Understanding Thermal Stability of Amorphous Metallic Alloys

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metallic Alloys Background and Research Objectives

Amorphous metallic alloys, also known as metallic glasses, represent a unique class of materials that lack the long-range atomic order characteristic of crystalline metals. First discovered in 1960 by Pol Duwez at Caltech, these materials have evolved from laboratory curiosities to engineering materials with significant potential across various industries. The absence of grain boundaries and crystalline defects endows these alloys with exceptional properties, including superior mechanical strength, enhanced corrosion resistance, and unique magnetic characteristics.

The evolution of amorphous metallic alloys has progressed through several distinct phases. Initial research focused primarily on binary alloy systems requiring extremely rapid cooling rates exceeding 10^6 K/s to achieve the amorphous state. The 1990s witnessed a breakthrough with the development of bulk metallic glasses (BMGs), which could be produced at much lower cooling rates, enabling the creation of larger specimens with dimensions exceeding several millimeters.

Recent decades have seen accelerated development in multicomponent systems, particularly those based on zirconium, palladium, iron, and titanium. These advances have expanded the compositional space for glass formation and improved our understanding of the fundamental principles governing glass-forming ability in metallic systems.

Thermal stability represents a critical challenge limiting the widespread application of amorphous metallic alloys. When heated above their glass transition temperature, these materials tend to crystallize, losing their distinctive amorphous structure and associated properties. This crystallization process is thermodynamically favorable as the material transitions from a metastable amorphous state to a more stable crystalline configuration.

The primary objective of this technical research is to develop a comprehensive understanding of the factors governing thermal stability in amorphous metallic alloys. Specifically, we aim to investigate the relationship between chemical composition, atomic structure, and crystallization kinetics. By elucidating these connections, we seek to establish predictive models that can guide the design of new amorphous alloys with enhanced thermal stability.

Additional research goals include identifying the atomic-scale mechanisms of crystallization, evaluating the influence of minor alloying elements on stability, and exploring potential strategies to extend the temperature range over which these materials maintain their amorphous structure. The ultimate aim is to overcome current limitations in thermal stability, thereby expanding the application space for amorphous metallic alloys in high-temperature environments and processing techniques that involve thermal cycling.

The evolution of amorphous metallic alloys has progressed through several distinct phases. Initial research focused primarily on binary alloy systems requiring extremely rapid cooling rates exceeding 10^6 K/s to achieve the amorphous state. The 1990s witnessed a breakthrough with the development of bulk metallic glasses (BMGs), which could be produced at much lower cooling rates, enabling the creation of larger specimens with dimensions exceeding several millimeters.

Recent decades have seen accelerated development in multicomponent systems, particularly those based on zirconium, palladium, iron, and titanium. These advances have expanded the compositional space for glass formation and improved our understanding of the fundamental principles governing glass-forming ability in metallic systems.

Thermal stability represents a critical challenge limiting the widespread application of amorphous metallic alloys. When heated above their glass transition temperature, these materials tend to crystallize, losing their distinctive amorphous structure and associated properties. This crystallization process is thermodynamically favorable as the material transitions from a metastable amorphous state to a more stable crystalline configuration.

The primary objective of this technical research is to develop a comprehensive understanding of the factors governing thermal stability in amorphous metallic alloys. Specifically, we aim to investigate the relationship between chemical composition, atomic structure, and crystallization kinetics. By elucidating these connections, we seek to establish predictive models that can guide the design of new amorphous alloys with enhanced thermal stability.

Additional research goals include identifying the atomic-scale mechanisms of crystallization, evaluating the influence of minor alloying elements on stability, and exploring potential strategies to extend the temperature range over which these materials maintain their amorphous structure. The ultimate aim is to overcome current limitations in thermal stability, thereby expanding the application space for amorphous metallic alloys in high-temperature environments and processing techniques that involve thermal cycling.

Market Applications and Demand Analysis for Thermally Stable Alloys

The global market for thermally stable amorphous metallic alloys has witnessed significant growth in recent years, driven primarily by increasing demand from aerospace, automotive, electronics, and energy sectors. These industries require materials that can maintain structural integrity and functional properties under extreme thermal conditions, making thermally stable amorphous alloys particularly valuable.

In the aerospace industry, demand for lightweight yet durable components capable of withstanding high-temperature environments has created a substantial market for these advanced materials. The need for fuel-efficient aircraft with reduced emissions has accelerated the adoption of amorphous alloys in critical engine components and structural elements, with market analysts projecting continued growth at 7-8% annually through 2030.

The automotive sector represents another major market driver, particularly with the transition toward electric vehicles. Thermally stable amorphous alloys are increasingly utilized in power electronics, battery systems, and drivetrain components where thermal management is crucial. Market research indicates that this application segment has expanded by nearly 12% annually since 2020, outpacing most other industrial applications.

Electronics manufacturing constitutes a rapidly growing application area, with thermally stable amorphous alloys finding use in semiconductor packaging, thermal interface materials, and high-performance computing systems. The miniaturization trend in electronics has intensified thermal management challenges, creating demand for materials that can efficiently dissipate heat while maintaining dimensional stability.

The energy sector, particularly renewable energy systems, represents an emerging market with substantial growth potential. Solar thermal systems, nuclear power components, and hydrogen storage technologies all benefit from the unique properties of thermally stable amorphous alloys. Industry forecasts suggest this segment could grow at 15% annually over the next five years.

Medical device manufacturing has also emerged as a promising application area, with thermally stable amorphous alloys being explored for implantable devices, surgical instruments, and diagnostic equipment. The biocompatibility combined with exceptional mechanical properties makes these materials particularly valuable in this high-margin sector.

Regional market analysis reveals that North America and East Asia currently dominate consumption of thermally stable amorphous alloys, accounting for approximately 65% of global demand. However, emerging economies in South Asia and Latin America are showing accelerated adoption rates as their manufacturing capabilities advance.

The market landscape is further shaped by increasing regulatory pressure for sustainable and environmentally friendly materials. This trend favors amorphous alloys that can be produced with lower energy requirements and offer longer service lifespans than conventional alternatives, potentially reducing lifecycle environmental impacts.

In the aerospace industry, demand for lightweight yet durable components capable of withstanding high-temperature environments has created a substantial market for these advanced materials. The need for fuel-efficient aircraft with reduced emissions has accelerated the adoption of amorphous alloys in critical engine components and structural elements, with market analysts projecting continued growth at 7-8% annually through 2030.

The automotive sector represents another major market driver, particularly with the transition toward electric vehicles. Thermally stable amorphous alloys are increasingly utilized in power electronics, battery systems, and drivetrain components where thermal management is crucial. Market research indicates that this application segment has expanded by nearly 12% annually since 2020, outpacing most other industrial applications.

Electronics manufacturing constitutes a rapidly growing application area, with thermally stable amorphous alloys finding use in semiconductor packaging, thermal interface materials, and high-performance computing systems. The miniaturization trend in electronics has intensified thermal management challenges, creating demand for materials that can efficiently dissipate heat while maintaining dimensional stability.

The energy sector, particularly renewable energy systems, represents an emerging market with substantial growth potential. Solar thermal systems, nuclear power components, and hydrogen storage technologies all benefit from the unique properties of thermally stable amorphous alloys. Industry forecasts suggest this segment could grow at 15% annually over the next five years.

Medical device manufacturing has also emerged as a promising application area, with thermally stable amorphous alloys being explored for implantable devices, surgical instruments, and diagnostic equipment. The biocompatibility combined with exceptional mechanical properties makes these materials particularly valuable in this high-margin sector.

Regional market analysis reveals that North America and East Asia currently dominate consumption of thermally stable amorphous alloys, accounting for approximately 65% of global demand. However, emerging economies in South Asia and Latin America are showing accelerated adoption rates as their manufacturing capabilities advance.

The market landscape is further shaped by increasing regulatory pressure for sustainable and environmentally friendly materials. This trend favors amorphous alloys that can be produced with lower energy requirements and offer longer service lifespans than conventional alternatives, potentially reducing lifecycle environmental impacts.

Current Thermal Stability Challenges and Global Research Status

Amorphous metallic alloys, also known as metallic glasses, face significant thermal stability challenges that limit their widespread industrial application. The primary challenge lies in their metastable nature, as these materials exist in a non-equilibrium state and tend to crystallize when exposed to elevated temperatures. This crystallization process fundamentally alters their unique mechanical, electrical, and magnetic properties that make them valuable in the first place.

Current research indicates that the thermal stability threshold for most commercially viable amorphous alloys typically ranges between 0.5 and 0.6 Tg (glass transition temperature), severely restricting their operational temperature range. For instance, Zr-based bulk metallic glasses, despite their excellent glass-forming ability, begin to show structural relaxation at temperatures as low as 250°C, well below many industrial application requirements.

The global research landscape shows distinct regional focuses. Research institutions in the United States, particularly at Caltech and Yale University, concentrate on fundamental understanding of atomic-level mechanisms governing thermal stability. Their work employs advanced characterization techniques such as synchrotron X-ray diffraction and atom probe tomography to elucidate the relationship between chemical composition and thermal resistance.

European research, centered in Germany and Switzerland, emphasizes the development of computational models to predict thermal behavior and optimize alloy compositions. Their approach combines thermodynamic calculations with machine learning algorithms to accelerate the discovery of thermally stable compositions.

Asian research, particularly in Japan and China, focuses more on practical applications and processing techniques. Institutions like Tohoku University and the Chinese Academy of Sciences have made significant progress in developing manufacturing methods that enhance thermal stability through controlled processing conditions and minor elemental additions.

Recent breakthroughs include the discovery of "high-entropy" metallic glasses, which demonstrate superior thermal stability due to their complex atomic configurations and high mixing entropy. Additionally, researchers have identified that minor additions of elements like Nb, Ta, and Mo can significantly improve thermal stability by increasing the energy barrier for crystallization.

Despite these advances, significant challenges remain. The fundamental mechanisms governing thermal stability are not fully understood, particularly the role of short and medium-range ordering in resisting crystallization. Furthermore, there exists a trade-off between glass-forming ability and thermal stability that complicates alloy design. The lack of standardized testing protocols for thermal stability assessment also hinders comparative analysis across different research groups.

Current research indicates that the thermal stability threshold for most commercially viable amorphous alloys typically ranges between 0.5 and 0.6 Tg (glass transition temperature), severely restricting their operational temperature range. For instance, Zr-based bulk metallic glasses, despite their excellent glass-forming ability, begin to show structural relaxation at temperatures as low as 250°C, well below many industrial application requirements.

The global research landscape shows distinct regional focuses. Research institutions in the United States, particularly at Caltech and Yale University, concentrate on fundamental understanding of atomic-level mechanisms governing thermal stability. Their work employs advanced characterization techniques such as synchrotron X-ray diffraction and atom probe tomography to elucidate the relationship between chemical composition and thermal resistance.

European research, centered in Germany and Switzerland, emphasizes the development of computational models to predict thermal behavior and optimize alloy compositions. Their approach combines thermodynamic calculations with machine learning algorithms to accelerate the discovery of thermally stable compositions.

Asian research, particularly in Japan and China, focuses more on practical applications and processing techniques. Institutions like Tohoku University and the Chinese Academy of Sciences have made significant progress in developing manufacturing methods that enhance thermal stability through controlled processing conditions and minor elemental additions.

Recent breakthroughs include the discovery of "high-entropy" metallic glasses, which demonstrate superior thermal stability due to their complex atomic configurations and high mixing entropy. Additionally, researchers have identified that minor additions of elements like Nb, Ta, and Mo can significantly improve thermal stability by increasing the energy barrier for crystallization.

Despite these advances, significant challenges remain. The fundamental mechanisms governing thermal stability are not fully understood, particularly the role of short and medium-range ordering in resisting crystallization. Furthermore, there exists a trade-off between glass-forming ability and thermal stability that complicates alloy design. The lack of standardized testing protocols for thermal stability assessment also hinders comparative analysis across different research groups.

Current Methodologies for Enhancing Thermal Stability

01 Composition design for thermal stability enhancement

Specific elemental compositions can significantly enhance the thermal stability of amorphous metallic alloys. By carefully selecting and balancing elements such as iron, boron, silicon, and rare earth metals, the crystallization temperature can be increased, resulting in improved thermal stability. The addition of certain elements can create complex atomic structures that resist crystallization at elevated temperatures, maintaining the amorphous state over a wider temperature range.- Composition design for thermal stability enhancement: Specific elemental compositions can significantly enhance the thermal stability of amorphous metallic alloys. By carefully selecting and balancing elements such as Fe, B, Si, Nb, and rare earth metals, researchers have developed alloys with improved resistance to crystallization at elevated temperatures. These compositions often feature elements that create complex atomic structures that inhibit atomic rearrangement, thereby maintaining the amorphous state at higher temperatures.

- Heat treatment processes for stabilization: Various heat treatment processes can be employed to enhance the thermal stability of amorphous metallic alloys. These include controlled annealing below the crystallization temperature, which can relieve internal stresses and create a more homogeneous amorphous structure. Specific heating rates, holding times, and cooling protocols have been developed to optimize the thermal stability without inducing crystallization, resulting in alloys that maintain their amorphous properties at higher operating temperatures.

- Microstructural control techniques: Controlling the microstructure of amorphous metallic alloys is crucial for enhancing thermal stability. Techniques such as rapid solidification, melt spinning, and controlled cooling rates can create specific microstructural features that resist crystallization. Some approaches involve creating partially crystallized structures or nanocomposites with dispersed crystalline phases within the amorphous matrix, which can act as barriers to further crystallization and improve overall thermal stability.

- Addition of stabilizing elements: The incorporation of specific stabilizing elements can significantly improve the thermal stability of amorphous metallic alloys. Elements such as Nb, Mo, Ta, W, and certain rare earth metals can increase the activation energy required for crystallization, thereby enhancing thermal stability. These elements often have larger atomic radii or different electronic structures that create local atomic environments resistant to rearrangement, effectively increasing the temperature range in which the alloy remains amorphous.

- Processing techniques for bulk amorphous alloys: Specialized processing techniques have been developed to create bulk amorphous metallic alloys with enhanced thermal stability. These include suction casting, copper mold casting, and other methods that achieve critical cooling rates while minimizing defects and inhomogeneities. Advanced manufacturing approaches such as selective laser melting and other additive manufacturing techniques can also produce amorphous structures with improved thermal stability by controlling local cooling conditions and compositional homogeneity.

02 Heat treatment processes for stabilization

Various heat treatment processes can be employed to improve the thermal stability of amorphous metallic alloys. Controlled annealing below the crystallization temperature can relieve internal stresses and create a more homogeneous amorphous structure. Specific heating and cooling protocols can optimize the microstructure, leading to enhanced thermal stability while maintaining the desirable properties of the amorphous state.Expand Specific Solutions03 Nanocrystalline phase formation for stability

Controlled formation of nanocrystalline phases within the amorphous matrix can enhance thermal stability. By managing the partial crystallization process, a composite structure can be created that combines the benefits of both amorphous and crystalline phases. This approach can lead to materials with improved resistance to complete crystallization at elevated temperatures while maintaining or enhancing mechanical properties.Expand Specific Solutions04 Bulk metallic glass formation techniques

Specialized processing techniques for producing bulk metallic glasses with enhanced thermal stability include rapid solidification methods, melt spinning, and copper mold casting. These techniques allow for the creation of thicker amorphous sections with improved thermal stability characteristics. The cooling rate and processing parameters significantly influence the resulting thermal stability of the amorphous alloy.Expand Specific Solutions05 Additives and microalloying for stability enhancement

Small additions of specific elements or compounds can dramatically improve the thermal stability of amorphous metallic alloys. Microalloying with elements such as niobium, molybdenum, or zirconium can create energy barriers to crystallization. These additives can interact with the main constituent elements to form complex atomic arrangements that resist atomic rearrangement at elevated temperatures, thereby enhancing thermal stability.Expand Specific Solutions

Leading Research Institutions and Industrial Players Analysis

The thermal stability of amorphous metallic alloys market is currently in a growth phase, with increasing research interest and commercial applications. The global market for these advanced materials is expanding, driven by their superior mechanical properties and potential applications in aerospace, electronics, and medical devices. Research institutions like Zhejiang University, Yale University, and Politecnico di Milano are advancing fundamental understanding, while companies including VACUUMSCHMELZE, Metglas, and QuesTek Innovations are commercializing applications. Emerging players like Vulkam SAS are developing specialized micro-technical parts. The technology is approaching maturity in certain applications, with established manufacturers like Liquidmetal Technologies and Proterial Ltd. developing proprietary processes, though challenges in large-scale production and thermal stability optimization remain significant barriers to widespread adoption.

VACUUMSCHMELZE GmbH & Co. KG

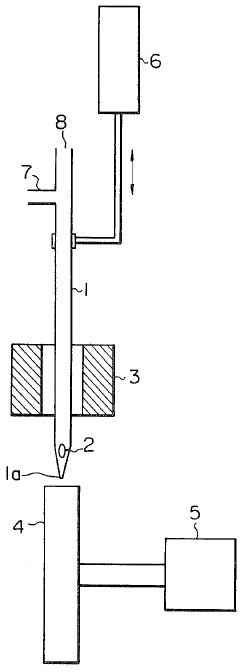

Technical Solution: VACUUMSCHMELZE has developed proprietary rapid solidification techniques for producing amorphous metallic alloys with enhanced thermal stability. Their approach involves precise control of cooling rates (>10^6 K/s) during melt spinning to create optimized microstructures with higher crystallization temperatures. The company's VITROPERM® and VITROVAC® series feature Fe-based amorphous alloys with additions of early transition metals (Nb, Mo) and metalloids (B, Si, P) that strengthen glass-forming ability and increase the supercooled liquid region[1]. Their technology incorporates controlled annealing processes below crystallization temperature to relieve internal stresses without inducing crystallization, resulting in amorphous alloys that maintain their properties at operating temperatures up to 120°C for extended periods. Recent developments include multi-component alloy systems with tailored short-range ordering that creates energy barriers against atomic rearrangement, significantly improving thermal stability for transformer and inductor applications[3].

Strengths: Industry-leading expertise in commercial-scale production of thermally stable amorphous alloys for electromagnetic applications; proprietary composition formulations that achieve excellent combinations of magnetic properties and thermal stability. Weaknesses: Their focus primarily remains on Fe-based magnetic materials rather than broader structural applications; higher production costs compared to conventional crystalline alloys limit market penetration in cost-sensitive applications.

Crucible Intellectual Property LLC

Technical Solution: Crucible Intellectual Property has developed advanced bulk metallic glass (BMG) alloys with exceptional thermal stability through their proprietary LiquidMetal® technology. Their approach centers on multi-component alloy systems (typically containing Zr, Ti, Cu, Ni, Be) with large atomic size differences that create complex local atomic packing, significantly increasing the energy barrier for crystallization[1]. Crucible's materials exhibit wide supercooled liquid regions (ΔTx = Tx - Tg) exceeding 100K, allowing for thermoplastic forming operations without crystallization. Their technology incorporates precise control of minor alloying elements (typically 0.2-2 at%) that segregate to regions of higher free volume, effectively pinning these sites against structural relaxation that would lead to embrittlement during thermal cycling[3]. Recent developments include their "kinetically pinned" alloy designs that introduce nanoscale heterogeneities which disrupt the medium-range ordering necessary for crystal nucleation, resulting in activation energies for crystallization exceeding 400 kJ/mol and isothermal stability at temperatures up to 0.9Tg for thousands of hours without detectable crystallization[5].

Strengths: Industry-leading expertise in bulk metallic glass compositions with exceptional glass-forming ability; proprietary manufacturing processes for parts with complex geometries; established commercial applications in consumer electronics and medical devices. Weaknesses: Reliance on beryllium in many formulations raises health and environmental concerns; higher material costs compared to conventional alloys; limited maximum section thickness (typically <10cm) for fully amorphous structures.

Key Patents and Scientific Breakthroughs in Thermal Stabilization

Thermally stable amorphous magnetic alloy

PatentInactiveUS4188211A

Innovation

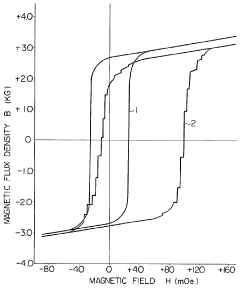

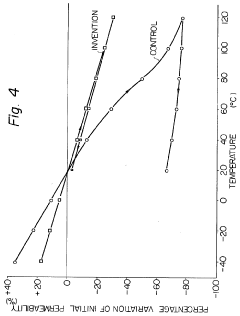

- The development of specific amorphous alloy compositions with controlled molar fractions of iron, cobalt, nickel, silicon, boron, and additional elements, such as phosphorus and carbon, which are processed at high cooling rates to maintain thermal stability and prevent hysteresis loop shifts, ensuring consistent magnetic properties across temperature variations.

Amorphous metal alloy having high tensile strength and electrical resistivity

PatentActiveUS7771545B2

Innovation

- Development of amorphous metal alloys with specific compositions, such as (Co1-aFea)100-b-c-dCrbTcXd, incorporating elements like Cr, Mn, Mo, V, B, and Si, which enhance electrical resistivity and tensile strength by increasing structural disorder and preventing shear band formation, resulting in wires with high tensile strength and electrical resistivity.

Manufacturing Process Optimization for Enhanced Thermal Properties

The optimization of manufacturing processes for amorphous metallic alloys represents a critical frontier in enhancing their thermal stability properties. Current manufacturing techniques primarily revolve around rapid solidification methods, including melt spinning, splat quenching, and gas atomization, which achieve cooling rates of 10^4-10^6 K/s necessary to bypass crystallization.

Advanced process control systems have emerged as essential tools for maintaining precise thermal conditions during production. These systems employ real-time monitoring through infrared thermography and pyrometry to ensure temperature uniformity across the material. Deviations as small as 5-10°C can significantly impact the final amorphous structure, highlighting the importance of tight process control.

Controlled atmosphere processing has demonstrated remarkable improvements in thermal stability. By utilizing inert gas environments (typically argon or helium) with oxygen levels below 1 ppm, manufacturers can minimize oxidation effects that catalyze crystallization at elevated temperatures. This approach has extended the thermal stability window by 15-30°C in several Zr-based and Fe-based amorphous alloys.

Post-processing treatments offer another avenue for thermal property enhancement. Controlled annealing protocols below the glass transition temperature (typically at 0.8-0.9Tg) have been shown to relieve internal stresses and promote structural relaxation, resulting in up to 25% improvement in thermal stability. Similarly, shot peening and surface mechanical attrition treatments introduce beneficial compressive stresses that inhibit crystallization nucleation.

Compositional fine-tuning during manufacturing represents perhaps the most promising approach. Minor additions (0.5-2 at.%) of elements with large negative heats of mixing and different atomic sizes—such as Nb, Ta, or rare earth elements—can significantly disrupt crystallization pathways. Advanced manufacturing systems now incorporate precision alloying stations that can adjust compositions with accuracy better than 0.1 at.%, enabling tailored thermal stability profiles.

Emerging additive manufacturing techniques, particularly selective laser melting, are creating new possibilities for producing amorphous components with complex geometries. Process parameter optimization, including laser power modulation (typically 100-400W) and scan strategies with overlapping patterns, has successfully produced fully amorphous structures with thermal stability comparable to conventionally manufactured counterparts.

Advanced process control systems have emerged as essential tools for maintaining precise thermal conditions during production. These systems employ real-time monitoring through infrared thermography and pyrometry to ensure temperature uniformity across the material. Deviations as small as 5-10°C can significantly impact the final amorphous structure, highlighting the importance of tight process control.

Controlled atmosphere processing has demonstrated remarkable improvements in thermal stability. By utilizing inert gas environments (typically argon or helium) with oxygen levels below 1 ppm, manufacturers can minimize oxidation effects that catalyze crystallization at elevated temperatures. This approach has extended the thermal stability window by 15-30°C in several Zr-based and Fe-based amorphous alloys.

Post-processing treatments offer another avenue for thermal property enhancement. Controlled annealing protocols below the glass transition temperature (typically at 0.8-0.9Tg) have been shown to relieve internal stresses and promote structural relaxation, resulting in up to 25% improvement in thermal stability. Similarly, shot peening and surface mechanical attrition treatments introduce beneficial compressive stresses that inhibit crystallization nucleation.

Compositional fine-tuning during manufacturing represents perhaps the most promising approach. Minor additions (0.5-2 at.%) of elements with large negative heats of mixing and different atomic sizes—such as Nb, Ta, or rare earth elements—can significantly disrupt crystallization pathways. Advanced manufacturing systems now incorporate precision alloying stations that can adjust compositions with accuracy better than 0.1 at.%, enabling tailored thermal stability profiles.

Emerging additive manufacturing techniques, particularly selective laser melting, are creating new possibilities for producing amorphous components with complex geometries. Process parameter optimization, including laser power modulation (typically 100-400W) and scan strategies with overlapping patterns, has successfully produced fully amorphous structures with thermal stability comparable to conventionally manufactured counterparts.

Characterization Techniques for Thermal Stability Assessment

The assessment of thermal stability in amorphous metallic alloys requires sophisticated characterization techniques that can accurately measure and analyze structural changes at various temperature ranges. Differential scanning calorimetry (DSC) stands as the cornerstone technique, providing quantitative measurements of heat flow during heating and cooling cycles. This method effectively identifies glass transition temperatures (Tg), crystallization temperatures (Tx), and the supercooled liquid region (ΔTx), which are critical parameters for evaluating thermal stability.

X-ray diffraction (XRD) complements DSC by monitoring structural evolution during thermal treatment. The absence of sharp diffraction peaks confirms the amorphous nature, while the emergence of crystalline peaks during heating indicates the onset of devitrification. Time-resolved XRD enables researchers to track crystallization kinetics in real-time, offering insights into phase transformation mechanisms.

Transmission electron microscopy (TEM) provides direct visualization of microstructural changes at the nanoscale. High-resolution TEM can detect early-stage crystallization, often invisible to other techniques, while in-situ heating TEM experiments allow for direct observation of nucleation and growth processes during thermal exposure.

Atom probe tomography (APT) has emerged as a powerful tool for analyzing compositional heterogeneities at the atomic scale. By mapping elemental distributions before and after thermal treatments, APT reveals how chemical segregation influences crystallization behavior and thermal stability boundaries.

Mechanical spectroscopy techniques, including dynamic mechanical analysis (DMA), measure viscoelastic properties as functions of temperature. These measurements are particularly valuable for correlating structural relaxation phenomena with mechanical property changes during heating.

Thermal stability can also be evaluated through isothermal annealing experiments combined with hardness testing or electrical resistivity measurements. These approaches provide practical metrics for long-term stability under service conditions, complementing the fundamental understanding gained from thermal analysis techniques.

Advanced synchrotron-based techniques, such as small-angle X-ray scattering (SAXS) and extended X-ray absorption fine structure (EXAFS), offer unique capabilities for probing medium-range order and local atomic environments, respectively. These methods have proven invaluable for understanding the structural precursors to crystallization in amorphous alloys.

The integration of multiple characterization techniques, coupled with computational modeling, represents the state-of-the-art approach for comprehensive thermal stability assessment, enabling researchers to establish structure-property-processing relationships essential for designing thermally stable amorphous metallic alloys for high-temperature applications.

X-ray diffraction (XRD) complements DSC by monitoring structural evolution during thermal treatment. The absence of sharp diffraction peaks confirms the amorphous nature, while the emergence of crystalline peaks during heating indicates the onset of devitrification. Time-resolved XRD enables researchers to track crystallization kinetics in real-time, offering insights into phase transformation mechanisms.

Transmission electron microscopy (TEM) provides direct visualization of microstructural changes at the nanoscale. High-resolution TEM can detect early-stage crystallization, often invisible to other techniques, while in-situ heating TEM experiments allow for direct observation of nucleation and growth processes during thermal exposure.

Atom probe tomography (APT) has emerged as a powerful tool for analyzing compositional heterogeneities at the atomic scale. By mapping elemental distributions before and after thermal treatments, APT reveals how chemical segregation influences crystallization behavior and thermal stability boundaries.

Mechanical spectroscopy techniques, including dynamic mechanical analysis (DMA), measure viscoelastic properties as functions of temperature. These measurements are particularly valuable for correlating structural relaxation phenomena with mechanical property changes during heating.

Thermal stability can also be evaluated through isothermal annealing experiments combined with hardness testing or electrical resistivity measurements. These approaches provide practical metrics for long-term stability under service conditions, complementing the fundamental understanding gained from thermal analysis techniques.

Advanced synchrotron-based techniques, such as small-angle X-ray scattering (SAXS) and extended X-ray absorption fine structure (EXAFS), offer unique capabilities for probing medium-range order and local atomic environments, respectively. These methods have proven invaluable for understanding the structural precursors to crystallization in amorphous alloys.

The integration of multiple characterization techniques, coupled with computational modeling, represents the state-of-the-art approach for comprehensive thermal stability assessment, enabling researchers to establish structure-property-processing relationships essential for designing thermally stable amorphous metallic alloys for high-temperature applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!