How induction motors facilitate smart manufacturing processes

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motors in Smart Manufacturing: Background and Objectives

Induction motors have played a pivotal role in industrial automation since their inception in the late 19th century. As manufacturing processes have evolved, so too has the application of these robust and reliable motors. The advent of smart manufacturing, characterized by interconnected systems, data-driven decision making, and adaptive production processes, has ushered in a new era for induction motor utilization.

The primary objective of integrating induction motors into smart manufacturing processes is to enhance overall efficiency, productivity, and flexibility of production lines. These motors, known for their simplicity and durability, are being reimagined as key components in the Industrial Internet of Things (IIoT) ecosystem. By incorporating advanced sensors, real-time monitoring capabilities, and intelligent control systems, induction motors are transforming from mere power sources to smart, communicative devices within the manufacturing environment.

The evolution of induction motors in smart manufacturing is closely tied to the broader trends of Industry 4.0 and the digital transformation of factories. As manufacturing facilities strive to become more agile and responsive to market demands, the role of induction motors has expanded beyond traditional applications. They now serve as critical data points in the vast network of interconnected machines, providing valuable insights into operational performance, energy consumption, and predictive maintenance needs.

One of the key technological advancements driving this transformation is the development of variable frequency drives (VFDs) and advanced motor control algorithms. These innovations allow for precise speed and torque control of induction motors, enabling manufacturers to optimize energy usage and adapt motor performance to specific production requirements in real-time. This level of control is essential for implementing flexible manufacturing processes that can quickly adjust to changes in product specifications or production volumes.

Furthermore, the integration of induction motors with smart sensors and IoT platforms has opened up new possibilities for condition monitoring and predictive maintenance. By continuously analyzing motor performance data, manufacturers can predict potential failures before they occur, schedule maintenance activities more efficiently, and minimize unplanned downtime. This proactive approach to equipment management is a cornerstone of smart manufacturing strategies, contributing to improved overall equipment effectiveness (OEE) and reduced operational costs.

As we look towards the future of smart manufacturing, the ongoing development of more efficient and intelligent induction motor systems will continue to play a crucial role. Research efforts are focused on improving motor designs for higher energy efficiency, developing more sophisticated control algorithms, and enhancing the integration of motors with other smart factory components. The goal is to create a seamless, highly responsive manufacturing ecosystem where induction motors not only power production processes but also actively contribute to the optimization and intelligence of the entire manufacturing operation.

The primary objective of integrating induction motors into smart manufacturing processes is to enhance overall efficiency, productivity, and flexibility of production lines. These motors, known for their simplicity and durability, are being reimagined as key components in the Industrial Internet of Things (IIoT) ecosystem. By incorporating advanced sensors, real-time monitoring capabilities, and intelligent control systems, induction motors are transforming from mere power sources to smart, communicative devices within the manufacturing environment.

The evolution of induction motors in smart manufacturing is closely tied to the broader trends of Industry 4.0 and the digital transformation of factories. As manufacturing facilities strive to become more agile and responsive to market demands, the role of induction motors has expanded beyond traditional applications. They now serve as critical data points in the vast network of interconnected machines, providing valuable insights into operational performance, energy consumption, and predictive maintenance needs.

One of the key technological advancements driving this transformation is the development of variable frequency drives (VFDs) and advanced motor control algorithms. These innovations allow for precise speed and torque control of induction motors, enabling manufacturers to optimize energy usage and adapt motor performance to specific production requirements in real-time. This level of control is essential for implementing flexible manufacturing processes that can quickly adjust to changes in product specifications or production volumes.

Furthermore, the integration of induction motors with smart sensors and IoT platforms has opened up new possibilities for condition monitoring and predictive maintenance. By continuously analyzing motor performance data, manufacturers can predict potential failures before they occur, schedule maintenance activities more efficiently, and minimize unplanned downtime. This proactive approach to equipment management is a cornerstone of smart manufacturing strategies, contributing to improved overall equipment effectiveness (OEE) and reduced operational costs.

As we look towards the future of smart manufacturing, the ongoing development of more efficient and intelligent induction motor systems will continue to play a crucial role. Research efforts are focused on improving motor designs for higher energy efficiency, developing more sophisticated control algorithms, and enhancing the integration of motors with other smart factory components. The goal is to create a seamless, highly responsive manufacturing ecosystem where induction motors not only power production processes but also actively contribute to the optimization and intelligence of the entire manufacturing operation.

Market Demand Analysis for Smart Manufacturing Solutions

The market demand for smart manufacturing solutions incorporating induction motors has been steadily increasing in recent years. This growth is driven by the need for enhanced efficiency, productivity, and automation in manufacturing processes across various industries. Induction motors play a crucial role in facilitating smart manufacturing by providing reliable and efficient power for a wide range of industrial applications.

One of the primary factors fueling the demand for smart manufacturing solutions is the push towards Industry 4.0 and the Industrial Internet of Things (IIoT). Manufacturers are increasingly adopting advanced technologies to improve their operations, and induction motors equipped with smart sensors and connectivity features are at the forefront of this transformation. These motors enable real-time monitoring, predictive maintenance, and data-driven decision-making, which are essential components of smart manufacturing processes.

The automotive industry has emerged as a significant driver of demand for smart manufacturing solutions incorporating induction motors. As vehicle production becomes more complex and automated, the need for precise control and efficient power delivery has increased. Induction motors are widely used in assembly lines, robotic systems, and material handling equipment within automotive manufacturing plants.

Another key market segment driving demand is the food and beverage industry. Smart manufacturing solutions featuring induction motors are being implemented to improve production efficiency, ensure product quality, and maintain strict hygiene standards. These motors are used in various applications such as mixing, conveying, and packaging, where precise control and reliability are paramount.

The aerospace and defense sector is also contributing to the growing demand for smart manufacturing solutions. Induction motors are utilized in the production of aircraft components, assembly of defense equipment, and testing facilities. The need for high-precision manufacturing and stringent quality control in this sector has led to increased adoption of smart motor systems.

In the pharmaceutical and healthcare industries, smart manufacturing solutions incorporating induction motors are gaining traction due to the need for precise control in drug manufacturing processes and medical device production. These motors enable accurate dosing, mixing, and packaging operations while ensuring compliance with strict regulatory requirements.

The market demand for smart manufacturing solutions is further bolstered by the increasing focus on energy efficiency and sustainability. Induction motors with advanced control systems and energy management features help manufacturers reduce their energy consumption and carbon footprint, aligning with global sustainability goals and regulations.

As manufacturers continue to seek ways to optimize their operations and stay competitive in the global market, the demand for smart manufacturing solutions incorporating induction motors is expected to grow further. This trend is likely to drive innovation in motor design, control systems, and integration technologies, leading to even more advanced and efficient smart manufacturing processes in the future.

One of the primary factors fueling the demand for smart manufacturing solutions is the push towards Industry 4.0 and the Industrial Internet of Things (IIoT). Manufacturers are increasingly adopting advanced technologies to improve their operations, and induction motors equipped with smart sensors and connectivity features are at the forefront of this transformation. These motors enable real-time monitoring, predictive maintenance, and data-driven decision-making, which are essential components of smart manufacturing processes.

The automotive industry has emerged as a significant driver of demand for smart manufacturing solutions incorporating induction motors. As vehicle production becomes more complex and automated, the need for precise control and efficient power delivery has increased. Induction motors are widely used in assembly lines, robotic systems, and material handling equipment within automotive manufacturing plants.

Another key market segment driving demand is the food and beverage industry. Smart manufacturing solutions featuring induction motors are being implemented to improve production efficiency, ensure product quality, and maintain strict hygiene standards. These motors are used in various applications such as mixing, conveying, and packaging, where precise control and reliability are paramount.

The aerospace and defense sector is also contributing to the growing demand for smart manufacturing solutions. Induction motors are utilized in the production of aircraft components, assembly of defense equipment, and testing facilities. The need for high-precision manufacturing and stringent quality control in this sector has led to increased adoption of smart motor systems.

In the pharmaceutical and healthcare industries, smart manufacturing solutions incorporating induction motors are gaining traction due to the need for precise control in drug manufacturing processes and medical device production. These motors enable accurate dosing, mixing, and packaging operations while ensuring compliance with strict regulatory requirements.

The market demand for smart manufacturing solutions is further bolstered by the increasing focus on energy efficiency and sustainability. Induction motors with advanced control systems and energy management features help manufacturers reduce their energy consumption and carbon footprint, aligning with global sustainability goals and regulations.

As manufacturers continue to seek ways to optimize their operations and stay competitive in the global market, the demand for smart manufacturing solutions incorporating induction motors is expected to grow further. This trend is likely to drive innovation in motor design, control systems, and integration technologies, leading to even more advanced and efficient smart manufacturing processes in the future.

Current State and Challenges of Induction Motors in Industry 4.0

Induction motors have become integral components in the evolution of Industry 4.0 and smart manufacturing processes. However, their integration into these advanced systems presents both opportunities and challenges. Currently, induction motors are widely used in various industrial applications due to their robustness, reliability, and cost-effectiveness. In smart manufacturing environments, these motors are being equipped with sensors and connected to industrial networks, enabling real-time monitoring and control.

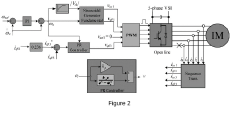

One of the primary challenges in implementing induction motors in Industry 4.0 is the need for advanced control systems. Traditional control methods may not be sufficient to meet the demands of smart manufacturing processes, which require precise speed and torque control. This has led to the development of more sophisticated control algorithms, such as vector control and direct torque control, to enhance motor performance and efficiency.

Another significant challenge is the integration of induction motors with Industrial Internet of Things (IIoT) platforms. While sensors can be added to motors to collect data, ensuring seamless communication between motors and other systems in the manufacturing ecosystem remains complex. Standardization of communication protocols and data formats is crucial to overcome this challenge and facilitate interoperability.

Energy efficiency is a key focus area in Industry 4.0, and induction motors are no exception. While these motors are generally efficient, there is still room for improvement, especially in variable speed applications. The development of more efficient motor designs and the implementation of advanced control strategies are ongoing challenges in maximizing energy savings.

Predictive maintenance is a critical aspect of smart manufacturing, and induction motors play a vital role in this area. However, accurately predicting motor failures and optimizing maintenance schedules based on real-time data remains challenging. Machine learning algorithms and big data analytics are being employed to improve predictive maintenance capabilities, but their effectiveness still needs refinement.

The increasing complexity of smart manufacturing systems also poses challenges for the workforce. Technicians and engineers need to acquire new skills to effectively manage and maintain induction motors integrated into Industry 4.0 environments. This skills gap necessitates ongoing training and education programs to ensure that the workforce can keep pace with technological advancements.

As Industry 4.0 continues to evolve, induction motors must adapt to meet the demands of flexible and reconfigurable manufacturing systems. This requires motors to be more modular and easily adaptable to different production scenarios, presenting design and implementation challenges for motor manufacturers and system integrators.

One of the primary challenges in implementing induction motors in Industry 4.0 is the need for advanced control systems. Traditional control methods may not be sufficient to meet the demands of smart manufacturing processes, which require precise speed and torque control. This has led to the development of more sophisticated control algorithms, such as vector control and direct torque control, to enhance motor performance and efficiency.

Another significant challenge is the integration of induction motors with Industrial Internet of Things (IIoT) platforms. While sensors can be added to motors to collect data, ensuring seamless communication between motors and other systems in the manufacturing ecosystem remains complex. Standardization of communication protocols and data formats is crucial to overcome this challenge and facilitate interoperability.

Energy efficiency is a key focus area in Industry 4.0, and induction motors are no exception. While these motors are generally efficient, there is still room for improvement, especially in variable speed applications. The development of more efficient motor designs and the implementation of advanced control strategies are ongoing challenges in maximizing energy savings.

Predictive maintenance is a critical aspect of smart manufacturing, and induction motors play a vital role in this area. However, accurately predicting motor failures and optimizing maintenance schedules based on real-time data remains challenging. Machine learning algorithms and big data analytics are being employed to improve predictive maintenance capabilities, but their effectiveness still needs refinement.

The increasing complexity of smart manufacturing systems also poses challenges for the workforce. Technicians and engineers need to acquire new skills to effectively manage and maintain induction motors integrated into Industry 4.0 environments. This skills gap necessitates ongoing training and education programs to ensure that the workforce can keep pace with technological advancements.

As Industry 4.0 continues to evolve, induction motors must adapt to meet the demands of flexible and reconfigurable manufacturing systems. This requires motors to be more modular and easily adaptable to different production scenarios, presenting design and implementation challenges for motor manufacturers and system integrators.

Existing Induction Motor Solutions for Smart Manufacturing

01 Design and construction of induction motors

This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. These advancements aim to enhance power output, reduce losses, and optimize overall motor operation.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

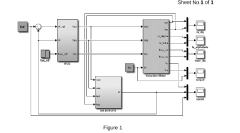

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category includes advancements in motor drives, power electronics, and control algorithms designed to optimize motor performance across various operating conditions.

- Efficiency improvements in induction motors: This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes improvements in motor design, materials, and manufacturing processes to reduce losses and increase overall motor efficiency.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers motor designs and modifications tailored for specific industries or operating environments, such as high-speed, high-temperature, or submersible applications.

- Maintenance and diagnostics of induction motors: This category encompasses methods and systems for monitoring, maintaining, and diagnosing induction motors. It includes techniques for fault detection, predictive maintenance, and condition monitoring to ensure optimal motor performance and longevity.

02 Control systems for induction motors

This point covers various control strategies and systems developed for induction motors. It includes methods for speed control, torque regulation, and power factor correction. Advanced control techniques such as vector control and direct torque control are also addressed, aiming to improve motor performance and energy efficiency across different operating conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category focuses on techniques and innovations aimed at improving the energy efficiency of induction motors. It includes methods for reducing losses, optimizing magnetic circuits, and enhancing thermal management. These advancements contribute to lower energy consumption and improved overall performance of induction motors in various applications.Expand Specific Solutions04 Specialized applications of induction motors

This point covers the adaptation and optimization of induction motors for specific applications. It includes designs for high-speed operations, heavy-duty industrial use, and integration into electric vehicles. These specialized motors are tailored to meet the unique requirements of different industries and operating environments.Expand Specific Solutions05 Diagnostics and maintenance of induction motors

This category focuses on methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance. These advancements aim to improve motor reliability, reduce downtime, and extend the operational lifespan of induction motors.Expand Specific Solutions

Key Players in Smart Manufacturing and Motor Industry

The induction motor market for smart manufacturing is in a growth phase, driven by increasing automation and Industry 4.0 adoption. The global market size is projected to expand significantly in the coming years. Technologically, induction motors are mature but evolving with advancements in control systems and IoT integration. Key players like FANUC, Nidec Motor, and Siemens are leading innovation, focusing on energy efficiency, precision control, and connectivity. Emerging companies such as Guangzhou Dabaowen and Chengdu Qinchuan IoT are also contributing to the competitive landscape, particularly in regional markets.

FANUC Corp.

Technical Solution: FANUC specializes in factory automation and robotics, incorporating advanced induction motor technology into their solutions. Their induction motors are designed for high-precision control in smart manufacturing environments, particularly in CNC machines and robotic systems. FANUC's motors feature built-in encoders for accurate position feedback and are optimized for use with their own drive systems[7]. The company has developed intelligent servo systems that utilize induction motors with advanced control algorithms, enabling adaptive machining and real-time process optimization. FANUC's induction motor solutions also integrate with their FIELD system, an open AI platform for manufacturing, allowing for data-driven improvements in production efficiency[8].

Strengths: Highly integrated solutions for robotics and CNC applications, strong expertise in motion control. Weaknesses: May be less flexible for use with non-FANUC systems, potentially limiting interoperability in diverse manufacturing environments.

Hitachi Energy Ltd.

Technical Solution: Hitachi Energy, formerly ABB Power Grids, offers advanced induction motor solutions for smart manufacturing. Their motors feature high efficiency designs, often meeting or exceeding IE4 standards, which contribute to energy savings in industrial processes[11]. Hitachi Energy's induction motors are designed to work seamlessly with their variable speed drives, enabling precise control and optimization of manufacturing processes. They have implemented digital technologies such as ABB Ability™ Smart Sensor, which allows for condition monitoring and predictive maintenance of motors[12]. This technology enables real-time data collection and analysis, facilitating improved asset management and reduced downtime in smart factories.

Strengths: High-efficiency motor designs, strong integration with digital platforms for monitoring and control. Weaknesses: May have higher initial costs compared to standard motor solutions, and full benefits may require investment in compatible control and monitoring systems.

Core Innovations in Induction Motor Technology for Industry 4.0

Novel and reliable sensorless induction motor speed control

PatentPendingIN202441001272A

Innovation

- The system employs advanced algorithms and machine learning techniques to accurately estimate motor speed and position in real-time without the need for external sensors, reducing complexity and cost while enhancing reliability and adaptability.

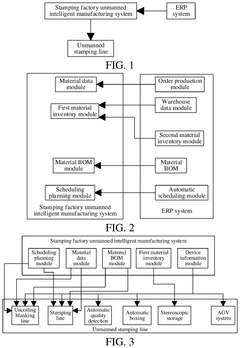

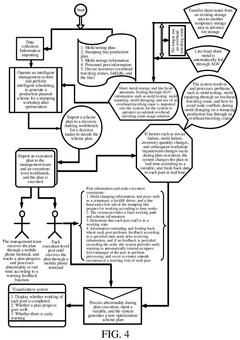

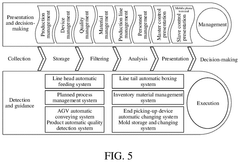

Unmanned intelligent manufacturing system

PatentPendingUS20240378684A1

Innovation

- An unmanned intelligent manufacturing system integrating an ERP system, unmanned stamping line, material data modules, scheduling planning modules, and an AGV system, which includes modules for material inventory, quality detection, and visualization, enabling automatic production and resource allocation.

Energy Efficiency and Sustainability Considerations

Induction motors play a crucial role in smart manufacturing processes, and their energy efficiency and sustainability considerations are of paramount importance. These motors are widely used in various industrial applications due to their robustness, reliability, and cost-effectiveness. However, as industries strive for more sustainable operations, the focus on energy efficiency has intensified.

In smart manufacturing environments, induction motors are increasingly being equipped with advanced monitoring and control systems. These systems allow for real-time performance tracking and optimization, leading to significant energy savings. Variable frequency drives (VFDs) are commonly employed to adjust motor speed according to load requirements, reducing energy consumption during periods of low demand.

The implementation of energy-efficient induction motors, such as those complying with IE3 and IE4 efficiency standards, has become a key strategy for manufacturers looking to reduce their carbon footprint. These high-efficiency motors utilize improved designs and materials, resulting in lower losses and higher overall efficiency. The initial investment in such motors is often offset by long-term energy savings and reduced operational costs.

Sustainability considerations extend beyond energy efficiency to the entire lifecycle of induction motors. Manufacturers are increasingly focusing on the use of sustainable materials in motor construction, such as recycled metals and environmentally friendly insulation materials. Additionally, the design for recyclability and ease of disassembly is becoming a priority, facilitating the recovery and reuse of components at the end of the motor's life.

Smart manufacturing processes also leverage predictive maintenance techniques for induction motors, which contribute to both energy efficiency and sustainability. By detecting potential issues before they lead to failures, these techniques help prevent unplanned downtime and energy waste associated with inefficient operation. This proactive approach extends the lifespan of motors, reducing the need for premature replacements and the associated environmental impact of manufacturing new units.

The integration of induction motors into the Industrial Internet of Things (IIoT) ecosystem further enhances their sustainability profile. Connected motors can provide valuable data for energy management systems, allowing for more informed decision-making and optimization of overall plant efficiency. This data-driven approach enables manufacturers to identify energy-intensive processes and implement targeted improvements.

As smart manufacturing continues to evolve, the role of induction motors in promoting energy efficiency and sustainability is expected to grow. Ongoing research and development efforts are focused on further improving motor efficiency, exploring alternative materials, and enhancing integration with renewable energy sources. These advancements will contribute to the broader goals of reducing industrial energy consumption and minimizing environmental impact in the manufacturing sector.

In smart manufacturing environments, induction motors are increasingly being equipped with advanced monitoring and control systems. These systems allow for real-time performance tracking and optimization, leading to significant energy savings. Variable frequency drives (VFDs) are commonly employed to adjust motor speed according to load requirements, reducing energy consumption during periods of low demand.

The implementation of energy-efficient induction motors, such as those complying with IE3 and IE4 efficiency standards, has become a key strategy for manufacturers looking to reduce their carbon footprint. These high-efficiency motors utilize improved designs and materials, resulting in lower losses and higher overall efficiency. The initial investment in such motors is often offset by long-term energy savings and reduced operational costs.

Sustainability considerations extend beyond energy efficiency to the entire lifecycle of induction motors. Manufacturers are increasingly focusing on the use of sustainable materials in motor construction, such as recycled metals and environmentally friendly insulation materials. Additionally, the design for recyclability and ease of disassembly is becoming a priority, facilitating the recovery and reuse of components at the end of the motor's life.

Smart manufacturing processes also leverage predictive maintenance techniques for induction motors, which contribute to both energy efficiency and sustainability. By detecting potential issues before they lead to failures, these techniques help prevent unplanned downtime and energy waste associated with inefficient operation. This proactive approach extends the lifespan of motors, reducing the need for premature replacements and the associated environmental impact of manufacturing new units.

The integration of induction motors into the Industrial Internet of Things (IIoT) ecosystem further enhances their sustainability profile. Connected motors can provide valuable data for energy management systems, allowing for more informed decision-making and optimization of overall plant efficiency. This data-driven approach enables manufacturers to identify energy-intensive processes and implement targeted improvements.

As smart manufacturing continues to evolve, the role of induction motors in promoting energy efficiency and sustainability is expected to grow. Ongoing research and development efforts are focused on further improving motor efficiency, exploring alternative materials, and enhancing integration with renewable energy sources. These advancements will contribute to the broader goals of reducing industrial energy consumption and minimizing environmental impact in the manufacturing sector.

Integration with Industrial IoT and Data Analytics

The integration of induction motors with Industrial IoT (IIoT) and data analytics is revolutionizing smart manufacturing processes. This convergence enables real-time monitoring, predictive maintenance, and optimized performance of induction motors, which are crucial components in many industrial applications.

IIoT sensors attached to induction motors collect vast amounts of data, including temperature, vibration, current, and voltage. This data is transmitted to cloud-based platforms or edge computing systems for analysis. Advanced analytics algorithms process this information to provide valuable insights into motor health, efficiency, and potential issues.

Predictive maintenance is a key benefit of this integration. By analyzing historical and real-time data, machine learning models can predict potential failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and extends the lifespan of induction motors. For instance, anomalies in vibration patterns or temperature fluctuations can indicate impending bearing failures or insulation degradation.

Energy efficiency optimization is another significant advantage. Data analytics can identify patterns of energy consumption and suggest operational adjustments to reduce power usage. This may involve optimizing motor speed, load distribution, or operating schedules based on production demands and energy costs.

The integration also facilitates performance optimization. By analyzing motor performance data across various operating conditions, manufacturers can fine-tune motor parameters for specific applications. This leads to improved productivity, reduced energy consumption, and enhanced product quality.

Digital twin technology is emerging as a powerful tool in this integration. A digital twin is a virtual replica of the physical induction motor, continuously updated with real-time data. This allows for simulation of different scenarios, optimization of motor design, and testing of new control strategies without risking the physical asset.

The combination of IIoT and data analytics enables more sophisticated control systems for induction motors. Adaptive control algorithms can adjust motor operation in real-time based on changing conditions, ensuring optimal performance across varying loads and environmental factors.

As this integration advances, it paves the way for autonomous manufacturing systems. Induction motors equipped with IIoT sensors and governed by AI-driven analytics can self-diagnose, self-optimize, and even self-repair to a certain extent, reducing the need for human intervention and moving towards lights-out manufacturing.

IIoT sensors attached to induction motors collect vast amounts of data, including temperature, vibration, current, and voltage. This data is transmitted to cloud-based platforms or edge computing systems for analysis. Advanced analytics algorithms process this information to provide valuable insights into motor health, efficiency, and potential issues.

Predictive maintenance is a key benefit of this integration. By analyzing historical and real-time data, machine learning models can predict potential failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and extends the lifespan of induction motors. For instance, anomalies in vibration patterns or temperature fluctuations can indicate impending bearing failures or insulation degradation.

Energy efficiency optimization is another significant advantage. Data analytics can identify patterns of energy consumption and suggest operational adjustments to reduce power usage. This may involve optimizing motor speed, load distribution, or operating schedules based on production demands and energy costs.

The integration also facilitates performance optimization. By analyzing motor performance data across various operating conditions, manufacturers can fine-tune motor parameters for specific applications. This leads to improved productivity, reduced energy consumption, and enhanced product quality.

Digital twin technology is emerging as a powerful tool in this integration. A digital twin is a virtual replica of the physical induction motor, continuously updated with real-time data. This allows for simulation of different scenarios, optimization of motor design, and testing of new control strategies without risking the physical asset.

The combination of IIoT and data analytics enables more sophisticated control systems for induction motors. Adaptive control algorithms can adjust motor operation in real-time based on changing conditions, ensuring optimal performance across varying loads and environmental factors.

As this integration advances, it paves the way for autonomous manufacturing systems. Induction motors equipped with IIoT sensors and governed by AI-driven analytics can self-diagnose, self-optimize, and even self-repair to a certain extent, reducing the need for human intervention and moving towards lights-out manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!