How Ethyl Acetate Contributes to Efficient Waste Management?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Waste Management: Background and Objectives

Ethyl acetate, a versatile organic compound, has emerged as a significant player in the field of waste management. Its unique properties and wide-ranging applications have positioned it as a valuable tool in addressing the growing challenges of waste disposal and environmental sustainability. The evolution of ethyl acetate's role in waste management can be traced back to the increasing global emphasis on sustainable practices and the need for more efficient waste treatment methods.

The primary objective of utilizing ethyl acetate in waste management is to enhance the efficiency and effectiveness of various waste treatment processes. This includes improving solvent extraction techniques, facilitating the separation of organic compounds from waste streams, and contributing to the development of more environmentally friendly cleaning and degreasing solutions. By leveraging ethyl acetate's properties, waste management professionals aim to reduce the environmental impact of waste disposal while simultaneously optimizing resource recovery.

One of the key trends driving the adoption of ethyl acetate in waste management is the growing focus on circular economy principles. As industries and governments worldwide strive to minimize waste generation and maximize resource utilization, ethyl acetate's ability to aid in the recovery and recycling of valuable materials from waste streams has become increasingly important. This aligns with the broader goal of transitioning from linear "take-make-dispose" models to more sustainable, circular approaches to resource management.

The technical evolution of ethyl acetate applications in waste management has been marked by several significant milestones. Early uses primarily focused on its solvent properties for cleaning and degreasing applications. However, as waste management challenges became more complex, researchers and industry professionals began exploring more sophisticated applications. This led to the development of advanced extraction techniques, where ethyl acetate's selective solubility properties could be harnessed to separate and recover specific compounds from complex waste mixtures.

Recent technological advancements have further expanded the potential of ethyl acetate in waste management. Innovations in process engineering have enabled the integration of ethyl acetate-based systems into larger waste treatment facilities, improving overall efficiency and reducing operational costs. Additionally, the development of novel catalysts and reaction pathways has opened up new possibilities for using ethyl acetate in the conversion of waste materials into valuable chemical feedstocks, contributing to the broader goals of waste valorization and resource recovery.

As we look towards the future, the role of ethyl acetate in waste management is expected to continue evolving. Emerging research areas include the exploration of ethyl acetate-based technologies for treating emerging contaminants, such as pharmaceutical residues and microplastics, as well as its potential applications in advanced recycling processes for complex materials like electronic waste. These developments underscore the ongoing importance of ethyl acetate as a key component in the pursuit of more efficient and sustainable waste management solutions.

The primary objective of utilizing ethyl acetate in waste management is to enhance the efficiency and effectiveness of various waste treatment processes. This includes improving solvent extraction techniques, facilitating the separation of organic compounds from waste streams, and contributing to the development of more environmentally friendly cleaning and degreasing solutions. By leveraging ethyl acetate's properties, waste management professionals aim to reduce the environmental impact of waste disposal while simultaneously optimizing resource recovery.

One of the key trends driving the adoption of ethyl acetate in waste management is the growing focus on circular economy principles. As industries and governments worldwide strive to minimize waste generation and maximize resource utilization, ethyl acetate's ability to aid in the recovery and recycling of valuable materials from waste streams has become increasingly important. This aligns with the broader goal of transitioning from linear "take-make-dispose" models to more sustainable, circular approaches to resource management.

The technical evolution of ethyl acetate applications in waste management has been marked by several significant milestones. Early uses primarily focused on its solvent properties for cleaning and degreasing applications. However, as waste management challenges became more complex, researchers and industry professionals began exploring more sophisticated applications. This led to the development of advanced extraction techniques, where ethyl acetate's selective solubility properties could be harnessed to separate and recover specific compounds from complex waste mixtures.

Recent technological advancements have further expanded the potential of ethyl acetate in waste management. Innovations in process engineering have enabled the integration of ethyl acetate-based systems into larger waste treatment facilities, improving overall efficiency and reducing operational costs. Additionally, the development of novel catalysts and reaction pathways has opened up new possibilities for using ethyl acetate in the conversion of waste materials into valuable chemical feedstocks, contributing to the broader goals of waste valorization and resource recovery.

As we look towards the future, the role of ethyl acetate in waste management is expected to continue evolving. Emerging research areas include the exploration of ethyl acetate-based technologies for treating emerging contaminants, such as pharmaceutical residues and microplastics, as well as its potential applications in advanced recycling processes for complex materials like electronic waste. These developments underscore the ongoing importance of ethyl acetate as a key component in the pursuit of more efficient and sustainable waste management solutions.

Market Demand for Eco-friendly Waste Management Solutions

The global market for eco-friendly waste management solutions has been experiencing significant growth in recent years, driven by increasing environmental awareness, stringent regulations, and the need for sustainable practices. The demand for innovative technologies that can efficiently handle waste while minimizing environmental impact is on the rise across various industries and sectors.

In the context of ethyl acetate's contribution to efficient waste management, there is a growing interest in its potential applications. Ethyl acetate, a versatile organic compound, has shown promise in several waste management processes, particularly in the treatment of organic waste and the recovery of valuable materials from waste streams.

The pharmaceutical and chemical industries have been at the forefront of adopting ethyl acetate-based waste management solutions. These sectors generate substantial amounts of organic waste and by-products, which can be effectively treated using ethyl acetate as a solvent or extraction medium. The ability of ethyl acetate to selectively dissolve and separate organic compounds makes it an attractive option for waste reduction and resource recovery.

Additionally, the food and beverage industry has shown increasing demand for eco-friendly waste management solutions involving ethyl acetate. As a naturally occurring compound in many fruits and vegetables, ethyl acetate is considered a green solvent for extracting valuable components from food waste. This aligns with the growing trend of circular economy practices in the food industry, where waste reduction and resource recovery are becoming paramount.

The electronics and semiconductor industries are also exploring the potential of ethyl acetate in managing electronic waste. Its ability to dissolve certain polymers and resins makes it useful in the recycling and recovery of precious metals and other materials from discarded electronic devices.

Municipal waste management authorities are increasingly looking for innovative solutions to handle organic waste more efficiently. Ethyl acetate-based processes for composting and biogas production are gaining attention as potential alternatives to traditional methods, offering improved efficiency and reduced environmental impact.

The market demand for eco-friendly waste management solutions utilizing ethyl acetate is further bolstered by the push for sustainable development goals and corporate social responsibility initiatives. Companies across various sectors are actively seeking ways to reduce their environmental footprint and improve their waste management practices, creating opportunities for technologies that leverage ethyl acetate's properties.

As awareness of the circular economy concept grows, there is an increasing focus on developing closed-loop systems where waste is minimized, and resources are recovered and reused. Ethyl acetate's role in such systems is gaining recognition, particularly in industries where organic waste and by-products are prevalent.

In the context of ethyl acetate's contribution to efficient waste management, there is a growing interest in its potential applications. Ethyl acetate, a versatile organic compound, has shown promise in several waste management processes, particularly in the treatment of organic waste and the recovery of valuable materials from waste streams.

The pharmaceutical and chemical industries have been at the forefront of adopting ethyl acetate-based waste management solutions. These sectors generate substantial amounts of organic waste and by-products, which can be effectively treated using ethyl acetate as a solvent or extraction medium. The ability of ethyl acetate to selectively dissolve and separate organic compounds makes it an attractive option for waste reduction and resource recovery.

Additionally, the food and beverage industry has shown increasing demand for eco-friendly waste management solutions involving ethyl acetate. As a naturally occurring compound in many fruits and vegetables, ethyl acetate is considered a green solvent for extracting valuable components from food waste. This aligns with the growing trend of circular economy practices in the food industry, where waste reduction and resource recovery are becoming paramount.

The electronics and semiconductor industries are also exploring the potential of ethyl acetate in managing electronic waste. Its ability to dissolve certain polymers and resins makes it useful in the recycling and recovery of precious metals and other materials from discarded electronic devices.

Municipal waste management authorities are increasingly looking for innovative solutions to handle organic waste more efficiently. Ethyl acetate-based processes for composting and biogas production are gaining attention as potential alternatives to traditional methods, offering improved efficiency and reduced environmental impact.

The market demand for eco-friendly waste management solutions utilizing ethyl acetate is further bolstered by the push for sustainable development goals and corporate social responsibility initiatives. Companies across various sectors are actively seeking ways to reduce their environmental footprint and improve their waste management practices, creating opportunities for technologies that leverage ethyl acetate's properties.

As awareness of the circular economy concept grows, there is an increasing focus on developing closed-loop systems where waste is minimized, and resources are recovered and reused. Ethyl acetate's role in such systems is gaining recognition, particularly in industries where organic waste and by-products are prevalent.

Current State and Challenges in Ethyl Acetate-based Waste Treatment

The current state of ethyl acetate-based waste treatment is characterized by a growing recognition of its potential in efficient waste management. Ethyl acetate, a versatile organic compound, has gained attention for its ability to dissolve a wide range of organic materials, making it valuable in waste treatment processes. Its low toxicity and biodegradability contribute to its appeal as an environmentally friendly solvent.

In industrial applications, ethyl acetate is increasingly used in waste treatment systems, particularly for the removal of organic contaminants from wastewater and industrial effluents. Its effectiveness in dissolving oils, greases, and other organic compounds allows for efficient separation and recovery of these materials from waste streams. This property is especially beneficial in industries such as pharmaceuticals, paints, and coatings, where organic waste is prevalent.

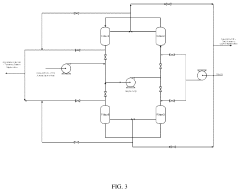

One of the key advantages of ethyl acetate in waste management is its recyclability. Advanced distillation and recovery systems have been developed to reclaim used ethyl acetate, reducing overall waste and making the process more economically viable. This closed-loop approach aligns well with circular economy principles, minimizing resource consumption and environmental impact.

However, the widespread adoption of ethyl acetate-based waste treatment faces several challenges. The primary concern is the initial cost of implementing ethyl acetate recovery systems, which can be substantial for smaller operations. Additionally, the energy requirements for the distillation and purification processes can be significant, potentially offsetting some of the environmental benefits.

Another challenge lies in the handling and storage of ethyl acetate. As a flammable solvent, it requires careful management and appropriate safety measures, which can increase operational complexity and costs. Furthermore, while ethyl acetate is less toxic than many alternative solvents, prolonged exposure can still pose health risks, necessitating robust occupational safety protocols.

The regulatory landscape surrounding ethyl acetate use in waste treatment is evolving. While its environmental profile is generally favorable, varying regulations across different regions can complicate its adoption in global waste management strategies. Harmonizing these regulations and establishing clear guidelines for its use in waste treatment remain ongoing challenges.

Research is ongoing to address these challenges and enhance the efficiency of ethyl acetate-based waste treatment. Current efforts focus on developing more energy-efficient recovery processes, improving safety in handling and storage, and exploring novel applications in waste management. As these challenges are addressed, ethyl acetate is poised to play an increasingly important role in sustainable waste management practices.

In industrial applications, ethyl acetate is increasingly used in waste treatment systems, particularly for the removal of organic contaminants from wastewater and industrial effluents. Its effectiveness in dissolving oils, greases, and other organic compounds allows for efficient separation and recovery of these materials from waste streams. This property is especially beneficial in industries such as pharmaceuticals, paints, and coatings, where organic waste is prevalent.

One of the key advantages of ethyl acetate in waste management is its recyclability. Advanced distillation and recovery systems have been developed to reclaim used ethyl acetate, reducing overall waste and making the process more economically viable. This closed-loop approach aligns well with circular economy principles, minimizing resource consumption and environmental impact.

However, the widespread adoption of ethyl acetate-based waste treatment faces several challenges. The primary concern is the initial cost of implementing ethyl acetate recovery systems, which can be substantial for smaller operations. Additionally, the energy requirements for the distillation and purification processes can be significant, potentially offsetting some of the environmental benefits.

Another challenge lies in the handling and storage of ethyl acetate. As a flammable solvent, it requires careful management and appropriate safety measures, which can increase operational complexity and costs. Furthermore, while ethyl acetate is less toxic than many alternative solvents, prolonged exposure can still pose health risks, necessitating robust occupational safety protocols.

The regulatory landscape surrounding ethyl acetate use in waste treatment is evolving. While its environmental profile is generally favorable, varying regulations across different regions can complicate its adoption in global waste management strategies. Harmonizing these regulations and establishing clear guidelines for its use in waste treatment remain ongoing challenges.

Research is ongoing to address these challenges and enhance the efficiency of ethyl acetate-based waste treatment. Current efforts focus on developing more energy-efficient recovery processes, improving safety in handling and storage, and exploring novel applications in waste management. As these challenges are addressed, ethyl acetate is poised to play an increasingly important role in sustainable waste management practices.

Existing Ethyl Acetate-based Waste Treatment Methods

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The production methods aim to optimize the synthesis of ethyl acetate from ethanol and acetic acid or other precursors.- Production methods for ethyl acetate: Various methods are employed for the production of ethyl acetate, including esterification of ethanol and acetic acid, dehydrogenation of ethanol, and catalytic processes. These methods often involve specific reaction conditions, catalysts, and purification steps to obtain high-quality ethyl acetate.

- Purification and separation techniques: Purification and separation of ethyl acetate from reaction mixtures or other compounds involve techniques such as distillation, extraction, and membrane separation. These processes aim to improve the purity and yield of ethyl acetate for various industrial applications.

- Applications in chemical processes: Ethyl acetate finds extensive use in various chemical processes as a solvent, reactant, or intermediate. It is utilized in the production of pharmaceuticals, polymers, and other organic compounds, showcasing its versatility in industrial chemistry.

- Environmental and safety considerations: The production and use of ethyl acetate involve environmental and safety considerations. Efforts are made to develop eco-friendly production methods, reduce emissions, and implement safety measures in handling and storage to minimize risks associated with its flammability and potential health effects.

- Novel catalysts and process improvements: Research focuses on developing novel catalysts and improving existing processes for ethyl acetate production. These advancements aim to enhance reaction efficiency, selectivity, and yield while reducing energy consumption and waste generation in industrial-scale manufacturing.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes as a solvent, reactant, or intermediate. It finds applications in the production of pharmaceuticals, polymers, and other organic compounds. The versatility of ethyl acetate in different chemical reactions and industrial processes is highlighted.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

The use of ethyl acetate as an extraction solvent or in separation processes is described. It is employed in liquid-liquid extraction, azeotropic distillation, and other separation techniques. The effectiveness of ethyl acetate in isolating specific compounds from mixtures is emphasized.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Methods for handling, storing, and disposing of ethyl acetate safely are discussed. This includes techniques for reducing emissions, recovering ethyl acetate from waste streams, and ensuring worker safety when using the compound. Environmental impact assessments and safety protocols for ethyl acetate usage are also addressed.Expand Specific Solutions05 Novel derivatives and modifications of ethyl acetate

Research on developing new derivatives or modified forms of ethyl acetate is presented. This includes the synthesis of ethyl acetate-based compounds with enhanced properties, such as improved stability or reactivity. The potential applications of these novel ethyl acetate derivatives in various industries are explored.Expand Specific Solutions

Key Players in Ethyl Acetate and Waste Management Industries

The ethyl acetate market for waste management is in a growth phase, driven by increasing environmental regulations and sustainability initiatives. The market size is expanding as more industries adopt eco-friendly solvents. Technologically, ethyl acetate production is mature, with established players like Wacker Chemie AG and Eastman Chemical Co. leading innovation. Emerging companies such as Viridis Chemical LLC are focusing on bio-based ethyl acetate, indicating a shift towards more sustainable production methods. The involvement of research institutions like South China University of Technology and Zhejiang University suggests ongoing efforts to improve efficiency and explore new applications in waste management.

China Petroleum & Chemical Corp.

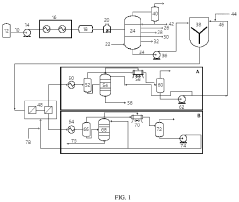

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to utilize ethyl acetate in waste management. Their process involves using ethyl acetate as a solvent in the extraction and recovery of valuable compounds from industrial waste streams. The company has implemented a closed-loop system where ethyl acetate is continuously recycled, minimizing waste generation. This method has shown to be particularly effective in treating organic waste from petrochemical and pharmaceutical industries[1]. Sinopec's technology allows for the recovery of up to 98% of the ethyl acetate used in the process, significantly reducing the environmental impact and operational costs[3]. The recovered compounds are then repurposed or safely disposed of, contributing to a more circular economy approach in waste management.

Strengths: High efficiency in compound recovery, significant reduction in waste generation, and cost-effective due to solvent recycling. Weaknesses: May require high initial investment for implementation and specialized handling due to the flammable nature of ethyl acetate.

Viridis Chemical LLC

Technical Solution: Viridis Chemical LLC has developed a cutting-edge approach to waste management utilizing ethyl acetate. Their technology focuses on the production of bio-based ethyl acetate from renewable feedstocks, which is then used in various waste treatment applications. The company's process involves fermenting agricultural waste to produce ethanol, which is subsequently converted to ethyl acetate through esterification[7]. This bio-based ethyl acetate is then employed in a novel waste treatment system that targets the removal of organic pollutants from industrial wastewater. The process uses ethyl acetate in a liquid-liquid extraction step, effectively separating harmful organic compounds from the water phase. The extracted pollutants are then further processed or safely disposed of, while the ethyl acetate is recovered and reused. Viridis Chemical's system has demonstrated removal efficiencies of up to 95% for a wide range of organic contaminants, including those typically resistant to conventional treatment methods[8].

Strengths: Utilizes renewable resources, reduces dependency on petroleum-based chemicals, and offers an effective solution for treating recalcitrant organic pollutants. Weaknesses: May face challenges in scaling up production to meet large-scale waste management needs, and potential competition from established petrochemical-based processes.

Core Innovations in Ethyl Acetate Waste Management Technologies

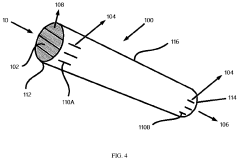

Method for removing asphaltenes, resins and heavy metals from crude oil

PatentPendingUS20230407188A1

Innovation

- The use of ethyl acetate as a solvent at ambient temperatures and pressures to precipitate asphaltenes, resins, and heavy metals in a single step, with a solvent-to-feed ratio that is less than conventional methods, allowing for efficient recovery and recycling of the solvent.

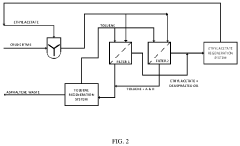

Process of low energy consumption for preparing a carboxylic acid ester

PatentWO2012123279A1

Innovation

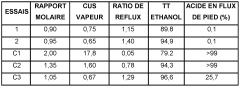

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a centrally placed reaction zone between upper and lower separation zones, optimizing the molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and controlling the reflux ratio between 1.0 and 1.5, significantly reduces energy costs and minimizes acetic acid at the column bottom.

Environmental Impact Assessment of Ethyl Acetate Use

The environmental impact assessment of ethyl acetate use in waste management reveals both positive and negative effects on ecosystems and human health. Ethyl acetate, a widely used organic solvent, plays a significant role in various industrial processes and waste treatment applications.

One of the primary environmental benefits of ethyl acetate in waste management is its biodegradability. Unlike many other solvents, ethyl acetate readily breaks down in the environment, reducing long-term pollution risks. This characteristic makes it a preferred choice for industries seeking to minimize their ecological footprint. Additionally, ethyl acetate's low toxicity compared to alternative solvents contributes to reduced environmental hazards during handling and disposal processes.

However, the production and use of ethyl acetate are not without environmental concerns. The manufacturing process of ethyl acetate involves the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. Furthermore, improper handling or accidental releases of ethyl acetate can lead to short-term air and water pollution, potentially affecting local ecosystems and human health.

In terms of waste management efficiency, ethyl acetate's solvent properties enable effective extraction and separation of various compounds from waste streams. This capability enhances the recovery of valuable materials and improves the overall efficiency of waste treatment processes. The use of ethyl acetate in waste management can lead to reduced energy consumption and lower volumes of residual waste, thereby minimizing the environmental impact of disposal activities.

Atmospheric emissions from ethyl acetate use in waste management facilities require careful consideration. While ethyl acetate has a relatively low global warming potential, its volatile organic compound (VOC) nature can contribute to the formation of ground-level ozone and photochemical smog under certain conditions. Proper ventilation and emission control systems are essential to mitigate these potential air quality impacts.

Water pollution risks associated with ethyl acetate use in waste management are generally low due to its high volatility and biodegradability. However, large-scale spills or continuous low-level releases into aquatic environments can temporarily disrupt ecosystems and affect water quality. Implementing robust containment measures and wastewater treatment protocols is crucial to prevent such incidents and protect water resources.

The life cycle assessment of ethyl acetate in waste management applications indicates a net positive environmental impact when used responsibly. Its ability to enhance resource recovery, coupled with its biodegradability, often outweighs the environmental costs associated with its production and potential emissions. However, continuous monitoring and improvement of handling practices are necessary to maximize the environmental benefits and minimize potential risks.

One of the primary environmental benefits of ethyl acetate in waste management is its biodegradability. Unlike many other solvents, ethyl acetate readily breaks down in the environment, reducing long-term pollution risks. This characteristic makes it a preferred choice for industries seeking to minimize their ecological footprint. Additionally, ethyl acetate's low toxicity compared to alternative solvents contributes to reduced environmental hazards during handling and disposal processes.

However, the production and use of ethyl acetate are not without environmental concerns. The manufacturing process of ethyl acetate involves the use of fossil fuel-derived raw materials, contributing to carbon emissions and resource depletion. Furthermore, improper handling or accidental releases of ethyl acetate can lead to short-term air and water pollution, potentially affecting local ecosystems and human health.

In terms of waste management efficiency, ethyl acetate's solvent properties enable effective extraction and separation of various compounds from waste streams. This capability enhances the recovery of valuable materials and improves the overall efficiency of waste treatment processes. The use of ethyl acetate in waste management can lead to reduced energy consumption and lower volumes of residual waste, thereby minimizing the environmental impact of disposal activities.

Atmospheric emissions from ethyl acetate use in waste management facilities require careful consideration. While ethyl acetate has a relatively low global warming potential, its volatile organic compound (VOC) nature can contribute to the formation of ground-level ozone and photochemical smog under certain conditions. Proper ventilation and emission control systems are essential to mitigate these potential air quality impacts.

Water pollution risks associated with ethyl acetate use in waste management are generally low due to its high volatility and biodegradability. However, large-scale spills or continuous low-level releases into aquatic environments can temporarily disrupt ecosystems and affect water quality. Implementing robust containment measures and wastewater treatment protocols is crucial to prevent such incidents and protect water resources.

The life cycle assessment of ethyl acetate in waste management applications indicates a net positive environmental impact when used responsibly. Its ability to enhance resource recovery, coupled with its biodegradability, often outweighs the environmental costs associated with its production and potential emissions. However, continuous monitoring and improvement of handling practices are necessary to maximize the environmental benefits and minimize potential risks.

Regulatory Framework for Chemical Use in Waste Management

The regulatory framework for chemical use in waste management plays a crucial role in ensuring the safe and responsible handling of substances like ethyl acetate. In the context of waste management, regulations govern the storage, transportation, and disposal of chemical waste, including solvents such as ethyl acetate.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the management of hazardous waste across borders. This convention influences national policies and regulations regarding the handling of chemical waste, including ethyl acetate-containing waste streams.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of chemical waste management under the Resource Conservation and Recovery Act (RCRA). The RCRA establishes a framework for the proper management of hazardous waste from cradle to grave, including specific requirements for the handling of solvents like ethyl acetate.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the Classification, Labeling, and Packaging (CLP) regulation provide comprehensive guidelines for chemical management, including waste handling. These regulations ensure that chemicals used in waste management processes are properly assessed for their environmental and health impacts.

Many countries have implemented their own regulatory frameworks aligned with international standards. For instance, China's Measures for the Administration of Hazardous Waste Transfer Manifests and Japan's Waste Management and Public Cleansing Law provide specific guidelines for managing chemical waste, including solvents used in industrial processes.

Regulatory bodies often require proper labeling, documentation, and tracking of chemical waste throughout its lifecycle. This includes maintaining detailed records of waste generation, storage, transportation, and disposal. Facilities handling ethyl acetate waste must often obtain permits and undergo regular inspections to ensure compliance with environmental regulations.

The regulatory framework also addresses the recycling and recovery of solvents like ethyl acetate. Many jurisdictions encourage or mandate the recycling of solvents when feasible, promoting circular economy principles in waste management. This aspect of regulation supports the efficient use of resources and minimizes environmental impact.

As environmental concerns grow, regulatory frameworks are evolving to incorporate more stringent requirements for chemical waste management. This includes increased focus on emission controls, worker safety, and the development of cleaner technologies for waste treatment and disposal.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the management of hazardous waste across borders. This convention influences national policies and regulations regarding the handling of chemical waste, including ethyl acetate-containing waste streams.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of chemical waste management under the Resource Conservation and Recovery Act (RCRA). The RCRA establishes a framework for the proper management of hazardous waste from cradle to grave, including specific requirements for the handling of solvents like ethyl acetate.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the Classification, Labeling, and Packaging (CLP) regulation provide comprehensive guidelines for chemical management, including waste handling. These regulations ensure that chemicals used in waste management processes are properly assessed for their environmental and health impacts.

Many countries have implemented their own regulatory frameworks aligned with international standards. For instance, China's Measures for the Administration of Hazardous Waste Transfer Manifests and Japan's Waste Management and Public Cleansing Law provide specific guidelines for managing chemical waste, including solvents used in industrial processes.

Regulatory bodies often require proper labeling, documentation, and tracking of chemical waste throughout its lifecycle. This includes maintaining detailed records of waste generation, storage, transportation, and disposal. Facilities handling ethyl acetate waste must often obtain permits and undergo regular inspections to ensure compliance with environmental regulations.

The regulatory framework also addresses the recycling and recovery of solvents like ethyl acetate. Many jurisdictions encourage or mandate the recycling of solvents when feasible, promoting circular economy principles in waste management. This aspect of regulation supports the efficient use of resources and minimizes environmental impact.

As environmental concerns grow, regulatory frameworks are evolving to incorporate more stringent requirements for chemical waste management. This includes increased focus on emission controls, worker safety, and the development of cleaner technologies for waste treatment and disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!