How fiber optics improve induction motor data communication

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fiber Optics in Motor Communication: Background and Objectives

Fiber optic technology has revolutionized data communication across various industries, and its application in induction motor systems represents a significant advancement in industrial automation. The evolution of fiber optics in motor communication can be traced back to the late 20th century when the need for faster, more reliable data transmission became paramount in industrial settings.

Traditionally, induction motors relied on copper wire-based communication systems, which were susceptible to electromagnetic interference (EMI) and had limitations in terms of data transmission speed and distance. As industrial processes became more complex and demanding, the need for a more robust communication solution became evident. Fiber optics emerged as a promising alternative, offering superior performance characteristics that address many of the challenges faced by conventional systems.

The primary objective of integrating fiber optics into induction motor communication is to enhance the overall efficiency, reliability, and performance of motor control systems. By leveraging the unique properties of light transmission through optical fibers, this technology aims to overcome the limitations of traditional copper-based communication methods. Specifically, fiber optic systems seek to improve data transmission speeds, reduce signal degradation over long distances, and eliminate electromagnetic interference issues that often plague industrial environments.

Furthermore, the adoption of fiber optics in motor communication aligns with the broader trend of industrial digitalization and the implementation of Industry 4.0 principles. As manufacturing processes become increasingly automated and data-driven, the need for high-speed, high-bandwidth communication between motors, controllers, and other industrial equipment has grown exponentially. Fiber optic technology is well-positioned to meet these demands, offering the potential for real-time monitoring, precise control, and advanced diagnostics of induction motors.

The technological trajectory of fiber optics in motor communication has been marked by continuous improvements in fiber manufacturing, light source technologies, and signal processing techniques. From early multimode fibers to advanced single-mode fibers, and from simple LED light sources to sophisticated laser diodes, each advancement has contributed to the increasing viability of fiber optic systems in industrial applications. The ongoing research and development in this field aim to further enhance the performance, reduce costs, and expand the applicability of fiber optic communication in motor control systems.

As we delve deeper into the current state of fiber optic technology in induction motor communication, it becomes clear that this field represents a convergence of optical physics, electrical engineering, and industrial automation. The potential benefits of this technology extend beyond mere improvements in data transmission, promising to enable new paradigms in motor control, energy efficiency, and predictive maintenance. Understanding the background and objectives of fiber optics in motor communication sets the stage for a comprehensive exploration of its technical aspects, market dynamics, and future prospects.

Traditionally, induction motors relied on copper wire-based communication systems, which were susceptible to electromagnetic interference (EMI) and had limitations in terms of data transmission speed and distance. As industrial processes became more complex and demanding, the need for a more robust communication solution became evident. Fiber optics emerged as a promising alternative, offering superior performance characteristics that address many of the challenges faced by conventional systems.

The primary objective of integrating fiber optics into induction motor communication is to enhance the overall efficiency, reliability, and performance of motor control systems. By leveraging the unique properties of light transmission through optical fibers, this technology aims to overcome the limitations of traditional copper-based communication methods. Specifically, fiber optic systems seek to improve data transmission speeds, reduce signal degradation over long distances, and eliminate electromagnetic interference issues that often plague industrial environments.

Furthermore, the adoption of fiber optics in motor communication aligns with the broader trend of industrial digitalization and the implementation of Industry 4.0 principles. As manufacturing processes become increasingly automated and data-driven, the need for high-speed, high-bandwidth communication between motors, controllers, and other industrial equipment has grown exponentially. Fiber optic technology is well-positioned to meet these demands, offering the potential for real-time monitoring, precise control, and advanced diagnostics of induction motors.

The technological trajectory of fiber optics in motor communication has been marked by continuous improvements in fiber manufacturing, light source technologies, and signal processing techniques. From early multimode fibers to advanced single-mode fibers, and from simple LED light sources to sophisticated laser diodes, each advancement has contributed to the increasing viability of fiber optic systems in industrial applications. The ongoing research and development in this field aim to further enhance the performance, reduce costs, and expand the applicability of fiber optic communication in motor control systems.

As we delve deeper into the current state of fiber optic technology in induction motor communication, it becomes clear that this field represents a convergence of optical physics, electrical engineering, and industrial automation. The potential benefits of this technology extend beyond mere improvements in data transmission, promising to enable new paradigms in motor control, energy efficiency, and predictive maintenance. Understanding the background and objectives of fiber optics in motor communication sets the stage for a comprehensive exploration of its technical aspects, market dynamics, and future prospects.

Market Demand for Advanced Motor Data Communication

The market demand for advanced motor data communication, particularly in the context of induction motors, has been steadily increasing due to the growing emphasis on industrial automation, energy efficiency, and predictive maintenance. As industries strive for greater operational efficiency and reduced downtime, the need for real-time, accurate, and reliable data from induction motors has become paramount.

Fiber optic technology has emerged as a promising solution to meet these evolving market demands. Traditional communication methods, such as copper wiring, often face limitations in industrial environments due to electromagnetic interference, signal degradation over long distances, and susceptibility to harsh conditions. Fiber optics, on the other hand, offer several advantages that align well with the requirements of modern industrial settings.

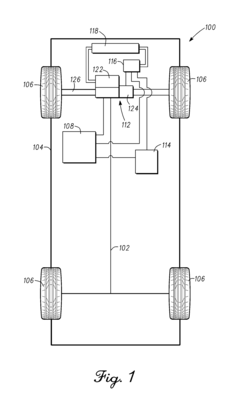

The automotive industry, for instance, has shown significant interest in fiber optic solutions for motor data communication. With the increasing electrification of vehicles and the need for more sophisticated control systems, fiber optics provide the high-speed, low-latency data transmission required for optimal motor performance and efficiency. This trend is expected to drive substantial market growth in the coming years.

Similarly, the renewable energy sector, particularly wind turbines, has been adopting fiber optic technology for motor monitoring and control. The ability of fiber optics to transmit data over long distances without signal degradation makes it ideal for large wind farms where motors are often located in remote or offshore locations.

In the manufacturing sector, the demand for advanced motor data communication is driven by the push towards Industry 4.0 and smart factories. Real-time monitoring of motor performance, early fault detection, and predictive maintenance are critical for minimizing production disruptions and optimizing energy consumption. Fiber optic technology enables the high-bandwidth, low-latency communication necessary for these applications.

The oil and gas industry, known for its harsh operating environments, has also shown increasing interest in fiber optic solutions for motor data communication. The technology's resistance to electromagnetic interference and ability to operate in extreme temperatures make it well-suited for use in drilling operations and offshore platforms.

As the Industrial Internet of Things (IIoT) continues to expand, the demand for advanced motor data communication is expected to grow further. Fiber optics play a crucial role in enabling the high-speed, reliable data transmission required for IIoT applications, driving adoption across various industrial sectors.

The market potential for fiber optic solutions in motor data communication is substantial, with analysts projecting significant growth in the coming years. This growth is fueled by the increasing awareness of the technology's benefits, ongoing industrial digitalization efforts, and the need for more efficient and reliable motor control systems across various industries.

Fiber optic technology has emerged as a promising solution to meet these evolving market demands. Traditional communication methods, such as copper wiring, often face limitations in industrial environments due to electromagnetic interference, signal degradation over long distances, and susceptibility to harsh conditions. Fiber optics, on the other hand, offer several advantages that align well with the requirements of modern industrial settings.

The automotive industry, for instance, has shown significant interest in fiber optic solutions for motor data communication. With the increasing electrification of vehicles and the need for more sophisticated control systems, fiber optics provide the high-speed, low-latency data transmission required for optimal motor performance and efficiency. This trend is expected to drive substantial market growth in the coming years.

Similarly, the renewable energy sector, particularly wind turbines, has been adopting fiber optic technology for motor monitoring and control. The ability of fiber optics to transmit data over long distances without signal degradation makes it ideal for large wind farms where motors are often located in remote or offshore locations.

In the manufacturing sector, the demand for advanced motor data communication is driven by the push towards Industry 4.0 and smart factories. Real-time monitoring of motor performance, early fault detection, and predictive maintenance are critical for minimizing production disruptions and optimizing energy consumption. Fiber optic technology enables the high-bandwidth, low-latency communication necessary for these applications.

The oil and gas industry, known for its harsh operating environments, has also shown increasing interest in fiber optic solutions for motor data communication. The technology's resistance to electromagnetic interference and ability to operate in extreme temperatures make it well-suited for use in drilling operations and offshore platforms.

As the Industrial Internet of Things (IIoT) continues to expand, the demand for advanced motor data communication is expected to grow further. Fiber optics play a crucial role in enabling the high-speed, reliable data transmission required for IIoT applications, driving adoption across various industrial sectors.

The market potential for fiber optic solutions in motor data communication is substantial, with analysts projecting significant growth in the coming years. This growth is fueled by the increasing awareness of the technology's benefits, ongoing industrial digitalization efforts, and the need for more efficient and reliable motor control systems across various industries.

Current Challenges in Induction Motor Data Transmission

Induction motors are widely used in industrial applications, but their data communication systems face several challenges that hinder optimal performance and monitoring. One of the primary issues is the electromagnetic interference (EMI) generated by the motor itself, which can significantly affect the quality and reliability of data transmission. This interference can lead to signal distortion, data loss, and reduced communication range.

Another challenge is the harsh operating environment of induction motors, which often includes high temperatures, vibrations, and exposure to various contaminants. These conditions can degrade traditional copper-based communication systems over time, leading to increased maintenance costs and potential system failures.

The limited bandwidth of conventional wired communication systems also poses a significant challenge, especially in applications requiring real-time monitoring and control. As the demand for more sophisticated motor control and diagnostics increases, the need for higher data transmission rates becomes crucial.

Furthermore, the physical constraints of installing and maintaining wired communication systems in complex industrial settings can be problematic. The routing of cables through tight spaces and around obstacles can be challenging and may compromise the integrity of the communication system.

Safety concerns also arise when dealing with high-voltage environments typically associated with induction motors. Traditional copper-based systems may pose risks of electrical shock or sparking, which can be particularly dangerous in hazardous environments.

The scalability of conventional communication systems is another limitation. As industrial processes become more complex and interconnected, the ability to easily expand and integrate motor communication networks becomes increasingly important.

Lastly, the long-term reliability of data transmission systems in induction motor applications is a critical concern. The constant stress from motor operation and environmental factors can lead to gradual degradation of communication performance, potentially resulting in unexpected downtime and production losses.

These challenges collectively highlight the need for innovative solutions in induction motor data communication. The limitations of traditional systems underscore the potential benefits of adopting advanced technologies like fiber optics, which can address many of these issues and provide a more robust, efficient, and future-proof communication infrastructure for induction motor applications.

Another challenge is the harsh operating environment of induction motors, which often includes high temperatures, vibrations, and exposure to various contaminants. These conditions can degrade traditional copper-based communication systems over time, leading to increased maintenance costs and potential system failures.

The limited bandwidth of conventional wired communication systems also poses a significant challenge, especially in applications requiring real-time monitoring and control. As the demand for more sophisticated motor control and diagnostics increases, the need for higher data transmission rates becomes crucial.

Furthermore, the physical constraints of installing and maintaining wired communication systems in complex industrial settings can be problematic. The routing of cables through tight spaces and around obstacles can be challenging and may compromise the integrity of the communication system.

Safety concerns also arise when dealing with high-voltage environments typically associated with induction motors. Traditional copper-based systems may pose risks of electrical shock or sparking, which can be particularly dangerous in hazardous environments.

The scalability of conventional communication systems is another limitation. As industrial processes become more complex and interconnected, the ability to easily expand and integrate motor communication networks becomes increasingly important.

Lastly, the long-term reliability of data transmission systems in induction motor applications is a critical concern. The constant stress from motor operation and environmental factors can lead to gradual degradation of communication performance, potentially resulting in unexpected downtime and production losses.

These challenges collectively highlight the need for innovative solutions in induction motor data communication. The limitations of traditional systems underscore the potential benefits of adopting advanced technologies like fiber optics, which can address many of these issues and provide a more robust, efficient, and future-proof communication infrastructure for induction motor applications.

Existing Fiber Optic Solutions for Motor Data Transmission

01 Optical fiber transmission systems

Fiber optic systems for high-speed data transmission, including components like transmitters, receivers, and optical fibers. These systems enable long-distance communication with high bandwidth and low signal loss, making them ideal for telecommunications and data centers.- Optical fiber transmission systems: Fiber optic systems for high-speed data transmission, including components like transmitters, receivers, and optical fibers. These systems enable long-distance, high-bandwidth communication with low signal loss and interference.

- Wavelength division multiplexing (WDM): Technique for multiplexing multiple optical carrier signals on a single optical fiber by using different wavelengths of laser light. This allows for increased bandwidth and efficient use of fiber optic infrastructure in data communication networks.

- Fiber optic connectors and interfaces: Specialized connectors and interfaces designed for fiber optic cables, ensuring efficient coupling of light between fibers and other optical components. These connectors minimize signal loss and maintain data integrity in optical communication systems.

- Optical amplifiers and repeaters: Devices used to boost optical signals in long-distance fiber optic communication systems. These components help maintain signal strength over extended distances without the need for electrical conversion, improving overall system performance.

- Fiber optic network management: Systems and methods for monitoring, controlling, and optimizing fiber optic networks. This includes fault detection, performance analysis, and dynamic reconfiguration of network resources to ensure reliable and efficient data communication.

02 Wavelength division multiplexing (WDM)

A technique that combines multiple optical signals at different wavelengths onto a single fiber, significantly increasing data capacity. WDM systems use specialized components such as multiplexers, demultiplexers, and optical amplifiers to manage multiple data streams simultaneously.Expand Specific Solutions03 Fiber optic connectors and interfaces

Specialized connectors and interfaces designed for fiber optic cables, ensuring efficient coupling of light between fibers and other optical components. These include various types of connectors, adapters, and transceivers that facilitate the integration of fiber optic systems with other network equipment.Expand Specific Solutions04 Optical signal processing and modulation

Techniques for manipulating optical signals to encode, transmit, and decode data more efficiently. This includes various modulation schemes, signal amplification, and regeneration methods to maintain signal integrity over long distances and improve overall system performance.Expand Specific Solutions05 Fiber optic network management and monitoring

Systems and methods for managing, monitoring, and troubleshooting fiber optic networks. This includes tools for performance analysis, fault detection, and network optimization to ensure reliable and efficient data communication across fiber optic infrastructure.Expand Specific Solutions

Key Players in Fiber Optic Motor Communication Systems

The fiber optic technology for improving induction motor data communication is in a growth phase, with increasing market size and advancing technical maturity. The industry is seeing significant developments from key players across various sectors. Companies like Sumitomo Electric Industries and CommScope Technologies are driving innovations in optical fiber cables and communication systems. Semiconductor firms such as Micron Technology and Xilinx are contributing to the advancement of related components. Major industrial players like Siemens and Honeywell are integrating these technologies into their motor control and automation systems. As the technology matures, we're witnessing a convergence of telecommunications, industrial automation, and data processing capabilities, promising enhanced performance and efficiency in induction motor applications.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed a cutting-edge fiber optic solution for induction motor data communication, leveraging their expertise in optical fiber manufacturing and network technologies. Their approach focuses on high-speed, long-distance data transmission capabilities, making it particularly suitable for large-scale industrial applications. Sumitomo's system utilizes advanced single-mode fibers with low attenuation and dispersion characteristics, enabling data rates of up to 100 Gbps over distances exceeding 10 kilometers[9]. The company has also developed specialized optical transceivers that can operate reliably in high-temperature and high-vibration environments typically found in industrial motor applications. Sumitomo's solution incorporates wavelength division multiplexing (WDM) technology, allowing multiple data streams to be transmitted simultaneously over a single fiber, significantly increasing overall bandwidth capacity. Additionally, they have implemented advanced forward error correction (FEC) algorithms to ensure data integrity in noisy industrial environments[10].

Strengths: Exceptional long-distance transmission capabilities, high bandwidth capacity, and robust performance in harsh industrial environments. Weaknesses: Potentially higher costs due to the use of advanced optical components and specialized installation requirements.

Siemens AG

Technical Solution: Siemens has pioneered a comprehensive fiber optic solution for induction motor data communication within their SIMOTICS portfolio. Their approach integrates fiber optic sensors directly into the motor design, allowing for real-time monitoring of critical parameters such as temperature, vibration, and magnetic field strength. The system utilizes Fiber Bragg Grating (FBG) technology, which enables multiplexed sensing along a single fiber strand[2]. Siemens' solution incorporates advanced signal processing algorithms to interpret the optical data and translate it into actionable insights for motor control and predictive maintenance. The fiber optic network is seamlessly integrated with their SIMATIC automation systems, enabling high-speed, noise-immune data transmission from the motor to the control room. Furthermore, Siemens has developed specialized optical connectors and cable designs to withstand the harsh conditions typically found in industrial motor applications[5].

Strengths: Highly integrated solution, excellent EMI immunity, and comprehensive motor health monitoring. Weaknesses: Proprietary system may limit interoperability with third-party components.

Core Innovations in Fiber Optic Motor Communication

Motors with built-in optical fiber communication

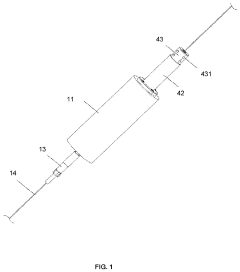

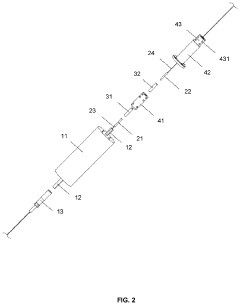

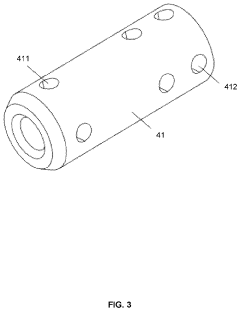

PatentPendingUS20240030778A1

Innovation

- A motor design with a slip ring section and a driving section where the driving shaft and rotor unit are fixedly connected along a centerline, incorporating adjustable collimators and fiber bundles within a hollow motor structure to minimize transmission noise and vibration, and reduce production costs.

Fiber optically communicated motor temperature and position signals

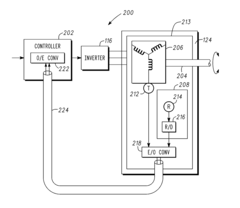

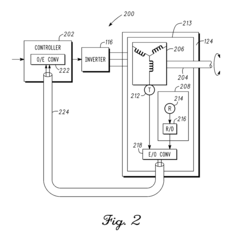

PatentInactiveUS20110109256A1

Innovation

- The system employs an electrical-to-optical (E/O) converter circuit and fiber optic cables to convert rotational and temperature sensor signals into optical signals, reducing EMI by eliminating electromagnetic interference traversal along sensor cables and minimizing mechanical failures associated with multiple wires.

Industrial Standards for Fiber Optic Motor Communication

Industrial standards play a crucial role in ensuring the reliability, interoperability, and performance of fiber optic communication systems in induction motor applications. These standards provide guidelines for the design, installation, and operation of fiber optic networks in industrial environments, specifically tailored for motor communication.

The International Electrotechnical Commission (IEC) has developed several standards relevant to fiber optic motor communication. IEC 61850, for instance, defines communication protocols for power utility automation systems, including those involving motor control. This standard encompasses fiber optic communication and provides specifications for data models, communication services, and system configuration.

Another important standard is IEC 60870-5, which focuses on telecontrol protocols. While not exclusively for fiber optics, it includes provisions for fiber optic communication in industrial control systems, including those for induction motors. This standard ensures reliable data transmission and interoperability between different manufacturers' equipment.

The Ethernet for Control Automation Technology (EtherCAT) standard, developed by Beckhoff Automation, has gained widespread adoption in industrial automation. It supports fiber optic communication and provides specifications for real-time control of motors and other industrial devices. EtherCAT's ability to achieve microsecond-level synchronization makes it particularly suitable for high-performance motor control applications.

PROFINET, an industrial Ethernet standard, also includes specifications for fiber optic communication in motor control systems. It offers scalable performance levels and supports various network topologies, making it adaptable to different industrial environments and motor control requirements.

The IEEE 802.3 standard, which defines Ethernet protocols, includes specifications for fiber optic communication that are applicable to motor control systems. Specifically, IEEE 802.3ae and IEEE 802.3ba define 10 Gigabit Ethernet and 40/100 Gigabit Ethernet over fiber, respectively, providing high-bandwidth options for data-intensive motor control applications.

Compliance with these standards ensures that fiber optic systems for motor communication meet industry-wide performance and safety requirements. They provide guidelines for factors such as signal integrity, electromagnetic compatibility, and environmental resistance, which are critical in industrial settings.

Furthermore, these standards facilitate interoperability between different manufacturers' equipment, allowing for more flexible and cost-effective system designs. They also provide a framework for future technological advancements, ensuring that new developments in fiber optic technology can be seamlessly integrated into existing motor control systems.

The International Electrotechnical Commission (IEC) has developed several standards relevant to fiber optic motor communication. IEC 61850, for instance, defines communication protocols for power utility automation systems, including those involving motor control. This standard encompasses fiber optic communication and provides specifications for data models, communication services, and system configuration.

Another important standard is IEC 60870-5, which focuses on telecontrol protocols. While not exclusively for fiber optics, it includes provisions for fiber optic communication in industrial control systems, including those for induction motors. This standard ensures reliable data transmission and interoperability between different manufacturers' equipment.

The Ethernet for Control Automation Technology (EtherCAT) standard, developed by Beckhoff Automation, has gained widespread adoption in industrial automation. It supports fiber optic communication and provides specifications for real-time control of motors and other industrial devices. EtherCAT's ability to achieve microsecond-level synchronization makes it particularly suitable for high-performance motor control applications.

PROFINET, an industrial Ethernet standard, also includes specifications for fiber optic communication in motor control systems. It offers scalable performance levels and supports various network topologies, making it adaptable to different industrial environments and motor control requirements.

The IEEE 802.3 standard, which defines Ethernet protocols, includes specifications for fiber optic communication that are applicable to motor control systems. Specifically, IEEE 802.3ae and IEEE 802.3ba define 10 Gigabit Ethernet and 40/100 Gigabit Ethernet over fiber, respectively, providing high-bandwidth options for data-intensive motor control applications.

Compliance with these standards ensures that fiber optic systems for motor communication meet industry-wide performance and safety requirements. They provide guidelines for factors such as signal integrity, electromagnetic compatibility, and environmental resistance, which are critical in industrial settings.

Furthermore, these standards facilitate interoperability between different manufacturers' equipment, allowing for more flexible and cost-effective system designs. They also provide a framework for future technological advancements, ensuring that new developments in fiber optic technology can be seamlessly integrated into existing motor control systems.

Cost-Benefit Analysis of Fiber Optic Implementation in Motors

The implementation of fiber optics in induction motor data communication systems presents a significant opportunity for cost savings and performance improvements. Initial investment costs for fiber optic infrastructure can be substantial, including expenses for cables, connectors, transmitters, and receivers. However, these costs are often offset by long-term benefits and operational savings.

Fiber optic systems offer superior electromagnetic interference (EMI) immunity compared to traditional copper-based communication systems. This characteristic is particularly valuable in industrial environments where motors generate significant electromagnetic noise. The reduction in EMI-related issues leads to decreased maintenance costs and improved system reliability, potentially saving companies thousands of dollars annually in downtime and repair expenses.

Energy efficiency is another key benefit of fiber optic systems. Optical fibers can transmit data over longer distances with less signal degradation, reducing the need for signal boosters and repeaters. This results in lower power consumption and associated energy costs. Additionally, the lightweight nature of fiber optic cables compared to copper alternatives can lead to reduced installation and support structure costs, especially in large-scale industrial applications.

The high bandwidth capacity of fiber optics enables more comprehensive real-time monitoring and control of induction motors. This enhanced data communication allows for predictive maintenance strategies, optimizing motor performance and extending equipment lifespan. The potential for early detection of motor issues can prevent catastrophic failures, saving significant replacement and downtime costs.

While the initial capital expenditure for fiber optic systems may be higher than traditional copper-based solutions, the total cost of ownership (TCO) over the system's lifetime is often lower. Fiber optic cables have a longer lifespan and require less frequent replacement, reducing long-term maintenance and upgrade costs. Furthermore, the scalability of fiber optic systems allows for easier future expansions without the need for complete infrastructure overhauls.

In conclusion, the cost-benefit analysis of implementing fiber optics in induction motor data communication systems generally favors adoption, especially for large-scale or long-term installations. The combination of improved reliability, reduced maintenance, enhanced performance, and future-proofing capabilities often justifies the initial investment, leading to substantial cost savings and operational benefits over time.

Fiber optic systems offer superior electromagnetic interference (EMI) immunity compared to traditional copper-based communication systems. This characteristic is particularly valuable in industrial environments where motors generate significant electromagnetic noise. The reduction in EMI-related issues leads to decreased maintenance costs and improved system reliability, potentially saving companies thousands of dollars annually in downtime and repair expenses.

Energy efficiency is another key benefit of fiber optic systems. Optical fibers can transmit data over longer distances with less signal degradation, reducing the need for signal boosters and repeaters. This results in lower power consumption and associated energy costs. Additionally, the lightweight nature of fiber optic cables compared to copper alternatives can lead to reduced installation and support structure costs, especially in large-scale industrial applications.

The high bandwidth capacity of fiber optics enables more comprehensive real-time monitoring and control of induction motors. This enhanced data communication allows for predictive maintenance strategies, optimizing motor performance and extending equipment lifespan. The potential for early detection of motor issues can prevent catastrophic failures, saving significant replacement and downtime costs.

While the initial capital expenditure for fiber optic systems may be higher than traditional copper-based solutions, the total cost of ownership (TCO) over the system's lifetime is often lower. Fiber optic cables have a longer lifespan and require less frequent replacement, reducing long-term maintenance and upgrade costs. Furthermore, the scalability of fiber optic systems allows for easier future expansions without the need for complete infrastructure overhauls.

In conclusion, the cost-benefit analysis of implementing fiber optics in induction motor data communication systems generally favors adoption, especially for large-scale or long-term installations. The combination of improved reliability, reduced maintenance, enhanced performance, and future-proofing capabilities often justifies the initial investment, leading to substantial cost savings and operational benefits over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!