Understanding Amorphous Metals in Advanced Tribological Systems

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals Evolution and Research Objectives

Amorphous metals, also known as metallic glasses, represent a revolutionary class of materials that defy conventional crystalline structures. First discovered in 1960 at Caltech through rapid cooling of Au-Si alloys, these materials have evolved from laboratory curiosities to engineering materials with significant potential in tribological applications. The unique atomic arrangement in amorphous metals—characterized by the absence of long-range order—confers exceptional mechanical properties including high hardness, elastic limit, and wear resistance that surpass their crystalline counterparts.

The evolution of amorphous metals has been marked by several technological breakthroughs. Initially limited to thin ribbons and wires due to critical cooling rate requirements, the development of bulk metallic glasses (BMGs) in the 1990s represented a paradigm shift, enabling the production of thicker specimens with reduced cooling rates. This advancement expanded potential applications dramatically, particularly in tribological systems where surface interactions govern performance.

Recent research has focused on multi-component alloy systems, particularly those based on Zr, Ti, Cu, Fe, and Pd, which demonstrate superior glass-forming ability. The incorporation of minor elements has proven effective in enhancing thermal stability and mechanical properties, critical factors for tribological performance under extreme conditions. Computational modeling and high-throughput experimentation have accelerated the discovery of new compositions with tailored properties.

In tribological contexts, amorphous metals exhibit remarkable resistance to adhesive wear, abrasion, and corrosion—properties that make them ideal candidates for components operating under severe conditions. Their homogeneous structure eliminates grain boundaries, reducing preferential wear paths and enhancing surface integrity during sliding contact. Additionally, their elastic deformation capacity allows for better accommodation of contact stresses without permanent deformation.

The primary research objectives in this field include developing cost-effective manufacturing processes to overcome current production limitations, enhancing thermal stability to expand operating temperature ranges, and understanding the fundamental wear mechanisms specific to amorphous structures. Particular emphasis is placed on investigating the relationship between atomic structure and tribological behavior, as well as exploring composite systems that combine amorphous metals with other materials to achieve synergistic effects.

Furthermore, research aims to establish standardized testing methodologies for evaluating tribological performance of amorphous metals, considering their unique deformation mechanisms differ significantly from crystalline materials. The ultimate goal is to translate fundamental understanding into practical applications, particularly in aerospace, biomedical, and energy sectors where extreme tribological demands exist.

The evolution of amorphous metals has been marked by several technological breakthroughs. Initially limited to thin ribbons and wires due to critical cooling rate requirements, the development of bulk metallic glasses (BMGs) in the 1990s represented a paradigm shift, enabling the production of thicker specimens with reduced cooling rates. This advancement expanded potential applications dramatically, particularly in tribological systems where surface interactions govern performance.

Recent research has focused on multi-component alloy systems, particularly those based on Zr, Ti, Cu, Fe, and Pd, which demonstrate superior glass-forming ability. The incorporation of minor elements has proven effective in enhancing thermal stability and mechanical properties, critical factors for tribological performance under extreme conditions. Computational modeling and high-throughput experimentation have accelerated the discovery of new compositions with tailored properties.

In tribological contexts, amorphous metals exhibit remarkable resistance to adhesive wear, abrasion, and corrosion—properties that make them ideal candidates for components operating under severe conditions. Their homogeneous structure eliminates grain boundaries, reducing preferential wear paths and enhancing surface integrity during sliding contact. Additionally, their elastic deformation capacity allows for better accommodation of contact stresses without permanent deformation.

The primary research objectives in this field include developing cost-effective manufacturing processes to overcome current production limitations, enhancing thermal stability to expand operating temperature ranges, and understanding the fundamental wear mechanisms specific to amorphous structures. Particular emphasis is placed on investigating the relationship between atomic structure and tribological behavior, as well as exploring composite systems that combine amorphous metals with other materials to achieve synergistic effects.

Furthermore, research aims to establish standardized testing methodologies for evaluating tribological performance of amorphous metals, considering their unique deformation mechanisms differ significantly from crystalline materials. The ultimate goal is to translate fundamental understanding into practical applications, particularly in aerospace, biomedical, and energy sectors where extreme tribological demands exist.

Market Analysis for Tribological Applications

The global market for tribological applications is experiencing significant growth, driven by increasing demands for energy efficiency, extended component lifespans, and reduced maintenance costs across multiple industries. The current market value for advanced tribological systems is estimated at $9.4 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. Amorphous metals, also known as metallic glasses, are emerging as premium solutions within this space due to their exceptional wear resistance and mechanical properties.

Key industries driving demand include automotive manufacturing, aerospace, industrial machinery, and medical devices. The automotive sector represents the largest market segment, accounting for approximately 32% of total demand, as manufacturers seek solutions to improve fuel efficiency and reduce emissions through decreased friction losses. Aerospace applications follow at 24%, where the extreme operating conditions necessitate materials with superior tribological performance.

Regional analysis reveals that North America and Europe currently dominate the market with a combined share of 58%, attributed to their advanced manufacturing capabilities and stringent efficiency regulations. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.3% annually, fueled by rapid industrialization in China and India, alongside Japan's established high-tech manufacturing sector.

The market segmentation by application type shows that bearing systems constitute 29% of demand, followed by gear systems (23%), sliding components (19%), and specialized coatings (17%). The remaining 12% encompasses various niche applications including microelectromechanical systems (MEMS) and biomedical implants, where amorphous metals offer unique advantages.

Customer demand patterns indicate a growing preference for integrated tribological solutions rather than standalone components. End-users increasingly prioritize total cost of ownership over initial acquisition costs, creating opportunities for premium materials like amorphous metals that deliver superior long-term performance despite higher upfront investments.

Market barriers include the relatively high production costs of amorphous metals compared to conventional materials, limited awareness among potential end-users, and technical challenges in scaling production processes. However, these barriers are gradually diminishing as manufacturing technologies improve and successful case studies demonstrate the value proposition of these advanced materials.

The competitive landscape features both established materials science corporations and specialized startups focusing exclusively on amorphous metal applications. Strategic partnerships between material developers and end-product manufacturers are becoming increasingly common, accelerating market penetration and technology adoption across industries.

Key industries driving demand include automotive manufacturing, aerospace, industrial machinery, and medical devices. The automotive sector represents the largest market segment, accounting for approximately 32% of total demand, as manufacturers seek solutions to improve fuel efficiency and reduce emissions through decreased friction losses. Aerospace applications follow at 24%, where the extreme operating conditions necessitate materials with superior tribological performance.

Regional analysis reveals that North America and Europe currently dominate the market with a combined share of 58%, attributed to their advanced manufacturing capabilities and stringent efficiency regulations. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.3% annually, fueled by rapid industrialization in China and India, alongside Japan's established high-tech manufacturing sector.

The market segmentation by application type shows that bearing systems constitute 29% of demand, followed by gear systems (23%), sliding components (19%), and specialized coatings (17%). The remaining 12% encompasses various niche applications including microelectromechanical systems (MEMS) and biomedical implants, where amorphous metals offer unique advantages.

Customer demand patterns indicate a growing preference for integrated tribological solutions rather than standalone components. End-users increasingly prioritize total cost of ownership over initial acquisition costs, creating opportunities for premium materials like amorphous metals that deliver superior long-term performance despite higher upfront investments.

Market barriers include the relatively high production costs of amorphous metals compared to conventional materials, limited awareness among potential end-users, and technical challenges in scaling production processes. However, these barriers are gradually diminishing as manufacturing technologies improve and successful case studies demonstrate the value proposition of these advanced materials.

The competitive landscape features both established materials science corporations and specialized startups focusing exclusively on amorphous metal applications. Strategic partnerships between material developers and end-product manufacturers are becoming increasingly common, accelerating market penetration and technology adoption across industries.

Current Limitations and Technical Barriers

Despite the promising properties of amorphous metals (metallic glasses) for tribological applications, several significant technical barriers currently limit their widespread implementation in advanced tribological systems. The inherent brittleness of bulk metallic glasses (BMGs) represents perhaps the most critical limitation, as these materials typically exhibit catastrophic failure under tensile loading without appreciable plastic deformation. This characteristic severely restricts their application in components subjected to complex stress states or impact loading conditions common in many tribological interfaces.

The size limitation presents another substantial challenge. While thin film metallic glasses can be produced with relatively large dimensions, bulk amorphous metals are typically restricted to critical casting thicknesses of several millimeters or less due to the required rapid cooling rates necessary to avoid crystallization. This dimensional constraint significantly limits the geometry and scale of tribological components that can be manufactured using these materials.

Manufacturing complexity further compounds implementation challenges. The production of amorphous metals requires precise control of cooling rates and processing parameters, making mass production difficult and costly. Conventional machining techniques can also induce crystallization in these materials, potentially degrading their unique properties and tribological performance.

The thermal stability of amorphous metals represents another significant barrier. Many metallic glasses exhibit crystallization at relatively low temperatures compared to their crystalline counterparts, limiting their application in high-temperature tribological environments. This crystallization not only alters their mechanical properties but can dramatically change their friction and wear characteristics.

Cost factors also present substantial obstacles to widespread adoption. The specialized processing requirements, expensive constituent elements (particularly in zirconium or palladium-based systems), and complex quality control measures significantly increase production costs compared to conventional tribological materials.

The limited understanding of structure-property relationships in amorphous metals specifically related to tribological behavior remains a significant knowledge gap. While considerable research has explored mechanical properties, the correlation between atomic structure, composition, and tribological performance remains incompletely characterized, hampering targeted material design efforts.

Additionally, long-term performance stability under real-world tribological conditions remains inadequately documented. Questions persist regarding potential property changes during extended service, particularly under cyclic loading, varying environmental conditions, and in the presence of lubricants or contaminants. This uncertainty creates hesitation among engineers considering these materials for critical applications where long-term reliability is paramount.

The size limitation presents another substantial challenge. While thin film metallic glasses can be produced with relatively large dimensions, bulk amorphous metals are typically restricted to critical casting thicknesses of several millimeters or less due to the required rapid cooling rates necessary to avoid crystallization. This dimensional constraint significantly limits the geometry and scale of tribological components that can be manufactured using these materials.

Manufacturing complexity further compounds implementation challenges. The production of amorphous metals requires precise control of cooling rates and processing parameters, making mass production difficult and costly. Conventional machining techniques can also induce crystallization in these materials, potentially degrading their unique properties and tribological performance.

The thermal stability of amorphous metals represents another significant barrier. Many metallic glasses exhibit crystallization at relatively low temperatures compared to their crystalline counterparts, limiting their application in high-temperature tribological environments. This crystallization not only alters their mechanical properties but can dramatically change their friction and wear characteristics.

Cost factors also present substantial obstacles to widespread adoption. The specialized processing requirements, expensive constituent elements (particularly in zirconium or palladium-based systems), and complex quality control measures significantly increase production costs compared to conventional tribological materials.

The limited understanding of structure-property relationships in amorphous metals specifically related to tribological behavior remains a significant knowledge gap. While considerable research has explored mechanical properties, the correlation between atomic structure, composition, and tribological performance remains incompletely characterized, hampering targeted material design efforts.

Additionally, long-term performance stability under real-world tribological conditions remains inadequately documented. Questions persist regarding potential property changes during extended service, particularly under cyclic loading, varying environmental conditions, and in the presence of lubricants or contaminants. This uncertainty creates hesitation among engineers considering these materials for critical applications where long-term reliability is paramount.

Existing Tribological Solutions Using Amorphous Metals

01 Manufacturing processes for amorphous metals

Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Techniques such as melt spinning, gas atomization, and vapor deposition are commonly used to achieve the necessary cooling rates. The processing parameters must be carefully controlled to maintain the amorphous structure throughout the material.- Manufacturing methods for amorphous metals: Various manufacturing techniques are employed to produce amorphous metals, including rapid solidification, melt spinning, and other specialized processes that prevent crystallization. These methods typically involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. The manufacturing processes significantly influence the final properties of the amorphous metals, including their mechanical strength, magnetic properties, and corrosion resistance.

- Composition and alloying of amorphous metals: The composition of amorphous metals typically includes specific combinations of elements that facilitate glass formation. These may include transition metals combined with metalloids or other elements that inhibit crystallization. The selection of alloying elements significantly affects the glass-forming ability, thermal stability, and mechanical properties of the resulting amorphous metal. Multicomponent alloy systems are often designed to achieve optimal combinations of properties for specific applications.

- Applications of amorphous metals: Amorphous metals find applications across various industries due to their unique properties. They are used in electronic devices, transformers, and magnetic sensors due to their soft magnetic properties. Their high strength and corrosion resistance make them suitable for structural components, medical implants, and sporting goods. Additionally, their unique atomic structure enables applications in energy storage, catalysis, and advanced manufacturing where conventional crystalline metals may be limited.

- Properties and characterization of amorphous metals: Amorphous metals exhibit distinctive properties due to their non-crystalline atomic structure, including high strength, hardness, and elastic limit compared to their crystalline counterparts. They often display excellent corrosion resistance, unique magnetic behavior, and superior wear resistance. Various characterization techniques are employed to analyze their structure and properties, including X-ray diffraction, electron microscopy, thermal analysis, and mechanical testing methods that help understand their behavior under different conditions.

- Thermal stability and crystallization behavior: Amorphous metals exist in a metastable state and tend to crystallize when heated above their glass transition temperature. Understanding and controlling this crystallization behavior is crucial for processing and application development. Thermal stability can be enhanced through careful composition design and processing techniques. The crystallization process often occurs in stages and can be studied using thermal analysis methods. Some amorphous metals can be processed in the supercooled liquid region before crystallization occurs, allowing for unique forming capabilities.

02 Composition and alloying of amorphous metals

The composition of amorphous metals significantly affects their properties and glass-forming ability. Specific alloying elements can enhance the stability of the amorphous structure by creating atomic size mismatches that inhibit crystallization. Multicomponent systems containing elements with different atomic sizes are particularly effective at forming bulk amorphous structures. These alloys often include combinations of transition metals, rare earth elements, and metalloids to achieve the desired amorphous structure and properties.Expand Specific Solutions03 Applications of amorphous metals

Amorphous metals find applications across various industries due to their unique properties. They are used in transformer cores and magnetic devices because of their soft magnetic properties and low core losses. Their high strength and corrosion resistance make them suitable for structural components in aerospace and automotive industries. Additionally, amorphous metals are utilized in medical implants, sporting goods, and electronic devices where their combination of properties offers advantages over conventional crystalline metals.Expand Specific Solutions04 Mechanical and physical properties of amorphous metals

Amorphous metals exhibit exceptional mechanical and physical properties compared to their crystalline counterparts. They typically demonstrate high strength, hardness, and elastic limits due to the absence of grain boundaries and dislocations. Their unique atomic structure also contributes to superior corrosion resistance, wear resistance, and unique magnetic properties. However, they often show limited ductility at room temperature, which can be addressed through specific processing techniques or compositional adjustments to create composite structures.Expand Specific Solutions05 Surface treatment and coating applications

Amorphous metals can be applied as coatings to enhance the surface properties of conventional materials. Various deposition techniques, including thermal spraying, laser cladding, and physical vapor deposition, can be used to create amorphous metal coatings. These coatings provide improved wear resistance, corrosion protection, and tribological properties to the substrate materials. The process parameters must be carefully controlled to maintain the amorphous structure during deposition and prevent crystallization that would compromise the desired properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The amorphous metals market in advanced tribological systems is currently in a growth phase, with increasing applications in automotive, aerospace, and industrial sectors. The market size is expanding due to superior wear resistance and mechanical properties of these materials. Technologically, the field is advancing from research to commercialization, with varying maturity levels across applications. Key players include established industrial giants like Schaeffler Technologies, 3M Innovative Properties, and Caterpillar, alongside specialized entities such as Heraeus Amloy Technologies and Amorphyx. Academic institutions (Zhejiang University, Northeastern University) and research organizations (Fraunhofer-Gesellschaft, Japan Science & Technology Agency) are driving fundamental innovations, while companies like BYD and Baker Hughes are exploring practical applications in energy and transportation sectors.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has integrated amorphous metal technology into their advanced bearing systems through their proprietary "Amorph-Bearing" product line. Their approach utilizes iron-based bulk metallic glass races with optimized composition for rolling contact fatigue resistance. The company employs a specialized controlled cooling process during manufacturing that ensures consistent amorphous structure throughout the bearing components. Schaeffler's amorphous metal bearings demonstrate significantly reduced friction coefficients (approximately 15-20% lower than conventional bearings) and exceptional resistance to micropitting and surface-initiated fatigue. Their technology incorporates specialized surface treatments that enhance the natural tribological advantages of amorphous metals, creating synergistic effects that extend bearing life by up to 40% in high-load applications. Schaeffler has successfully implemented these bearings in wind turbine gearboxes and other demanding industrial applications where conventional materials face premature failure.

Strengths: Extensive bearing design expertise combined with advanced materials science; established manufacturing infrastructure allowing for scale production; comprehensive testing capabilities for tribological performance validation. Weaknesses: Higher initial cost compared to conventional bearing materials; application-specific designs limiting universal adoption; potential challenges in repair and maintenance compared to traditional bearings.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed specialized amorphous metal coatings for oil and gas drilling equipment operating in extreme tribological environments. Their technology focuses on iron-molybdenum-boron based amorphous alloys applied through high-velocity oxygen fuel (HVOF) thermal spray processes. These coatings provide exceptional resistance to abrasive wear from drilling mud containing silica particles and other abrasives. Baker Hughes' proprietary post-deposition treatment process optimizes the microstructure at the coating-substrate interface, enhancing adhesion and preventing delamination under cyclic loading conditions. Their amorphous metal coatings have demonstrated up to 300% improvement in service life for downhole components exposed to corrosive fluids and abrasive particles compared to conventional hard-facing materials. The company has successfully implemented this technology in mud motor stators, drill bit bearings, and other critical components operating in high-pressure, high-temperature environments where tribological performance is paramount.

Strengths: Exceptional resistance to combined erosion-corrosion damage; ability to be applied as coatings on existing components; proven field performance in extreme operating environments. Weaknesses: Complex application process requiring specialized equipment; thickness limitations of spray-applied coatings; potential for thermal degradation during application process.

Key Patents and Scientific Breakthroughs

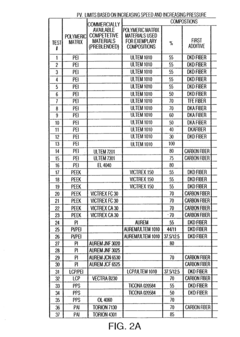

Tribological materials and structures and methods for making the same

PatentInactiveUS20070249506A1

Innovation

- The development of plastic compositions incorporating a polymeric matrix material with lubricious reinforcing fibers and additives such as Thermalgraph DKD, Dialead K223HG, and boron nitride, which provide improved thermal conductivity, wear resistance, and reduced friction, allowing for the creation of bearings with enhanced tribological properties, including low wear, low friction, and high limiting PVs.

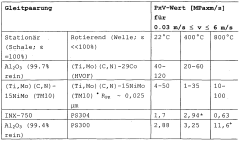

Friction materials/tribological materials for radial and axial film bearings

PatentWO2006029827A1

Innovation

- A tribological system featuring a base body and counter-body with metallically bonded (Ti, Mo)(C, N) and solid phase solutions of TiO2-Cr2O3, which form discrete phases with planar oxygen defects, and a metallic binder, optimized for atmospheric plasma spraying, to enhance wear resistance and friction performance.

Environmental Impact and Sustainability Factors

The integration of amorphous metals in tribological systems presents significant environmental advantages compared to conventional materials. These non-crystalline alloys demonstrate superior wear resistance and durability, extending component lifespans by up to 300% in certain applications. This longevity directly translates to reduced material consumption and waste generation throughout product lifecycles, addressing growing sustainability concerns in industrial sectors.

Amorphous metals require lower processing temperatures than their crystalline counterparts, typically 30-40% less energy during manufacturing. This energy efficiency extends to operational phases, where the exceptional hardness-to-weight ratio and lower friction coefficients of amorphous metals reduce energy consumption in moving systems. Studies indicate potential energy savings of 15-25% in automotive and aerospace applications through the implementation of amorphous metal bearings and wear surfaces.

The recyclability profile of amorphous metals further enhances their environmental credentials. Unlike many composite materials that present recycling challenges, amorphous metals can be reprocessed with minimal property degradation. Their homogeneous structure facilitates more efficient material recovery processes, with reclamation rates exceeding 90% in controlled industrial environments.

From a toxicity perspective, many amorphous metal formulations avoid environmentally problematic elements common in traditional tribological materials. The elimination or significant reduction of lead, cadmium, and certain rare earth elements addresses regulatory compliance challenges while minimizing ecological impact throughout the material lifecycle.

Life Cycle Assessment (LCA) studies comparing amorphous metal components to conventional alternatives demonstrate favorable environmental performance metrics. Carbon footprint reductions of 20-35% have been documented when accounting for raw material extraction, processing, use phase, and end-of-life scenarios. These advantages become particularly pronounced in high-stress applications where traditional materials require frequent replacement.

The adoption of amorphous metals aligns with circular economy principles through enabling design strategies that emphasize material efficiency and component reusability. Their exceptional mechanical properties permit the development of lighter, more compact tribological systems that maintain performance while reducing resource intensity. This dimensional optimization contributes to transportation efficiency gains when implemented in mobile applications.

Amorphous metals require lower processing temperatures than their crystalline counterparts, typically 30-40% less energy during manufacturing. This energy efficiency extends to operational phases, where the exceptional hardness-to-weight ratio and lower friction coefficients of amorphous metals reduce energy consumption in moving systems. Studies indicate potential energy savings of 15-25% in automotive and aerospace applications through the implementation of amorphous metal bearings and wear surfaces.

The recyclability profile of amorphous metals further enhances their environmental credentials. Unlike many composite materials that present recycling challenges, amorphous metals can be reprocessed with minimal property degradation. Their homogeneous structure facilitates more efficient material recovery processes, with reclamation rates exceeding 90% in controlled industrial environments.

From a toxicity perspective, many amorphous metal formulations avoid environmentally problematic elements common in traditional tribological materials. The elimination or significant reduction of lead, cadmium, and certain rare earth elements addresses regulatory compliance challenges while minimizing ecological impact throughout the material lifecycle.

Life Cycle Assessment (LCA) studies comparing amorphous metal components to conventional alternatives demonstrate favorable environmental performance metrics. Carbon footprint reductions of 20-35% have been documented when accounting for raw material extraction, processing, use phase, and end-of-life scenarios. These advantages become particularly pronounced in high-stress applications where traditional materials require frequent replacement.

The adoption of amorphous metals aligns with circular economy principles through enabling design strategies that emphasize material efficiency and component reusability. Their exceptional mechanical properties permit the development of lighter, more compact tribological systems that maintain performance while reducing resource intensity. This dimensional optimization contributes to transportation efficiency gains when implemented in mobile applications.

Performance Benchmarking Methodologies

Establishing standardized performance benchmarking methodologies is crucial for evaluating amorphous metals in tribological applications. The assessment framework must encompass multiple dimensions including wear resistance, friction coefficient stability, and performance under varying environmental conditions. Current benchmarking approaches typically utilize pin-on-disk tribometers, reciprocating wear testers, and high-temperature friction analyzers to simulate real-world operational conditions.

Comparative analysis between amorphous metals and conventional materials requires carefully controlled testing parameters. Standard testing protocols such as ASTM G99 (pin-on-disk), ASTM G133 (linear reciprocating), and DIN 50324 (tribological testing) provide foundational methodologies that can be adapted specifically for amorphous metal evaluation. These standards ensure reproducibility and comparability across different research institutions and industrial settings.

Load-bearing capacity assessment represents a critical benchmarking metric for amorphous metals in tribological systems. Progressive load tests, starting from minimal contact pressure and gradually increasing until material failure, help determine the critical load threshold. This methodology reveals the superior load-bearing capabilities of certain amorphous compositions compared to crystalline counterparts, particularly under high-stress sliding conditions.

Environmental response testing constitutes another essential benchmarking approach. Amorphous metals must be evaluated under varying humidity levels (typically 5-95% RH), temperature ranges (-40°C to 400°C), and in the presence of different lubricants or corrosive media. These tests reveal the exceptional corrosion resistance of many amorphous alloys while identifying potential environmental limitations.

Long-term performance stability assessment requires accelerated aging protocols. Cyclic loading tests conducted over millions of cycles help predict the tribological behavior throughout the expected service life. Data collection at regular intervals enables the creation of performance degradation curves, allowing for accurate service life predictions and maintenance scheduling in industrial applications.

Microstructural evolution monitoring during tribological testing provides insights into wear mechanisms. Surface analytical techniques including SEM, TEM, and XPS applied before and after tribological testing help correlate performance metrics with microstructural changes. This approach is particularly valuable for understanding the unique deformation mechanisms in amorphous metals that differ significantly from crystalline materials.

Standardized reporting formats enhance benchmarking value across the scientific community. Key performance indicators should include wear rate (mm³/Nm), friction coefficient stability, critical load thresholds, and environmental resistance metrics. These standardized metrics facilitate direct comparison between different amorphous compositions and against conventional materials, driving material selection decisions for specific tribological applications.

Comparative analysis between amorphous metals and conventional materials requires carefully controlled testing parameters. Standard testing protocols such as ASTM G99 (pin-on-disk), ASTM G133 (linear reciprocating), and DIN 50324 (tribological testing) provide foundational methodologies that can be adapted specifically for amorphous metal evaluation. These standards ensure reproducibility and comparability across different research institutions and industrial settings.

Load-bearing capacity assessment represents a critical benchmarking metric for amorphous metals in tribological systems. Progressive load tests, starting from minimal contact pressure and gradually increasing until material failure, help determine the critical load threshold. This methodology reveals the superior load-bearing capabilities of certain amorphous compositions compared to crystalline counterparts, particularly under high-stress sliding conditions.

Environmental response testing constitutes another essential benchmarking approach. Amorphous metals must be evaluated under varying humidity levels (typically 5-95% RH), temperature ranges (-40°C to 400°C), and in the presence of different lubricants or corrosive media. These tests reveal the exceptional corrosion resistance of many amorphous alloys while identifying potential environmental limitations.

Long-term performance stability assessment requires accelerated aging protocols. Cyclic loading tests conducted over millions of cycles help predict the tribological behavior throughout the expected service life. Data collection at regular intervals enables the creation of performance degradation curves, allowing for accurate service life predictions and maintenance scheduling in industrial applications.

Microstructural evolution monitoring during tribological testing provides insights into wear mechanisms. Surface analytical techniques including SEM, TEM, and XPS applied before and after tribological testing help correlate performance metrics with microstructural changes. This approach is particularly valuable for understanding the unique deformation mechanisms in amorphous metals that differ significantly from crystalline materials.

Standardized reporting formats enhance benchmarking value across the scientific community. Key performance indicators should include wear rate (mm³/Nm), friction coefficient stability, critical load thresholds, and environmental resistance metrics. These standardized metrics facilitate direct comparison between different amorphous compositions and against conventional materials, driving material selection decisions for specific tribological applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!