How Amorphous Metals Influence Thermal Conductivity in Electronics

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals Background and Research Objectives

Amorphous metals, also known as metallic glasses, represent a unique class of materials that lack the long-range atomic order characteristic of crystalline metals. First discovered in 1960 by Pol Duwez at Caltech, these materials are formed through rapid cooling processes that prevent crystallization, resulting in a disordered atomic structure. This fundamental structural difference from conventional crystalline metals imparts amorphous metals with distinctive thermal, mechanical, and electrical properties that have garnered significant attention in the electronics industry over the past few decades.

The thermal conductivity characteristics of amorphous metals differ substantially from their crystalline counterparts. While crystalline metals typically exhibit high thermal conductivity due to efficient phonon and electron transport through their ordered lattice structure, amorphous metals demonstrate significantly lower thermal conductivity owing to increased phonon scattering in their disordered atomic arrangement. This property has profound implications for thermal management in electronic devices, where controlled heat dissipation is crucial for performance and reliability.

Recent technological advancements in electronics, particularly the trend toward miniaturization and increased power density, have intensified the challenges of thermal management. As electronic components become smaller and more powerful, effective heat dissipation becomes increasingly critical to prevent performance degradation and premature failure. This technological evolution has sparked renewed interest in exploring how amorphous metals can be strategically employed to address these thermal management challenges.

The primary objective of this research is to comprehensively investigate the influence of amorphous metals on thermal conductivity in electronic applications. Specifically, we aim to understand the fundamental mechanisms governing heat transfer in amorphous metallic structures and how these mechanisms can be manipulated to achieve desired thermal properties. This includes examining the effects of composition, processing conditions, and structural modifications on thermal behavior.

Additionally, this research seeks to explore the potential of amorphous metals in developing novel thermal interface materials, heat spreaders, and thermal barriers for next-generation electronic devices. By understanding the relationship between atomic structure and thermal properties, we aim to design amorphous metal-based solutions that can effectively manage heat in increasingly demanding electronic environments.

Furthermore, this investigation will assess the technological feasibility and economic viability of incorporating amorphous metals into commercial electronic products. This includes evaluating manufacturing scalability, long-term reliability, and compatibility with existing electronic fabrication processes. The ultimate goal is to determine whether amorphous metals can offer practical and cost-effective solutions to the thermal management challenges facing modern electronics.

The thermal conductivity characteristics of amorphous metals differ substantially from their crystalline counterparts. While crystalline metals typically exhibit high thermal conductivity due to efficient phonon and electron transport through their ordered lattice structure, amorphous metals demonstrate significantly lower thermal conductivity owing to increased phonon scattering in their disordered atomic arrangement. This property has profound implications for thermal management in electronic devices, where controlled heat dissipation is crucial for performance and reliability.

Recent technological advancements in electronics, particularly the trend toward miniaturization and increased power density, have intensified the challenges of thermal management. As electronic components become smaller and more powerful, effective heat dissipation becomes increasingly critical to prevent performance degradation and premature failure. This technological evolution has sparked renewed interest in exploring how amorphous metals can be strategically employed to address these thermal management challenges.

The primary objective of this research is to comprehensively investigate the influence of amorphous metals on thermal conductivity in electronic applications. Specifically, we aim to understand the fundamental mechanisms governing heat transfer in amorphous metallic structures and how these mechanisms can be manipulated to achieve desired thermal properties. This includes examining the effects of composition, processing conditions, and structural modifications on thermal behavior.

Additionally, this research seeks to explore the potential of amorphous metals in developing novel thermal interface materials, heat spreaders, and thermal barriers for next-generation electronic devices. By understanding the relationship between atomic structure and thermal properties, we aim to design amorphous metal-based solutions that can effectively manage heat in increasingly demanding electronic environments.

Furthermore, this investigation will assess the technological feasibility and economic viability of incorporating amorphous metals into commercial electronic products. This includes evaluating manufacturing scalability, long-term reliability, and compatibility with existing electronic fabrication processes. The ultimate goal is to determine whether amorphous metals can offer practical and cost-effective solutions to the thermal management challenges facing modern electronics.

Market Analysis for Thermal Management in Electronics

The thermal management market in electronics is experiencing robust growth, driven by increasing power densities and miniaturization trends across multiple sectors. Currently valued at approximately $8.6 billion, this market is projected to reach $11.4 billion by 2025, representing a compound annual growth rate of 7.2%. This growth is particularly pronounced in high-performance computing, telecommunications, and automotive electronics sectors.

Consumer electronics continues to be the largest segment, accounting for nearly 35% of the thermal management market. However, the fastest growth is observed in data centers and AI infrastructure, where thermal challenges have become critical bottlenecks for performance scaling. The introduction of amorphous metals as thermal interface materials represents a significant opportunity within this landscape.

Regionally, Asia-Pacific dominates the market with over 40% share, primarily due to the concentration of electronics manufacturing. North America follows with approximately 30% market share, driven by innovation in high-performance computing and defense applications. Europe represents about 20% of the market, with particular strength in automotive electronics thermal solutions.

The thermal interface materials (TIMs) segment, where amorphous metals are positioned to make significant impact, currently represents a $1.2 billion sub-market. Traditional materials like thermal greases, phase change materials, and metal-based TIMs collectively hold over 85% market share, while novel solutions including amorphous metal-based materials are gaining traction with double-digit growth rates.

Market demand is increasingly focused on materials that can simultaneously provide high thermal conductivity, mechanical compliance, and long-term reliability. This trend aligns perfectly with the unique properties of amorphous metals, which offer thermal conductivity values up to 20 W/mK while maintaining excellent conformability to irregular surfaces.

Industry surveys indicate that electronics manufacturers are willing to pay premium prices for thermal management solutions that can demonstrably extend product lifespans and enable higher performance. The average price premium tolerance ranges from 15-25% for solutions that can reduce operating temperatures by at least 10°C compared to conventional approaches.

The competitive landscape features established players like Henkel, 3M, and Laird Technologies dominating the traditional TIM market, while specialized materials companies including Liquidmetal Technologies and Materion are pioneering amorphous metal solutions. Strategic partnerships between material developers and electronics manufacturers are becoming increasingly common, accelerating the commercialization timeline for novel thermal management technologies.

Consumer electronics continues to be the largest segment, accounting for nearly 35% of the thermal management market. However, the fastest growth is observed in data centers and AI infrastructure, where thermal challenges have become critical bottlenecks for performance scaling. The introduction of amorphous metals as thermal interface materials represents a significant opportunity within this landscape.

Regionally, Asia-Pacific dominates the market with over 40% share, primarily due to the concentration of electronics manufacturing. North America follows with approximately 30% market share, driven by innovation in high-performance computing and defense applications. Europe represents about 20% of the market, with particular strength in automotive electronics thermal solutions.

The thermal interface materials (TIMs) segment, where amorphous metals are positioned to make significant impact, currently represents a $1.2 billion sub-market. Traditional materials like thermal greases, phase change materials, and metal-based TIMs collectively hold over 85% market share, while novel solutions including amorphous metal-based materials are gaining traction with double-digit growth rates.

Market demand is increasingly focused on materials that can simultaneously provide high thermal conductivity, mechanical compliance, and long-term reliability. This trend aligns perfectly with the unique properties of amorphous metals, which offer thermal conductivity values up to 20 W/mK while maintaining excellent conformability to irregular surfaces.

Industry surveys indicate that electronics manufacturers are willing to pay premium prices for thermal management solutions that can demonstrably extend product lifespans and enable higher performance. The average price premium tolerance ranges from 15-25% for solutions that can reduce operating temperatures by at least 10°C compared to conventional approaches.

The competitive landscape features established players like Henkel, 3M, and Laird Technologies dominating the traditional TIM market, while specialized materials companies including Liquidmetal Technologies and Materion are pioneering amorphous metal solutions. Strategic partnerships between material developers and electronics manufacturers are becoming increasingly common, accelerating the commercialization timeline for novel thermal management technologies.

Current Challenges in Amorphous Metal Thermal Conductivity

Despite significant advancements in amorphous metal technology, several critical challenges persist in optimizing their thermal conductivity for electronics applications. The inherent atomic disorder in amorphous metals creates fundamental limitations in heat transfer mechanisms, resulting in thermal conductivity values typically ranging from 1-10 W/m·K—significantly lower than their crystalline counterparts. This limitation becomes particularly problematic as electronic devices continue to miniaturize while generating increasing amounts of heat.

One major challenge is the trade-off between electrical and thermal properties. While amorphous metals offer excellent electrical characteristics and corrosion resistance, their disordered structure impedes phonon propagation, the primary heat transfer mechanism in these materials. Engineers struggle to enhance thermal conductivity without compromising the beneficial electrical properties that make these materials attractive for electronics applications.

Manufacturing consistency presents another significant obstacle. Current production methods for amorphous metals, including rapid solidification techniques and vapor deposition, often result in variations in atomic arrangement and density. These inconsistencies lead to unpredictable thermal behavior across different production batches, making standardization difficult for high-volume electronics manufacturing.

Interface thermal resistance emerges as a critical challenge when integrating amorphous metals with other materials in electronic assemblies. The boundary between amorphous metals and adjacent materials creates thermal bottlenecks that can significantly reduce overall heat dissipation efficiency. Current joining and bonding technologies have not adequately addressed these interface issues.

Temperature stability poses additional complications. Many amorphous metals undergo structural relaxation or even crystallization when exposed to elevated temperatures, altering their thermal conductivity properties during operation. This instability creates reliability concerns for electronic devices operating in variable temperature environments or those generating significant heat during normal operation.

Computational modeling of thermal behavior in amorphous structures remains inadequate. Unlike crystalline materials with well-defined atomic arrangements, the random structure of amorphous metals makes accurate prediction of thermal properties extremely difficult. Current simulation tools struggle to account for the complex atomic interactions and localized variations that influence heat transfer in these materials.

Cost factors further complicate widespread adoption. The specialized processing required to produce high-quality amorphous metals with consistent thermal properties significantly increases manufacturing expenses compared to conventional materials. This cost premium limits their application to high-end electronics where performance benefits can justify the additional expense.

One major challenge is the trade-off between electrical and thermal properties. While amorphous metals offer excellent electrical characteristics and corrosion resistance, their disordered structure impedes phonon propagation, the primary heat transfer mechanism in these materials. Engineers struggle to enhance thermal conductivity without compromising the beneficial electrical properties that make these materials attractive for electronics applications.

Manufacturing consistency presents another significant obstacle. Current production methods for amorphous metals, including rapid solidification techniques and vapor deposition, often result in variations in atomic arrangement and density. These inconsistencies lead to unpredictable thermal behavior across different production batches, making standardization difficult for high-volume electronics manufacturing.

Interface thermal resistance emerges as a critical challenge when integrating amorphous metals with other materials in electronic assemblies. The boundary between amorphous metals and adjacent materials creates thermal bottlenecks that can significantly reduce overall heat dissipation efficiency. Current joining and bonding technologies have not adequately addressed these interface issues.

Temperature stability poses additional complications. Many amorphous metals undergo structural relaxation or even crystallization when exposed to elevated temperatures, altering their thermal conductivity properties during operation. This instability creates reliability concerns for electronic devices operating in variable temperature environments or those generating significant heat during normal operation.

Computational modeling of thermal behavior in amorphous structures remains inadequate. Unlike crystalline materials with well-defined atomic arrangements, the random structure of amorphous metals makes accurate prediction of thermal properties extremely difficult. Current simulation tools struggle to account for the complex atomic interactions and localized variations that influence heat transfer in these materials.

Cost factors further complicate widespread adoption. The specialized processing required to produce high-quality amorphous metals with consistent thermal properties significantly increases manufacturing expenses compared to conventional materials. This cost premium limits their application to high-end electronics where performance benefits can justify the additional expense.

Current Thermal Management Solutions Using Amorphous Metals

01 Thermal conductivity characteristics of amorphous metals

Amorphous metals, also known as metallic glasses, exhibit unique thermal conductivity properties different from their crystalline counterparts. These materials typically show lower thermal conductivity due to their disordered atomic structure which impedes phonon propagation. The absence of grain boundaries and crystalline defects creates distinctive heat transfer mechanisms. Understanding these fundamental thermal properties is essential for applications requiring specific heat management capabilities.- Thermal conductivity characteristics of amorphous metals: Amorphous metals, also known as metallic glasses, exhibit unique thermal conductivity properties different from their crystalline counterparts. These materials typically show lower thermal conductivity due to their disordered atomic structure which impedes phonon propagation. The thermal conductivity can be influenced by composition, processing conditions, and the degree of structural relaxation. Understanding these characteristics is crucial for applications requiring specific heat transfer properties.

- Methods to enhance thermal conductivity in amorphous metals: Various techniques can be employed to improve the thermal conductivity of amorphous metals. These include partial crystallization, addition of high-conductivity elements, controlled annealing processes, and creation of composite structures. By manipulating the microstructure or introducing specific elements, the thermal transport properties can be significantly enhanced while maintaining the beneficial mechanical properties of amorphous metals.

- Measurement and characterization of thermal conductivity: Specialized techniques and equipment are used to accurately measure and characterize the thermal conductivity of amorphous metals. These include laser flash analysis, steady-state heat flow methods, and thermal transient techniques. Advanced characterization methods allow for the correlation between atomic structure and thermal transport properties, enabling the development of materials with tailored thermal conductivity for specific applications.

- Applications leveraging thermal conductivity properties: The unique thermal conductivity characteristics of amorphous metals make them suitable for various specialized applications. These include thermal management components in electronics, heat exchangers, thermal barriers, magnetic devices, and energy conversion systems. By utilizing the controllable thermal properties of amorphous metals, engineers can design more efficient thermal systems and components with improved performance characteristics.

- Relationship between composition and thermal conductivity: The chemical composition of amorphous metals significantly influences their thermal conductivity. Elements with high intrinsic thermal conductivity, such as copper or silver, can enhance heat transfer when incorporated into amorphous alloys. Conversely, elements that increase structural disorder or electron scattering can reduce thermal conductivity. Understanding these compositional effects allows for the design of amorphous metal alloys with specific thermal transport properties tailored for particular applications.

02 Methods to enhance thermal conductivity in amorphous metals

Various techniques have been developed to improve the thermal conductivity of amorphous metals. These include controlled partial crystallization, addition of high-conductivity elements, formation of composite structures, and specialized heat treatments. By manipulating the microstructure and composition, researchers can achieve targeted thermal conductivity values while maintaining the beneficial mechanical properties of amorphous metals. These enhancement methods enable the tailoring of thermal properties for specific applications.Expand Specific Solutions03 Applications leveraging thermal properties of amorphous metals

The unique thermal conductivity characteristics of amorphous metals make them suitable for various specialized applications. These include thermal management components in electronics, heat exchangers, thermal barriers, sensors, and energy conversion devices. Their combination of controlled thermal conductivity with other properties such as high strength, corrosion resistance, and magnetic behavior enables novel solutions to engineering challenges where conventional materials fall short.Expand Specific Solutions04 Measurement and characterization techniques for thermal conductivity

Specialized methods have been developed to accurately measure and characterize the thermal conductivity of amorphous metals. These include laser flash analysis, steady-state heat flow methods, transient plane source techniques, and thermal diffusivity measurements. Advanced characterization approaches allow researchers to understand the relationship between atomic structure and thermal transport properties, enabling more precise material design and selection for thermal applications.Expand Specific Solutions05 Composition effects on thermal conductivity of amorphous alloys

The chemical composition of amorphous metals significantly influences their thermal conductivity. Different elemental additions can either enhance or reduce thermal transport properties. Heavy elements typically decrease thermal conductivity while certain light elements may increase it. Multi-component systems often exhibit complex thermal behavior based on atomic size differences, electronic structure, and bonding characteristics. Understanding these compositional effects allows for the design of amorphous metals with tailored thermal properties.Expand Specific Solutions

Leading Companies and Research Institutions in Amorphous Metallurgy

The amorphous metals thermal conductivity market in electronics is in a growth phase, with increasing demand driven by miniaturization trends and thermal management challenges. Key players form a diverse ecosystem spanning research institutions (Oregon State University, California Institute of Technology) and commercial entities. Industry leaders include established electronics manufacturers (Samsung Electronics, IBM) alongside specialized materials companies (Metglas, VACUUMSCHMELZE). Research-focused organizations like Semiconductor Energy Laboratory and Amorphyx are advancing fundamental technologies, while manufacturing giants like Murata and ABB Group integrate these innovations into commercial applications. The technology shows promising maturity with ongoing R&D efforts focused on enhancing performance characteristics and expanding application areas in next-generation electronic devices.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE (VAC) has developed specialized amorphous and nanocrystalline alloys under their VITROPERM® and VITROVAC® product lines that address thermal conductivity challenges in advanced electronics. Their approach utilizes iron-cobalt-based amorphous metal compositions with precisely controlled additions of silicon, boron, and other elements to achieve specific thermal transport properties. VAC employs a sophisticated rapid quenching process that creates ribbons with extremely uniform thicknesses (typically 15-30 μm), ensuring consistent thermal performance across large surface areas[2]. Their technology includes proprietary surface treatments that enhance thermal contact conductance when these materials are integrated into electronic assemblies. VAC has pioneered laminated composite structures that combine layers of amorphous metals with different thermal conductivities to create thermal management solutions with anisotropic heat flow capabilities, directing heat away from sensitive components along preferred pathways[6]. Recent developments include amorphous metal heat spreaders with thermal conductivity values of 10-18 W/m·K that maintain performance stability across temperature ranges from -40°C to +150°C.

Strengths: Exceptional quality control and consistency in thermal properties; ability to create large-area thin ribbons with uniform characteristics; excellent thermal cycling stability; sophisticated lamination capabilities for complex thermal management solutions. Weaknesses: Higher cost compared to conventional materials; limited thickness options; requires specialized handling during assembly processes.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed innovative thermal management solutions utilizing amorphous metal technology for their high-performance electronic devices. Their approach incorporates zirconium-based and iron-based amorphous metal alloys as thermal interface materials and heat spreaders in compact electronic assemblies. Samsung's proprietary technology involves creating ultra-thin amorphous metal layers (5-20 μm) through advanced physical vapor deposition (PVD) and sputtering techniques, allowing for direct integration into semiconductor packaging[3]. This approach enables thermal conductivity values of 7-22 W/m·K while maintaining electrical isolation properties critical for semiconductor applications. Samsung has pioneered the use of amorphous metal-based thermal management in their flagship mobile devices, where the materials' combination of thermal conductivity and mechanical flexibility addresses the challenges of dissipating heat from increasingly powerful processors in ultra-thin form factors[7]. Their latest innovation involves creating gradient-composition amorphous metals that provide tailored thermal conductivity profiles across different regions of a single component, optimizing heat flow paths away from critical thermal hotspots.

Strengths: Seamless integration with existing semiconductor manufacturing processes; excellent mechanical flexibility for mobile applications; ability to create ultra-thin thermal management layers; compatibility with advanced packaging technologies. Weaknesses: Higher implementation costs compared to conventional thermal solutions; requires specialized deposition equipment; limited thermal conductivity compared to crystalline copper or aluminum.

Key Patents and Research on Amorphous Metal Thermal Properties

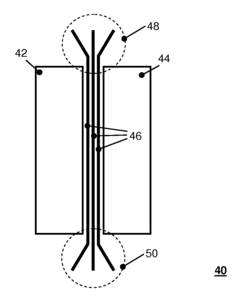

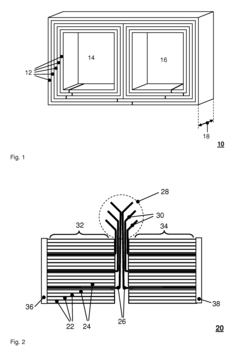

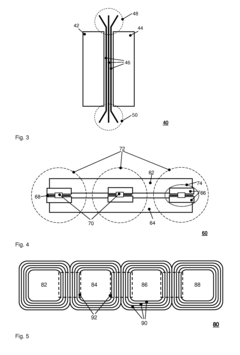

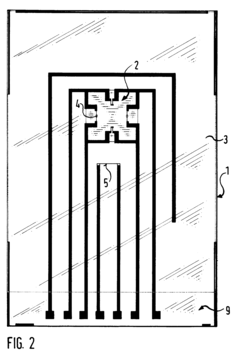

Amorphous transformer core

PatentInactiveUS20120139682A1

Innovation

- Incorporating heat dissipating plates made of high thermal conductivity materials into the amorphous transformer core, which extend into a heat exchange region outside the core for efficient heat dissipation, allowing for better temperature distribution and reduced core size without increasing material usage.

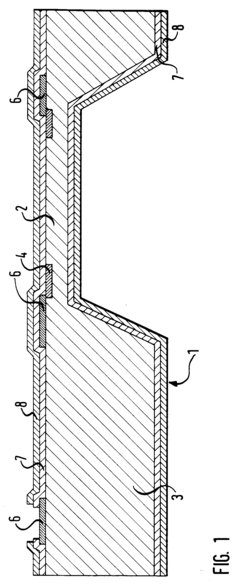

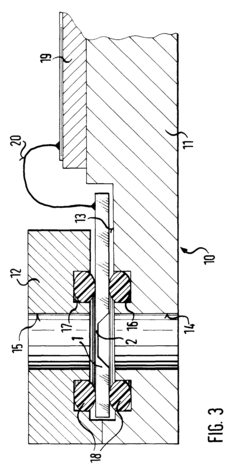

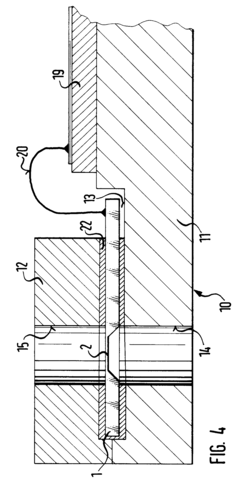

Electronic component

PatentInactiveEP0801150A2

Innovation

- An amorphous metal layer is applied to the electronic component, which is electrically insulated to prevent short circuits, offering liquid-tight protection, high thermal conductivity, and accurate force transmission, while being corrosion-resistant and conductive for shielding.

Environmental Impact and Sustainability Considerations

The adoption of amorphous metals in electronics presents significant environmental and sustainability advantages compared to traditional crystalline materials. These metallic glasses require less energy during manufacturing due to their lower melting points and simplified processing requirements. The elimination of multiple heat treatment steps typically needed for crystalline alloys results in a reduced carbon footprint across the production lifecycle, with some studies indicating energy savings of up to 30% compared to conventional metal processing.

Amorphous metals also demonstrate superior durability and corrosion resistance, extending the operational lifespan of electronic components. This longevity directly addresses the growing electronic waste crisis by reducing replacement frequency and associated resource consumption. The enhanced thermal conductivity properties of certain amorphous metal compositions enable more efficient heat dissipation in electronic devices, lowering energy consumption during operation and further reducing environmental impact throughout the product lifecycle.

From a materials perspective, many amorphous metal formulations utilize more abundant elements compared to rare earth metals commonly found in specialized electronic components. This shift toward more accessible raw materials reduces mining impacts and supply chain vulnerabilities. Additionally, the unique atomic structure of amorphous metals allows for greater flexibility in composition, potentially enabling the substitution of toxic elements with more environmentally benign alternatives without sacrificing performance.

Recycling considerations represent another important sustainability dimension. While the complex compositions of some amorphous metals can present recycling challenges, their homogeneous microstructure theoretically simplifies material separation compared to multi-phase crystalline alloys. Research into specialized recycling processes for amorphous metals is advancing, with promising developments in selective dissolution techniques that could enable more efficient recovery of valuable elements from end-of-life electronic components.

The thermal management benefits of amorphous metals also contribute to sustainability through improved energy efficiency in data centers and high-performance computing applications. By enabling more effective heat dissipation, these materials can reduce cooling requirements, which typically account for 30-50% of data center energy consumption. This efficiency gain translates to significant reductions in operational carbon emissions for digital infrastructure, aligning with global decarbonization goals.

Future sustainability research directions include developing amorphous metal compositions specifically optimized for circular economy principles, including design for disassembly and material recovery. Lifecycle assessment studies comparing amorphous and crystalline metal implementations across various electronic applications will be crucial for quantifying environmental benefits and identifying optimization opportunities.

Amorphous metals also demonstrate superior durability and corrosion resistance, extending the operational lifespan of electronic components. This longevity directly addresses the growing electronic waste crisis by reducing replacement frequency and associated resource consumption. The enhanced thermal conductivity properties of certain amorphous metal compositions enable more efficient heat dissipation in electronic devices, lowering energy consumption during operation and further reducing environmental impact throughout the product lifecycle.

From a materials perspective, many amorphous metal formulations utilize more abundant elements compared to rare earth metals commonly found in specialized electronic components. This shift toward more accessible raw materials reduces mining impacts and supply chain vulnerabilities. Additionally, the unique atomic structure of amorphous metals allows for greater flexibility in composition, potentially enabling the substitution of toxic elements with more environmentally benign alternatives without sacrificing performance.

Recycling considerations represent another important sustainability dimension. While the complex compositions of some amorphous metals can present recycling challenges, their homogeneous microstructure theoretically simplifies material separation compared to multi-phase crystalline alloys. Research into specialized recycling processes for amorphous metals is advancing, with promising developments in selective dissolution techniques that could enable more efficient recovery of valuable elements from end-of-life electronic components.

The thermal management benefits of amorphous metals also contribute to sustainability through improved energy efficiency in data centers and high-performance computing applications. By enabling more effective heat dissipation, these materials can reduce cooling requirements, which typically account for 30-50% of data center energy consumption. This efficiency gain translates to significant reductions in operational carbon emissions for digital infrastructure, aligning with global decarbonization goals.

Future sustainability research directions include developing amorphous metal compositions specifically optimized for circular economy principles, including design for disassembly and material recovery. Lifecycle assessment studies comparing amorphous and crystalline metal implementations across various electronic applications will be crucial for quantifying environmental benefits and identifying optimization opportunities.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of amorphous metals for electronics thermal management presents significant challenges compared to conventional crystalline materials. Current production methods for amorphous metals, including rapid solidification techniques such as melt spinning and splat quenching, are inherently limited in their throughput and maximum sample dimensions. These constraints have restricted the widespread adoption of amorphous metals in electronic cooling applications despite their promising thermal properties.

Production costs remain substantially higher than traditional thermal management materials, with estimates suggesting a 3-5x price premium over copper-based solutions. This cost differential stems primarily from the specialized equipment required for rapid cooling rates (typically 10^4-10^6 K/s) and the relatively low production volumes. The raw material costs for amorphous metal alloys containing zirconium, palladium, or rare earth elements further compound the economic barriers to adoption.

Recent advancements in manufacturing technologies show promising directions for improved scalability. Powder metallurgy approaches combined with spark plasma sintering have demonstrated the ability to produce bulk amorphous metal components while maintaining their unique thermal conductivity characteristics. Additionally, selective laser melting techniques adapted from additive manufacturing offer potential pathways for creating complex thermal management structures with customized geometries.

Economic analysis indicates that economies of scale could significantly reduce production costs, with modeling suggesting a potential 40-60% cost reduction at high-volume production. Several industry partnerships between amorphous metal producers and electronics manufacturers have emerged to address these scaling challenges, including collaborative efforts to develop standardized production methods and quality control protocols.

The environmental impact of amorphous metal manufacturing must also be considered in scalability assessments. While production processes are energy-intensive due to rapid cooling requirements, the enhanced durability and potential for material recovery may offset these impacts over product lifecycles. Life cycle assessments indicate that amorphous metal thermal solutions could achieve carbon footprint parity with conventional materials if production volumes reach approximately 100,000 units annually.

For widespread commercial viability, manufacturing innovations must focus on increasing production rates while maintaining the critical cooling thresholds necessary for amorphous structure formation. Continuous casting adaptations and controlled atmosphere processing show particular promise for scaling production while preserving the unique thermal conductivity properties that make these materials valuable for next-generation electronics cooling solutions.

Production costs remain substantially higher than traditional thermal management materials, with estimates suggesting a 3-5x price premium over copper-based solutions. This cost differential stems primarily from the specialized equipment required for rapid cooling rates (typically 10^4-10^6 K/s) and the relatively low production volumes. The raw material costs for amorphous metal alloys containing zirconium, palladium, or rare earth elements further compound the economic barriers to adoption.

Recent advancements in manufacturing technologies show promising directions for improved scalability. Powder metallurgy approaches combined with spark plasma sintering have demonstrated the ability to produce bulk amorphous metal components while maintaining their unique thermal conductivity characteristics. Additionally, selective laser melting techniques adapted from additive manufacturing offer potential pathways for creating complex thermal management structures with customized geometries.

Economic analysis indicates that economies of scale could significantly reduce production costs, with modeling suggesting a potential 40-60% cost reduction at high-volume production. Several industry partnerships between amorphous metal producers and electronics manufacturers have emerged to address these scaling challenges, including collaborative efforts to develop standardized production methods and quality control protocols.

The environmental impact of amorphous metal manufacturing must also be considered in scalability assessments. While production processes are energy-intensive due to rapid cooling requirements, the enhanced durability and potential for material recovery may offset these impacts over product lifecycles. Life cycle assessments indicate that amorphous metal thermal solutions could achieve carbon footprint parity with conventional materials if production volumes reach approximately 100,000 units annually.

For widespread commercial viability, manufacturing innovations must focus on increasing production rates while maintaining the critical cooling thresholds necessary for amorphous structure formation. Continuous casting adaptations and controlled atmosphere processing show particular promise for scaling production while preserving the unique thermal conductivity properties that make these materials valuable for next-generation electronics cooling solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!