How induction motors improve water conservation in pumps

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Pump Evolution

The evolution of induction motor pumps represents a significant milestone in the quest for water conservation and energy efficiency. This technological progression can be traced back to the late 19th century when Nikola Tesla invented the induction motor. Initially, these motors were not specifically designed for pump applications, but their robust and efficient nature soon made them an attractive option for various industrial uses, including water pumping systems.

In the early 20th century, the integration of induction motors with centrifugal pumps began to gain traction. This combination offered several advantages over previous pump designs, such as improved reliability, reduced maintenance requirements, and increased energy efficiency. As urbanization and industrialization accelerated, the demand for efficient water distribution systems grew, further driving the development of induction motor pumps.

The 1950s and 1960s saw significant advancements in induction motor design, including the introduction of better insulation materials and more efficient cooling systems. These improvements allowed for the creation of more compact and powerful motors, which in turn enabled the development of higher-capacity pumps suitable for large-scale water distribution and irrigation projects.

The energy crisis of the 1970s sparked a renewed focus on energy efficiency across all industries. This led to further refinements in induction motor pump technology, with manufacturers striving to reduce energy consumption without compromising performance. Variable frequency drives (VFDs) emerged as a game-changing innovation during this period, allowing for precise control of motor speed and significantly improving the overall efficiency of pumping systems.

In the 1980s and 1990s, the advent of computer-aided design and simulation tools revolutionized the development process for induction motor pumps. Engineers could now optimize designs more effectively, leading to pumps with higher efficiencies and better performance characteristics. This era also saw the introduction of advanced materials, such as high-strength alloys and corrosion-resistant coatings, which extended the lifespan and reliability of pumps in various applications.

The turn of the 21st century brought about a new wave of innovation in induction motor pump technology, driven by increasing environmental concerns and stricter energy efficiency regulations. Manufacturers began incorporating smart technologies, such as IoT sensors and advanced control algorithms, to create intelligent pumping systems capable of real-time monitoring and optimization. These smart pumps could adjust their operation based on demand, further reducing energy consumption and water waste.

Today, the latest generation of induction motor pumps represents the culmination of over a century of technological advancement. These modern systems boast unprecedented levels of efficiency, with some models achieving energy savings of up to 70% compared to their predecessors. The integration of artificial intelligence and machine learning algorithms is pushing the boundaries of what's possible in pump optimization, paving the way for even more significant water conservation efforts in the future.

In the early 20th century, the integration of induction motors with centrifugal pumps began to gain traction. This combination offered several advantages over previous pump designs, such as improved reliability, reduced maintenance requirements, and increased energy efficiency. As urbanization and industrialization accelerated, the demand for efficient water distribution systems grew, further driving the development of induction motor pumps.

The 1950s and 1960s saw significant advancements in induction motor design, including the introduction of better insulation materials and more efficient cooling systems. These improvements allowed for the creation of more compact and powerful motors, which in turn enabled the development of higher-capacity pumps suitable for large-scale water distribution and irrigation projects.

The energy crisis of the 1970s sparked a renewed focus on energy efficiency across all industries. This led to further refinements in induction motor pump technology, with manufacturers striving to reduce energy consumption without compromising performance. Variable frequency drives (VFDs) emerged as a game-changing innovation during this period, allowing for precise control of motor speed and significantly improving the overall efficiency of pumping systems.

In the 1980s and 1990s, the advent of computer-aided design and simulation tools revolutionized the development process for induction motor pumps. Engineers could now optimize designs more effectively, leading to pumps with higher efficiencies and better performance characteristics. This era also saw the introduction of advanced materials, such as high-strength alloys and corrosion-resistant coatings, which extended the lifespan and reliability of pumps in various applications.

The turn of the 21st century brought about a new wave of innovation in induction motor pump technology, driven by increasing environmental concerns and stricter energy efficiency regulations. Manufacturers began incorporating smart technologies, such as IoT sensors and advanced control algorithms, to create intelligent pumping systems capable of real-time monitoring and optimization. These smart pumps could adjust their operation based on demand, further reducing energy consumption and water waste.

Today, the latest generation of induction motor pumps represents the culmination of over a century of technological advancement. These modern systems boast unprecedented levels of efficiency, with some models achieving energy savings of up to 70% compared to their predecessors. The integration of artificial intelligence and machine learning algorithms is pushing the boundaries of what's possible in pump optimization, paving the way for even more significant water conservation efforts in the future.

Water Conservation Market Demand

The global water conservation market has been experiencing significant growth in recent years, driven by increasing awareness of water scarcity and the need for sustainable resource management. This trend has created a substantial demand for efficient water pumping systems, particularly those utilizing induction motors for improved performance and energy savings.

In the industrial sector, water-intensive industries such as agriculture, manufacturing, and power generation are actively seeking solutions to reduce water consumption and improve overall efficiency. The adoption of advanced pumping systems with induction motors has become a key strategy for these industries to achieve their water conservation goals while simultaneously reducing operational costs.

The municipal water sector also presents a substantial market opportunity for water-conserving pump systems. As urban populations continue to grow and water infrastructure ages, cities and municipalities are investing in upgrading their water distribution networks. This includes the implementation of smart water management systems that incorporate efficient pumping technologies to minimize water loss and optimize distribution.

The agricultural sector, being one of the largest consumers of water globally, has shown a strong interest in water-conserving irrigation systems. Farmers are increasingly adopting precision irrigation techniques that rely on efficient pumping systems to deliver water accurately and reduce waste. This trend is particularly pronounced in regions facing water scarcity or drought conditions.

Commercial and residential buildings represent another significant market segment for water-conserving pump systems. Property managers and homeowners are increasingly focused on reducing water consumption and associated costs. This has led to a growing demand for efficient water circulation and distribution systems in applications such as HVAC, swimming pools, and general water supply.

The market demand for water-conserving pump systems is further bolstered by government regulations and incentives aimed at promoting water efficiency. Many countries have implemented stricter water use standards and offer financial incentives for the adoption of water-saving technologies, including efficient pumping systems.

Emerging economies, particularly in Asia and Africa, are expected to be key growth drivers for the water conservation market. Rapid industrialization, urbanization, and agricultural expansion in these regions are creating a pressing need for efficient water management solutions, including advanced pumping systems with induction motors.

As the global focus on sustainability intensifies, the water conservation market is projected to continue its upward trajectory. The integration of induction motors in pump systems is poised to play a crucial role in meeting this growing demand, offering a combination of improved efficiency, reliability, and environmental benefits that align with the market's evolving needs.

In the industrial sector, water-intensive industries such as agriculture, manufacturing, and power generation are actively seeking solutions to reduce water consumption and improve overall efficiency. The adoption of advanced pumping systems with induction motors has become a key strategy for these industries to achieve their water conservation goals while simultaneously reducing operational costs.

The municipal water sector also presents a substantial market opportunity for water-conserving pump systems. As urban populations continue to grow and water infrastructure ages, cities and municipalities are investing in upgrading their water distribution networks. This includes the implementation of smart water management systems that incorporate efficient pumping technologies to minimize water loss and optimize distribution.

The agricultural sector, being one of the largest consumers of water globally, has shown a strong interest in water-conserving irrigation systems. Farmers are increasingly adopting precision irrigation techniques that rely on efficient pumping systems to deliver water accurately and reduce waste. This trend is particularly pronounced in regions facing water scarcity or drought conditions.

Commercial and residential buildings represent another significant market segment for water-conserving pump systems. Property managers and homeowners are increasingly focused on reducing water consumption and associated costs. This has led to a growing demand for efficient water circulation and distribution systems in applications such as HVAC, swimming pools, and general water supply.

The market demand for water-conserving pump systems is further bolstered by government regulations and incentives aimed at promoting water efficiency. Many countries have implemented stricter water use standards and offer financial incentives for the adoption of water-saving technologies, including efficient pumping systems.

Emerging economies, particularly in Asia and Africa, are expected to be key growth drivers for the water conservation market. Rapid industrialization, urbanization, and agricultural expansion in these regions are creating a pressing need for efficient water management solutions, including advanced pumping systems with induction motors.

As the global focus on sustainability intensifies, the water conservation market is projected to continue its upward trajectory. The integration of induction motors in pump systems is poised to play a crucial role in meeting this growing demand, offering a combination of improved efficiency, reliability, and environmental benefits that align with the market's evolving needs.

Induction Motor Pump Challenges

Induction motors in pump systems face several challenges that impact their efficiency and water conservation capabilities. One of the primary issues is the mismatch between pump capacity and system requirements. Many pumps are oversized for their applications, leading to excessive energy consumption and water waste. This occurs due to the difficulty in accurately predicting system demands and the tendency to err on the side of caution during design phases.

Another significant challenge is the lack of speed control in traditional induction motor-driven pumps. These systems often operate at a fixed speed, regardless of the actual demand. This results in unnecessary energy expenditure and potential water loss, especially during periods of low demand. The inability to adjust motor speed in response to varying system needs leads to inefficient operation and increased wear on pump components.

Maintenance and reliability issues also pose challenges for induction motor pumps. Wear and tear on bearings, seals, and impellers can lead to decreased efficiency over time. This gradual decline in performance may go unnoticed, resulting in increased energy consumption and potential water leakage. Regular maintenance is crucial but often overlooked, leading to premature equipment failure and system inefficiencies.

The starting characteristics of induction motors present another challenge. The high inrush current during motor start-up can cause voltage dips in the electrical system, potentially affecting other equipment. This issue is particularly problematic in areas with weak power grids or when frequent start-stop cycles are required. The stress on the motor and pump components during these start-ups can also lead to reduced equipment lifespan and increased maintenance needs.

Heat generation is a persistent issue in induction motor-driven pumps. As motors operate, they generate heat, which can affect their efficiency and lifespan. Inadequate cooling or ventilation can exacerbate this problem, leading to increased energy losses and potential motor failure. In water pumping applications, this heat generation can also impact the temperature of the pumped water, which may be undesirable in certain processes.

Power factor correction is another challenge associated with induction motors in pump systems. Induction motors typically operate at a lagging power factor, which can result in increased electrical losses and potential penalties from utility companies. Implementing power factor correction measures adds complexity and cost to the system, but is often necessary for optimal performance and compliance with utility regulations.

Lastly, the integration of induction motor pumps with modern control systems and IoT technologies presents both opportunities and challenges. While these technologies offer the potential for improved monitoring and control, they require significant investment in hardware, software, and training. The complexity of implementing advanced control strategies and the need for skilled personnel to manage these systems can be barriers to adoption, particularly for smaller operations or in regions with limited technical resources.

Another significant challenge is the lack of speed control in traditional induction motor-driven pumps. These systems often operate at a fixed speed, regardless of the actual demand. This results in unnecessary energy expenditure and potential water loss, especially during periods of low demand. The inability to adjust motor speed in response to varying system needs leads to inefficient operation and increased wear on pump components.

Maintenance and reliability issues also pose challenges for induction motor pumps. Wear and tear on bearings, seals, and impellers can lead to decreased efficiency over time. This gradual decline in performance may go unnoticed, resulting in increased energy consumption and potential water leakage. Regular maintenance is crucial but often overlooked, leading to premature equipment failure and system inefficiencies.

The starting characteristics of induction motors present another challenge. The high inrush current during motor start-up can cause voltage dips in the electrical system, potentially affecting other equipment. This issue is particularly problematic in areas with weak power grids or when frequent start-stop cycles are required. The stress on the motor and pump components during these start-ups can also lead to reduced equipment lifespan and increased maintenance needs.

Heat generation is a persistent issue in induction motor-driven pumps. As motors operate, they generate heat, which can affect their efficiency and lifespan. Inadequate cooling or ventilation can exacerbate this problem, leading to increased energy losses and potential motor failure. In water pumping applications, this heat generation can also impact the temperature of the pumped water, which may be undesirable in certain processes.

Power factor correction is another challenge associated with induction motors in pump systems. Induction motors typically operate at a lagging power factor, which can result in increased electrical losses and potential penalties from utility companies. Implementing power factor correction measures adds complexity and cost to the system, but is often necessary for optimal performance and compliance with utility regulations.

Lastly, the integration of induction motor pumps with modern control systems and IoT technologies presents both opportunities and challenges. While these technologies offer the potential for improved monitoring and control, they require significant investment in hardware, software, and training. The complexity of implementing advanced control strategies and the need for skilled personnel to manage these systems can be barriers to adoption, particularly for smaller operations or in regions with limited technical resources.

Current Water-Saving Pump Tech

01 Energy-efficient induction motor systems

Improved designs for induction motor systems that focus on energy efficiency and water conservation. These systems incorporate advanced control mechanisms and optimized components to reduce power consumption while maintaining or improving performance in water-related applications.- Energy-efficient induction motor systems: Induction motor systems designed for improved energy efficiency in water conservation applications. These systems incorporate advanced control mechanisms and optimized motor designs to reduce power consumption while maintaining performance in water pumping and distribution systems.

- Water-saving irrigation systems with induction motors: Irrigation systems utilizing induction motors for precise water distribution and conservation. These systems employ sensors, automated controls, and variable speed drives to optimize water usage in agricultural and landscaping applications.

- Induction motor-driven water recycling and treatment systems: Water recycling and treatment systems powered by induction motors, designed to conserve water through efficient purification and reuse processes. These systems incorporate advanced filtration technologies and motor control strategies to minimize energy consumption and water waste.

- Smart water distribution systems with induction motor pumps: Intelligent water distribution systems utilizing induction motor-driven pumps for efficient water management. These systems integrate IoT technologies, real-time monitoring, and predictive maintenance to optimize water flow and reduce losses in municipal and industrial applications.

- Induction motor-powered water conservation appliances: Household and commercial appliances incorporating induction motors for water-saving operations. These appliances, such as washing machines and dishwashers, use advanced motor control techniques and water-efficient cycles to minimize water consumption while maintaining cleaning performance.

02 Water pump control using induction motors

Innovative control systems for water pumps powered by induction motors. These systems utilize sensors, variable frequency drives, and intelligent algorithms to optimize water flow, pressure, and energy usage based on demand, resulting in significant water and energy savings.Expand Specific Solutions03 Induction motor-driven irrigation systems

Advanced irrigation systems utilizing induction motors for water distribution and conservation in agricultural applications. These systems incorporate precision control, scheduling, and monitoring features to minimize water waste and optimize crop yield.Expand Specific Solutions04 Water treatment and recycling with induction motors

Innovative water treatment and recycling systems powered by induction motors. These solutions integrate efficient motor designs with advanced filtration and purification technologies to conserve water in industrial and municipal applications.Expand Specific Solutions05 Smart monitoring and control for water conservation

Intelligent monitoring and control systems that integrate with induction motor-driven water applications. These systems utilize IoT technologies, data analytics, and machine learning algorithms to optimize water usage, detect leaks, and provide predictive maintenance, resulting in improved water conservation.Expand Specific Solutions

Key Induction Motor Manufacturers

The induction motor technology for water conservation in pumps is in a mature stage of development, with a significant market presence and ongoing innovations. The global market for energy-efficient pumps, including those utilizing induction motors, is substantial and growing, driven by increasing focus on sustainability and water conservation. Major players like Robert Bosch GmbH, Hitachi Ltd., and Toyota Motor Corp. are investing in research and development to improve motor efficiency and reduce water consumption. Companies such as OASE GmbH and Wuxi Haoyu Energy Saving and Environmental Protection Equipment Co., Ltd. are specializing in pump technologies, while automotive giants like Honda Motor Co., Ltd. and Nissan Motor Co., Ltd. are incorporating these advancements into their vehicle cooling systems.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed innovative induction motor-driven pump systems for large-scale water conservation projects. Their technology incorporates high-voltage, high-power induction motors with efficiency ratings exceeding 97% [7]. These motors feature advanced rotor designs with optimized slot geometries and low-loss magnetic materials to minimize energy losses. State Grid's pump systems utilize sophisticated control algorithms that integrate real-time data from multiple sources, including weather forecasts and water demand patterns, to optimize pump operation and minimize energy consumption [8]. The company has also implemented advanced power electronics and soft-start technologies to reduce mechanical stress on the pumps and extend their operational lifespan. Additionally, State Grid has developed a comprehensive monitoring and control system that allows for remote operation and predictive maintenance of pump stations across vast geographic areas, ensuring efficient water distribution and conservation on a national scale [9].

Strengths: High-power, high-efficiency motors suitable for large-scale applications, advanced control systems, and extensive monitoring capabilities. Weaknesses: High initial investment costs, may be overly complex for smaller water systems.

Hitachi Industrial Equipment Systems Co., Ltd.

Technical Solution: Hitachi Industrial Equipment Systems has developed a range of high-efficiency induction motor-driven pumps specifically designed for water conservation applications. Their pumps utilize advanced motor designs with low-loss magnetic materials and optimized winding configurations, achieving efficiency ratings of up to 96% [2]. The company's pump systems incorporate intelligent control algorithms that adjust motor speed and torque based on real-time demand, reducing energy consumption by up to 60% compared to conventional fixed-speed pumps [4]. Hitachi's pumps also feature innovative impeller designs that minimize turbulence and cavitation, improving overall hydraulic efficiency and reducing water waste. Furthermore, the company has implemented predictive maintenance technologies using IoT sensors and data analytics to optimize pump performance and prevent unexpected failures, ensuring consistent water conservation over the long term [6].

Strengths: Highly efficient motor designs, intelligent control systems, and advanced hydraulic components. Weaknesses: May have a higher upfront cost, requires specialized expertise for installation and maintenance.

Core Induction Motor Innovations

“an improved motor”

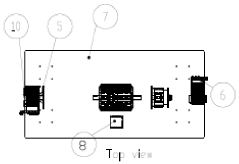

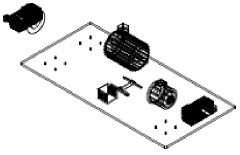

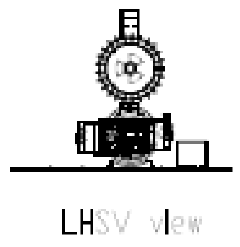

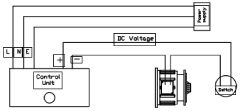

PatentActiveIN202121020334A

Innovation

- A compact and efficient 3-phase induction motor design that includes a motor wire box, clutch, clutch wire box, two pumps, an AC/DC volt control unit, control unit box, and auto cut-off pressure switch, allowing for simultaneous or sequential operation of two high pressure piston/plunger pumps, with automatic clutch engagement and disengagement to maintain operation even if one pump fails.

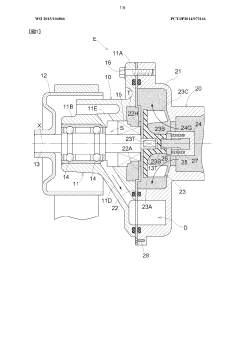

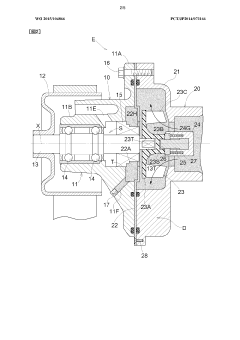

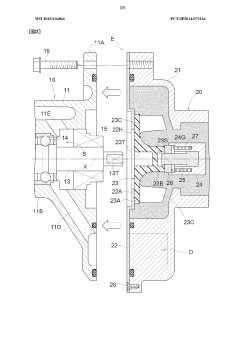

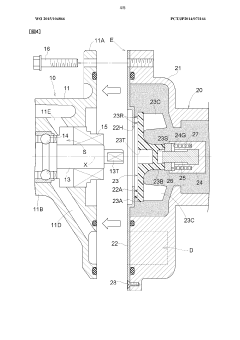

Water pump

PatentWO2015104866A1

Innovation

- A water pump design featuring a first unit with a drive shaft and partition wall insertion hole, where the impeller acts as a closing member to prevent leakage during maintenance, eliminating the need for draining and refilling cooling water by using an urging member to ensure the impeller closes the insertion hole automatically.

Energy Regulations for Pumps

Energy regulations for pumps have become increasingly stringent in recent years, driven by the global imperative to reduce energy consumption and mitigate environmental impact. These regulations aim to improve the efficiency of pump systems, which are significant consumers of energy in various industrial and commercial applications.

The European Union has been at the forefront of implementing comprehensive energy efficiency standards for pumps. The EU's Ecodesign Directive, specifically EU Regulation 547/2012, sets minimum efficiency requirements for water pumps. This regulation applies to clean water pumps between 0.75 kW and 375 kW, covering a wide range of applications from residential to industrial use.

In the United States, the Department of Energy (DOE) has established energy conservation standards for certain types of pumps. These standards, codified in 10 CFR Part 431, set minimum efficiency levels for clean water pumps used in commercial and industrial applications. The regulations cover five categories of rotodynamic pumps, including end suction close-coupled (ESCC) and end suction frame mounted (ESFM) pumps.

China has also implemented energy efficiency regulations for pumps through its GB 19762 standard. This standard sets minimum energy performance requirements for centrifugal pumps, aiming to reduce energy consumption in the world's largest pump market.

The impact of these regulations on pump manufacturers and users has been significant. Manufacturers have been compelled to invest in research and development to improve pump designs and incorporate more efficient motors, including advanced induction motors. Users, particularly in industrial settings, have had to reassess their pump systems and often upgrade to more efficient models to comply with regulations and reduce operating costs.

Energy regulations have also spurred innovation in pump control systems. Variable frequency drives (VFDs) have become more prevalent, allowing pumps to operate at optimal efficiency points across a range of flow conditions. This technology, often used in conjunction with efficient induction motors, has greatly contributed to energy savings and water conservation efforts.

The implementation of these regulations has led to measurable improvements in pump efficiency. For example, the EU estimates that its pump regulations will lead to annual electricity savings of 3.3 TWh by 2020. In the U.S., the DOE projects that its pump efficiency standards will result in cumulative energy savings of 0.29 quads over 30 years of shipments.

As water scarcity becomes an increasingly pressing global issue, energy regulations for pumps are likely to become even more stringent. Future regulations may expand to cover a broader range of pump types and sizes, and may also incorporate requirements for smart pump technologies that can adapt to changing system conditions for optimal efficiency.

The European Union has been at the forefront of implementing comprehensive energy efficiency standards for pumps. The EU's Ecodesign Directive, specifically EU Regulation 547/2012, sets minimum efficiency requirements for water pumps. This regulation applies to clean water pumps between 0.75 kW and 375 kW, covering a wide range of applications from residential to industrial use.

In the United States, the Department of Energy (DOE) has established energy conservation standards for certain types of pumps. These standards, codified in 10 CFR Part 431, set minimum efficiency levels for clean water pumps used in commercial and industrial applications. The regulations cover five categories of rotodynamic pumps, including end suction close-coupled (ESCC) and end suction frame mounted (ESFM) pumps.

China has also implemented energy efficiency regulations for pumps through its GB 19762 standard. This standard sets minimum energy performance requirements for centrifugal pumps, aiming to reduce energy consumption in the world's largest pump market.

The impact of these regulations on pump manufacturers and users has been significant. Manufacturers have been compelled to invest in research and development to improve pump designs and incorporate more efficient motors, including advanced induction motors. Users, particularly in industrial settings, have had to reassess their pump systems and often upgrade to more efficient models to comply with regulations and reduce operating costs.

Energy regulations have also spurred innovation in pump control systems. Variable frequency drives (VFDs) have become more prevalent, allowing pumps to operate at optimal efficiency points across a range of flow conditions. This technology, often used in conjunction with efficient induction motors, has greatly contributed to energy savings and water conservation efforts.

The implementation of these regulations has led to measurable improvements in pump efficiency. For example, the EU estimates that its pump regulations will lead to annual electricity savings of 3.3 TWh by 2020. In the U.S., the DOE projects that its pump efficiency standards will result in cumulative energy savings of 0.29 quads over 30 years of shipments.

As water scarcity becomes an increasingly pressing global issue, energy regulations for pumps are likely to become even more stringent. Future regulations may expand to cover a broader range of pump types and sizes, and may also incorporate requirements for smart pump technologies that can adapt to changing system conditions for optimal efficiency.

Environmental Impact Assessment

The implementation of induction motors in pump systems has significant environmental implications, particularly in the realm of water conservation. These motors, when properly integrated, can substantially reduce water waste and improve overall system efficiency. By precisely controlling pump speed and output, induction motors allow for more accurate water distribution, minimizing excess flow and reducing unnecessary water consumption.

One of the primary environmental benefits is the reduction in energy usage. Induction motors, especially when coupled with variable frequency drives (VFDs), can adjust their speed to match the exact pumping requirements. This results in lower power consumption during periods of reduced demand, leading to decreased electricity usage and, consequently, lower greenhouse gas emissions associated with power generation.

The improved efficiency of pump systems equipped with induction motors also contributes to the conservation of water resources. By eliminating over-pumping and maintaining optimal pressure levels, these systems prevent water loss through leaks and excessive discharge. This is particularly crucial in regions facing water scarcity, where every drop saved contributes to sustainable water management.

Furthermore, the enhanced control offered by induction motors allows for more effective implementation of smart water management systems. These systems can respond dynamically to changing demand patterns, weather conditions, and other environmental factors, ensuring that water distribution is optimized at all times. This level of precision not only conserves water but also reduces the strain on water treatment facilities and distribution infrastructure.

The environmental impact extends beyond direct water and energy savings. By reducing the overall water demand, induction motor-equipped pumps help alleviate pressure on natural water sources such as rivers, lakes, and aquifers. This contributes to the preservation of aquatic ecosystems and biodiversity, which are often negatively affected by excessive water extraction.

Additionally, the longevity and reliability of induction motors lead to reduced maintenance requirements and less frequent replacements. This translates to fewer resources consumed in manufacturing and disposing of pump components, further minimizing the environmental footprint of water distribution systems.

In urban environments, the noise reduction achieved through the use of induction motors in pump systems contributes to improved quality of life and reduced noise pollution. This aspect, while often overlooked, is an important environmental consideration, particularly in densely populated areas where pump stations are located near residential zones.

One of the primary environmental benefits is the reduction in energy usage. Induction motors, especially when coupled with variable frequency drives (VFDs), can adjust their speed to match the exact pumping requirements. This results in lower power consumption during periods of reduced demand, leading to decreased electricity usage and, consequently, lower greenhouse gas emissions associated with power generation.

The improved efficiency of pump systems equipped with induction motors also contributes to the conservation of water resources. By eliminating over-pumping and maintaining optimal pressure levels, these systems prevent water loss through leaks and excessive discharge. This is particularly crucial in regions facing water scarcity, where every drop saved contributes to sustainable water management.

Furthermore, the enhanced control offered by induction motors allows for more effective implementation of smart water management systems. These systems can respond dynamically to changing demand patterns, weather conditions, and other environmental factors, ensuring that water distribution is optimized at all times. This level of precision not only conserves water but also reduces the strain on water treatment facilities and distribution infrastructure.

The environmental impact extends beyond direct water and energy savings. By reducing the overall water demand, induction motor-equipped pumps help alleviate pressure on natural water sources such as rivers, lakes, and aquifers. This contributes to the preservation of aquatic ecosystems and biodiversity, which are often negatively affected by excessive water extraction.

Additionally, the longevity and reliability of induction motors lead to reduced maintenance requirements and less frequent replacements. This translates to fewer resources consumed in manufacturing and disposing of pump components, further minimizing the environmental footprint of water distribution systems.

In urban environments, the noise reduction achieved through the use of induction motors in pump systems contributes to improved quality of life and reduced noise pollution. This aspect, while often overlooked, is an important environmental consideration, particularly in densely populated areas where pump stations are located near residential zones.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!