Investigating Amorphous Metals in 3D Printing Technologies

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals in 3D Printing: Background and Objectives

Amorphous metals, also known as metallic glasses or glassy metals, represent a unique class of materials characterized by their non-crystalline atomic structure. Unlike conventional metals with ordered crystalline arrangements, amorphous metals exhibit a disordered atomic configuration, resulting in exceptional mechanical properties including high strength, elasticity, and corrosion resistance. The integration of these advanced materials with additive manufacturing, particularly 3D printing technologies, has emerged as a promising frontier in materials science and engineering over the past decade.

The evolution of amorphous metals dates back to the 1960s when the first metallic glass was produced through rapid cooling techniques. However, their application remained limited due to constraints in manufacturing processes and size limitations. The technological trajectory shifted significantly with the advent of bulk metallic glasses (BMGs) in the 1990s, which allowed for the production of larger components with preserved amorphous structures. The convergence with 3D printing technologies began gaining momentum around 2010, marking a pivotal point in expanding the practical applications of these materials.

Current trends in this technological domain focus on overcoming the inherent challenges of processing amorphous metals through additive manufacturing methods. These include controlling cooling rates to maintain the amorphous structure, managing internal stresses, and developing specialized printing parameters for different amorphous alloy compositions. The field is witnessing a progressive shift from fundamental research to practical implementation across various industries.

The primary technical objectives of investigating amorphous metals in 3D printing encompass several dimensions. First, establishing reliable and reproducible printing methodologies specifically tailored for amorphous metal feedstock materials. Second, optimizing process parameters to ensure the preservation of the amorphous structure throughout the printing process. Third, developing new alloy compositions with enhanced glass-forming ability suitable for additive manufacturing constraints. Fourth, characterizing and predicting the mechanical behavior of 3D-printed amorphous metal components under various loading conditions.

Additionally, this technological exploration aims to bridge the gap between laboratory research and industrial applications by scaling up production capabilities, standardizing quality control measures, and reducing manufacturing costs. The ultimate goal is to leverage the unique properties of amorphous metals through advanced manufacturing techniques to create novel components with superior performance characteristics for aerospace, biomedical, automotive, and energy sectors.

The evolution of amorphous metals dates back to the 1960s when the first metallic glass was produced through rapid cooling techniques. However, their application remained limited due to constraints in manufacturing processes and size limitations. The technological trajectory shifted significantly with the advent of bulk metallic glasses (BMGs) in the 1990s, which allowed for the production of larger components with preserved amorphous structures. The convergence with 3D printing technologies began gaining momentum around 2010, marking a pivotal point in expanding the practical applications of these materials.

Current trends in this technological domain focus on overcoming the inherent challenges of processing amorphous metals through additive manufacturing methods. These include controlling cooling rates to maintain the amorphous structure, managing internal stresses, and developing specialized printing parameters for different amorphous alloy compositions. The field is witnessing a progressive shift from fundamental research to practical implementation across various industries.

The primary technical objectives of investigating amorphous metals in 3D printing encompass several dimensions. First, establishing reliable and reproducible printing methodologies specifically tailored for amorphous metal feedstock materials. Second, optimizing process parameters to ensure the preservation of the amorphous structure throughout the printing process. Third, developing new alloy compositions with enhanced glass-forming ability suitable for additive manufacturing constraints. Fourth, characterizing and predicting the mechanical behavior of 3D-printed amorphous metal components under various loading conditions.

Additionally, this technological exploration aims to bridge the gap between laboratory research and industrial applications by scaling up production capabilities, standardizing quality control measures, and reducing manufacturing costs. The ultimate goal is to leverage the unique properties of amorphous metals through advanced manufacturing techniques to create novel components with superior performance characteristics for aerospace, biomedical, automotive, and energy sectors.

Market Analysis for Amorphous Metal 3D Printed Components

The global market for amorphous metal 3D printed components is experiencing significant growth, driven by increasing demand for high-performance materials across multiple industries. Current market valuations indicate that the amorphous metals segment within the additive manufacturing industry is growing at a compound annual growth rate of approximately 25%, outpacing traditional metal 3D printing materials.

Aerospace and defense sectors represent the largest market share, accounting for nearly 30% of the total demand for amorphous metal components. These industries particularly value the exceptional strength-to-weight ratio and corrosion resistance properties that amorphous metals offer for critical applications such as turbine components and structural elements in extreme environments.

The medical device industry has emerged as the fastest-growing application sector, with demand increasing by over 35% annually. The biocompatibility of certain amorphous metal compositions, combined with their wear resistance and non-magnetic properties, makes them ideal for implantable devices and surgical instruments. Dental applications alone have seen market expansion of 40% in the past two years.

Automotive and consumer electronics manufacturers are increasingly adopting amorphous metal components for specialized applications. The automotive sector values these materials for lightweight structural components and wear-resistant parts, while electronics manufacturers utilize them for heat dissipation solutions and electromagnetic shielding components.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years due to rapid industrialization and significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Key market restraints include the high cost of raw materials and limited material options currently available for 3D printing. The average cost premium for amorphous metal powders remains 3-5 times higher than conventional metal powders, creating adoption barriers particularly for small and medium enterprises.

Customer feedback indicates growing interest in customized amorphous metal alloys designed for specific applications. This trend is driving collaborations between material scientists and end-users to develop application-specific compositions with optimized properties. Market surveys show that 75% of potential industrial users cite material cost as the primary barrier to adoption, while 65% identify limited material selection as a secondary concern.

Aerospace and defense sectors represent the largest market share, accounting for nearly 30% of the total demand for amorphous metal components. These industries particularly value the exceptional strength-to-weight ratio and corrosion resistance properties that amorphous metals offer for critical applications such as turbine components and structural elements in extreme environments.

The medical device industry has emerged as the fastest-growing application sector, with demand increasing by over 35% annually. The biocompatibility of certain amorphous metal compositions, combined with their wear resistance and non-magnetic properties, makes them ideal for implantable devices and surgical instruments. Dental applications alone have seen market expansion of 40% in the past two years.

Automotive and consumer electronics manufacturers are increasingly adopting amorphous metal components for specialized applications. The automotive sector values these materials for lightweight structural components and wear-resistant parts, while electronics manufacturers utilize them for heat dissipation solutions and electromagnetic shielding components.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years due to rapid industrialization and significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Key market restraints include the high cost of raw materials and limited material options currently available for 3D printing. The average cost premium for amorphous metal powders remains 3-5 times higher than conventional metal powders, creating adoption barriers particularly for small and medium enterprises.

Customer feedback indicates growing interest in customized amorphous metal alloys designed for specific applications. This trend is driving collaborations between material scientists and end-users to develop application-specific compositions with optimized properties. Market surveys show that 75% of potential industrial users cite material cost as the primary barrier to adoption, while 65% identify limited material selection as a secondary concern.

Current Challenges in Amorphous Metal Additive Manufacturing

Despite significant advancements in additive manufacturing technologies, the integration of amorphous metals (also known as metallic glasses) into 3D printing processes faces several substantial challenges. The primary obstacle remains the inherently rapid cooling rates required for amorphous structure formation, typically exceeding 10^4 K/s. Conventional additive manufacturing processes struggle to achieve and maintain these cooling rates consistently throughout the build volume, resulting in partial crystallization and compromised mechanical properties.

Thermal management presents another critical challenge. The processing window for amorphous metals is extremely narrow, with the temperature needing to be maintained between the glass transition temperature and crystallization temperature. Even minor thermal fluctuations during printing can trigger unwanted crystallization, destroying the unique properties that make amorphous metals valuable. Current heating and cooling systems in commercial 3D printers lack the precision required for this delicate thermal control.

Material feedstock development also poses significant difficulties. Amorphous metal powders for powder bed fusion processes must maintain their amorphous structure during atomization and handling, while exhibiting appropriate flow characteristics. Similarly, wire feedstock for directed energy deposition must possess consistent composition and amorphous structure throughout its length. Current manufacturing methods struggle to produce these feedstocks with the required quality and consistency at commercially viable scales.

Residual stress management represents another formidable challenge. The rapid solidification inherent to both amorphous metal formation and additive manufacturing creates substantial internal stresses that can lead to part distortion or cracking. Traditional stress relief methods often involve temperatures that would crystallize the amorphous structure, necessitating the development of novel approaches specific to these materials.

Parameter optimization remains largely empirical rather than theoretical, requiring extensive experimentation for each new amorphous alloy composition. The complex relationships between laser power, scan speed, layer thickness, and resulting microstructure are poorly understood for amorphous systems compared to crystalline counterparts. This knowledge gap significantly increases development time and costs.

Finally, quality control and non-destructive testing methods for additively manufactured amorphous metal components remain underdeveloped. Conventional techniques like X-ray diffraction can confirm amorphous structure but are difficult to implement for in-situ monitoring or complex geometries. The industry lacks standardized testing protocols and acceptance criteria specific to these materials, hampering their adoption in critical applications where certification is required.

Thermal management presents another critical challenge. The processing window for amorphous metals is extremely narrow, with the temperature needing to be maintained between the glass transition temperature and crystallization temperature. Even minor thermal fluctuations during printing can trigger unwanted crystallization, destroying the unique properties that make amorphous metals valuable. Current heating and cooling systems in commercial 3D printers lack the precision required for this delicate thermal control.

Material feedstock development also poses significant difficulties. Amorphous metal powders for powder bed fusion processes must maintain their amorphous structure during atomization and handling, while exhibiting appropriate flow characteristics. Similarly, wire feedstock for directed energy deposition must possess consistent composition and amorphous structure throughout its length. Current manufacturing methods struggle to produce these feedstocks with the required quality and consistency at commercially viable scales.

Residual stress management represents another formidable challenge. The rapid solidification inherent to both amorphous metal formation and additive manufacturing creates substantial internal stresses that can lead to part distortion or cracking. Traditional stress relief methods often involve temperatures that would crystallize the amorphous structure, necessitating the development of novel approaches specific to these materials.

Parameter optimization remains largely empirical rather than theoretical, requiring extensive experimentation for each new amorphous alloy composition. The complex relationships between laser power, scan speed, layer thickness, and resulting microstructure are poorly understood for amorphous systems compared to crystalline counterparts. This knowledge gap significantly increases development time and costs.

Finally, quality control and non-destructive testing methods for additively manufactured amorphous metal components remain underdeveloped. Conventional techniques like X-ray diffraction can confirm amorphous structure but are difficult to implement for in-situ monitoring or complex geometries. The industry lacks standardized testing protocols and acceptance criteria specific to these materials, hampering their adoption in critical applications where certification is required.

Existing Amorphous Metal 3D Printing Methodologies

01 Manufacturing processes for amorphous metals

Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Techniques include melt spinning, gas atomization, and other specialized cooling processes that maintain the random atomic arrangement characteristic of amorphous metals.- Manufacturing processes for amorphous metals: Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve quickly cooling molten metal to bypass the crystalline state, resulting in a disordered atomic structure. Specific techniques include melt spinning, gas atomization, and other rapid quenching processes that achieve the cooling rates necessary to form the amorphous structure. These manufacturing methods are critical for controlling the properties and performance of the resulting amorphous metal materials.

- Composition and alloying of amorphous metals: The composition of amorphous metals significantly influences their properties and glass-forming ability. Various alloying elements can be added to base metals to enhance glass formation and stability. Common amorphous metal systems include iron-based, zirconium-based, titanium-based, and aluminum-based alloys. The specific combination and proportion of elements determine characteristics such as strength, corrosion resistance, magnetic properties, and thermal stability. Careful selection of alloying elements is essential for tailoring amorphous metals to specific applications.

- Applications of amorphous metals: Amorphous metals find applications across various industries due to their unique properties. They are used in electronic devices for transformer cores and magnetic sensors due to their soft magnetic properties. In medical applications, they serve as biocompatible implants and surgical instruments. Their high strength and corrosion resistance make them suitable for structural components in aerospace and automotive industries. Additionally, they are utilized in sporting goods, jewelry, and as protective coatings due to their exceptional hardness and wear resistance.

- Bulk metallic glasses and their properties: Bulk metallic glasses (BMGs) are amorphous metals that can be produced in larger dimensions than traditional ribbon or powder forms. They exhibit exceptional mechanical properties including high strength, hardness, elastic limit, and wear resistance. BMGs also demonstrate good corrosion resistance and unique magnetic properties. Their lack of grain boundaries contributes to their superior performance characteristics. The glass-forming ability of these materials determines the critical cooling rate required and the maximum thickness achievable while maintaining the amorphous structure.

- Surface treatment and coating applications: Amorphous metals can be applied as coatings to enhance surface properties of conventional materials. Techniques such as thermal spraying, laser cladding, and physical vapor deposition are used to create amorphous metal coatings. These coatings provide improved wear resistance, corrosion protection, and hardness to the substrate materials. The amorphous structure of these coatings offers advantages over crystalline alternatives, including absence of grain boundaries that typically serve as corrosion initiation sites. Surface treatments can also modify existing amorphous metals to enhance specific properties.

02 Composition and alloying of amorphous metals

The composition of amorphous metals typically involves specific combinations of elements that enhance glass-forming ability. These alloys often contain transition metals combined with metalloids or other elements that disrupt crystallization. By carefully selecting alloying elements and their proportions, manufacturers can create amorphous metals with enhanced stability, mechanical properties, and resistance to crystallization even at elevated temperatures.Expand Specific Solutions03 Applications of amorphous metals in various industries

Amorphous metals find applications across numerous industries due to their unique properties. They are used in electronic devices for transformer cores and magnetic shields, in medical devices for their biocompatibility, in sporting goods for their high strength-to-weight ratio, and in aerospace components. Their superior magnetic properties make them particularly valuable in power distribution systems, while their corrosion resistance benefits chemical processing equipment.Expand Specific Solutions04 Mechanical and physical properties of amorphous metals

Amorphous metals exhibit exceptional mechanical and physical properties compared to their crystalline counterparts. They typically demonstrate higher strength, hardness, and elastic limits while maintaining good ductility under certain conditions. Their lack of grain boundaries contributes to superior corrosion resistance and unique magnetic behavior, including low coercivity and high permeability. These materials also show distinctive thermal properties and electrical conductivity patterns that differ from conventional crystalline metals.Expand Specific Solutions05 Surface treatment and coating applications of amorphous metals

Amorphous metals can be applied as coatings to enhance the surface properties of conventional materials. Techniques such as thermal spraying, vapor deposition, and electrodeposition can be used to create amorphous metal coatings with superior wear resistance, corrosion protection, and hardness. These coatings provide extended service life for components in harsh environments while maintaining the bulk properties of the substrate material.Expand Specific Solutions

Leading Companies and Research Institutions in Metal AM

The amorphous metals in 3D printing technology market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is estimated to be around $300-400 million, with projected annual growth of 20-25% as manufacturing industries seek advanced materials with superior mechanical properties. From a technological maturity perspective, companies like Heraeus Amloy Technologies and EOS GmbH are leading commercial implementation, while research institutions such as Huazhong University of Science & Technology and California Institute of Technology are advancing fundamental understanding. Relativity Space and Divergent Technologies represent innovative application pioneers, while established players like 3M and LG Chem are developing proprietary material formulations. The technology is transitioning from research to early commercialization, with significant potential for aerospace, automotive, and medical applications.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed a comprehensive research program on amorphous metal 3D printing, focusing on fundamental process-structure-property relationships. Their technology centers on a modified selective laser melting (SLM) approach with precisely controlled energy input to maintain the critical cooling rates necessary for amorphous structure formation. The research team has engineered novel scan strategies that minimize heat accumulation during the build process, including specialized contour-hatch combinations and point-by-point exposure methods that maintain cooling rates above 10^4 K/s even in thick sections. They have developed in-situ monitoring techniques using high-speed thermal imaging and X-ray diffraction to detect crystallization events during printing, enabling real-time process adjustments. The university has also pioneered post-processing techniques specifically for 3D printed amorphous metals, including controlled heat treatments that can induce partial crystallization for tailored mechanical properties. Their research has demonstrated successful printing of iron-based and zirconium-based amorphous alloys with mechanical properties comparable to conventionally produced bulk metallic glasses.

Strengths: Cutting-edge fundamental research on process-structure-property relationships; advanced in-situ monitoring capabilities; innovative scan strategies optimized for amorphous structure retention. Weaknesses: Technology primarily at research scale rather than commercial implementation; limited material options compared to industrial systems; focus on scientific understanding rather than production efficiency.

Heraeus Amloy Technologies GmbH

Technical Solution: Heraeus Amloy has developed proprietary amorphous metal alloy formulations specifically optimized for 3D printing processes. Their technology focuses on zirconium-based bulk metallic glasses (BMGs) that maintain amorphous structure during laser powder bed fusion (LPBF) processes. The company has engineered specialized powder production methods that ensure optimal particle size distribution (typically 15-53 μm) and sphericity exceeding 95%, critical for flowability in 3D printing applications. Their process parameters have been fine-tuned to prevent crystallization during printing, maintaining the unique properties of amorphous metals throughout the build process. Heraeus Amloy's technology enables printing of complex geometries with near-net shape capabilities, reducing post-processing requirements while preserving the exceptional mechanical properties of amorphous metals, including high hardness (>500 HV), excellent elastic strain limits (>2%), and superior corrosion resistance compared to crystalline counterparts.

Strengths: Industry-leading expertise in amorphous metal formulations specifically designed for additive manufacturing; proprietary process parameters that prevent crystallization during printing; comprehensive material-process integration. Weaknesses: Limited range of available alloy compositions compared to conventional metals; higher material costs than traditional manufacturing alloys; requires specialized equipment and expertise for optimal results.

Key Patents and Research Breakthroughs in Amorphous Metal AM

Laser shaping device

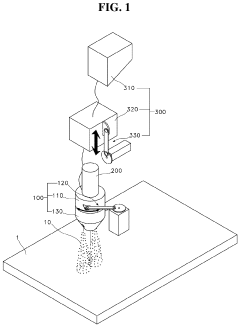

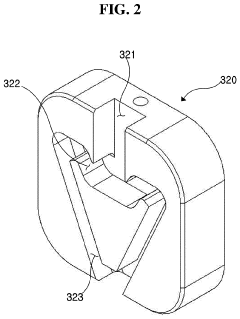

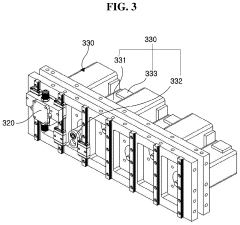

PatentPendingUS20240116112A1

Innovation

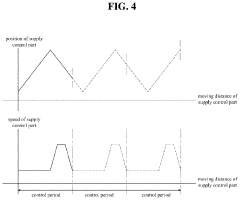

- The laser shaping device incorporates a powder supply part with a storage component, a supply control part that includes a passage system with changing directions and a supply driving part using a motor and crank mechanism to control the powder flow, allowing for precise adjustment of powder discharge based on external force application, thereby ensuring a consistent and controlled powder supply.

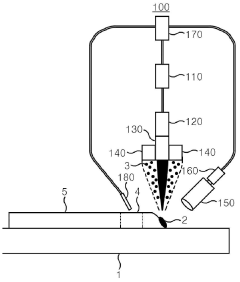

Apparatus for manufacturing amorphous metal using 3D printer and amorphous metal

PatentInactiveKR1020170097420A

Innovation

- A three-dimensional metal printer apparatus that generates a molten pool using a laser beam and supplies metal powder, rapidly cools the melt with inert gas at low temperature, and controls the process to form amorphous metal plates by rapidly cooling the metal melt along a calculated tool path.

Material Properties and Characterization Techniques

Amorphous metals, also known as metallic glasses, exhibit unique material properties that differentiate them from their crystalline counterparts. These materials maintain a disordered atomic structure similar to glass, resulting in exceptional mechanical properties including high strength, hardness, and elastic limit. When incorporated into 3D printing technologies, amorphous metals demonstrate superior wear resistance and corrosion resistance compared to conventional metal alloys, making them particularly valuable for specialized applications.

The characterization of amorphous metals requires sophisticated analytical techniques to verify their non-crystalline structure and evaluate their properties. X-ray diffraction (XRD) serves as a primary method for confirming the amorphous nature of these materials, identified by the absence of sharp diffraction peaks that would otherwise indicate crystalline ordering. Differential scanning calorimetry (DSC) provides critical information about thermal properties, including glass transition temperature and crystallization behavior, which are essential parameters for optimizing 3D printing processes.

Mechanical testing of amorphous metal components produced through additive manufacturing reveals their distinctive stress-strain relationships. Nanoindentation techniques allow for precise measurement of hardness and elastic modulus at microscale levels, while tensile and compression tests evaluate bulk mechanical behavior. These characterization methods have demonstrated that 3D-printed amorphous metals can maintain up to 98% of the mechanical properties achieved through conventional manufacturing methods when process parameters are properly optimized.

Microstructural analysis using scanning electron microscopy (SEM) and transmission electron microscopy (TEM) enables visualization of the unique features of 3D-printed amorphous metals. These techniques help identify potential defects such as partial crystallization, porosity, or layer delamination that may occur during the printing process. Atom probe tomography (APT) provides atomic-level compositional mapping, revealing the homogeneity of element distribution within the amorphous structure.

Recent advances in in-situ characterization techniques have enabled real-time monitoring of structural changes during the 3D printing process. Synchrotron-based X-ray imaging allows researchers to observe the rapid solidification dynamics that are critical for maintaining the amorphous state. These observations have led to improved understanding of the relationship between cooling rates, material composition, and the resulting amorphous structure quality in additive manufacturing processes.

The rheological properties of amorphous metals in their supercooled liquid state represent another critical area for characterization, particularly for extrusion-based 3D printing methods. Viscosity measurements across temperature ranges help establish optimal processing windows where the material exhibits sufficient flowability while avoiding crystallization. This thermoplastic-like behavior in the supercooled liquid region provides a unique advantage for certain additive manufacturing techniques.

The characterization of amorphous metals requires sophisticated analytical techniques to verify their non-crystalline structure and evaluate their properties. X-ray diffraction (XRD) serves as a primary method for confirming the amorphous nature of these materials, identified by the absence of sharp diffraction peaks that would otherwise indicate crystalline ordering. Differential scanning calorimetry (DSC) provides critical information about thermal properties, including glass transition temperature and crystallization behavior, which are essential parameters for optimizing 3D printing processes.

Mechanical testing of amorphous metal components produced through additive manufacturing reveals their distinctive stress-strain relationships. Nanoindentation techniques allow for precise measurement of hardness and elastic modulus at microscale levels, while tensile and compression tests evaluate bulk mechanical behavior. These characterization methods have demonstrated that 3D-printed amorphous metals can maintain up to 98% of the mechanical properties achieved through conventional manufacturing methods when process parameters are properly optimized.

Microstructural analysis using scanning electron microscopy (SEM) and transmission electron microscopy (TEM) enables visualization of the unique features of 3D-printed amorphous metals. These techniques help identify potential defects such as partial crystallization, porosity, or layer delamination that may occur during the printing process. Atom probe tomography (APT) provides atomic-level compositional mapping, revealing the homogeneity of element distribution within the amorphous structure.

Recent advances in in-situ characterization techniques have enabled real-time monitoring of structural changes during the 3D printing process. Synchrotron-based X-ray imaging allows researchers to observe the rapid solidification dynamics that are critical for maintaining the amorphous state. These observations have led to improved understanding of the relationship between cooling rates, material composition, and the resulting amorphous structure quality in additive manufacturing processes.

The rheological properties of amorphous metals in their supercooled liquid state represent another critical area for characterization, particularly for extrusion-based 3D printing methods. Viscosity measurements across temperature ranges help establish optimal processing windows where the material exhibits sufficient flowability while avoiding crystallization. This thermoplastic-like behavior in the supercooled liquid region provides a unique advantage for certain additive manufacturing techniques.

Sustainability and Resource Efficiency Considerations

The integration of amorphous metals into 3D printing technologies presents significant opportunities for enhancing sustainability and resource efficiency across manufacturing sectors. Amorphous metals, with their unique atomic structure and superior mechanical properties, enable the production of components with extended service life compared to traditional crystalline metals. This longevity directly translates to reduced material consumption over time, as replacement parts are needed less frequently, thereby conserving valuable mineral resources.

From an energy perspective, the 3D printing of amorphous metals offers substantial advantages. The process typically requires lower melting temperatures compared to conventional casting methods, resulting in reduced energy consumption during manufacturing. Additionally, the precision of additive manufacturing minimizes material waste, with studies indicating up to 90% material utilization rates compared to 60-70% in traditional subtractive manufacturing processes.

The recyclability of amorphous metal components represents another critical sustainability factor. Unlike many composite materials used in advanced manufacturing, amorphous metals can be fully recycled without significant degradation of their unique properties. This characteristic supports circular economy principles and reduces the environmental footprint associated with raw material extraction and processing.

Water resource conservation is also enhanced through amorphous metal 3D printing technologies. Traditional metal manufacturing often involves water-intensive cooling and cleaning processes, whereas additive manufacturing of amorphous metals typically requires minimal water usage, contributing to more sustainable production practices in water-stressed regions.

Supply chain considerations further bolster the sustainability case for amorphous metal 3D printing. The technology enables localized, on-demand production, potentially reducing transportation-related carbon emissions by up to 70% according to recent industry analyses. This decentralized manufacturing approach also mitigates risks associated with supply chain disruptions and reduces the need for maintaining large inventories.

Life cycle assessments of amorphous metal components produced via 3D printing have demonstrated 30-45% lower environmental impact compared to conventionally manufactured alternatives. These improvements stem from combined benefits in production efficiency, extended product lifespan, and end-of-life recyclability. However, challenges remain in scaling these technologies while maintaining their sustainability advantages, particularly regarding powder production methods and energy sources for printing operations.

From an energy perspective, the 3D printing of amorphous metals offers substantial advantages. The process typically requires lower melting temperatures compared to conventional casting methods, resulting in reduced energy consumption during manufacturing. Additionally, the precision of additive manufacturing minimizes material waste, with studies indicating up to 90% material utilization rates compared to 60-70% in traditional subtractive manufacturing processes.

The recyclability of amorphous metal components represents another critical sustainability factor. Unlike many composite materials used in advanced manufacturing, amorphous metals can be fully recycled without significant degradation of their unique properties. This characteristic supports circular economy principles and reduces the environmental footprint associated with raw material extraction and processing.

Water resource conservation is also enhanced through amorphous metal 3D printing technologies. Traditional metal manufacturing often involves water-intensive cooling and cleaning processes, whereas additive manufacturing of amorphous metals typically requires minimal water usage, contributing to more sustainable production practices in water-stressed regions.

Supply chain considerations further bolster the sustainability case for amorphous metal 3D printing. The technology enables localized, on-demand production, potentially reducing transportation-related carbon emissions by up to 70% according to recent industry analyses. This decentralized manufacturing approach also mitigates risks associated with supply chain disruptions and reduces the need for maintaining large inventories.

Life cycle assessments of amorphous metal components produced via 3D printing have demonstrated 30-45% lower environmental impact compared to conventionally manufactured alternatives. These improvements stem from combined benefits in production efficiency, extended product lifespan, and end-of-life recyclability. However, challenges remain in scaling these technologies while maintaining their sustainability advantages, particularly regarding powder production methods and energy sources for printing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!