HALE) unmanned aerial vehicles, and renewed interest in supersonic and hypersonic flight. These applications have pushed engineers to develop engines capable of maintaining optimal combustion efficiency across dramatically varying atmospheric conditions.

Current technical objectives in this field center around several key areas: developing advanced materials capable of withstanding extreme temperature differentials encountered during rapid altitude changes; creating more sophisticated variable geometry systems that can continuously optimize airflow parameters; improving fuel injection systems for consistent atomization regardless of ambient pressure; and implementing adaptive control algorithms that can predict and compensate for altitude-related performance variations in real-time.

The ultimate goal of contemporary high-altitude turbine engine research is to develop propulsion systems with "altitude-agnostic" performance—engines that can maintain near-optimal efficiency, thrust, and fuel consumption regardless of operating altitude. This represents a significant departure from traditional design philosophies that accepted inevitable performance degradation at altitude in favor of optimizing for specific flight envelopes.

Market Analysis for High-altitude Turbine Applications

The high-altitude turbine engine market is experiencing significant growth driven by increasing demand in aviation, defense, and space exploration sectors. Current market valuations indicate the global high-altitude turbine engine market reached approximately $12.5 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. This growth trajectory is primarily fueled by expanding commercial aviation routes over polar regions and mountainous terrains, where high-altitude performance optimization becomes critical for operational efficiency and safety.

Military applications represent the largest market segment, accounting for roughly 45% of the total market share. The defense sector's demand stems from the strategic advantage offered by aircraft capable of operating efficiently at high altitudes, where detection and interception become more challenging. Countries with mountainous terrains or high-altitude borders, such as India, China, and several Central Asian nations, are investing heavily in high-altitude capable aircraft and the corresponding engine technologies.

Commercial aviation follows closely behind, constituting approximately 38% of the market. Airlines are increasingly seeking fuel efficiency improvements for trans-Himalayan and trans-Andean routes, where traditional engines experience significant performance degradation. The remaining market share is distributed among general aviation, research applications, and emerging space tourism ventures requiring specialized high-altitude propulsion solutions.

Geographically, North America dominates the market with a 36% share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.2% annually, driven by China's and India's expanding aviation sectors and military modernization programs focused on high-altitude capabilities.

Customer requirements are evolving toward engines that maintain optimal performance at altitudes above 40,000 feet while simultaneously reducing fuel consumption. Market research indicates that operators prioritize three key performance metrics: specific fuel consumption reduction (targeted at 15-20% improvement over conventional designs), consistent thrust delivery across varying altitudes, and reduced maintenance requirements resulting from high-altitude operation stresses.

The market also shows increasing demand for retrofitting solutions that can upgrade existing engine fleets for improved high-altitude performance, representing a growing segment with lower entry barriers for specialized engineering firms. This sub-segment is projected to grow at 9.3% annually, outpacing the overall market growth rate.

Military applications represent the largest market segment, accounting for roughly 45% of the total market share. The defense sector's demand stems from the strategic advantage offered by aircraft capable of operating efficiently at high altitudes, where detection and interception become more challenging. Countries with mountainous terrains or high-altitude borders, such as India, China, and several Central Asian nations, are investing heavily in high-altitude capable aircraft and the corresponding engine technologies.

Commercial aviation follows closely behind, constituting approximately 38% of the market. Airlines are increasingly seeking fuel efficiency improvements for trans-Himalayan and trans-Andean routes, where traditional engines experience significant performance degradation. The remaining market share is distributed among general aviation, research applications, and emerging space tourism ventures requiring specialized high-altitude propulsion solutions.

Geographically, North America dominates the market with a 36% share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.2% annually, driven by China's and India's expanding aviation sectors and military modernization programs focused on high-altitude capabilities.

Customer requirements are evolving toward engines that maintain optimal performance at altitudes above 40,000 feet while simultaneously reducing fuel consumption. Market research indicates that operators prioritize three key performance metrics: specific fuel consumption reduction (targeted at 15-20% improvement over conventional designs), consistent thrust delivery across varying altitudes, and reduced maintenance requirements resulting from high-altitude operation stresses.

The market also shows increasing demand for retrofitting solutions that can upgrade existing engine fleets for improved high-altitude performance, representing a growing segment with lower entry barriers for specialized engineering firms. This sub-segment is projected to grow at 9.3% annually, outpacing the overall market growth rate.

Current Technical Challenges in High-altitude Engine Operation

Turbine engines operating at high altitudes face significant challenges due to the unique atmospheric conditions. The reduced air density at elevations above 30,000 feet results in decreased oxygen availability, directly impacting combustion efficiency and overall engine performance. This phenomenon, known as "altitude lapse," can reduce engine thrust by up to 40% compared to sea-level operation, creating a fundamental challenge for high-altitude propulsion systems.

Temperature variations present another critical challenge. At cruising altitudes of 35,000-45,000 feet, ambient temperatures can plummet to -60°C, affecting fuel viscosity and atomization characteristics. These extreme cold conditions necessitate specialized fuel formulations and heating systems to maintain proper combustion parameters, adding complexity to engine design and operation protocols.

The reduced atmospheric pressure at high altitudes significantly alters the aerodynamic behavior within compressor stages. Engineers must contend with narrower compressor stall margins and increased risk of surge conditions, which can lead to catastrophic engine failure if not properly managed. Current compressor designs struggle to maintain optimal pressure ratios across the wide operational envelope required for high-altitude flight.

Water vapor content changes dramatically with altitude, creating challenges for combustion stability and emissions control. The extremely dry air at high altitudes affects flame propagation characteristics and can lead to increased NOx formation due to higher flame temperatures. This presents a technical contradiction between maintaining combustion efficiency and meeting increasingly stringent emissions regulations.

Material performance under combined low-temperature and low-pressure conditions represents another significant technical hurdle. Thermal gradients within engine components become more pronounced at altitude, accelerating thermal fatigue and potentially reducing component lifespan. Advanced materials with consistent performance across extreme temperature ranges are required but remain technically challenging to develop and implement cost-effectively.

Control system responsiveness becomes particularly critical at high altitudes where engine operating margins are reduced. Current engine control architectures struggle to provide the necessary adaptive response to rapidly changing atmospheric conditions during climb and descent phases. The integration of predictive algorithms and real-time atmospheric sensing capabilities remains an active area of development with significant technical barriers.

Icing prevention and management systems face heightened challenges at altitude, where supercooled water droplets can form rapidly on critical engine components. Current anti-icing technologies consume valuable engine bleed air, creating an efficiency penalty that compounds the already reduced performance at altitude. More energy-efficient icing protection systems are needed but face significant technical implementation challenges.

Temperature variations present another critical challenge. At cruising altitudes of 35,000-45,000 feet, ambient temperatures can plummet to -60°C, affecting fuel viscosity and atomization characteristics. These extreme cold conditions necessitate specialized fuel formulations and heating systems to maintain proper combustion parameters, adding complexity to engine design and operation protocols.

The reduced atmospheric pressure at high altitudes significantly alters the aerodynamic behavior within compressor stages. Engineers must contend with narrower compressor stall margins and increased risk of surge conditions, which can lead to catastrophic engine failure if not properly managed. Current compressor designs struggle to maintain optimal pressure ratios across the wide operational envelope required for high-altitude flight.

Water vapor content changes dramatically with altitude, creating challenges for combustion stability and emissions control. The extremely dry air at high altitudes affects flame propagation characteristics and can lead to increased NOx formation due to higher flame temperatures. This presents a technical contradiction between maintaining combustion efficiency and meeting increasingly stringent emissions regulations.

Material performance under combined low-temperature and low-pressure conditions represents another significant technical hurdle. Thermal gradients within engine components become more pronounced at altitude, accelerating thermal fatigue and potentially reducing component lifespan. Advanced materials with consistent performance across extreme temperature ranges are required but remain technically challenging to develop and implement cost-effectively.

Control system responsiveness becomes particularly critical at high altitudes where engine operating margins are reduced. Current engine control architectures struggle to provide the necessary adaptive response to rapidly changing atmospheric conditions during climb and descent phases. The integration of predictive algorithms and real-time atmospheric sensing capabilities remains an active area of development with significant technical barriers.

Icing prevention and management systems face heightened challenges at altitude, where supercooled water droplets can form rapidly on critical engine components. Current anti-icing technologies consume valuable engine bleed air, creating an efficiency penalty that compounds the already reduced performance at altitude. More energy-efficient icing protection systems are needed but face significant technical implementation challenges.

Current High-altitude Performance Enhancement Solutions

01 Performance monitoring and diagnostics systems

Advanced monitoring systems are implemented to track turbine engine performance parameters in real-time, enabling early detection of performance degradation and potential failures. These systems utilize various sensors to collect data on temperature, pressure, vibration, and other critical parameters. The collected data is analyzed using sophisticated algorithms to identify anomalies and predict maintenance needs, thereby optimizing engine performance and extending operational life.- Performance monitoring and diagnostics systems: Advanced monitoring systems are employed to track turbine engine performance parameters in real-time, enabling early detection of performance degradation and potential failures. These systems utilize various sensors and data analysis techniques to monitor critical engine parameters such as temperature, pressure, and vibration. By continuously analyzing these parameters, the systems can identify deviations from normal operating conditions and provide diagnostic information to optimize engine performance and maintenance schedules.

- Combustion efficiency optimization: Methods and systems for optimizing the combustion process in turbine engines to improve overall performance and reduce emissions. These innovations focus on fuel-air mixture control, combustion chamber design, and advanced fuel injection systems to achieve more complete combustion. By optimizing the combustion process, these technologies enhance thermal efficiency, reduce fuel consumption, and minimize the production of harmful emissions while maintaining or improving engine power output.

- Adaptive control systems for turbine engines: Adaptive control systems that dynamically adjust turbine engine parameters based on operating conditions to optimize performance. These systems use real-time data and advanced algorithms to make continuous adjustments to fuel flow, air intake, and other critical parameters. By adapting to changing environmental conditions, load requirements, and engine health status, these control systems can maintain optimal performance across a wide range of operating scenarios, extending engine life and improving fuel efficiency.

- Thermal management and cooling systems: Innovative cooling and thermal management solutions designed to maintain optimal operating temperatures in turbine engines. These technologies include advanced cooling passages, thermal barrier coatings, and heat exchange systems that effectively manage the extreme temperatures generated during operation. Proper thermal management prevents component degradation, extends part life, and allows engines to operate at higher temperatures for improved thermodynamic efficiency and overall performance.

- Performance prediction and modeling techniques: Computational methods and models used to predict turbine engine performance under various operating conditions. These techniques employ physics-based models, machine learning algorithms, and digital twins to simulate engine behavior and forecast performance metrics. By accurately predicting how engines will perform in different scenarios, these tools enable better design decisions, more effective maintenance planning, and optimization of operational parameters to achieve maximum efficiency and reliability.

02 Combustion efficiency optimization

Various methods and systems are employed to optimize the combustion process in turbine engines, resulting in improved performance and reduced emissions. These include advanced fuel injection systems, precise control of air-fuel ratios, and innovative combustion chamber designs. By enhancing combustion efficiency, these technologies contribute to increased power output, reduced fuel consumption, and compliance with stringent environmental regulations.Expand Specific Solutions03 Adaptive control systems for turbine engines

Adaptive control systems dynamically adjust turbine engine parameters based on operating conditions and performance requirements. These systems incorporate feedback mechanisms that continuously monitor engine performance and make real-time adjustments to optimize efficiency across various flight regimes or operating conditions. The adaptive approach allows for maintaining optimal performance despite changing environmental conditions, component wear, or varying power demands.Expand Specific Solutions04 Thermal management and cooling technologies

Effective thermal management is crucial for maintaining turbine engine performance and durability. Advanced cooling technologies are implemented to control temperature distribution within engine components, particularly in high-temperature zones such as turbine blades and combustion chambers. These include innovative cooling passage designs, thermal barrier coatings, and advanced materials that can withstand extreme temperatures, resulting in improved engine efficiency and extended component life.Expand Specific Solutions05 Performance prediction and simulation models

Sophisticated computational models are developed to predict turbine engine performance under various operating conditions. These models simulate the thermodynamic processes, fluid dynamics, and mechanical interactions within the engine, enabling engineers to optimize designs and operating parameters without extensive physical testing. The simulation capabilities help in identifying performance limitations, predicting the impact of design changes, and developing strategies to enhance overall engine efficiency and reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high-altitude turbine engine optimization market is currently in a growth phase, with increasing demand driven by aviation expansion into challenging environments and efficiency requirements. The global market size is estimated at $3.5-4 billion annually with projected 6-8% CAGR through 2030. Leading players form a competitive landscape dominated by established aerospace giants like Rolls-Royce, GE, and Safran Aircraft Engines who possess mature technologies for commercial applications. Research institutions including Beihang University and AVIC Shenyang Engine Research Institute are advancing fundamental technologies, while emerging players like AECC Commercial Aircraft Engine are gaining ground. The technology maturity varies significantly across applications, with commercial aviation solutions at TRL 7-9, while military and specialized high-altitude applications remain at TRL 5-7, indicating substantial room for innovation and market disruption.

General Electric Company

Technical Solution: GE's high-altitude turbine engine optimization program centers on their HAPS (High Altitude Propulsion System) technology, which incorporates advanced aerodynamic designs specifically engineered for thin-air operation. Their engines utilize variable geometry turbine nozzles that automatically adjust flow parameters based on altitude conditions, maintaining optimal pressure ratios despite decreasing air density. GE has pioneered specialized combustor designs featuring multi-zone fuel injection systems that ensure stable combustion at altitudes exceeding 40,000 feet, where oxygen concentration is significantly reduced. Their engines incorporate advanced materials including ceramic matrix composites (CMCs) in high-temperature components, which maintain structural integrity while reducing weight by approximately 30% compared to traditional metal alloys. GE's digital twin technology enables real-time performance monitoring and predictive maintenance specifically calibrated for high-altitude operation parameters, allowing operators to optimize engine performance across varying atmospheric conditions.

Strengths: Extensive experience with military and commercial high-altitude applications; superior materials technology with CMCs providing excellent thermal efficiency and weight reduction. Weaknesses: Higher initial acquisition costs; complex digital systems require specialized maintenance infrastructure and expertise.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed specialized high-altitude turbine engine solutions through their HAPE (High Altitude Performance Enhancement) program. Their technology incorporates advanced compressor designs with optimized blade aerodynamics that maintain efficiency in thin air conditions. Safran's engines feature specialized combustion chambers with altitude-adaptive fuel nozzles that maintain optimal spray patterns despite changing atmospheric pressures. Their proprietary ECMU (Engine Control and Monitoring Unit) includes specific high-altitude algorithms that continuously adjust engine parameters based on atmospheric conditions. Safran has developed specialized thermal management systems that efficiently handle the extreme temperature differentials encountered at high altitudes, where ambient temperatures can drop below -60°C while maintaining hot section temperatures above 1500°C. Their engines incorporate advanced materials including titanium aluminides in compressor sections, reducing weight by approximately 20% while maintaining structural integrity under the stress conditions specific to high-altitude operations.

Strengths: Superior fuel efficiency at cruise altitudes between 30,000-45,000 feet; excellent integration with aircraft systems through advanced digital interfaces. Weaknesses: Higher manufacturing complexity leads to increased production costs; more limited experience with military ultra-high altitude applications compared to some competitors.

Key Patents and Innovations in Altitude Compensation

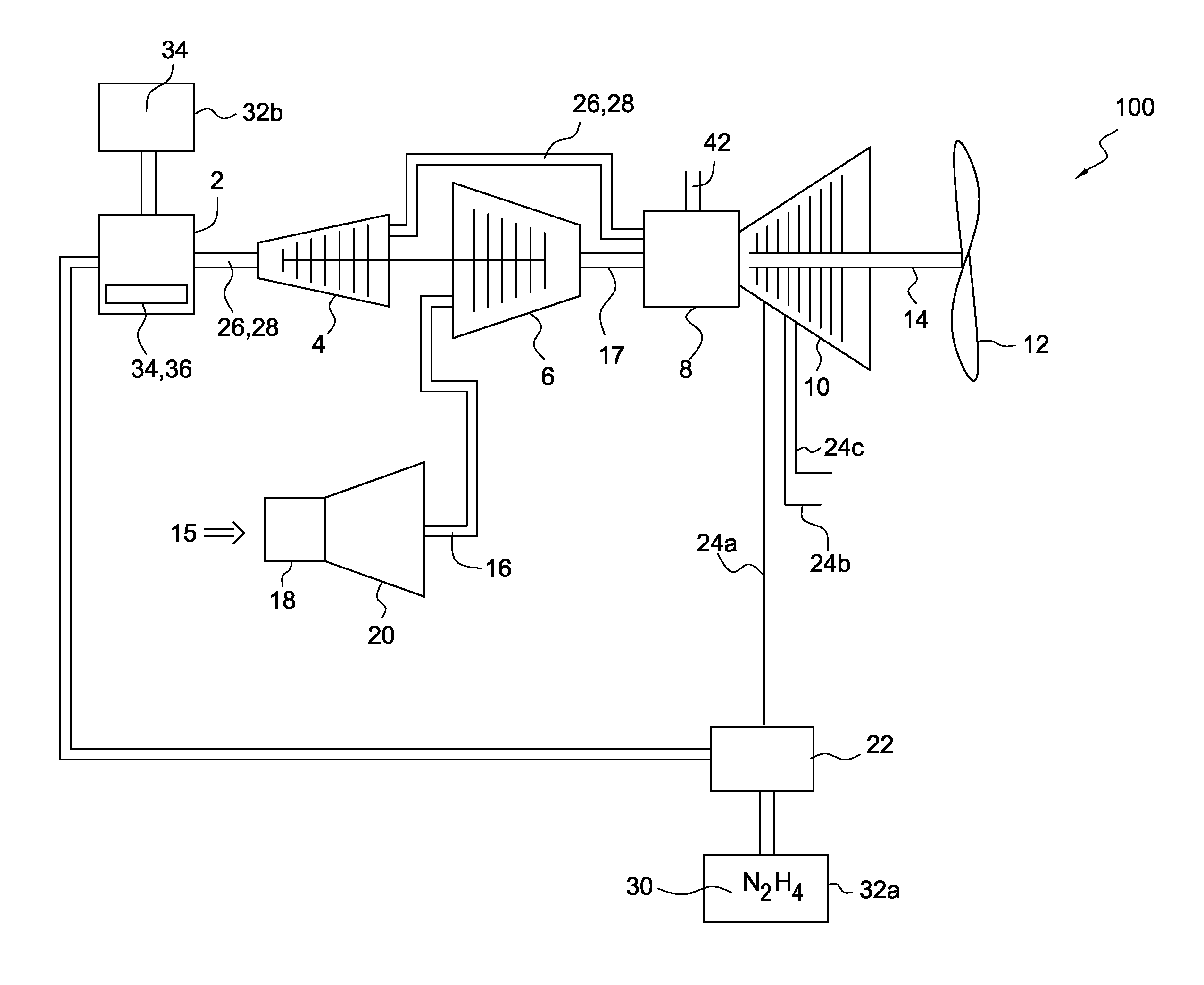

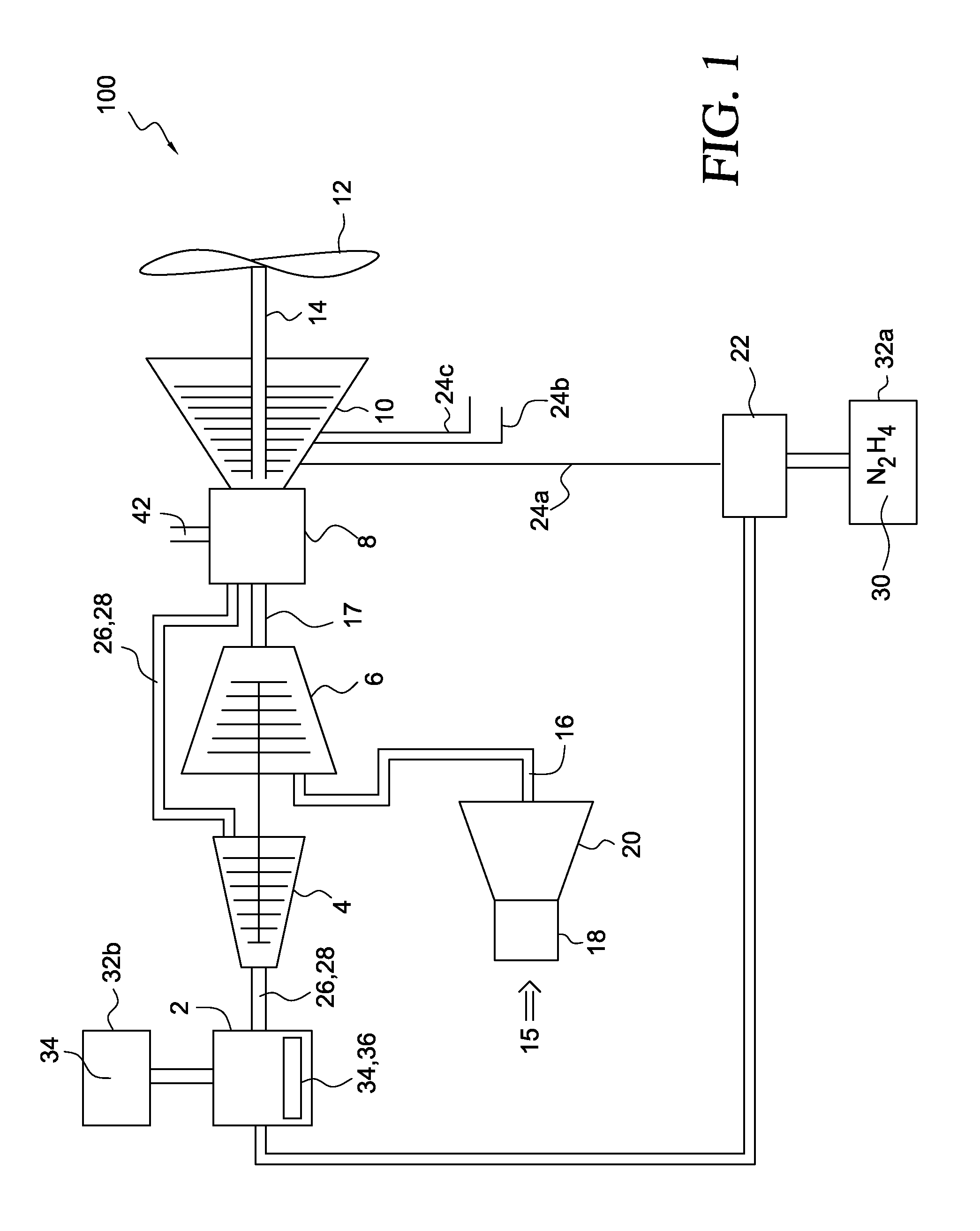

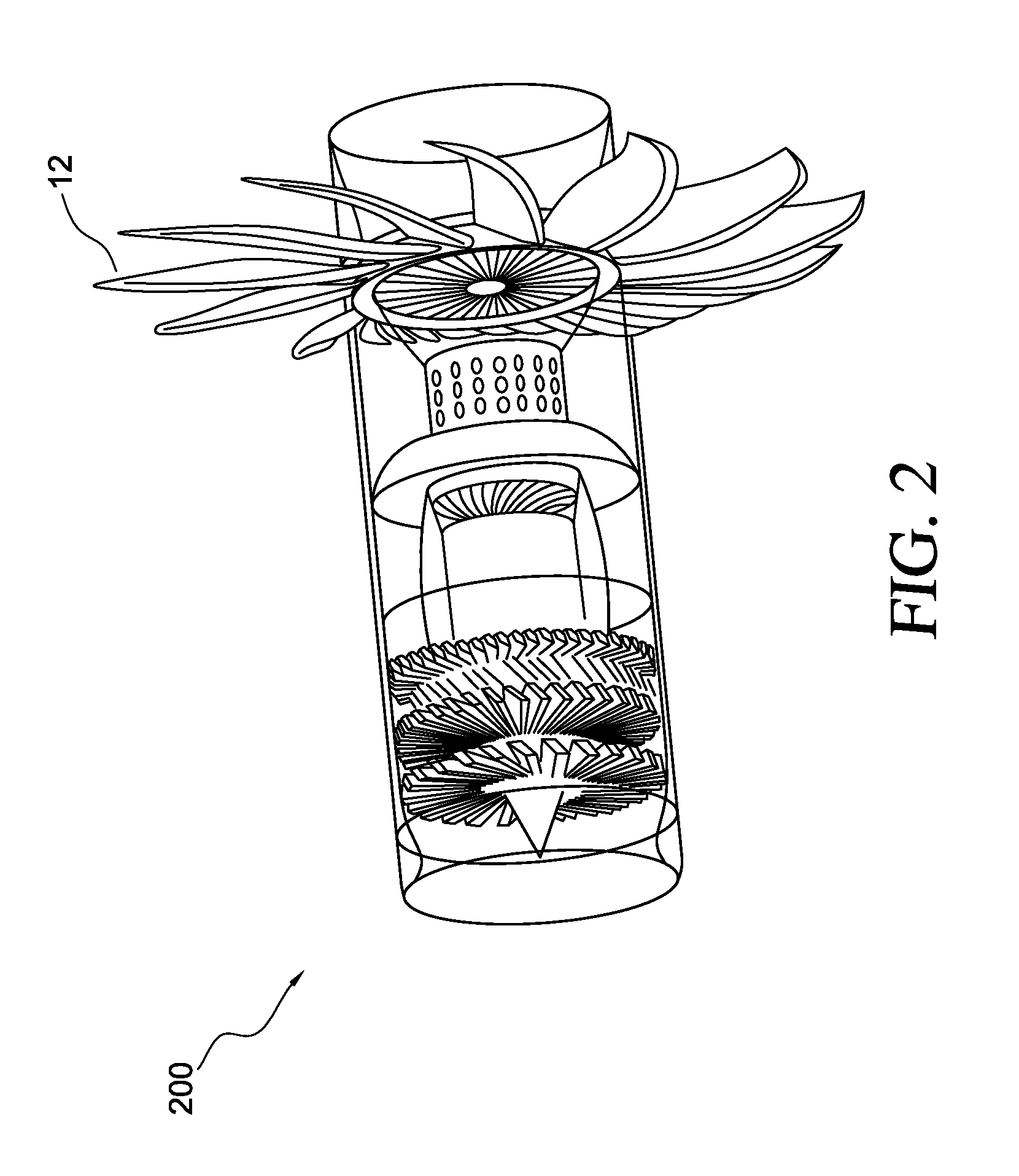

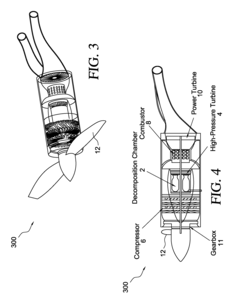

Hydrazine monopropellant decomposition air turboprop engine

PatentInactiveUS8205827B2

Innovation

- A hydrazine monopropellant decomposition air turboprop engine that uses a decomposition chamber to release heat and expand combustible constituents, driving a turbine to compress air and generate power, allowing stable combustion even at very high altitudes.

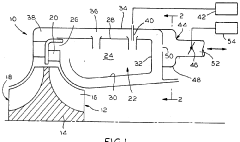

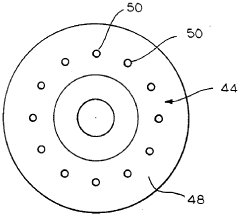

High altitude turbine engine starting system

PatentInactiveUS5231822A

Innovation

- A high altitude turbine engine system with an annular combustor and integrated fuel injection and compressed air bleeding mechanisms, responsive to instantaneous operating conditions, to optimize fuel flow and air mixing, featuring a controller for adjusting valve settings to enhance starting reliability and efficiency.

Environmental Impact and Sustainability Considerations

The environmental impact of high-altitude turbine engine operations has become increasingly significant as aviation continues to expand globally. Emissions at high altitudes have a disproportionate effect on atmospheric chemistry and climate forcing compared to ground-level emissions. Nitrogen oxides (NOx), carbon dioxide (CO2), water vapor, and particulate matter released at cruising altitudes directly contribute to the formation of contrails and cirrus clouds, which affect the Earth's radiation balance and potentially accelerate climate change.

Recent studies indicate that high-altitude engine optimization must consider not only performance metrics but also environmental sustainability. Traditional optimization approaches focusing solely on fuel efficiency inadvertently increase combustion temperatures, which can lead to higher NOx production. This creates a technical paradox where improvements in fuel consumption may result in more harmful emissions profiles, particularly in the sensitive upper troposphere and lower stratosphere regions.

Water vapor emissions at high altitudes present another environmental challenge. While often overlooked in ground-level emission assessments, water vapor released at cruising altitudes can persist as ice crystals, forming contrails that evolve into cirrus clouds. These anthropogenic clouds can trap outgoing longwave radiation, contributing to positive radiative forcing and warming effects that may offset gains achieved through fuel efficiency improvements.

Sustainable high-altitude engine design now incorporates advanced combustion technologies such as lean-burn systems and staged combustion chambers that maintain performance while reducing environmental impact. These technologies aim to optimize the combustion process to minimize both NOx formation and unburned hydrocarbon emissions without compromising altitude performance. Manufacturers are increasingly adopting these approaches to meet stringent international environmental standards like ICAO's CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation).

Material sustainability also factors into modern high-altitude engine design. The extreme operating conditions at high altitudes demand specialized materials that can withstand temperature fluctuations and reduced atmospheric pressure. Developing sustainable alternatives to rare earth elements and reducing the environmental footprint of manufacturing processes for high-performance alloys represents a frontier in sustainable aviation technology.

Life cycle assessment (LCA) methodologies are now being applied to evaluate the complete environmental impact of high-altitude engine technologies from raw material extraction through manufacturing, operation, and end-of-life disposal. This holistic approach ensures that environmental benefits achieved during operation are not offset by unsustainable practices elsewhere in the product lifecycle, providing a more comprehensive framework for truly sustainable high-altitude engine optimization.

Recent studies indicate that high-altitude engine optimization must consider not only performance metrics but also environmental sustainability. Traditional optimization approaches focusing solely on fuel efficiency inadvertently increase combustion temperatures, which can lead to higher NOx production. This creates a technical paradox where improvements in fuel consumption may result in more harmful emissions profiles, particularly in the sensitive upper troposphere and lower stratosphere regions.

Water vapor emissions at high altitudes present another environmental challenge. While often overlooked in ground-level emission assessments, water vapor released at cruising altitudes can persist as ice crystals, forming contrails that evolve into cirrus clouds. These anthropogenic clouds can trap outgoing longwave radiation, contributing to positive radiative forcing and warming effects that may offset gains achieved through fuel efficiency improvements.

Sustainable high-altitude engine design now incorporates advanced combustion technologies such as lean-burn systems and staged combustion chambers that maintain performance while reducing environmental impact. These technologies aim to optimize the combustion process to minimize both NOx formation and unburned hydrocarbon emissions without compromising altitude performance. Manufacturers are increasingly adopting these approaches to meet stringent international environmental standards like ICAO's CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation).

Material sustainability also factors into modern high-altitude engine design. The extreme operating conditions at high altitudes demand specialized materials that can withstand temperature fluctuations and reduced atmospheric pressure. Developing sustainable alternatives to rare earth elements and reducing the environmental footprint of manufacturing processes for high-performance alloys represents a frontier in sustainable aviation technology.

Life cycle assessment (LCA) methodologies are now being applied to evaluate the complete environmental impact of high-altitude engine technologies from raw material extraction through manufacturing, operation, and end-of-life disposal. This holistic approach ensures that environmental benefits achieved during operation are not offset by unsustainable practices elsewhere in the product lifecycle, providing a more comprehensive framework for truly sustainable high-altitude engine optimization.

Materials Science Advancements for Extreme Conditions

The extreme operating conditions at high altitudes present significant materials science challenges for turbine engine components. At elevations above 30,000 feet, temperatures can plummet below -50°C while combustion chambers simultaneously maintain temperatures exceeding 1,500°C. This severe thermal gradient demands materials with exceptional thermal stability and resistance to thermal fatigue.

Recent advancements in nickel-based superalloys have revolutionized high-altitude turbine performance. These materials exhibit remarkable strength-to-weight ratios and maintain structural integrity at temperatures approaching 90% of their melting points. Innovations in precipitation hardening techniques have yielded superalloys with improved creep resistance, extending component lifespan by up to 30% compared to previous generations.

Ceramic matrix composites (CMCs) represent another breakthrough for extreme altitude applications. Silicon carbide-based CMCs offer superior temperature capabilities exceeding traditional metallic components by 200-300°C while reducing weight by approximately 30%. These materials demonstrate exceptional resistance to oxidation and thermal shock, critical properties for the rapid temperature fluctuations experienced during altitude changes.

Thermal barrier coatings (TBCs) have undergone significant evolution to address high-altitude challenges. Advanced yttria-stabilized zirconia coatings with engineered porosity structures provide enhanced thermal insulation while maintaining adhesion during thermal cycling. Recent developments in nanostructured TBCs have demonstrated a 15-20% improvement in thermal protection compared to conventional coatings.

Environmental barrier coatings (EBCs) specifically designed for high-altitude operation protect underlying materials from water vapor and other corrosive elements present in the upper atmosphere. Multi-layer rare earth silicate systems have shown promising results in laboratory testing, with resistance to calcium-magnesium-alumino-silicate (CMAS) degradation—a particular concern at high altitudes where volcanic ash particles may be encountered.

Additive manufacturing techniques have enabled the production of complex geometries with internal cooling channels that were previously impossible to manufacture. These structures optimize material distribution and cooling efficiency, allowing engines to operate at higher temperatures without compromising structural integrity. Laser powder bed fusion processes using specialized high-temperature alloys have demonstrated superior mechanical properties compared to traditionally manufactured components.

Future materials science research focuses on self-healing materials capable of mitigating crack propagation during thermal cycling. Preliminary studies on MAX phase materials (where M is a transition metal, A is an A-group element, and X is carbon or nitrogen) show promising self-healing capabilities at high temperatures, potentially extending component lifespans by up to 40% in extreme altitude conditions.

Recent advancements in nickel-based superalloys have revolutionized high-altitude turbine performance. These materials exhibit remarkable strength-to-weight ratios and maintain structural integrity at temperatures approaching 90% of their melting points. Innovations in precipitation hardening techniques have yielded superalloys with improved creep resistance, extending component lifespan by up to 30% compared to previous generations.

Ceramic matrix composites (CMCs) represent another breakthrough for extreme altitude applications. Silicon carbide-based CMCs offer superior temperature capabilities exceeding traditional metallic components by 200-300°C while reducing weight by approximately 30%. These materials demonstrate exceptional resistance to oxidation and thermal shock, critical properties for the rapid temperature fluctuations experienced during altitude changes.

Thermal barrier coatings (TBCs) have undergone significant evolution to address high-altitude challenges. Advanced yttria-stabilized zirconia coatings with engineered porosity structures provide enhanced thermal insulation while maintaining adhesion during thermal cycling. Recent developments in nanostructured TBCs have demonstrated a 15-20% improvement in thermal protection compared to conventional coatings.

Environmental barrier coatings (EBCs) specifically designed for high-altitude operation protect underlying materials from water vapor and other corrosive elements present in the upper atmosphere. Multi-layer rare earth silicate systems have shown promising results in laboratory testing, with resistance to calcium-magnesium-alumino-silicate (CMAS) degradation—a particular concern at high altitudes where volcanic ash particles may be encountered.

Additive manufacturing techniques have enabled the production of complex geometries with internal cooling channels that were previously impossible to manufacture. These structures optimize material distribution and cooling efficiency, allowing engines to operate at higher temperatures without compromising structural integrity. Laser powder bed fusion processes using specialized high-temperature alloys have demonstrated superior mechanical properties compared to traditionally manufactured components.

Future materials science research focuses on self-healing materials capable of mitigating crack propagation during thermal cycling. Preliminary studies on MAX phase materials (where M is a transition metal, A is an A-group element, and X is carbon or nitrogen) show promising self-healing capabilities at high temperatures, potentially extending component lifespans by up to 40% in extreme altitude conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!