How custom exhaust tuning affects V16 engine performance

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Exhaust Evolution and Objectives

The V16 engine, a marvel of automotive engineering, has undergone significant evolution in its exhaust systems over the years. This progression has been driven by the continuous pursuit of enhanced performance, efficiency, and environmental compliance. The journey began with simple, straight-through exhaust systems that prioritized power output over all else. As technology advanced, engineers recognized the potential for exhaust tuning to dramatically influence engine performance.

The primary objective of custom exhaust tuning for V16 engines is to optimize the engine's breathing capabilities, thereby improving overall performance. This involves carefully balancing backpressure, scavenging effects, and sound characteristics. By manipulating these factors, engineers aim to extract maximum power and torque across the engine's entire operating range while maintaining drivability and meeting increasingly stringent emissions standards.

One of the key goals in V16 exhaust evolution has been to harness the power of exhaust pulse tuning. This technique involves designing the exhaust system to create pressure waves that assist in evacuating exhaust gases and drawing in fresh air-fuel mixture. The complexity of a V16 engine's firing order presents both challenges and opportunities in this regard, requiring intricate exhaust manifold designs and precisely calculated pipe lengths.

Another critical objective has been weight reduction without compromising structural integrity. As V16 engines are often used in high-performance and luxury vehicles, every gram saved in the exhaust system contributes to improved power-to-weight ratios and fuel efficiency. This has led to the adoption of advanced materials such as titanium alloys and carbon fiber composites in modern V16 exhaust systems.

The pursuit of the perfect exhaust note has also been a driving force in V16 exhaust development. Engineers strive to create a signature sound that reflects the engine's power and prestige while complying with noise regulations. This has resulted in the integration of sophisticated sound management technologies, including variable valve systems and active exhaust flaps.

As environmental concerns have grown, a significant objective in V16 exhaust evolution has been to reduce emissions without sacrificing performance. This has necessitated the development of more efficient catalytic converters, particulate filters, and advanced exhaust gas recirculation systems tailored to the unique characteristics of V16 engines.

Looking forward, the objectives for V16 exhaust tuning continue to evolve. There is an increasing focus on integrating smart technologies that can adapt exhaust characteristics in real-time based on driving conditions and driver preferences. Additionally, as the automotive industry shifts towards electrification, the role of exhaust tuning in hybrid V16 powertrains presents new challenges and opportunities for innovation.

The primary objective of custom exhaust tuning for V16 engines is to optimize the engine's breathing capabilities, thereby improving overall performance. This involves carefully balancing backpressure, scavenging effects, and sound characteristics. By manipulating these factors, engineers aim to extract maximum power and torque across the engine's entire operating range while maintaining drivability and meeting increasingly stringent emissions standards.

One of the key goals in V16 exhaust evolution has been to harness the power of exhaust pulse tuning. This technique involves designing the exhaust system to create pressure waves that assist in evacuating exhaust gases and drawing in fresh air-fuel mixture. The complexity of a V16 engine's firing order presents both challenges and opportunities in this regard, requiring intricate exhaust manifold designs and precisely calculated pipe lengths.

Another critical objective has been weight reduction without compromising structural integrity. As V16 engines are often used in high-performance and luxury vehicles, every gram saved in the exhaust system contributes to improved power-to-weight ratios and fuel efficiency. This has led to the adoption of advanced materials such as titanium alloys and carbon fiber composites in modern V16 exhaust systems.

The pursuit of the perfect exhaust note has also been a driving force in V16 exhaust development. Engineers strive to create a signature sound that reflects the engine's power and prestige while complying with noise regulations. This has resulted in the integration of sophisticated sound management technologies, including variable valve systems and active exhaust flaps.

As environmental concerns have grown, a significant objective in V16 exhaust evolution has been to reduce emissions without sacrificing performance. This has necessitated the development of more efficient catalytic converters, particulate filters, and advanced exhaust gas recirculation systems tailored to the unique characteristics of V16 engines.

Looking forward, the objectives for V16 exhaust tuning continue to evolve. There is an increasing focus on integrating smart technologies that can adapt exhaust characteristics in real-time based on driving conditions and driver preferences. Additionally, as the automotive industry shifts towards electrification, the role of exhaust tuning in hybrid V16 powertrains presents new challenges and opportunities for innovation.

Market Analysis for High-Performance V16 Engines

The market for high-performance V16 engines represents a niche but lucrative segment within the automotive industry. These powerful engines are primarily found in ultra-luxury and high-performance vehicles, catering to a select group of enthusiasts and collectors who demand the utmost in power, prestige, and exclusivity. The global market for V16 engines is relatively small but has shown steady growth in recent years, driven by increasing demand for luxury vehicles and a growing population of high-net-worth individuals.

In terms of market size, the V16 engine segment is estimated to account for a small fraction of the overall automotive engine market. However, the high price points of vehicles equipped with V16 engines contribute significantly to the revenue generated in this sector. The primary markets for V16-powered vehicles are North America, Europe, and parts of Asia, particularly in countries with a strong luxury car culture and high disposable incomes.

The demand for high-performance V16 engines is influenced by several factors. Firstly, there is a growing trend among ultra-luxury car manufacturers to differentiate their top-tier models with increasingly powerful and sophisticated engines. This has led to a resurgence of interest in V16 configurations, which offer unparalleled smoothness and power delivery. Secondly, the rise of electric vehicles has paradoxically increased the appeal of high-performance combustion engines among enthusiasts, who view them as a last bastion of traditional automotive engineering.

Custom exhaust tuning plays a crucial role in the market for V16 engines, as it directly impacts performance, sound, and overall driving experience. Enthusiasts and manufacturers alike recognize the importance of exhaust systems in maximizing engine output and creating a distinctive auditory signature. This has led to a growing sub-market for aftermarket exhaust systems and tuning services specifically tailored for V16 engines.

The market for V16 engines faces challenges, including increasingly stringent emissions regulations and a global shift towards electrification. However, manufacturers are responding by incorporating hybrid technologies and advanced materials to improve efficiency while maintaining performance. This adaptation is crucial for the long-term viability of V16 engines in the high-performance automotive market.

Looking ahead, the market for high-performance V16 engines is expected to remain stable, with potential for modest growth in certain regions. The emphasis on custom exhaust tuning and other performance enhancements is likely to increase as manufacturers and enthusiasts seek to extract maximum performance and character from these impressive powerplants. As the automotive industry evolves, V16 engines may increasingly be positioned as halo products, showcasing the pinnacle of internal combustion engine technology and craftsmanship.

In terms of market size, the V16 engine segment is estimated to account for a small fraction of the overall automotive engine market. However, the high price points of vehicles equipped with V16 engines contribute significantly to the revenue generated in this sector. The primary markets for V16-powered vehicles are North America, Europe, and parts of Asia, particularly in countries with a strong luxury car culture and high disposable incomes.

The demand for high-performance V16 engines is influenced by several factors. Firstly, there is a growing trend among ultra-luxury car manufacturers to differentiate their top-tier models with increasingly powerful and sophisticated engines. This has led to a resurgence of interest in V16 configurations, which offer unparalleled smoothness and power delivery. Secondly, the rise of electric vehicles has paradoxically increased the appeal of high-performance combustion engines among enthusiasts, who view them as a last bastion of traditional automotive engineering.

Custom exhaust tuning plays a crucial role in the market for V16 engines, as it directly impacts performance, sound, and overall driving experience. Enthusiasts and manufacturers alike recognize the importance of exhaust systems in maximizing engine output and creating a distinctive auditory signature. This has led to a growing sub-market for aftermarket exhaust systems and tuning services specifically tailored for V16 engines.

The market for V16 engines faces challenges, including increasingly stringent emissions regulations and a global shift towards electrification. However, manufacturers are responding by incorporating hybrid technologies and advanced materials to improve efficiency while maintaining performance. This adaptation is crucial for the long-term viability of V16 engines in the high-performance automotive market.

Looking ahead, the market for high-performance V16 engines is expected to remain stable, with potential for modest growth in certain regions. The emphasis on custom exhaust tuning and other performance enhancements is likely to increase as manufacturers and enthusiasts seek to extract maximum performance and character from these impressive powerplants. As the automotive industry evolves, V16 engines may increasingly be positioned as halo products, showcasing the pinnacle of internal combustion engine technology and craftsmanship.

Current Challenges in V16 Exhaust Tuning

Custom exhaust tuning for V16 engines presents several significant challenges that engineers and designers must overcome to optimize performance. One of the primary difficulties lies in managing the complex exhaust gas flow dynamics resulting from the engine's 16 cylinders. The sheer number of exhaust pulses generated creates intricate pressure waves that can interfere with each other, potentially leading to power losses if not properly addressed.

Another major challenge is balancing the need for increased exhaust flow with noise reduction requirements. V16 engines are often used in high-performance or luxury applications where both power output and refined sound characteristics are crucial. Achieving an optimal compromise between these competing factors requires sophisticated design solutions and extensive testing.

The physical packaging constraints of V16 engines also pose significant hurdles for exhaust system design. The limited space available in most vehicle configurations makes it challenging to implement ideal exhaust geometries, particularly when considering the need for efficient catalytic converters and mufflers. This spatial limitation often necessitates creative routing solutions and compact component designs.

Heat management is another critical issue in V16 exhaust tuning. The substantial heat generated by 16 cylinders can lead to thermal expansion problems and potential material fatigue. Engineers must carefully select materials and design heat shields to ensure longevity and consistent performance across various operating conditions.

Furthermore, the complexity of V16 engines makes precise tuning of individual cylinder exhaust pulses extremely challenging. Optimizing the scavenging effect for each cylinder while maintaining overall system harmony requires advanced simulation tools and extensive real-world testing. This process is further complicated by the need to account for various engine speeds and load conditions.

Lastly, regulatory compliance presents an ongoing challenge in V16 exhaust tuning. Stringent emissions standards and noise regulations vary across different markets, necessitating adaptable designs that can meet diverse requirements without compromising performance. This often involves integrating sophisticated aftertreatment systems and variable exhaust geometries, adding layers of complexity to the already intricate tuning process.

Another major challenge is balancing the need for increased exhaust flow with noise reduction requirements. V16 engines are often used in high-performance or luxury applications where both power output and refined sound characteristics are crucial. Achieving an optimal compromise between these competing factors requires sophisticated design solutions and extensive testing.

The physical packaging constraints of V16 engines also pose significant hurdles for exhaust system design. The limited space available in most vehicle configurations makes it challenging to implement ideal exhaust geometries, particularly when considering the need for efficient catalytic converters and mufflers. This spatial limitation often necessitates creative routing solutions and compact component designs.

Heat management is another critical issue in V16 exhaust tuning. The substantial heat generated by 16 cylinders can lead to thermal expansion problems and potential material fatigue. Engineers must carefully select materials and design heat shields to ensure longevity and consistent performance across various operating conditions.

Furthermore, the complexity of V16 engines makes precise tuning of individual cylinder exhaust pulses extremely challenging. Optimizing the scavenging effect for each cylinder while maintaining overall system harmony requires advanced simulation tools and extensive real-world testing. This process is further complicated by the need to account for various engine speeds and load conditions.

Lastly, regulatory compliance presents an ongoing challenge in V16 exhaust tuning. Stringent emissions standards and noise regulations vary across different markets, necessitating adaptable designs that can meet diverse requirements without compromising performance. This often involves integrating sophisticated aftertreatment systems and variable exhaust geometries, adding layers of complexity to the already intricate tuning process.

Existing V16 Exhaust Tuning Methodologies

01 Engine design and configuration

V16 engines are designed with 16 cylinders arranged in a V-shape, offering high power output and smooth operation. The configuration allows for compact packaging while maintaining performance. Advanced design techniques are employed to optimize cylinder firing order, balance, and overall engine efficiency.- Engine design and configuration: V16 engines are designed with 16 cylinders arranged in a V-shape configuration. This layout allows for increased power output and smoother operation compared to smaller engines. The design often incorporates advanced materials and manufacturing techniques to optimize performance and efficiency.

- Performance optimization and tuning: Various methods are employed to enhance V16 engine performance, including optimizing fuel injection systems, improving combustion efficiency, and fine-tuning engine control units. Advanced sensors and monitoring systems are used to gather real-time data for performance analysis and adjustment.

- Cooling and thermal management: Effective cooling systems are crucial for maintaining optimal V16 engine performance. This includes advanced radiator designs, precision coolant flow control, and innovative heat dissipation techniques to manage the high temperatures generated by these powerful engines.

- Emissions control and environmental considerations: To meet stringent emissions standards while maintaining high performance, V16 engines incorporate advanced exhaust aftertreatment systems, catalytic converters, and precise air-fuel mixture control. Some designs also explore hybrid or alternative fuel technologies to reduce environmental impact.

- Diagnostics and maintenance: Sophisticated diagnostic systems are integrated into V16 engines to monitor performance, detect potential issues, and facilitate maintenance. These systems may include predictive analytics, real-time performance monitoring, and advanced error detection algorithms to ensure optimal engine operation and longevity.

02 Performance optimization and control

Various methods are used to optimize V16 engine performance, including electronic control systems, fuel injection technologies, and advanced combustion strategies. These systems monitor and adjust engine parameters in real-time to maximize power output, fuel efficiency, and emissions control across different operating conditions.Expand Specific Solutions03 Turbocharging and supercharging

Forced induction systems, such as turbochargers and superchargers, are often employed in V16 engines to boost performance. These systems increase air intake, allowing for more fuel combustion and higher power output. Advanced control mechanisms ensure optimal boost pressure across the engine's operating range.Expand Specific Solutions04 Cooling and thermal management

Effective cooling systems are crucial for maintaining V16 engine performance. Advanced thermal management techniques, including precision coolant flow control and heat exchanger designs, help maintain optimal operating temperatures across all cylinders, ensuring consistent performance and longevity.Expand Specific Solutions05 Performance monitoring and diagnostics

Sophisticated monitoring systems are implemented to track V16 engine performance in real-time. These systems use various sensors and data analysis techniques to assess engine health, predict maintenance needs, and optimize performance. Advanced diagnostics help identify and address potential issues before they impact engine operation.Expand Specific Solutions

Major Players in V16 Engine and Exhaust Manufacturing

The competitive landscape for custom exhaust tuning in V16 engine performance is in a mature stage, with a significant market size driven by high-end automotive and motorsport applications. The technology is well-established, with major players like BMW, Toyota, and Honda leading research and development efforts. Specialized companies such as AVL List GmbH and Southwest Research Institute provide advanced engineering services in this field. The market is characterized by continuous innovation, with companies like BorgWarner and Volkswagen AG investing in performance optimization technologies. While the V16 engine market is niche, the broader custom exhaust tuning sector remains competitive, with both established automotive manufacturers and specialized aftermarket companies vying for market share.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to custom exhaust tuning for V16 engines focuses on a combination of passive and active technologies. Their system employs variable-length exhaust runners that can adjust the effective length of the exhaust path to optimize gas flow dynamics at different engine speeds[2]. This is complemented by electronically controlled exhaust flaps that can alter the exhaust flow path and back pressure. BMW has also developed a unique resonator system that can be tuned to enhance specific frequency ranges of the exhaust note, allowing for a customizable auditory experience[4]. Their exhaust tuning solution is integrated with the engine's valve timing system, enabling precise control over exhaust pulse timing to maximize scavenging effects and minimize pumping losses.

Strengths: Balanced approach combining passive and active technologies, focus on both performance and sound quality. Weaknesses: May not offer the same level of fine control as fully active systems, potential weight increase due to mechanical components.

AVL List GmbH

Technical Solution: AVL's approach to custom exhaust tuning for V16 engines leverages their extensive experience in powertrain development and testing. Their system utilizes advanced computational fluid dynamics (CFD) modeling to optimize exhaust manifold design and flow characteristics[9]. AVL has developed a proprietary exhaust pulse control technology that can manipulate the timing and shape of exhaust pressure waves to enhance scavenging and reduce pumping losses. This is combined with an active exhaust valve system that can adjust exhaust back pressure in real-time based on engine load and speed. AVL's solution also incorporates advanced materials and coatings to manage exhaust temperatures and reduce thermal expansion, ensuring consistent performance across a wide operating range. Their exhaust tuning system is designed to work in conjunction with their engine development tools, allowing for rapid prototyping and optimization of exhaust configurations[10].

Strengths: Highly optimized system based on advanced modeling and testing capabilities, integrated approach to powertrain development. Weaknesses: May require significant customization for each specific V16 engine application, potentially higher initial development costs.

Key Innovations in V16 Exhaust Technology

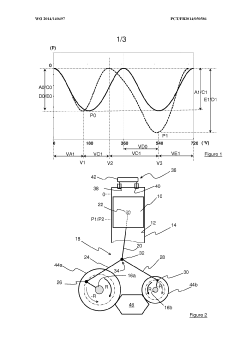

Method for controlling the progress of an operating cycle of an internal combustion engine with an extended expansion phase

PatentWO2014140497A1

Innovation

- A method for controlling the engine cycle by reversing the direction of rotation of the crankshafts and adjusting the phase shift between them, along with a variable valve timing system, to enhance piston speed and reduce the expansion phase duration, thereby optimizing energy recovery and reducing heat losses.

Environmental Impact of V16 Exhaust Systems

The environmental impact of V16 exhaust systems is a critical consideration in the context of custom exhaust tuning and engine performance. These large, powerful engines are known for their significant emissions and noise pollution, which have far-reaching consequences for both local and global environments.

V16 engines, due to their size and power output, typically produce higher levels of carbon dioxide (CO2) emissions compared to smaller engines. This contributes to the overall greenhouse gas effect and climate change concerns. Additionally, these engines often emit higher levels of nitrogen oxides (NOx) and particulate matter, which can lead to local air quality issues and potential health risks for nearby populations.

Custom exhaust tuning, while primarily focused on enhancing engine performance, can have both positive and negative effects on environmental impact. On one hand, well-designed exhaust systems can improve engine efficiency, potentially reducing fuel consumption and emissions. Advanced catalytic converters and particulate filters can be integrated into custom exhaust systems to mitigate harmful emissions.

However, some performance-oriented modifications may prioritize power gains over environmental considerations. Removing or modifying emission control devices, such as catalytic converters, can significantly increase pollutant emissions. Furthermore, alterations that increase exhaust noise can contribute to noise pollution, affecting both urban and natural environments.

The regulatory landscape surrounding V16 exhaust systems is becoming increasingly stringent. Many countries and regions are implementing stricter emission standards and noise regulations, which directly impact the design and operation of these high-performance engines. Manufacturers and tuners must navigate these regulations while striving to meet performance goals.

Emerging technologies in exhaust system design offer promising solutions for reducing environmental impact. Advanced materials and manufacturing techniques allow for the creation of more efficient exhaust systems that can better manage heat, reduce backpressure, and improve overall engine performance while still meeting emission standards. Additionally, active noise cancellation technologies are being developed to address noise pollution concerns without compromising on performance.

As environmental awareness grows, there is an increasing focus on sustainable practices in high-performance engine design. This includes exploring alternative fuels, hybrid technologies, and even fully electric powertrains that could potentially replace traditional V16 engines in certain applications. The challenge lies in balancing the desire for high performance with the need for environmental responsibility.

V16 engines, due to their size and power output, typically produce higher levels of carbon dioxide (CO2) emissions compared to smaller engines. This contributes to the overall greenhouse gas effect and climate change concerns. Additionally, these engines often emit higher levels of nitrogen oxides (NOx) and particulate matter, which can lead to local air quality issues and potential health risks for nearby populations.

Custom exhaust tuning, while primarily focused on enhancing engine performance, can have both positive and negative effects on environmental impact. On one hand, well-designed exhaust systems can improve engine efficiency, potentially reducing fuel consumption and emissions. Advanced catalytic converters and particulate filters can be integrated into custom exhaust systems to mitigate harmful emissions.

However, some performance-oriented modifications may prioritize power gains over environmental considerations. Removing or modifying emission control devices, such as catalytic converters, can significantly increase pollutant emissions. Furthermore, alterations that increase exhaust noise can contribute to noise pollution, affecting both urban and natural environments.

The regulatory landscape surrounding V16 exhaust systems is becoming increasingly stringent. Many countries and regions are implementing stricter emission standards and noise regulations, which directly impact the design and operation of these high-performance engines. Manufacturers and tuners must navigate these regulations while striving to meet performance goals.

Emerging technologies in exhaust system design offer promising solutions for reducing environmental impact. Advanced materials and manufacturing techniques allow for the creation of more efficient exhaust systems that can better manage heat, reduce backpressure, and improve overall engine performance while still meeting emission standards. Additionally, active noise cancellation technologies are being developed to address noise pollution concerns without compromising on performance.

As environmental awareness grows, there is an increasing focus on sustainable practices in high-performance engine design. This includes exploring alternative fuels, hybrid technologies, and even fully electric powertrains that could potentially replace traditional V16 engines in certain applications. The challenge lies in balancing the desire for high performance with the need for environmental responsibility.

Noise Regulations for High-Performance Engines

Noise regulations for high-performance engines have become increasingly stringent in recent years, posing significant challenges for manufacturers and enthusiasts of V16 engines. These regulations aim to mitigate the environmental impact and noise pollution associated with powerful engines, particularly in urban areas and motorsports events.

The primary focus of these regulations is to limit the maximum noise levels produced by high-performance engines, including V16 configurations. Typically, noise limits are measured in decibels (dB) and vary depending on the specific application and jurisdiction. For instance, many racing series impose strict noise limits, often ranging from 95 to 110 dB, measured at a specified distance from the vehicle.

To comply with these regulations, manufacturers and tuners must implement various noise reduction techniques in their exhaust systems. One common approach is the use of multi-chamber mufflers, which utilize a series of expansion chambers and baffles to reduce exhaust noise. These mufflers are designed to attenuate specific frequencies while minimizing the impact on engine performance.

Another technique employed is the integration of active noise control systems. These systems use electronic sensors and actuators to generate sound waves that cancel out unwanted exhaust noise. While effective, this approach can be complex and expensive to implement, particularly for aftermarket applications.

Exhaust valve control systems have also gained popularity as a means of managing noise levels. These systems allow for variable exhaust flow, effectively reducing noise at lower engine speeds or when operating in noise-sensitive areas. However, they can open fully during high-performance driving to maximize engine output.

For V16 engines specifically, the challenge lies in managing the exhaust pulses from 16 cylinders while maintaining optimal performance. Custom exhaust tuning often involves carefully designed headers and collectors to balance exhaust scavenging effects with noise reduction requirements. This may include the use of unequal length headers or pulse-separated exhaust systems to optimize both performance and sound characteristics.

Compliance with noise regulations often requires a delicate balance between performance optimization and noise reduction. Manufacturers and tuners must consider factors such as exhaust gas velocity, back pressure, and resonance frequencies when designing exhaust systems for V16 engines. Advanced computer modeling and simulation tools are frequently employed to predict and optimize exhaust system performance within regulatory constraints.

As regulations continue to evolve, the development of innovative noise reduction technologies for high-performance engines remains an active area of research and development. Future advancements may include improved materials for sound absorption, more sophisticated active noise cancellation systems, and novel exhaust design concepts that further enhance the balance between performance and regulatory compliance.

The primary focus of these regulations is to limit the maximum noise levels produced by high-performance engines, including V16 configurations. Typically, noise limits are measured in decibels (dB) and vary depending on the specific application and jurisdiction. For instance, many racing series impose strict noise limits, often ranging from 95 to 110 dB, measured at a specified distance from the vehicle.

To comply with these regulations, manufacturers and tuners must implement various noise reduction techniques in their exhaust systems. One common approach is the use of multi-chamber mufflers, which utilize a series of expansion chambers and baffles to reduce exhaust noise. These mufflers are designed to attenuate specific frequencies while minimizing the impact on engine performance.

Another technique employed is the integration of active noise control systems. These systems use electronic sensors and actuators to generate sound waves that cancel out unwanted exhaust noise. While effective, this approach can be complex and expensive to implement, particularly for aftermarket applications.

Exhaust valve control systems have also gained popularity as a means of managing noise levels. These systems allow for variable exhaust flow, effectively reducing noise at lower engine speeds or when operating in noise-sensitive areas. However, they can open fully during high-performance driving to maximize engine output.

For V16 engines specifically, the challenge lies in managing the exhaust pulses from 16 cylinders while maintaining optimal performance. Custom exhaust tuning often involves carefully designed headers and collectors to balance exhaust scavenging effects with noise reduction requirements. This may include the use of unequal length headers or pulse-separated exhaust systems to optimize both performance and sound characteristics.

Compliance with noise regulations often requires a delicate balance between performance optimization and noise reduction. Manufacturers and tuners must consider factors such as exhaust gas velocity, back pressure, and resonance frequencies when designing exhaust systems for V16 engines. Advanced computer modeling and simulation tools are frequently employed to predict and optimize exhaust system performance within regulatory constraints.

As regulations continue to evolve, the development of innovative noise reduction technologies for high-performance engines remains an active area of research and development. Future advancements may include improved materials for sound absorption, more sophisticated active noise cancellation systems, and novel exhaust design concepts that further enhance the balance between performance and regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!