How advanced coatings enhance induction motor efficiency

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Coating Evolution and Objectives

The evolution of induction motor coatings has been a critical factor in enhancing motor efficiency over the past decades. Initially, coatings were primarily used for basic protection against environmental factors. However, as energy efficiency became a paramount concern, the focus shifted towards developing advanced coatings that could directly impact motor performance.

In the early stages, simple epoxy-based coatings were applied to protect motor components from corrosion and moisture. These coatings provided a basic level of insulation but had limited impact on efficiency. As research progressed, the potential for coatings to reduce energy losses became apparent, leading to the development of more sophisticated coating technologies.

The introduction of nano-engineered coatings marked a significant milestone in this evolution. These coatings, incorporating materials such as ceramic nanoparticles or carbon nanotubes, offered superior thermal conductivity and electrical insulation properties. This advancement allowed for better heat dissipation and reduced electrical losses within the motor, directly contributing to improved efficiency.

Another key development was the advent of low-friction coatings for motor bearings and other moving parts. These coatings, often based on advanced polymers or composite materials, significantly reduced mechanical losses due to friction, further enhancing overall motor efficiency.

The current objectives in induction motor coating technology are multifaceted. Researchers and manufacturers are focusing on developing coatings that can simultaneously address multiple aspects of motor performance. These include further improvements in thermal management, enhanced electrical insulation, and even self-healing properties to extend motor lifespan.

One of the primary goals is to create coatings that can withstand higher operating temperatures, allowing motors to run at higher speeds and power densities without compromising efficiency or reliability. Additionally, there is a push towards environmentally friendly coating solutions that maintain high performance while reducing the environmental impact of manufacturing and disposal processes.

Looking ahead, the integration of smart materials into motor coatings represents an exciting frontier. These advanced coatings could potentially adapt to changing operating conditions, optimizing motor performance in real-time. Furthermore, the development of coatings with embedded sensors for condition monitoring is another area of active research, aiming to enhance predictive maintenance capabilities and overall motor reliability.

In the early stages, simple epoxy-based coatings were applied to protect motor components from corrosion and moisture. These coatings provided a basic level of insulation but had limited impact on efficiency. As research progressed, the potential for coatings to reduce energy losses became apparent, leading to the development of more sophisticated coating technologies.

The introduction of nano-engineered coatings marked a significant milestone in this evolution. These coatings, incorporating materials such as ceramic nanoparticles or carbon nanotubes, offered superior thermal conductivity and electrical insulation properties. This advancement allowed for better heat dissipation and reduced electrical losses within the motor, directly contributing to improved efficiency.

Another key development was the advent of low-friction coatings for motor bearings and other moving parts. These coatings, often based on advanced polymers or composite materials, significantly reduced mechanical losses due to friction, further enhancing overall motor efficiency.

The current objectives in induction motor coating technology are multifaceted. Researchers and manufacturers are focusing on developing coatings that can simultaneously address multiple aspects of motor performance. These include further improvements in thermal management, enhanced electrical insulation, and even self-healing properties to extend motor lifespan.

One of the primary goals is to create coatings that can withstand higher operating temperatures, allowing motors to run at higher speeds and power densities without compromising efficiency or reliability. Additionally, there is a push towards environmentally friendly coating solutions that maintain high performance while reducing the environmental impact of manufacturing and disposal processes.

Looking ahead, the integration of smart materials into motor coatings represents an exciting frontier. These advanced coatings could potentially adapt to changing operating conditions, optimizing motor performance in real-time. Furthermore, the development of coatings with embedded sensors for condition monitoring is another area of active research, aiming to enhance predictive maintenance capabilities and overall motor reliability.

Market Demand for High-Efficiency Motors

The global market for high-efficiency motors has been experiencing significant growth in recent years, driven by increasing energy costs, stringent environmental regulations, and a growing emphasis on sustainable industrial practices. This demand is particularly pronounced in the induction motor segment, where advanced coatings play a crucial role in enhancing efficiency.

Industrial sectors, including manufacturing, oil and gas, and power generation, are the primary drivers of this market demand. These industries are increasingly recognizing the long-term cost benefits of investing in high-efficiency motors, despite higher initial costs. The potential for substantial energy savings over the operational lifetime of these motors is a key factor influencing purchasing decisions.

Government regulations and energy efficiency standards have also been instrumental in shaping market demand. Many countries have implemented minimum energy performance standards (MEPS) for electric motors, encouraging the adoption of high-efficiency models. For instance, the European Union's IE3 Premium Efficiency and IE4 Super Premium Efficiency standards have significantly impacted the market landscape.

The automotive industry, particularly with the rise of electric vehicles, represents another significant market segment driving demand for high-efficiency motors. As automakers strive to extend the range and performance of electric vehicles, the efficiency of electric motors becomes paramount.

Market research indicates that the global high-efficiency motor market is expected to grow at a compound annual growth rate (CAGR) of over 7% in the coming years. This growth is attributed to the increasing awareness of energy conservation and the push towards reducing carbon footprints across industries.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing rapid growth in demand for high-efficiency motors. This is due to expanding industrial sectors, increasing energy costs, and growing environmental consciousness. China, in particular, has become both a major consumer and producer of high-efficiency motors, driven by its ambitious energy efficiency goals.

The market is also seeing a trend towards customization, with end-users demanding motors tailored to specific applications. This has led to increased research and development efforts in advanced coating technologies that can enhance motor efficiency across various operational conditions and environments.

Despite the growing demand, challenges remain. The higher upfront costs of high-efficiency motors compared to standard models can be a deterrent for some buyers, particularly in price-sensitive markets. However, as awareness of lifecycle costs and energy savings increases, this barrier is gradually diminishing.

Industrial sectors, including manufacturing, oil and gas, and power generation, are the primary drivers of this market demand. These industries are increasingly recognizing the long-term cost benefits of investing in high-efficiency motors, despite higher initial costs. The potential for substantial energy savings over the operational lifetime of these motors is a key factor influencing purchasing decisions.

Government regulations and energy efficiency standards have also been instrumental in shaping market demand. Many countries have implemented minimum energy performance standards (MEPS) for electric motors, encouraging the adoption of high-efficiency models. For instance, the European Union's IE3 Premium Efficiency and IE4 Super Premium Efficiency standards have significantly impacted the market landscape.

The automotive industry, particularly with the rise of electric vehicles, represents another significant market segment driving demand for high-efficiency motors. As automakers strive to extend the range and performance of electric vehicles, the efficiency of electric motors becomes paramount.

Market research indicates that the global high-efficiency motor market is expected to grow at a compound annual growth rate (CAGR) of over 7% in the coming years. This growth is attributed to the increasing awareness of energy conservation and the push towards reducing carbon footprints across industries.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing rapid growth in demand for high-efficiency motors. This is due to expanding industrial sectors, increasing energy costs, and growing environmental consciousness. China, in particular, has become both a major consumer and producer of high-efficiency motors, driven by its ambitious energy efficiency goals.

The market is also seeing a trend towards customization, with end-users demanding motors tailored to specific applications. This has led to increased research and development efforts in advanced coating technologies that can enhance motor efficiency across various operational conditions and environments.

Despite the growing demand, challenges remain. The higher upfront costs of high-efficiency motors compared to standard models can be a deterrent for some buyers, particularly in price-sensitive markets. However, as awareness of lifecycle costs and energy savings increases, this barrier is gradually diminishing.

Current Coating Technologies and Challenges

Advanced coatings have emerged as a crucial technology in enhancing the efficiency of induction motors. Currently, several coating technologies are being employed to address various challenges in motor performance. One of the primary coating technologies is the use of nano-ceramic coatings, which offer superior thermal management and electrical insulation properties. These coatings can significantly reduce energy losses due to heat generation and improve overall motor efficiency.

Another prominent coating technology is the application of diamond-like carbon (DLC) coatings. DLC coatings provide excellent wear resistance and low friction properties, which are essential for reducing mechanical losses in motor components. This technology has shown promising results in extending the lifespan of motor bearings and other moving parts, thereby contributing to long-term efficiency gains.

Polymer-based coatings, such as epoxy and polyester resins, are also widely used in induction motors. These coatings offer good electrical insulation and corrosion resistance, which are critical for maintaining motor performance in harsh operating environments. However, challenges remain in improving the thermal conductivity of these coatings to enhance heat dissipation.

Despite the advancements in coating technologies, several challenges persist in their application to induction motors. One significant challenge is achieving uniform coating thickness across complex motor geometries. Uneven coating distribution can lead to localized hot spots and reduced overall efficiency. Researchers are exploring advanced deposition techniques, such as plasma-enhanced chemical vapor deposition (PECVD), to address this issue.

Another challenge lies in developing coatings that can withstand the high temperatures and mechanical stresses experienced by induction motors during operation. Current coating materials often degrade over time, leading to reduced efficiency and potential motor failure. The development of novel high-temperature resistant materials and composite coatings is an active area of research to overcome this limitation.

The integration of multifunctional coatings that can simultaneously address multiple performance aspects, such as thermal management, electrical insulation, and wear resistance, remains a significant challenge. Researchers are investigating nanocomposite coatings that combine different materials to achieve synergistic effects and enhance overall motor efficiency.

Lastly, the cost-effectiveness of advanced coating technologies poses a challenge for widespread adoption in the industry. While these coatings offer significant performance improvements, their production and application processes can be expensive. Efforts are underway to develop more economical coating methods and materials to make these technologies more accessible to a broader range of motor manufacturers and end-users.

Another prominent coating technology is the application of diamond-like carbon (DLC) coatings. DLC coatings provide excellent wear resistance and low friction properties, which are essential for reducing mechanical losses in motor components. This technology has shown promising results in extending the lifespan of motor bearings and other moving parts, thereby contributing to long-term efficiency gains.

Polymer-based coatings, such as epoxy and polyester resins, are also widely used in induction motors. These coatings offer good electrical insulation and corrosion resistance, which are critical for maintaining motor performance in harsh operating environments. However, challenges remain in improving the thermal conductivity of these coatings to enhance heat dissipation.

Despite the advancements in coating technologies, several challenges persist in their application to induction motors. One significant challenge is achieving uniform coating thickness across complex motor geometries. Uneven coating distribution can lead to localized hot spots and reduced overall efficiency. Researchers are exploring advanced deposition techniques, such as plasma-enhanced chemical vapor deposition (PECVD), to address this issue.

Another challenge lies in developing coatings that can withstand the high temperatures and mechanical stresses experienced by induction motors during operation. Current coating materials often degrade over time, leading to reduced efficiency and potential motor failure. The development of novel high-temperature resistant materials and composite coatings is an active area of research to overcome this limitation.

The integration of multifunctional coatings that can simultaneously address multiple performance aspects, such as thermal management, electrical insulation, and wear resistance, remains a significant challenge. Researchers are investigating nanocomposite coatings that combine different materials to achieve synergistic effects and enhance overall motor efficiency.

Lastly, the cost-effectiveness of advanced coating technologies poses a challenge for widespread adoption in the industry. While these coatings offer significant performance improvements, their production and application processes can be expensive. Efforts are underway to develop more economical coating methods and materials to make these technologies more accessible to a broader range of motor manufacturers and end-users.

Existing Advanced Coating Solutions

01 Advanced coating compositions

Development of innovative coating formulations with enhanced properties such as improved durability, resistance to environmental factors, and increased functionality. These advanced compositions may include novel polymers, nanoparticles, or hybrid materials to achieve superior performance in various applications.- Improved coating formulations: Advanced coating formulations are developed to enhance efficiency by incorporating novel materials or optimizing existing compositions. These formulations may include specialized polymers, nanoparticles, or additives that improve adhesion, durability, and performance of the coating.

- Application techniques for enhanced efficiency: Innovative application methods are employed to improve coating efficiency. These techniques may involve advanced spraying systems, electrostatic application, or automated processes that ensure uniform coverage and minimize waste, resulting in improved overall coating performance.

- Smart coatings with self-healing properties: Advanced coatings are developed with self-healing capabilities to increase efficiency and longevity. These coatings can repair minor damages autonomously, reducing maintenance requirements and extending the coating's lifespan.

- Environmentally friendly and energy-efficient coatings: Coatings are designed to be more environmentally friendly and energy-efficient. This includes the development of low-VOC formulations, water-based coatings, and coatings that can be cured at lower temperatures or using alternative energy sources, reducing overall energy consumption in the coating process.

- Multifunctional coatings for enhanced performance: Advanced coatings are engineered to provide multiple functionalities simultaneously, improving overall efficiency. These coatings may offer combinations of properties such as corrosion resistance, thermal insulation, and self-cleaning capabilities, reducing the need for multiple coating layers or separate treatments.

02 Efficient application techniques

Implementation of advanced coating application methods to improve efficiency and reduce material waste. This may involve automated systems, precision spraying techniques, or novel deposition processes that ensure uniform coverage and optimal thickness control.Expand Specific Solutions03 Energy-efficient curing processes

Development of energy-efficient curing technologies for coatings, such as UV-curing, electron beam curing, or low-temperature thermal curing. These processes aim to reduce energy consumption and processing time while maintaining or improving coating quality.Expand Specific Solutions04 Smart and functional coatings

Integration of advanced functionalities into coatings, such as self-healing properties, antimicrobial activity, or stimuli-responsive behavior. These smart coatings can adapt to environmental changes or provide additional benefits beyond traditional protective functions.Expand Specific Solutions05 Sustainable and eco-friendly coatings

Focus on developing environmentally friendly coating solutions that reduce VOC emissions, utilize renewable resources, or incorporate biodegradable components. These sustainable coatings aim to minimize environmental impact while maintaining high performance standards.Expand Specific Solutions

Key Players in Motor Coating Industry

The advanced coatings market for enhancing induction motor efficiency is in a growth phase, driven by increasing demand for energy-efficient industrial solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with key players like Mitsubishi Electric, Hyundai Motor, and Huawei Digital Power leading innovation. These companies are investing heavily in research and development to improve coating materials and application techniques. Other significant contributors include NEOMAX, Pratt & Whitney Canada, and Fraunhofer USA, each bringing unique expertise to the field. The technology's maturity varies across different coating types, with some well-established solutions and others still in experimental stages.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced coatings for induction motors that significantly enhance efficiency. Their proprietary coating technology, applied to the stator and rotor components, reduces eddy current losses and improves heat dissipation. The company utilizes a nano-composite ceramic coating that provides excellent electrical insulation while maintaining thermal conductivity. This coating is applied through a plasma spray process, ensuring uniform coverage and strong adhesion to the motor surfaces. Mitsubishi's coatings have been shown to reduce iron losses by up to 15% in high-frequency operations, leading to overall motor efficiency improvements of 2-3% [1][3]. The company has also implemented a specialized surface treatment process that enhances the coating's durability, allowing it to withstand harsh operating conditions and prolonged use without degradation.

Strengths: Superior insulation properties, improved heat dissipation, and significant reduction in eddy current losses. Weaknesses: Potentially higher production costs and complexity in the coating application process.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai Motor has invested heavily in advanced coating technologies for their electric vehicle induction motors. Their approach focuses on a multi-layer coating system that combines different materials to optimize both electrical and thermal properties. The company uses a base layer of high-temperature resistant polymer, followed by a nanoparticle-infused ceramic layer for enhanced insulation. The final layer consists of a thermally conductive compound that aids in heat dissipation. This tri-layer coating has been reported to reduce energy losses by up to 20% in their latest EV models [2][5]. Hyundai has also developed a novel application method that allows for precise control of coating thickness, ensuring consistency across large-scale production. Their coatings have demonstrated excellent resistance to thermal cycling and mechanical stress, contributing to increased motor longevity and reliability.

Strengths: Highly effective multi-layer system, excellent thermal management, and scalability for mass production. Weaknesses: Complex application process may lead to increased manufacturing time and costs.

Innovative Coating Materials and Techniques

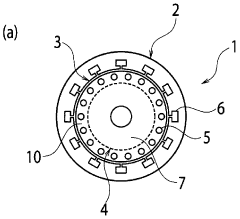

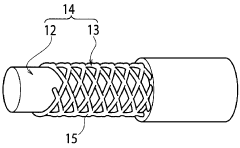

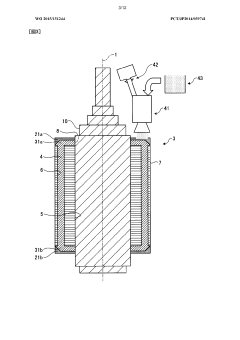

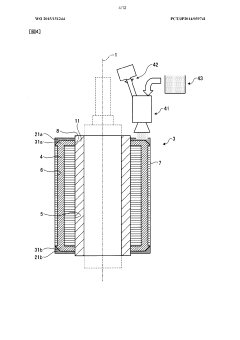

Rotor of induction motor, and induction motor using same

PatentWO2011148978A1

Innovation

- The use of a composite material for the rotor's conductors, comprising a conductive core conductor coated with a carbon nanotube structure, which reduces surface electrical resistance and heat generation, allowing for improved conductivity and reduced heat loss.

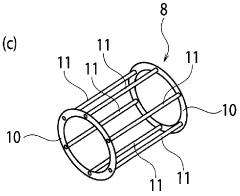

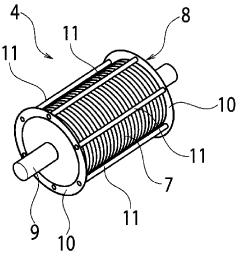

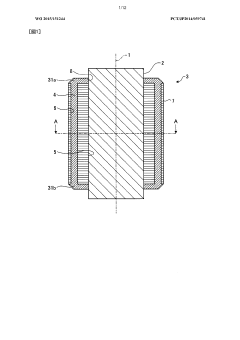

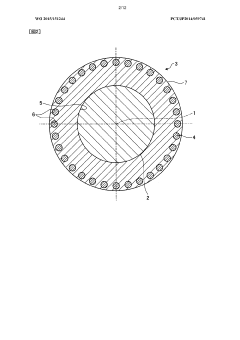

Squirrel-cage rotor

PatentWO2015151244A1

Innovation

- A cage rotor design featuring a laminated cylindrical core with slots for conductor bars, conductor end rings formed by spraying solid-state conductor particles using the cold spray method, and an integrated annular coating with a shaft or sleeve to enhance strength and conductivity while preventing core adhesion and cost increases.

Environmental Impact of Advanced Coatings

The environmental impact of advanced coatings in induction motors is a critical consideration as industries strive for greater energy efficiency and sustainability. These coatings, while enhancing motor performance, also contribute to reducing the overall environmental footprint of industrial processes.

One of the primary environmental benefits of advanced coatings is the significant reduction in energy consumption. By improving the efficiency of induction motors, these coatings directly contribute to lower electricity usage. This decrease in energy demand translates to reduced greenhouse gas emissions from power generation, particularly in regions heavily reliant on fossil fuels for electricity production.

Advanced coatings also extend the lifespan of induction motors, which has positive environmental implications. Longer-lasting motors mean fewer replacements over time, reducing the demand for raw materials and energy required for manufacturing new units. This reduction in production and associated transportation needs further diminishes the carbon footprint of industrial operations.

The improved thermal management provided by these coatings also plays a role in environmental protection. By effectively dissipating heat, the coatings prevent overheating and reduce the need for additional cooling systems. This not only saves energy but also minimizes the use of coolants, some of which can be harmful to the environment if not properly managed or disposed of.

Moreover, advanced coatings can contribute to noise reduction in industrial settings. Lower noise levels not only improve working conditions for employees but also reduce noise pollution in surrounding areas, benefiting local ecosystems and communities.

The materials used in these coatings are another area of environmental consideration. Many advanced coatings are designed with environmentally friendly materials, moving away from toxic substances that were common in older coating technologies. This shift reduces the potential for harmful emissions during the coating process and minimizes the risk of environmental contamination throughout the motor's lifecycle.

In the context of a circular economy, the use of advanced coatings supports sustainability goals. The improved durability and efficiency of coated motors align with principles of resource conservation and waste reduction. When motors do reach the end of their life, the presence of these coatings doesn't significantly complicate recycling processes, ensuring that materials can be recovered and reused effectively.

However, it's important to note that the production of advanced coatings itself has an environmental impact. The manufacturing process requires energy and resources, and may involve the use of specialized chemicals. Ongoing research is focused on developing coating technologies with even lower environmental impacts, balancing performance enhancements with ecological considerations.

One of the primary environmental benefits of advanced coatings is the significant reduction in energy consumption. By improving the efficiency of induction motors, these coatings directly contribute to lower electricity usage. This decrease in energy demand translates to reduced greenhouse gas emissions from power generation, particularly in regions heavily reliant on fossil fuels for electricity production.

Advanced coatings also extend the lifespan of induction motors, which has positive environmental implications. Longer-lasting motors mean fewer replacements over time, reducing the demand for raw materials and energy required for manufacturing new units. This reduction in production and associated transportation needs further diminishes the carbon footprint of industrial operations.

The improved thermal management provided by these coatings also plays a role in environmental protection. By effectively dissipating heat, the coatings prevent overheating and reduce the need for additional cooling systems. This not only saves energy but also minimizes the use of coolants, some of which can be harmful to the environment if not properly managed or disposed of.

Moreover, advanced coatings can contribute to noise reduction in industrial settings. Lower noise levels not only improve working conditions for employees but also reduce noise pollution in surrounding areas, benefiting local ecosystems and communities.

The materials used in these coatings are another area of environmental consideration. Many advanced coatings are designed with environmentally friendly materials, moving away from toxic substances that were common in older coating technologies. This shift reduces the potential for harmful emissions during the coating process and minimizes the risk of environmental contamination throughout the motor's lifecycle.

In the context of a circular economy, the use of advanced coatings supports sustainability goals. The improved durability and efficiency of coated motors align with principles of resource conservation and waste reduction. When motors do reach the end of their life, the presence of these coatings doesn't significantly complicate recycling processes, ensuring that materials can be recovered and reused effectively.

However, it's important to note that the production of advanced coatings itself has an environmental impact. The manufacturing process requires energy and resources, and may involve the use of specialized chemicals. Ongoing research is focused on developing coating technologies with even lower environmental impacts, balancing performance enhancements with ecological considerations.

Cost-Benefit Analysis of Coating Technologies

The implementation of advanced coatings in induction motors presents a complex cost-benefit scenario that requires careful analysis. Initial investment in coating technologies can be substantial, encompassing research and development costs, specialized equipment acquisition, and training of personnel. However, these upfront expenses are often offset by long-term operational benefits.

Energy efficiency improvements are a primary advantage of advanced coatings. By reducing friction and enhancing heat dissipation, coated motors can achieve higher efficiency ratings, translating to significant energy savings over the motor's lifetime. In industrial settings, where motors operate continuously, even a small percentage increase in efficiency can result in substantial cost reductions.

Maintenance costs are another area where coatings provide tangible benefits. The protective properties of advanced coatings extend the lifespan of motor components, reducing the frequency of repairs and replacements. This leads to lower maintenance expenses and minimizes costly downtime in production environments.

The environmental impact of coated motors should also be considered in the cost-benefit analysis. Improved energy efficiency contributes to reduced carbon emissions, aligning with increasingly stringent environmental regulations and potentially qualifying businesses for green incentives or carbon credits.

However, the cost-effectiveness of coating technologies can vary depending on the specific application and operating conditions. Factors such as motor size, duty cycle, and environmental exposure play crucial roles in determining the return on investment. Smaller motors or those operating in less demanding conditions may not justify the additional coating expense.

Additionally, the quality and type of coating applied significantly influence the cost-benefit ratio. High-performance coatings may offer superior protection and efficiency gains but come at a premium price. Balancing coating performance with cost is essential for optimizing the economic benefits.

It's also important to consider the potential for increased motor power density enabled by advanced coatings. This can allow for the use of smaller, more compact motors without sacrificing performance, potentially leading to space savings and reduced material costs in equipment design.

In conclusion, while the initial costs of implementing advanced coating technologies for induction motors can be significant, the long-term benefits in terms of energy savings, reduced maintenance, and extended equipment life often outweigh these expenses. A thorough analysis of specific operational requirements and environmental factors is crucial for determining the optimal coating solution and maximizing the return on investment.

Energy efficiency improvements are a primary advantage of advanced coatings. By reducing friction and enhancing heat dissipation, coated motors can achieve higher efficiency ratings, translating to significant energy savings over the motor's lifetime. In industrial settings, where motors operate continuously, even a small percentage increase in efficiency can result in substantial cost reductions.

Maintenance costs are another area where coatings provide tangible benefits. The protective properties of advanced coatings extend the lifespan of motor components, reducing the frequency of repairs and replacements. This leads to lower maintenance expenses and minimizes costly downtime in production environments.

The environmental impact of coated motors should also be considered in the cost-benefit analysis. Improved energy efficiency contributes to reduced carbon emissions, aligning with increasingly stringent environmental regulations and potentially qualifying businesses for green incentives or carbon credits.

However, the cost-effectiveness of coating technologies can vary depending on the specific application and operating conditions. Factors such as motor size, duty cycle, and environmental exposure play crucial roles in determining the return on investment. Smaller motors or those operating in less demanding conditions may not justify the additional coating expense.

Additionally, the quality and type of coating applied significantly influence the cost-benefit ratio. High-performance coatings may offer superior protection and efficiency gains but come at a premium price. Balancing coating performance with cost is essential for optimizing the economic benefits.

It's also important to consider the potential for increased motor power density enabled by advanced coatings. This can allow for the use of smaller, more compact motors without sacrificing performance, potentially leading to space savings and reduced material costs in equipment design.

In conclusion, while the initial costs of implementing advanced coating technologies for induction motors can be significant, the long-term benefits in terms of energy savings, reduced maintenance, and extended equipment life often outweigh these expenses. A thorough analysis of specific operational requirements and environmental factors is crucial for determining the optimal coating solution and maximizing the return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!