Understanding the Correlation Between Amorphous Metals and Dielectric Properties

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals and Dielectric Properties: Background and Objectives

Amorphous metals, also known as metallic glasses, represent a unique class of materials that lack the long-range atomic order characteristic of crystalline metals. Since their discovery in the 1960s, these materials have garnered significant attention due to their exceptional mechanical, magnetic, and corrosion-resistant properties. The evolution of amorphous metals has progressed from thin ribbons produced by rapid quenching techniques to bulk metallic glasses with critical dimensions exceeding several centimeters, marking a substantial advancement in materials science.

The dielectric properties of materials, which describe how they interact with electromagnetic fields, have become increasingly important in modern electronic applications. These properties, including permittivity, dielectric loss, and breakdown strength, determine a material's suitability for various electronic components such as capacitors, insulators, and electromagnetic shielding. The historical development of dielectric materials has been driven by the growing demands of the electronics industry for miniaturization, higher operating frequencies, and improved energy efficiency.

The intersection of amorphous metals and dielectric properties represents a relatively unexplored frontier in materials science. While traditional research has focused primarily on the mechanical and magnetic aspects of amorphous metals, their dielectric behavior has received comparatively less attention. Recent studies suggest that the unique atomic structure of amorphous metals may confer distinctive dielectric characteristics that differ significantly from their crystalline counterparts.

The technical objective of this research is to establish a comprehensive understanding of the correlation between the amorphous structure of metallic glasses and their resultant dielectric properties. This includes investigating how composition, processing conditions, and structural relaxation influence dielectric response across different frequency ranges and temperature conditions. Additionally, we aim to identify potential mechanisms that link atomic-level disorder to macroscopic dielectric behavior.

The evolution trend in this field points toward developing predictive models that can guide the design of amorphous metal compositions with tailored dielectric properties for specific applications. As electronic devices continue to advance in complexity and performance requirements, the demand for materials with precisely controlled dielectric characteristics will likely increase, potentially positioning amorphous metals as candidates for next-generation electronic components.

This research seeks to bridge the knowledge gap between metallurgy and electronics, potentially opening new avenues for material applications in fields ranging from telecommunications to energy storage. By elucidating the fundamental relationship between amorphous structure and dielectric function, we aim to establish design principles that could guide future development of specialized metallic glasses with optimized dielectric performance.

The dielectric properties of materials, which describe how they interact with electromagnetic fields, have become increasingly important in modern electronic applications. These properties, including permittivity, dielectric loss, and breakdown strength, determine a material's suitability for various electronic components such as capacitors, insulators, and electromagnetic shielding. The historical development of dielectric materials has been driven by the growing demands of the electronics industry for miniaturization, higher operating frequencies, and improved energy efficiency.

The intersection of amorphous metals and dielectric properties represents a relatively unexplored frontier in materials science. While traditional research has focused primarily on the mechanical and magnetic aspects of amorphous metals, their dielectric behavior has received comparatively less attention. Recent studies suggest that the unique atomic structure of amorphous metals may confer distinctive dielectric characteristics that differ significantly from their crystalline counterparts.

The technical objective of this research is to establish a comprehensive understanding of the correlation between the amorphous structure of metallic glasses and their resultant dielectric properties. This includes investigating how composition, processing conditions, and structural relaxation influence dielectric response across different frequency ranges and temperature conditions. Additionally, we aim to identify potential mechanisms that link atomic-level disorder to macroscopic dielectric behavior.

The evolution trend in this field points toward developing predictive models that can guide the design of amorphous metal compositions with tailored dielectric properties for specific applications. As electronic devices continue to advance in complexity and performance requirements, the demand for materials with precisely controlled dielectric characteristics will likely increase, potentially positioning amorphous metals as candidates for next-generation electronic components.

This research seeks to bridge the knowledge gap between metallurgy and electronics, potentially opening new avenues for material applications in fields ranging from telecommunications to energy storage. By elucidating the fundamental relationship between amorphous structure and dielectric function, we aim to establish design principles that could guide future development of specialized metallic glasses with optimized dielectric performance.

Market Applications and Demand Analysis for Amorphous Dielectric Materials

The global market for amorphous dielectric materials has witnessed significant growth in recent years, driven primarily by the expanding electronics and telecommunications sectors. Current market valuations indicate that amorphous dielectric materials represent a substantial segment within the broader advanced materials market, with particularly strong demand in regions with developed electronics manufacturing ecosystems such as East Asia, North America, and Europe.

The electronics industry constitutes the largest application sector for amorphous dielectric materials, particularly in semiconductor manufacturing where these materials play a crucial role in miniaturization efforts. As device dimensions continue to shrink according to Moore's Law, the demand for high-performance dielectric materials with precise property control has intensified. The correlation between amorphous metals and dielectric properties has become increasingly important as manufacturers seek materials that can maintain electrical isolation while operating at higher frequencies and smaller scales.

Energy storage represents another rapidly growing application area. The unique properties of amorphous metal-based dielectrics, including high breakdown strength and low energy loss, make them ideal candidates for next-generation capacitors and energy storage devices. This market segment is experiencing double-digit growth rates as renewable energy integration and electric vehicle adoption accelerate globally.

Telecommunications infrastructure, particularly with the ongoing deployment of 5G networks, has emerged as a significant demand driver. The higher operating frequencies of advanced communication systems require dielectric materials with minimal signal loss and consistent performance across varying environmental conditions. Amorphous metal-dielectric composites have demonstrated superior performance in these applications compared to conventional crystalline alternatives.

Market analysis reveals a growing trend toward customized amorphous dielectric solutions tailored to specific applications. This shift from generic to application-specific materials has created new market opportunities for specialized material developers and has increased profit margins in this sector. Companies capable of engineering precise dielectric properties through controlled amorphization processes are positioned advantageously in this evolving landscape.

Regulatory factors are increasingly influencing market dynamics, with environmental regulations and RoHS compliance driving demand for lead-free and environmentally sustainable dielectric formulations. This regulatory pressure has accelerated research into novel amorphous metal compositions that maintain desired dielectric properties while meeting stringent environmental standards.

Future market growth is expected to be driven by emerging applications in quantum computing, advanced medical devices, and aerospace technologies, where the unique combination of properties offered by amorphous metal-based dielectrics addresses critical performance requirements that cannot be met by conventional materials.

The electronics industry constitutes the largest application sector for amorphous dielectric materials, particularly in semiconductor manufacturing where these materials play a crucial role in miniaturization efforts. As device dimensions continue to shrink according to Moore's Law, the demand for high-performance dielectric materials with precise property control has intensified. The correlation between amorphous metals and dielectric properties has become increasingly important as manufacturers seek materials that can maintain electrical isolation while operating at higher frequencies and smaller scales.

Energy storage represents another rapidly growing application area. The unique properties of amorphous metal-based dielectrics, including high breakdown strength and low energy loss, make them ideal candidates for next-generation capacitors and energy storage devices. This market segment is experiencing double-digit growth rates as renewable energy integration and electric vehicle adoption accelerate globally.

Telecommunications infrastructure, particularly with the ongoing deployment of 5G networks, has emerged as a significant demand driver. The higher operating frequencies of advanced communication systems require dielectric materials with minimal signal loss and consistent performance across varying environmental conditions. Amorphous metal-dielectric composites have demonstrated superior performance in these applications compared to conventional crystalline alternatives.

Market analysis reveals a growing trend toward customized amorphous dielectric solutions tailored to specific applications. This shift from generic to application-specific materials has created new market opportunities for specialized material developers and has increased profit margins in this sector. Companies capable of engineering precise dielectric properties through controlled amorphization processes are positioned advantageously in this evolving landscape.

Regulatory factors are increasingly influencing market dynamics, with environmental regulations and RoHS compliance driving demand for lead-free and environmentally sustainable dielectric formulations. This regulatory pressure has accelerated research into novel amorphous metal compositions that maintain desired dielectric properties while meeting stringent environmental standards.

Future market growth is expected to be driven by emerging applications in quantum computing, advanced medical devices, and aerospace technologies, where the unique combination of properties offered by amorphous metal-based dielectrics addresses critical performance requirements that cannot be met by conventional materials.

Current State and Technical Challenges in Amorphous Metal Research

Amorphous metals, also known as metallic glasses, represent a unique class of materials that lack the long-range atomic order characteristic of crystalline metals. Research into these materials has accelerated significantly over the past decade, driven by their exceptional mechanical, magnetic, and corrosion-resistant properties. Currently, the global research landscape is dominated by institutions in the United States, China, Japan, and Germany, with emerging contributions from South Korea and India.

The fabrication of amorphous metals presents significant technical challenges. Traditional methods include rapid quenching techniques such as melt spinning and splat quenching, which require cooling rates exceeding 10^6 K/s to prevent crystallization. Recent advancements have introduced solid-state processing routes like mechanical alloying and severe plastic deformation, expanding the compositional range of achievable amorphous structures.

A critical limitation in the field remains the size constraint of bulk metallic glasses (BMGs). While some zirconium and palladium-based alloys can form amorphous structures at cooling rates as low as 10^1 K/s, producing large-volume components remains challenging. This "critical casting thickness" problem continues to restrict industrial applications despite theoretical advances in alloy design.

The correlation between amorphous structure and dielectric properties represents an emerging research frontier. Current understanding suggests that the absence of grain boundaries and the homogeneous electron distribution in amorphous metals significantly influences their interaction with electromagnetic fields. However, systematic studies linking structural parameters to dielectric response remain limited, particularly in the high-frequency regime.

Characterization techniques pose another substantial challenge. While X-ray diffraction and transmission electron microscopy provide structural insights, quantifying short and medium-range order parameters that influence dielectric behavior requires advanced techniques like fluctuation electron microscopy and synchrotron-based methods. The integration of these characterization approaches with dielectric spectroscopy remains underdeveloped.

Computational modeling of amorphous metals has advanced through molecular dynamics and density functional theory approaches, but accurately predicting dielectric properties from structural models remains computationally intensive. The multi-scale nature of the problem—spanning from atomic arrangements to macroscopic electromagnetic responses—necessitates novel computational frameworks that can bridge these disparate length scales.

Environmental stability presents another significant challenge, as many amorphous metals exhibit structural relaxation and crystallization at elevated temperatures or under mechanical stress. This structural evolution can dramatically alter dielectric properties, complicating the design of stable components for electronic applications. Recent research has focused on developing thermally stable compositions through minor alloying additions, though comprehensive solutions remain elusive.

The fabrication of amorphous metals presents significant technical challenges. Traditional methods include rapid quenching techniques such as melt spinning and splat quenching, which require cooling rates exceeding 10^6 K/s to prevent crystallization. Recent advancements have introduced solid-state processing routes like mechanical alloying and severe plastic deformation, expanding the compositional range of achievable amorphous structures.

A critical limitation in the field remains the size constraint of bulk metallic glasses (BMGs). While some zirconium and palladium-based alloys can form amorphous structures at cooling rates as low as 10^1 K/s, producing large-volume components remains challenging. This "critical casting thickness" problem continues to restrict industrial applications despite theoretical advances in alloy design.

The correlation between amorphous structure and dielectric properties represents an emerging research frontier. Current understanding suggests that the absence of grain boundaries and the homogeneous electron distribution in amorphous metals significantly influences their interaction with electromagnetic fields. However, systematic studies linking structural parameters to dielectric response remain limited, particularly in the high-frequency regime.

Characterization techniques pose another substantial challenge. While X-ray diffraction and transmission electron microscopy provide structural insights, quantifying short and medium-range order parameters that influence dielectric behavior requires advanced techniques like fluctuation electron microscopy and synchrotron-based methods. The integration of these characterization approaches with dielectric spectroscopy remains underdeveloped.

Computational modeling of amorphous metals has advanced through molecular dynamics and density functional theory approaches, but accurately predicting dielectric properties from structural models remains computationally intensive. The multi-scale nature of the problem—spanning from atomic arrangements to macroscopic electromagnetic responses—necessitates novel computational frameworks that can bridge these disparate length scales.

Environmental stability presents another significant challenge, as many amorphous metals exhibit structural relaxation and crystallization at elevated temperatures or under mechanical stress. This structural evolution can dramatically alter dielectric properties, complicating the design of stable components for electronic applications. Recent research has focused on developing thermally stable compositions through minor alloying additions, though comprehensive solutions remain elusive.

Current Methodologies for Correlating Structure and Dielectric Properties

01 Amorphous metal thin films for dielectric applications

Amorphous metal thin films exhibit unique dielectric properties that make them suitable for various electronic applications. These films can be deposited using techniques such as sputtering or chemical vapor deposition to create layers with controlled dielectric constants. The amorphous structure provides uniform electrical properties without grain boundaries, resulting in improved performance in capacitors, transistors, and other electronic components.- Amorphous metal thin films for dielectric applications: Amorphous metal thin films exhibit unique dielectric properties that make them suitable for various electronic applications. These films can be deposited using techniques such as sputtering or chemical vapor deposition to create layers with controlled dielectric constants. The amorphous structure provides uniform electrical properties without grain boundaries, resulting in improved performance in capacitors, memory devices, and other electronic components requiring specific dielectric characteristics.

- Amorphous metal alloys with enhanced dielectric breakdown strength: Certain amorphous metal alloys demonstrate superior dielectric breakdown strength compared to their crystalline counterparts. These materials can withstand higher electric fields before experiencing dielectric breakdown, making them valuable for high-voltage applications. The composition of these alloys can be tailored to optimize their dielectric properties, with elements such as zirconium, iron, and boron commonly incorporated to enhance performance in transformers, inductors, and other electrical components.

- Integration of amorphous metals in semiconductor devices: Amorphous metals can be integrated into semiconductor devices as dielectric layers or electrodes. Their unique electrical properties allow for improved device performance, including reduced leakage current and enhanced reliability. The amorphous structure provides better interface characteristics with other materials in the device stack, leading to fewer defects and improved overall functionality. These materials are particularly valuable in advanced microelectronic applications where conventional crystalline metals may not meet performance requirements.

- Temperature dependence of dielectric properties in amorphous metals: The dielectric properties of amorphous metals exhibit distinct temperature dependencies that differ from crystalline materials. As temperature changes, parameters such as dielectric constant, loss tangent, and electrical resistivity may vary in ways that can be advantageous for specific applications. Understanding these temperature-dependent behaviors is crucial for designing devices that must operate across wide temperature ranges. Some amorphous metal compositions show remarkable stability in their dielectric properties even under extreme temperature conditions.

- Manufacturing processes affecting dielectric properties of amorphous metals: Various manufacturing processes significantly influence the dielectric properties of amorphous metals. Techniques such as rapid quenching, melt spinning, and controlled cooling can produce amorphous structures with specific dielectric characteristics. Post-processing treatments, including annealing and surface modification, can further tune these properties. The processing parameters must be carefully controlled to achieve desired dielectric constants, loss factors, and frequency responses, making manufacturing methodology a critical factor in developing amorphous metals for specific dielectric applications.

02 Amorphous metal alloys with enhanced dielectric breakdown strength

Certain amorphous metal alloys demonstrate superior dielectric breakdown strength compared to their crystalline counterparts. These materials can withstand higher electric fields before experiencing dielectric breakdown, making them valuable for high-voltage applications. The composition of these alloys can be tailored to optimize their dielectric properties, with elements such as zirconium, iron, and boron commonly incorporated to enhance performance.Expand Specific Solutions03 Integration of amorphous metals with dielectric materials in semiconductor devices

Amorphous metals can be effectively integrated with dielectric materials in semiconductor manufacturing to create advanced device structures. The interface between amorphous metals and dielectrics plays a crucial role in determining the overall electrical performance of the device. Various techniques have been developed to optimize this interface, including surface treatments and buffer layers that enhance adhesion and reduce defects, resulting in improved device reliability and performance.Expand Specific Solutions04 Temperature effects on dielectric properties of amorphous metals

The dielectric properties of amorphous metals exhibit significant temperature dependence, which is important for applications in various thermal environments. As temperature increases, changes in the electronic structure and atomic mobility within the amorphous matrix can alter dielectric constants and loss factors. Understanding these temperature-related effects is crucial for designing devices that maintain stable dielectric performance across operating temperature ranges, particularly in high-temperature or thermally variable environments.Expand Specific Solutions05 Novel amorphous metal compositions for specific dielectric applications

Researchers have developed novel amorphous metal compositions specifically engineered for their dielectric properties. These include multi-component alloys and nanostructured amorphous metals with tailored electronic structures. By carefully controlling the elemental composition and processing conditions, materials with specific dielectric constants, low loss tangents, and frequency-stable properties can be created. These materials find applications in high-frequency electronics, electromagnetic shielding, and advanced energy storage systems.Expand Specific Solutions

Key Industry Players and Research Institutions in Amorphous Materials

The correlation between amorphous metals and dielectric properties represents an emerging technological frontier at the intersection of materials science and electronics. Currently in its growth phase, this field is witnessing increasing market interest due to applications in energy storage, electronics, and telecommunications. The market is projected to expand significantly as industries seek advanced materials with superior electromagnetic performance. From a technical maturity perspective, research institutions like Industrial Technology Research Institute and University of Science & Technology Beijing are advancing fundamental understanding, while commercial players including TDK Corp., NGK Insulators, and TSMC are developing practical applications. BYD and Honda are exploring implementations in electric vehicles, while Skyworks Solutions and GLOBALFOUNDRIES focus on semiconductor applications, indicating a technology transitioning from research to commercial viability.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a comprehensive approach to understanding amorphous metal-dielectric correlations through their proprietary glass-ceramic processing techniques. Their methodology involves creating controlled amorphous metal inclusions within ceramic dielectric matrices to study interfacial effects on overall dielectric performance. NGK's research has revealed that nanoscale amorphous metal particles dispersed in ceramic dielectrics can significantly enhance permittivity while maintaining low dielectric loss at specific frequency ranges. Their technical approach includes advanced characterization using high-resolution transmission electron microscopy coupled with dielectric spectroscopy to establish structure-property relationships. NGK has particularly focused on the role of local atomic ordering in amorphous metals and how this influences polarization mechanisms and dielectric relaxation phenomena in composite systems.

Strengths: Exceptional expertise in ceramic processing technology enables precise control of amorphous-crystalline interfaces; established manufacturing infrastructure for scaling laboratory findings. Weaknesses: Limited focus on purely metallic amorphous systems; research primarily oriented toward composite materials rather than fundamental metal physics.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed a multidisciplinary approach to investigating amorphous metal-dielectric correlations through their advanced materials characterization platform. ITRI's methodology combines in-situ structural analysis during rapid solidification with simultaneous dielectric property measurements. Their research has established quantitative relationships between short-range ordering in amorphous metals and resulting dielectric responses across broad frequency spectra. ITRI has pioneered techniques for controlling the free electron concentration and mobility in amorphous metal systems through precise compositional tuning, directly influencing dielectric properties. Their approach includes computational modeling of electron localization effects in amorphous structures and experimental validation using broadband dielectric spectroscopy. ITRI has demonstrated that specific amorphous metal compositions exhibit anomalous dielectric behavior that can be exploited for specialized electronic applications.

Strengths: Comprehensive research infrastructure spanning from theoretical modeling to practical applications; strong collaborative network with both academic and industrial partners. Weaknesses: Research efforts somewhat fragmented across multiple application domains; challenges in translating fundamental insights into commercial products.

Critical Patents and Research Breakthroughs in Structure-Property Relationships

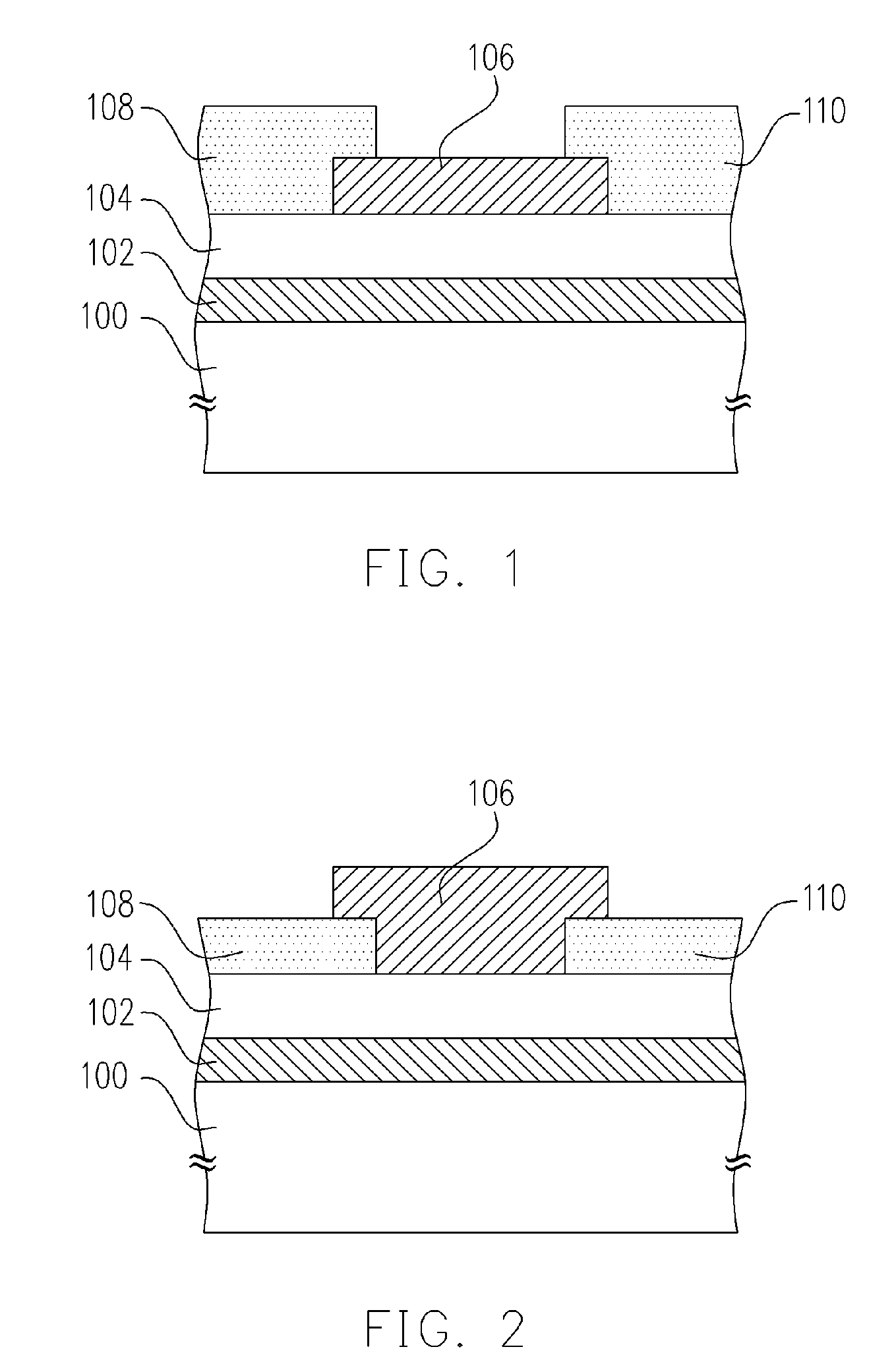

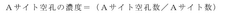

Dielectric layer, composition and method for forming the same

PatentInactiveUS20070172583A1

Innovation

- A dielectric layer composition comprising a liquid organometallic compound and a photo-sensitive or non-photo-sensitive polymer, which forms an amorphous metal oxide upon baking, offering high dielectric constant, low leakage current, and improved uniformity, suitable for use in field effect transistors and high-frequency devices, and can be processed at low temperatures.

Dielectric material exhibiting polarization twist, dielectric structure in which polarization can be controlled and capacitor and piezoelectric element each using same, and ceramic and capacitor and piezoelectric element each using same

PatentWO2020004670A1

Innovation

- A dielectric material with a perovskite structure (ABX3) exhibiting polarization twist, where the concentration of A-site vacancies is 1% or less, and oxygen vacancies is also controlled, allowing for significant changes in permittivity and piezoelectric strain constant by applying an electric field, thereby enabling controlled polarization.

Manufacturing Processes and Scalability Considerations

The manufacturing of amorphous metals with specific dielectric properties presents unique challenges that differ significantly from conventional metal processing. Traditional manufacturing methods often fail to preserve the amorphous structure, which is critical for maintaining the desired dielectric characteristics. Currently, rapid solidification techniques such as melt spinning and splat quenching dominate the production landscape, as they enable cooling rates exceeding 10^6 K/s necessary to prevent crystallization.

Melt spinning, the most commercially viable process, involves ejecting molten metal onto a rapidly rotating copper wheel, producing thin ribbons typically 20-50 μm thick. While effective for research purposes, scaling this process for industrial applications remains problematic due to thickness limitations and dimensional constraints. Alternative methods like gas atomization can produce amorphous metal powders suitable for powder metallurgy or additive manufacturing, but controlling particle size distribution and preventing oxidation during processing requires sophisticated equipment and controlled atmospheres.

Recent advancements in selective laser melting (SLM) and electron beam melting (EBM) show promise for fabricating bulk amorphous metal components with tailored dielectric properties. These additive manufacturing techniques allow for precise control of local cooling rates, potentially enabling the production of geometrically complex components with spatially varied dielectric characteristics. However, the build volume limitations and high equipment costs currently restrict widespread adoption.

The scalability of amorphous metal production with controlled dielectric properties faces several critical bottlenecks. First, the extreme cooling rates required for amorphization limit component dimensions, with most commercially available amorphous metals restricted to thicknesses below 100 μm. Second, compositional homogeneity across large volumes remains difficult to achieve, leading to inconsistent dielectric performance. Third, post-processing treatments like annealing, which can enhance dielectric properties, must be carefully controlled to avoid crystallization.

Economic considerations further complicate industrial scaling. The specialized equipment required for rapid solidification techniques represents significant capital investment, while process yields often remain below those of conventional metallurgy. Material costs are elevated due to the need for high-purity precursors to achieve desired dielectric performance. These factors collectively contribute to production costs that currently exceed those of competing materials by 3-5 times, limiting market penetration despite superior technical performance.

Future manufacturing innovations will likely focus on hybrid approaches combining rapid solidification with subsequent consolidation techniques, potentially enabling larger components while maintaining the amorphous structure critical for dielectric applications. Computational modeling of process parameters will play an increasingly important role in optimizing manufacturing conditions for specific dielectric property targets.

Melt spinning, the most commercially viable process, involves ejecting molten metal onto a rapidly rotating copper wheel, producing thin ribbons typically 20-50 μm thick. While effective for research purposes, scaling this process for industrial applications remains problematic due to thickness limitations and dimensional constraints. Alternative methods like gas atomization can produce amorphous metal powders suitable for powder metallurgy or additive manufacturing, but controlling particle size distribution and preventing oxidation during processing requires sophisticated equipment and controlled atmospheres.

Recent advancements in selective laser melting (SLM) and electron beam melting (EBM) show promise for fabricating bulk amorphous metal components with tailored dielectric properties. These additive manufacturing techniques allow for precise control of local cooling rates, potentially enabling the production of geometrically complex components with spatially varied dielectric characteristics. However, the build volume limitations and high equipment costs currently restrict widespread adoption.

The scalability of amorphous metal production with controlled dielectric properties faces several critical bottlenecks. First, the extreme cooling rates required for amorphization limit component dimensions, with most commercially available amorphous metals restricted to thicknesses below 100 μm. Second, compositional homogeneity across large volumes remains difficult to achieve, leading to inconsistent dielectric performance. Third, post-processing treatments like annealing, which can enhance dielectric properties, must be carefully controlled to avoid crystallization.

Economic considerations further complicate industrial scaling. The specialized equipment required for rapid solidification techniques represents significant capital investment, while process yields often remain below those of conventional metallurgy. Material costs are elevated due to the need for high-purity precursors to achieve desired dielectric performance. These factors collectively contribute to production costs that currently exceed those of competing materials by 3-5 times, limiting market penetration despite superior technical performance.

Future manufacturing innovations will likely focus on hybrid approaches combining rapid solidification with subsequent consolidation techniques, potentially enabling larger components while maintaining the amorphous structure critical for dielectric applications. Computational modeling of process parameters will play an increasingly important role in optimizing manufacturing conditions for specific dielectric property targets.

Environmental Impact and Sustainability of Amorphous Metal Materials

The environmental impact of amorphous metals represents a critical consideration in their development and application, particularly when examining their correlation with dielectric properties. Amorphous metals, with their unique atomic structure and superior electromagnetic characteristics, offer significant sustainability advantages over their crystalline counterparts.

Production processes for amorphous metals typically require less energy than conventional metal manufacturing, as they often involve rapid cooling techniques that bypass energy-intensive crystallization phases. This energy efficiency translates to reduced carbon emissions during manufacturing, with some studies indicating up to 30% lower carbon footprint compared to traditional metal processing methods.

The enhanced durability and corrosion resistance of amorphous metals contribute substantially to their sustainability profile. These materials can maintain their dielectric properties and structural integrity for extended periods without degradation, reducing replacement frequency and associated resource consumption. The longer lifecycle of amorphous metal components in electronic applications directly correlates with reduced electronic waste generation, addressing a growing environmental concern in the technology sector.

Recycling capabilities present both opportunities and challenges for amorphous metals. Their homogeneous structure theoretically makes them ideal candidates for recycling, as they lack grain boundaries that often complicate conventional metal recycling processes. However, specialized recycling infrastructure for these advanced materials remains underdeveloped, creating a potential sustainability gap that requires industry attention.

The relationship between dielectric properties and environmental impact manifests in energy efficiency applications. Amorphous metals with optimized dielectric characteristics enable more efficient power transformers, reducing energy losses by up to 80% compared to silicon steel alternatives. This efficiency translates to significant energy conservation across power distribution networks globally.

Toxicity assessments of amorphous metals indicate generally favorable environmental profiles, with minimal leaching of harmful substances compared to some conventional materials. However, certain alloying elements used to enhance dielectric properties may present environmental concerns if not properly managed throughout the material lifecycle.

Future sustainability improvements in amorphous metal technology will likely focus on developing manufacturing processes with even lower energy requirements, expanding recycling capabilities, and identifying environmentally benign alloying elements that maintain or enhance desired dielectric properties. The integration of life cycle assessment methodologies into amorphous metal research represents a promising approach to comprehensively evaluate and optimize their environmental performance.

Production processes for amorphous metals typically require less energy than conventional metal manufacturing, as they often involve rapid cooling techniques that bypass energy-intensive crystallization phases. This energy efficiency translates to reduced carbon emissions during manufacturing, with some studies indicating up to 30% lower carbon footprint compared to traditional metal processing methods.

The enhanced durability and corrosion resistance of amorphous metals contribute substantially to their sustainability profile. These materials can maintain their dielectric properties and structural integrity for extended periods without degradation, reducing replacement frequency and associated resource consumption. The longer lifecycle of amorphous metal components in electronic applications directly correlates with reduced electronic waste generation, addressing a growing environmental concern in the technology sector.

Recycling capabilities present both opportunities and challenges for amorphous metals. Their homogeneous structure theoretically makes them ideal candidates for recycling, as they lack grain boundaries that often complicate conventional metal recycling processes. However, specialized recycling infrastructure for these advanced materials remains underdeveloped, creating a potential sustainability gap that requires industry attention.

The relationship between dielectric properties and environmental impact manifests in energy efficiency applications. Amorphous metals with optimized dielectric characteristics enable more efficient power transformers, reducing energy losses by up to 80% compared to silicon steel alternatives. This efficiency translates to significant energy conservation across power distribution networks globally.

Toxicity assessments of amorphous metals indicate generally favorable environmental profiles, with minimal leaching of harmful substances compared to some conventional materials. However, certain alloying elements used to enhance dielectric properties may present environmental concerns if not properly managed throughout the material lifecycle.

Future sustainability improvements in amorphous metal technology will likely focus on developing manufacturing processes with even lower energy requirements, expanding recycling capabilities, and identifying environmentally benign alloying elements that maintain or enhance desired dielectric properties. The integration of life cycle assessment methodologies into amorphous metal research represents a promising approach to comprehensively evaluate and optimize their environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!