The Significance of Amorphous Metals in Wearable Technology

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals Evolution and Wearable Tech Goals

Amorphous metals, also known as metallic glasses, represent a revolutionary class of materials that have evolved significantly since their discovery in the 1960s. Initially produced only as thin ribbons through rapid quenching techniques, these non-crystalline alloys have progressed to bulk metallic glasses (BMGs) that can be manufactured in larger dimensions. This evolution has been driven by the unique combination of properties they offer: exceptional strength, elasticity, corrosion resistance, and biocompatibility—all characteristics highly valuable for wearable technology applications.

The technological trajectory of amorphous metals has been marked by continuous improvements in composition design and processing methods. Early limitations in size and shape have been gradually overcome through innovations in casting techniques, powder metallurgy, and more recently, additive manufacturing approaches. These advancements have expanded the potential applications from primarily academic interest to practical industrial uses, particularly in sectors requiring high-performance materials.

In parallel, wearable technology has undergone its own remarkable evolution, transitioning from simple fitness trackers to sophisticated health monitoring systems, augmented reality devices, and smart clothing. The convergence of these two technological paths presents significant opportunities for innovation. The primary goal in this intersection is to develop wearable devices that are simultaneously robust, comfortable, and functionally superior.

The technical objectives for amorphous metals in wearable applications are multifaceted. First, there is a push toward developing compositions that maintain their amorphous structure at larger dimensions while exhibiting enhanced mechanical properties. Second, researchers aim to improve processing techniques to enable more complex geometries and integration with other materials. Third, there is significant interest in exploiting the unique electromagnetic properties of certain amorphous compositions for sensing and communication functions in wearables.

Looking forward, the field is trending toward personalized wearable solutions where amorphous metals could enable adaptive devices that respond to user needs and environmental conditions. The miniaturization trend continues to drive research into thinner, lighter components that maintain structural integrity. Additionally, sustainability considerations are becoming increasingly important, with efforts focused on developing recyclable amorphous metal compositions and environmentally friendly manufacturing processes.

The ultimate technological goal is to create a new generation of wearable devices that seamlessly integrate with the human body, providing enhanced functionality without compromising comfort or safety—a vision where amorphous metals play a pivotal role due to their exceptional property profile and processing versatility.

The technological trajectory of amorphous metals has been marked by continuous improvements in composition design and processing methods. Early limitations in size and shape have been gradually overcome through innovations in casting techniques, powder metallurgy, and more recently, additive manufacturing approaches. These advancements have expanded the potential applications from primarily academic interest to practical industrial uses, particularly in sectors requiring high-performance materials.

In parallel, wearable technology has undergone its own remarkable evolution, transitioning from simple fitness trackers to sophisticated health monitoring systems, augmented reality devices, and smart clothing. The convergence of these two technological paths presents significant opportunities for innovation. The primary goal in this intersection is to develop wearable devices that are simultaneously robust, comfortable, and functionally superior.

The technical objectives for amorphous metals in wearable applications are multifaceted. First, there is a push toward developing compositions that maintain their amorphous structure at larger dimensions while exhibiting enhanced mechanical properties. Second, researchers aim to improve processing techniques to enable more complex geometries and integration with other materials. Third, there is significant interest in exploiting the unique electromagnetic properties of certain amorphous compositions for sensing and communication functions in wearables.

Looking forward, the field is trending toward personalized wearable solutions where amorphous metals could enable adaptive devices that respond to user needs and environmental conditions. The miniaturization trend continues to drive research into thinner, lighter components that maintain structural integrity. Additionally, sustainability considerations are becoming increasingly important, with efforts focused on developing recyclable amorphous metal compositions and environmentally friendly manufacturing processes.

The ultimate technological goal is to create a new generation of wearable devices that seamlessly integrate with the human body, providing enhanced functionality without compromising comfort or safety—a vision where amorphous metals play a pivotal role due to their exceptional property profile and processing versatility.

Market Demand Analysis for Amorphous Metals in Wearables

The wearable technology market has witnessed remarkable growth in recent years, with global revenues reaching $116 billion in 2021 and projected to surpass $265 billion by 2026. Within this expanding ecosystem, amorphous metals (also known as metallic glasses) are emerging as a critical material innovation that addresses multiple market demands simultaneously.

Consumer demand for more durable and aesthetically pleasing wearable devices continues to rise. Market research indicates that 67% of wearable device users cite durability as a primary concern, while 58% prioritize comfort and design. Amorphous metals directly address these needs through their exceptional strength-to-weight ratio, scratch resistance, and unique finishing capabilities that traditional crystalline metals cannot match.

Healthcare applications represent the fastest-growing segment for amorphous metal integration in wearables, expanding at 24% annually. The biocompatibility of certain amorphous metal compositions makes them ideal for continuous health monitoring devices that maintain direct skin contact. Market surveys reveal that 72% of healthcare providers express interest in wearable solutions utilizing advanced materials that can withstand constant use while maintaining sensor accuracy.

The fitness and sports wearables sector, valued at $41 billion globally, demonstrates particular demand for amorphous metals' corrosion resistance and mechanical properties. These devices frequently encounter sweat, water, and physical impacts, conditions where traditional materials often underperform. Consumer feedback shows 83% of active users would pay premium prices for wearables with enhanced durability features.

Industrial and enterprise wearables represent an emerging market segment with projected 31% annual growth, where amorphous metals' electromagnetic properties offer significant advantages. The ability to shield sensitive components while maintaining structural integrity addresses critical requirements for workplace safety and functionality in harsh environments.

Supply chain analysis reveals growing material availability as production scales, with manufacturing costs decreasing approximately 18% annually as new fabrication techniques mature. This trend aligns with consumer expectations, as 64% of potential buyers indicate willingness to invest in premium wearable devices if they offer demonstrably superior durability and performance.

Regional market analysis shows North America leading adoption with 38% market share, followed by Asia-Pacific at 34% with the fastest growth trajectory. European markets demonstrate particular interest in sustainable and recyclable aspects of amorphous metal implementation, aligning with regional regulatory frameworks emphasizing circular economy principles.

Consumer demand for more durable and aesthetically pleasing wearable devices continues to rise. Market research indicates that 67% of wearable device users cite durability as a primary concern, while 58% prioritize comfort and design. Amorphous metals directly address these needs through their exceptional strength-to-weight ratio, scratch resistance, and unique finishing capabilities that traditional crystalline metals cannot match.

Healthcare applications represent the fastest-growing segment for amorphous metal integration in wearables, expanding at 24% annually. The biocompatibility of certain amorphous metal compositions makes them ideal for continuous health monitoring devices that maintain direct skin contact. Market surveys reveal that 72% of healthcare providers express interest in wearable solutions utilizing advanced materials that can withstand constant use while maintaining sensor accuracy.

The fitness and sports wearables sector, valued at $41 billion globally, demonstrates particular demand for amorphous metals' corrosion resistance and mechanical properties. These devices frequently encounter sweat, water, and physical impacts, conditions where traditional materials often underperform. Consumer feedback shows 83% of active users would pay premium prices for wearables with enhanced durability features.

Industrial and enterprise wearables represent an emerging market segment with projected 31% annual growth, where amorphous metals' electromagnetic properties offer significant advantages. The ability to shield sensitive components while maintaining structural integrity addresses critical requirements for workplace safety and functionality in harsh environments.

Supply chain analysis reveals growing material availability as production scales, with manufacturing costs decreasing approximately 18% annually as new fabrication techniques mature. This trend aligns with consumer expectations, as 64% of potential buyers indicate willingness to invest in premium wearable devices if they offer demonstrably superior durability and performance.

Regional market analysis shows North America leading adoption with 38% market share, followed by Asia-Pacific at 34% with the fastest growth trajectory. European markets demonstrate particular interest in sustainable and recyclable aspects of amorphous metal implementation, aligning with regional regulatory frameworks emphasizing circular economy principles.

Current State and Challenges of Amorphous Metals Integration

The integration of amorphous metals into wearable technology represents a significant technological frontier with both promising advancements and substantial challenges. Globally, research institutions and technology companies have made considerable progress in developing amorphous metal alloys suitable for wearable applications, with notable achievements in Japan, the United States, Germany, and China. These regions have established specialized research centers focused on metallic glass development and application.

Currently, amorphous metals offer exceptional mechanical properties including high strength-to-weight ratios, superior elasticity, and remarkable wear resistance—characteristics that make them ideal candidates for next-generation wearable devices. Their unique atomic structure provides corrosion resistance far exceeding that of conventional metals, addressing a critical requirement for devices in constant contact with human skin and environmental elements.

Despite these advantages, several significant challenges impede widespread adoption. Manufacturing constraints represent the primary obstacle, as producing amorphous metals requires extremely rapid cooling rates (typically 10^6 K/s) to prevent crystallization. This requirement limits both the dimensions and geometries achievable in production, creating difficulties for wearable device designs that often demand complex shapes and thin profiles.

Cost factors present another substantial barrier. Current production methods for amorphous metals remain expensive compared to conventional materials, with specialized equipment and precise process control adding to manufacturing expenses. This cost differential makes mass-market adoption challenging, particularly in consumer wearables where price sensitivity is high.

Biocompatibility testing of amorphous metals remains incomplete, with long-term studies still ongoing. While initial results appear promising, comprehensive understanding of potential allergic reactions or long-term biological interactions is still developing. This uncertainty creates regulatory hurdles for medical-grade wearable applications.

Technical integration challenges also persist. Joining amorphous metals with other materials commonly used in wearables (polymers, ceramics, semiconductors) requires specialized techniques that are not yet standardized. Traditional welding and bonding methods often induce crystallization, compromising the unique properties that make amorphous metals valuable.

The recyclability and environmental impact of amorphous metal components in wearable devices remain inadequately addressed. As sustainability becomes increasingly important in product development, this knowledge gap represents a significant challenge for responsible implementation.

Geographical distribution of expertise shows concentration in specific research hubs, with limited knowledge transfer to manufacturing centers, creating bottlenecks in the commercialization pipeline. This uneven distribution of technical capability hampers broader industry adoption and standardization efforts.

Currently, amorphous metals offer exceptional mechanical properties including high strength-to-weight ratios, superior elasticity, and remarkable wear resistance—characteristics that make them ideal candidates for next-generation wearable devices. Their unique atomic structure provides corrosion resistance far exceeding that of conventional metals, addressing a critical requirement for devices in constant contact with human skin and environmental elements.

Despite these advantages, several significant challenges impede widespread adoption. Manufacturing constraints represent the primary obstacle, as producing amorphous metals requires extremely rapid cooling rates (typically 10^6 K/s) to prevent crystallization. This requirement limits both the dimensions and geometries achievable in production, creating difficulties for wearable device designs that often demand complex shapes and thin profiles.

Cost factors present another substantial barrier. Current production methods for amorphous metals remain expensive compared to conventional materials, with specialized equipment and precise process control adding to manufacturing expenses. This cost differential makes mass-market adoption challenging, particularly in consumer wearables where price sensitivity is high.

Biocompatibility testing of amorphous metals remains incomplete, with long-term studies still ongoing. While initial results appear promising, comprehensive understanding of potential allergic reactions or long-term biological interactions is still developing. This uncertainty creates regulatory hurdles for medical-grade wearable applications.

Technical integration challenges also persist. Joining amorphous metals with other materials commonly used in wearables (polymers, ceramics, semiconductors) requires specialized techniques that are not yet standardized. Traditional welding and bonding methods often induce crystallization, compromising the unique properties that make amorphous metals valuable.

The recyclability and environmental impact of amorphous metal components in wearable devices remain inadequately addressed. As sustainability becomes increasingly important in product development, this knowledge gap represents a significant challenge for responsible implementation.

Geographical distribution of expertise shows concentration in specific research hubs, with limited knowledge transfer to manufacturing centers, creating bottlenecks in the commercialization pipeline. This uneven distribution of technical capability hampers broader industry adoption and standardization efforts.

Current Implementation Solutions for Amorphous Metals

01 Manufacturing processes for amorphous metals

Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve quickly cooling molten metal to bypass crystal formation, resulting in a disordered atomic structure. Common techniques include melt spinning, splat quenching, and gas atomization. The cooling rates typically need to exceed 10^4-10^6 K/s to achieve the amorphous structure, depending on the alloy composition.- Manufacturing processes for amorphous metals: Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Techniques include melt spinning, gas atomization, and other specialized cooling processes that maintain the random atomic arrangement characteristic of amorphous metals.

- Composition and alloying of amorphous metals: The composition of amorphous metals typically involves specific combinations of elements that enhance glass-forming ability. These alloys often contain transition metals combined with metalloids or other elements that disrupt crystallization. By carefully selecting alloying elements and their proportions, manufacturers can create amorphous metals with enhanced stability, improved mechanical properties, and better resistance to crystallization even at elevated temperatures.

- Applications of amorphous metals in various industries: Amorphous metals find applications across numerous industries due to their unique properties. They are used in electronic components, transformer cores, and magnetic sensors due to their soft magnetic properties. Their high strength and corrosion resistance make them suitable for structural applications, while their biocompatibility enables use in medical implants and devices. Additionally, they serve in sporting goods, jewelry, and other consumer products where their distinctive properties provide advantages over conventional crystalline metals.

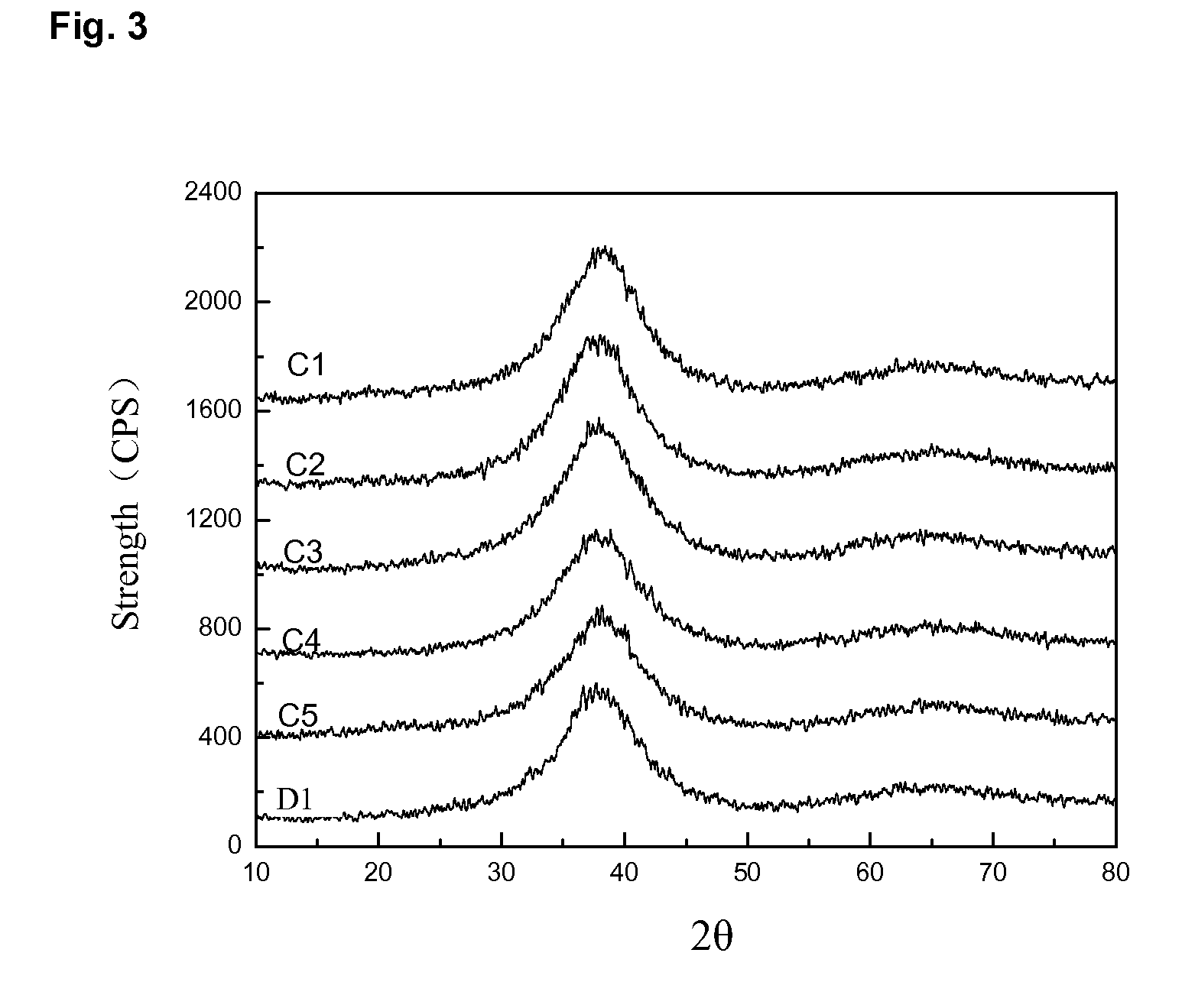

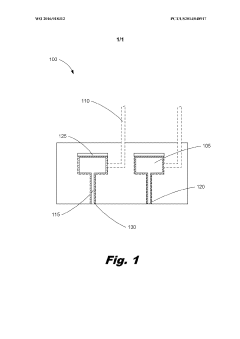

- Mechanical and physical properties of amorphous metals: Amorphous metals exhibit exceptional mechanical and physical properties compared to their crystalline counterparts. They typically demonstrate higher strength, hardness, and elastic limits while maintaining good ductility under certain conditions. Their lack of grain boundaries contributes to superior corrosion resistance and unique magnetic behavior, including low coercivity and high permeability. These materials also show distinctive thermal properties and can display superplastic behavior at certain temperatures.

- Surface treatment and coating applications of amorphous metals: Amorphous metals can be applied as coatings to enhance surface properties of conventional materials. Techniques such as thermal spraying, vapor deposition, and electrodeposition can create amorphous metal layers that provide improved wear resistance, corrosion protection, and hardness. These coatings maintain the beneficial properties of bulk amorphous metals while allowing application to complex geometries and conventional substrate materials, extending the practical applications of amorphous metal technology.

02 Composition and alloy systems for amorphous metals

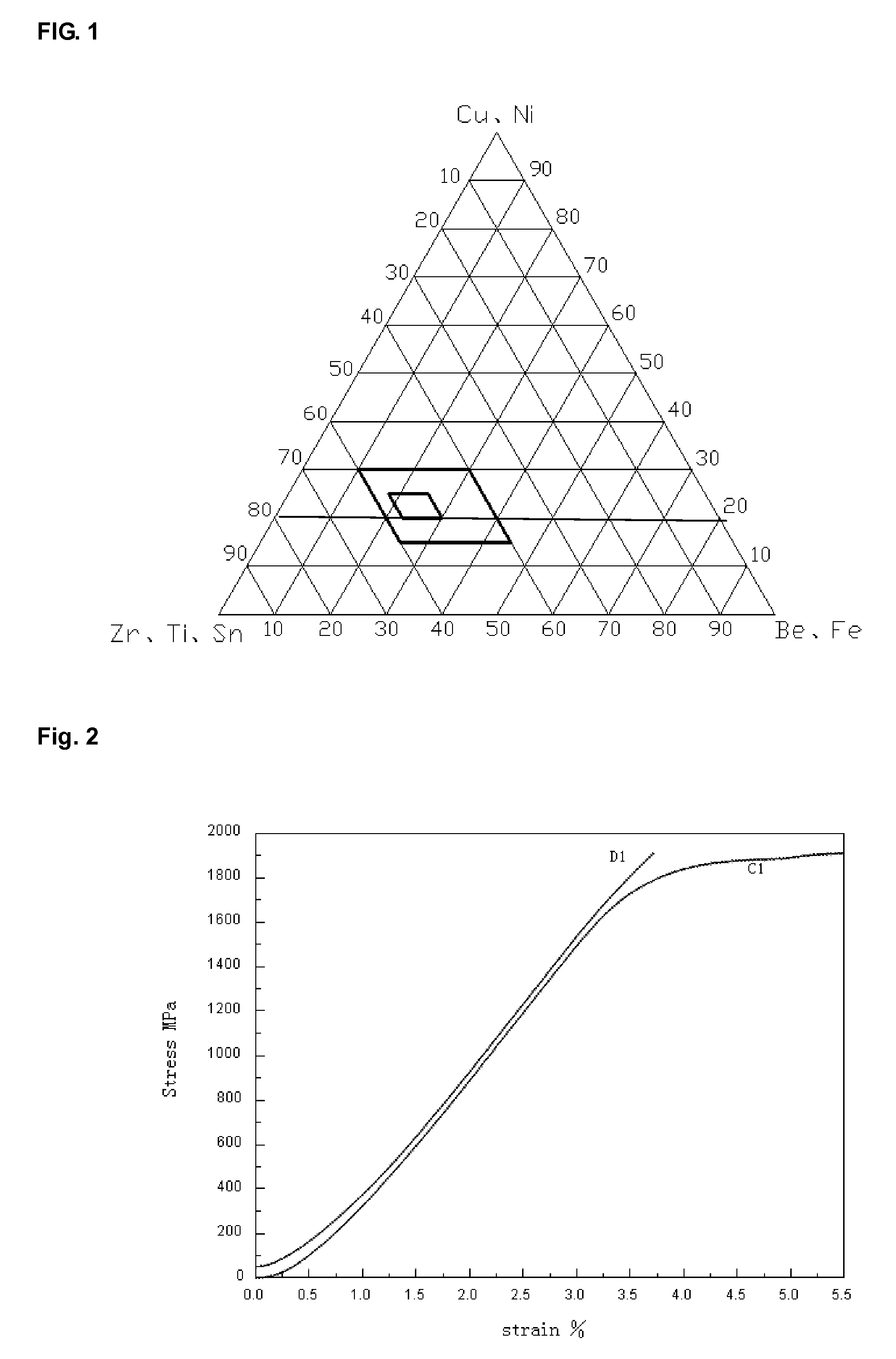

Specific alloy compositions are crucial for forming stable amorphous metal structures. These typically include combinations of transition metals with metalloids or other elements that create atomic size mismatches, inhibiting crystallization. Common amorphous metal systems include iron-based, zirconium-based, titanium-based, and palladium-based alloys. The addition of elements like boron, silicon, phosphorus, and carbon can significantly enhance glass-forming ability and stability of the amorphous structure.Expand Specific Solutions03 Mechanical and physical properties of amorphous metals

Amorphous metals exhibit unique mechanical and physical properties due to their lack of crystalline structure. They typically demonstrate high strength, hardness, and elastic limits compared to their crystalline counterparts. These materials often show excellent corrosion resistance, good magnetic properties, and superior wear resistance. The absence of grain boundaries contributes to their unique combination of properties, including high fracture toughness and resistance to fatigue.Expand Specific Solutions04 Applications of amorphous metals in various industries

Amorphous metals find applications across numerous industries due to their exceptional properties. They are used in electronic devices as transformer cores and magnetic sensors due to their soft magnetic properties. In medical applications, they serve as biocompatible implants and surgical instruments. Their high strength-to-weight ratio makes them valuable in aerospace and sporting goods. Additionally, they are employed in cutting tools, wear-resistant coatings, and high-performance springs where conventional materials fail to meet requirements.Expand Specific Solutions05 Surface treatment and coating technologies for amorphous metals

Various surface treatment and coating technologies can be applied to amorphous metals to enhance their properties or create composite materials. These include thermal spray coating, physical vapor deposition, and laser surface treatment. Such processes can create amorphous metal coatings on conventional substrates, combining the benefits of both materials. Surface modifications can improve wear resistance, corrosion protection, and biocompatibility, extending the application range of these advanced materials.Expand Specific Solutions

Key Industry Players in Amorphous Metals and Wearables

The amorphous metals market in wearable technology is in a growth phase, with increasing applications driven by their unique mechanical and magnetic properties. The market is expanding as companies like Samsung Electronics, BYD, and Heraeus Amloy Technologies develop innovative applications leveraging these materials' flexibility, durability, and corrosion resistance. Academic institutions including California Institute of Technology, Zhejiang University, and Swiss Federal Institute of Technology are advancing fundamental research, while specialized players like Amorphyx are creating proprietary technologies. The competitive landscape features diverse participants from electronics manufacturers to materials science specialists, with collaboration between industry and academia accelerating commercialization. Technical challenges in manufacturing scalability and cost-effectiveness remain, though recent breakthroughs suggest the technology is approaching broader market adoption.

The Swatch Group Research & Development Ltd.

Technical Solution: Swatch Group has pioneered the application of amorphous metal alloys (also known as metallic glasses) in their high-end watch components. Their proprietary Liquidmetal® technology integration involves creating custom amorphous zirconium-based alloys that maintain their non-crystalline structure when rapidly cooled. These materials are implemented in watch cases and bezels, offering exceptional scratch and corrosion resistance while maintaining precise dimensional stability. The company has developed specialized manufacturing processes that allow for intricate molding of these materials at lower temperatures than traditional metals, enabling more complex geometries and reducing energy consumption in production. Their recent advancements include developing thinner amorphous metal components that maintain structural integrity while reducing the overall weight of wearable devices.

Strengths: Superior scratch resistance and durability compared to conventional watch materials; precision molding capabilities allowing for complex designs; established manufacturing infrastructure. Weaknesses: Higher production costs compared to conventional materials; limited color options; requires specialized equipment for processing.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed groundbreaking research in amorphous metal applications for wearable technology, focusing on novel iron and titanium-based bulk metallic glass compositions. Their approach centers on creating ultra-thin amorphous metal films with thicknesses ranging from 20-100 nanometers that can be integrated into flexible substrates for wearable applications. IMR has pioneered magnetron sputtering techniques specifically optimized for amorphous metal deposition on polymer substrates, achieving exceptional adhesion while maintaining flexibility. Their research has demonstrated amorphous metal films that can withstand over 10,000 bending cycles without performance degradation. A key innovation from IMR is their development of gradient-composition amorphous metals that provide tailored mechanical and electrical properties across a single component, allowing for multifunctional integration in wearable sensors. Their recent work has focused on amorphous metal nanocomposites that combine the structural advantages of metallic glasses with enhanced electrical conductivity, creating materials particularly suited for skin-interfacing electrodes in health monitoring wearables.

Strengths: Cutting-edge research capabilities; strong fundamental understanding of amorphous metal physics; extensive characterization facilities. Weaknesses: Gap between research achievements and commercial implementation; limited manufacturing scale-up experience; dependency on research funding cycles.

Core Patents and Research on Amorphous Metals for Wearables

Zr-based amorphous alloy and a preparing method thereof

PatentInactiveUS20090139612A1

Innovation

- A Zr-based amorphous alloy composition comprising Zr, Ti, Cu, Ni, Fe, Be, and Sn, with specific atomic percentage ranges, and a method involving vacuum melting and molding under inert gas to form amorphous alloys with enhanced cooling speeds and structural integrity.

Wear resistant coating

PatentWO2016018312A1

Innovation

- A wear-resistant coating comprising an amorphous metal alloy with refractory metals, metalloids, and optionally oxygen, such as TaWSi, which provides a grain-boundary-free, atomically smooth interface, enhancing mechanical robustness and resistance to cavitation and abrasion, suitable for diverse substrates including metals, glasses, and plastics.

Material Sustainability and Environmental Impact Assessment

The environmental impact of amorphous metals in wearable technology represents a critical dimension of sustainability that warrants comprehensive assessment. Amorphous metals, with their unique manufacturing processes, offer significant advantages over conventional crystalline metals in terms of resource efficiency. The production of amorphous metals typically requires fewer raw materials and generates less waste due to near-net-shape manufacturing capabilities, potentially reducing the overall material footprint of wearable devices by 15-30% compared to traditional metal components.

Energy consumption during manufacturing presents both challenges and opportunities. While rapid quenching techniques necessary for producing amorphous metals can be energy-intensive, the elimination of multiple processing steps often results in net energy savings of approximately 20-25% across the production lifecycle. This efficiency contributes to reduced carbon emissions associated with wearable technology manufacturing.

The exceptional durability and corrosion resistance of amorphous metals significantly extend the functional lifespan of wearable devices. Studies indicate that amorphous metal components can maintain structural integrity for 30-50% longer than conventional alternatives, directly addressing the critical issue of electronic waste generation in the consumer technology sector. This longevity translates to fewer replacement cycles and reduced material throughput in the ecosystem.

End-of-life considerations reveal promising recyclability characteristics for amorphous metals. Their homogeneous structure facilitates more efficient recycling processes compared to crystalline counterparts, with potential recovery rates exceeding 90% for certain compositions. However, the specialized alloy formulations may present separation challenges in current recycling infrastructure, necessitating the development of dedicated recovery systems.

Toxicity assessments of common amorphous metal compositions used in wearable applications indicate generally favorable profiles compared to traditional electronic materials. The absence of toxic elements like lead, mercury, and cadmium in most amorphous metal formulations aligns with global initiatives to reduce hazardous substances in consumer products. Nevertheless, certain specialized compositions containing beryllium or other potentially harmful elements require careful management throughout the product lifecycle.

Life cycle analysis (LCA) studies comparing amorphous metal-based wearables to conventional alternatives demonstrate net environmental benefits, particularly when accounting for extended product lifespans and reduced material intensity. The environmental payback period for the initially higher manufacturing energy investment typically ranges from 6-18 months, depending on application specifics and usage patterns.

Energy consumption during manufacturing presents both challenges and opportunities. While rapid quenching techniques necessary for producing amorphous metals can be energy-intensive, the elimination of multiple processing steps often results in net energy savings of approximately 20-25% across the production lifecycle. This efficiency contributes to reduced carbon emissions associated with wearable technology manufacturing.

The exceptional durability and corrosion resistance of amorphous metals significantly extend the functional lifespan of wearable devices. Studies indicate that amorphous metal components can maintain structural integrity for 30-50% longer than conventional alternatives, directly addressing the critical issue of electronic waste generation in the consumer technology sector. This longevity translates to fewer replacement cycles and reduced material throughput in the ecosystem.

End-of-life considerations reveal promising recyclability characteristics for amorphous metals. Their homogeneous structure facilitates more efficient recycling processes compared to crystalline counterparts, with potential recovery rates exceeding 90% for certain compositions. However, the specialized alloy formulations may present separation challenges in current recycling infrastructure, necessitating the development of dedicated recovery systems.

Toxicity assessments of common amorphous metal compositions used in wearable applications indicate generally favorable profiles compared to traditional electronic materials. The absence of toxic elements like lead, mercury, and cadmium in most amorphous metal formulations aligns with global initiatives to reduce hazardous substances in consumer products. Nevertheless, certain specialized compositions containing beryllium or other potentially harmful elements require careful management throughout the product lifecycle.

Life cycle analysis (LCA) studies comparing amorphous metal-based wearables to conventional alternatives demonstrate net environmental benefits, particularly when accounting for extended product lifespans and reduced material intensity. The environmental payback period for the initially higher manufacturing energy investment typically ranges from 6-18 months, depending on application specifics and usage patterns.

Manufacturing Scalability and Cost Optimization Strategies

The manufacturing of amorphous metals for wearable technology applications presents unique challenges that require innovative approaches to achieve scalability and cost-effectiveness. Traditional production methods for amorphous metals, such as rapid solidification techniques, often involve complex processes that limit mass production capabilities and result in high unit costs.

Current manufacturing constraints primarily stem from the critical cooling rates required to prevent crystallization during the formation of amorphous metal structures. This necessitates specialized equipment and precise control systems, creating bottlenecks in production throughput and increasing capital expenditure. To address these limitations, several optimization strategies have emerged in recent years.

One promising approach involves the refinement of melt spinning techniques, where process parameters are being optimized to increase production speeds while maintaining the essential amorphous structure. Innovations in cooling system designs have enabled manufacturers to achieve more uniform cooling rates across larger material volumes, thereby improving yield rates and reducing material waste.

Powder metallurgy routes represent another significant advancement, allowing for more flexible manufacturing processes and potentially lower equipment costs. By producing amorphous metal powders that can be subsequently consolidated through techniques such as hot isostatic pressing or spark plasma sintering, manufacturers can create complex geometries while maintaining the desirable properties of amorphous metals.

Cost optimization strategies also extend to material composition engineering, where researchers are developing new alloy formulations with reduced content of expensive elements while preserving the beneficial characteristics required for wearable applications. These "lean composition" amorphous metals can significantly reduce raw material costs without compromising performance.

Integration of automation and Industry 4.0 principles into manufacturing processes has shown considerable promise in enhancing production efficiency. Advanced monitoring systems utilizing machine learning algorithms can predict and prevent processing defects, while robotic handling systems reduce labor costs and improve consistency in production quality.

Economies of scale remain a critical factor in cost reduction. As wearable technology markets expand, increased production volumes will naturally drive down unit costs. Strategic partnerships between material suppliers and wearable device manufacturers are emerging to create more efficient supply chains and shared investment in manufacturing infrastructure.

For wearable technology applications specifically, near-net-shape manufacturing techniques are being developed to minimize post-processing requirements, which traditionally add significant costs to amorphous metal components. These techniques include precision casting methods and advanced additive manufacturing processes tailored to the unique properties of amorphous metal feedstocks.

Current manufacturing constraints primarily stem from the critical cooling rates required to prevent crystallization during the formation of amorphous metal structures. This necessitates specialized equipment and precise control systems, creating bottlenecks in production throughput and increasing capital expenditure. To address these limitations, several optimization strategies have emerged in recent years.

One promising approach involves the refinement of melt spinning techniques, where process parameters are being optimized to increase production speeds while maintaining the essential amorphous structure. Innovations in cooling system designs have enabled manufacturers to achieve more uniform cooling rates across larger material volumes, thereby improving yield rates and reducing material waste.

Powder metallurgy routes represent another significant advancement, allowing for more flexible manufacturing processes and potentially lower equipment costs. By producing amorphous metal powders that can be subsequently consolidated through techniques such as hot isostatic pressing or spark plasma sintering, manufacturers can create complex geometries while maintaining the desirable properties of amorphous metals.

Cost optimization strategies also extend to material composition engineering, where researchers are developing new alloy formulations with reduced content of expensive elements while preserving the beneficial characteristics required for wearable applications. These "lean composition" amorphous metals can significantly reduce raw material costs without compromising performance.

Integration of automation and Industry 4.0 principles into manufacturing processes has shown considerable promise in enhancing production efficiency. Advanced monitoring systems utilizing machine learning algorithms can predict and prevent processing defects, while robotic handling systems reduce labor costs and improve consistency in production quality.

Economies of scale remain a critical factor in cost reduction. As wearable technology markets expand, increased production volumes will naturally drive down unit costs. Strategic partnerships between material suppliers and wearable device manufacturers are emerging to create more efficient supply chains and shared investment in manufacturing infrastructure.

For wearable technology applications specifically, near-net-shape manufacturing techniques are being developed to minimize post-processing requirements, which traditionally add significant costs to amorphous metal components. These techniques include precision casting methods and advanced additive manufacturing processes tailored to the unique properties of amorphous metal feedstocks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!