How Synthetic Additives Enhance Power Steering Fluid Efficiency

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Synthetic Additives in Power Steering: Evolution and Objectives

Power steering fluid has undergone significant evolution since its inception in the automotive industry. Initially, mineral oil-based fluids were the standard, offering basic lubrication and hydraulic properties. However, as vehicle technologies advanced and performance demands increased, the limitations of conventional fluids became apparent, leading to the development of synthetic additives.

The primary objective of incorporating synthetic additives into power steering fluids is to enhance overall system efficiency and longevity. These additives are designed to improve the fluid's performance across a wide range of operating conditions, from extreme temperatures to high-pressure environments. By modifying the base fluid's properties, synthetic additives aim to reduce friction, minimize wear, and maintain consistent viscosity.

One of the key evolutionary steps in power steering fluid technology has been the introduction of anti-wear additives. These compounds form protective layers on metal surfaces, significantly reducing component wear and extending the life of power steering systems. Concurrently, viscosity modifiers have been developed to ensure that the fluid maintains optimal thickness across varying temperatures, crucial for consistent steering performance in diverse climates.

Corrosion inhibitors represent another critical advancement in synthetic additive technology. These additives form protective barriers on metal surfaces, preventing oxidation and corrosion that can lead to system failure. This innovation has been particularly important in extending the service life of power steering components and reducing maintenance requirements.

The evolution of synthetic additives has also focused on improving the fluid's ability to dissipate heat. Thermal stability additives ensure that the fluid maintains its properties even under high-temperature conditions, preventing breakdown and maintaining system efficiency. This advancement has been crucial in meeting the demands of modern vehicles with more compact engine compartments and higher operating temperatures.

Recent developments in synthetic additive technology have targeted the reduction of noise and vibration in power steering systems. Specialized additives have been formulated to dampen hydraulic pulsations and minimize the transmission of vibrations through the steering column, resulting in a smoother and more refined driving experience.

Looking forward, the objectives for synthetic additives in power steering fluids continue to evolve. Current research is focused on developing bio-based additives that offer similar or superior performance to traditional synthetic compounds while reducing environmental impact. Additionally, there is a growing emphasis on creating additives that are compatible with electric power steering systems, which have different requirements compared to hydraulic systems.

The primary objective of incorporating synthetic additives into power steering fluids is to enhance overall system efficiency and longevity. These additives are designed to improve the fluid's performance across a wide range of operating conditions, from extreme temperatures to high-pressure environments. By modifying the base fluid's properties, synthetic additives aim to reduce friction, minimize wear, and maintain consistent viscosity.

One of the key evolutionary steps in power steering fluid technology has been the introduction of anti-wear additives. These compounds form protective layers on metal surfaces, significantly reducing component wear and extending the life of power steering systems. Concurrently, viscosity modifiers have been developed to ensure that the fluid maintains optimal thickness across varying temperatures, crucial for consistent steering performance in diverse climates.

Corrosion inhibitors represent another critical advancement in synthetic additive technology. These additives form protective barriers on metal surfaces, preventing oxidation and corrosion that can lead to system failure. This innovation has been particularly important in extending the service life of power steering components and reducing maintenance requirements.

The evolution of synthetic additives has also focused on improving the fluid's ability to dissipate heat. Thermal stability additives ensure that the fluid maintains its properties even under high-temperature conditions, preventing breakdown and maintaining system efficiency. This advancement has been crucial in meeting the demands of modern vehicles with more compact engine compartments and higher operating temperatures.

Recent developments in synthetic additive technology have targeted the reduction of noise and vibration in power steering systems. Specialized additives have been formulated to dampen hydraulic pulsations and minimize the transmission of vibrations through the steering column, resulting in a smoother and more refined driving experience.

Looking forward, the objectives for synthetic additives in power steering fluids continue to evolve. Current research is focused on developing bio-based additives that offer similar or superior performance to traditional synthetic compounds while reducing environmental impact. Additionally, there is a growing emphasis on creating additives that are compatible with electric power steering systems, which have different requirements compared to hydraulic systems.

Market Demand for Enhanced Power Steering Performance

The demand for enhanced power steering performance has been steadily increasing in recent years, driven by several key factors in the automotive industry. Consumers are increasingly seeking vehicles that offer improved handling, responsiveness, and overall driving experience. This trend has led to a growing market for power steering systems that can deliver smoother operation, reduced steering effort, and better feedback to the driver.

In the passenger vehicle segment, there is a notable shift towards electric power steering (EPS) systems, which offer advantages in terms of energy efficiency and compatibility with advanced driver assistance systems (ADAS). However, hydraulic power steering systems remain prevalent in many vehicle types, particularly in larger vehicles, trucks, and heavy-duty applications. This dual-market scenario has created a demand for both advanced EPS technologies and improved hydraulic power steering fluids.

The commercial vehicle sector, including trucks and buses, has shown a significant interest in enhanced power steering performance. Fleet operators are looking for solutions that can reduce driver fatigue, improve vehicle maneuverability, and increase overall operational efficiency. This has led to a growing demand for power steering fluids that can maintain their performance under extreme conditions and extended use.

The aftermarket segment has also witnessed an uptick in demand for high-performance power steering fluids. Vehicle owners are becoming more aware of the importance of proper maintenance and are willing to invest in premium products that promise improved steering performance and longevity of steering components.

Environmental concerns and regulatory pressures have further shaped the market demand. There is an increasing focus on developing power steering fluids that are more environmentally friendly, biodegradable, and compliant with stringent regulations. This has led to a growing interest in synthetic additives that can enhance the efficiency of power steering fluids while meeting environmental standards.

The racing and high-performance vehicle market represents a niche but influential segment driving innovation in power steering technology. The demand for ultra-responsive steering systems in this sector often translates into advancements that eventually trickle down to mainstream vehicles, creating a ripple effect in the broader market for enhanced power steering performance.

As vehicle electrification continues to gain momentum, there is a parallel demand for power steering solutions that can seamlessly integrate with electric and hybrid powertrains. This has spurred research into power steering fluids and additives that are compatible with the unique requirements of electrified vehicle architectures.

In the passenger vehicle segment, there is a notable shift towards electric power steering (EPS) systems, which offer advantages in terms of energy efficiency and compatibility with advanced driver assistance systems (ADAS). However, hydraulic power steering systems remain prevalent in many vehicle types, particularly in larger vehicles, trucks, and heavy-duty applications. This dual-market scenario has created a demand for both advanced EPS technologies and improved hydraulic power steering fluids.

The commercial vehicle sector, including trucks and buses, has shown a significant interest in enhanced power steering performance. Fleet operators are looking for solutions that can reduce driver fatigue, improve vehicle maneuverability, and increase overall operational efficiency. This has led to a growing demand for power steering fluids that can maintain their performance under extreme conditions and extended use.

The aftermarket segment has also witnessed an uptick in demand for high-performance power steering fluids. Vehicle owners are becoming more aware of the importance of proper maintenance and are willing to invest in premium products that promise improved steering performance and longevity of steering components.

Environmental concerns and regulatory pressures have further shaped the market demand. There is an increasing focus on developing power steering fluids that are more environmentally friendly, biodegradable, and compliant with stringent regulations. This has led to a growing interest in synthetic additives that can enhance the efficiency of power steering fluids while meeting environmental standards.

The racing and high-performance vehicle market represents a niche but influential segment driving innovation in power steering technology. The demand for ultra-responsive steering systems in this sector often translates into advancements that eventually trickle down to mainstream vehicles, creating a ripple effect in the broader market for enhanced power steering performance.

As vehicle electrification continues to gain momentum, there is a parallel demand for power steering solutions that can seamlessly integrate with electric and hybrid powertrains. This has spurred research into power steering fluids and additives that are compatible with the unique requirements of electrified vehicle architectures.

Current State and Challenges in Power Steering Fluid Technology

Power steering fluid technology has undergone significant advancements in recent years, with synthetic additives playing a crucial role in enhancing efficiency. The current state of power steering fluid technology is characterized by a focus on improving performance, extending fluid life, and reducing environmental impact.

One of the primary challenges in power steering fluid technology is the need for increased durability and stability under extreme conditions. Modern vehicles are subject to higher temperatures and pressures, which can cause conventional fluids to break down more quickly. Synthetic additives have been developed to address this issue, providing improved thermal and oxidative stability.

Another significant challenge is the reduction of friction and wear within power steering systems. Synthetic additives, such as friction modifiers and anti-wear agents, have been formulated to create a more robust protective film on metal surfaces, reducing friction and minimizing component wear. This not only improves system efficiency but also extends the lifespan of power steering components.

The automotive industry's shift towards electric power steering systems has presented new challenges for fluid technology. While these systems generally require less fluid, they demand higher performance and longevity from the fluids used. Synthetic additives are being tailored to meet these specific requirements, offering enhanced electrical properties and compatibility with new materials used in electric power steering systems.

Environmental concerns have also driven innovation in power steering fluid technology. There is a growing demand for more environmentally friendly fluids that maintain high performance standards. Synthetic additives are being developed to create biodegradable fluids with reduced toxicity, addressing both regulatory requirements and consumer preferences for greener automotive products.

The integration of nanotechnology in power steering fluid formulations represents a cutting-edge development in the field. Nanoparticle additives are being explored for their potential to further reduce friction, improve heat transfer, and enhance the overall efficiency of power steering systems. However, the long-term effects and potential risks of these nanoparticles are still under investigation.

A persistent challenge in the industry is the balance between cost and performance. While synthetic additives offer superior properties, they often come at a higher price point. Manufacturers are continually working to optimize formulations that provide the best performance-to-cost ratio, making advanced power steering fluids more accessible to a broader market.

Standardization of power steering fluid specifications across different vehicle manufacturers remains an ongoing challenge. The diversity of requirements can lead to confusion among consumers and potential compatibility issues. Efforts are being made to develop more universal fluid standards that can meet the needs of various vehicle types and brands.

One of the primary challenges in power steering fluid technology is the need for increased durability and stability under extreme conditions. Modern vehicles are subject to higher temperatures and pressures, which can cause conventional fluids to break down more quickly. Synthetic additives have been developed to address this issue, providing improved thermal and oxidative stability.

Another significant challenge is the reduction of friction and wear within power steering systems. Synthetic additives, such as friction modifiers and anti-wear agents, have been formulated to create a more robust protective film on metal surfaces, reducing friction and minimizing component wear. This not only improves system efficiency but also extends the lifespan of power steering components.

The automotive industry's shift towards electric power steering systems has presented new challenges for fluid technology. While these systems generally require less fluid, they demand higher performance and longevity from the fluids used. Synthetic additives are being tailored to meet these specific requirements, offering enhanced electrical properties and compatibility with new materials used in electric power steering systems.

Environmental concerns have also driven innovation in power steering fluid technology. There is a growing demand for more environmentally friendly fluids that maintain high performance standards. Synthetic additives are being developed to create biodegradable fluids with reduced toxicity, addressing both regulatory requirements and consumer preferences for greener automotive products.

The integration of nanotechnology in power steering fluid formulations represents a cutting-edge development in the field. Nanoparticle additives are being explored for their potential to further reduce friction, improve heat transfer, and enhance the overall efficiency of power steering systems. However, the long-term effects and potential risks of these nanoparticles are still under investigation.

A persistent challenge in the industry is the balance between cost and performance. While synthetic additives offer superior properties, they often come at a higher price point. Manufacturers are continually working to optimize formulations that provide the best performance-to-cost ratio, making advanced power steering fluids more accessible to a broader market.

Standardization of power steering fluid specifications across different vehicle manufacturers remains an ongoing challenge. The diversity of requirements can lead to confusion among consumers and potential compatibility issues. Efforts are being made to develop more universal fluid standards that can meet the needs of various vehicle types and brands.

Existing Synthetic Additive Solutions for Power Steering Fluids

01 Synthetic additives for improved fuel efficiency

Synthetic additives are used to enhance fuel efficiency in various applications. These additives can improve combustion, reduce friction, and optimize engine performance. They are designed to work synergistically with fuel components to increase overall efficiency and reduce emissions.- Synthetic additives for improved fuel efficiency: Synthetic additives are developed to enhance fuel efficiency in various applications. These additives can improve combustion processes, reduce friction, and optimize engine performance. They are designed to work at the molecular level, modifying fuel properties to achieve better energy utilization and reduced emissions.

- Efficiency enhancement in lubricants and greases: Synthetic additives are formulated to improve the efficiency of lubricants and greases. These additives can reduce friction, enhance wear protection, and extend the lifespan of mechanical components. They are particularly useful in high-temperature and high-pressure environments, where traditional lubricants may break down.

- Synthetic additives for polymer processing: Efficiency-enhancing synthetic additives are developed for polymer processing applications. These additives can improve flow characteristics, reduce cycle times, and enhance the overall quality of polymer products. They may also contribute to energy savings during the manufacturing process by optimizing processing conditions.

- Water treatment and purification efficiency: Synthetic additives are designed to improve the efficiency of water treatment and purification processes. These additives can enhance coagulation, flocculation, and filtration, leading to more effective removal of contaminants. They may also reduce the amount of chemicals needed in the treatment process, resulting in cost savings and environmental benefits.

- Efficiency improvement in chemical reactions and catalysis: Synthetic additives are developed to enhance the efficiency of chemical reactions and catalytic processes. These additives can increase reaction rates, improve selectivity, and reduce energy requirements. They are particularly valuable in industrial applications where process optimization can lead to significant cost savings and reduced environmental impact.

02 Efficiency-enhancing additives for lubricants

Synthetic additives are formulated to improve the efficiency of lubricants. These additives can reduce friction, enhance wear protection, and extend the life of mechanical components. They are particularly useful in automotive and industrial applications where improved energy efficiency is crucial.Expand Specific Solutions03 Synthetic additives for textile processing efficiency

In the textile industry, synthetic additives are used to enhance processing efficiency. These additives can improve dyeing, finishing, and overall fabric quality. They help in reducing water and energy consumption during textile manufacturing processes, leading to increased productivity and reduced environmental impact.Expand Specific Solutions04 Efficiency-boosting additives for polymer production

Synthetic additives play a crucial role in improving the efficiency of polymer production processes. These additives can enhance polymerization rates, improve polymer properties, and reduce energy consumption during manufacturing. They contribute to the development of high-performance plastics and composites with improved efficiency.Expand Specific Solutions05 Synthetic additives for enhanced agricultural efficiency

In agriculture, synthetic additives are used to improve the efficiency of various processes. These additives can enhance fertilizer uptake, improve pest resistance, and optimize crop yields. They contribute to more sustainable farming practices by reducing resource consumption and increasing overall agricultural productivity.Expand Specific Solutions

Key Players in Synthetic Additive and Automotive Fluid Industry

The market for synthetic additives in power steering fluid is in a mature stage, with established players like Afton Chemical Corp., The Lubrizol Corp., and Infineum International Ltd. dominating the landscape. The global power steering fluid market size is estimated to be in the billions, driven by the automotive industry's growth and increasing demand for fuel-efficient vehicles. Technologically, the field is advancing, with companies like BASF Corp. and Exxonmobil Upstream Research Co. investing in research to develop more efficient and environmentally friendly formulations. Major automotive manufacturers such as Ford Global Technologies LLC and Mercedes-Benz Group AG are also actively involved in enhancing power steering fluid performance through synthetic additives, indicating the technology's critical role in vehicle efficiency and performance.

Afton Chemical Corp.

Technical Solution: Afton Chemical has developed a suite of synthetic additives specifically tailored for power steering fluid applications. Their technology focuses on improving the fluid's low-temperature performance and high-temperature stability, crucial for consistent operation in diverse climates. Afton's additives incorporate advanced pour point depressants that prevent fluid thickening at low temperatures, ensuring smooth steering even in cold starts [7]. The company has also introduced novel anti-foam agents that reduce air entrainment, maintaining the fluid's incompressibility and responsiveness [9]. Afton's synthetic package includes proprietary corrosion inhibitors that form a protective layer on metal surfaces, extending the life of power steering components and preventing system failures due to corrosion [11]. Additionally, their additives are designed to be compatible with seal materials, preventing leaks and maintaining system integrity over extended periods [13].

Strengths: Excellent low-temperature performance, superior foam control, and enhanced corrosion protection. Weaknesses: May have higher production costs and require more complex formulation processes.

BASF Corp.

Technical Solution: BASF has engineered a comprehensive range of synthetic additives for power steering fluids that focus on enhancing overall system efficiency and longevity. Their approach involves the use of advanced polymer technology to improve the fluid's viscosity-temperature relationship, ensuring optimal performance across a wide operating range [10]. BASF's additives incorporate novel friction modifiers that reduce energy loss in the power steering system, leading to improved fuel economy and smoother operation [12]. The company has also developed unique anti-wear compounds that form protective films on metal surfaces, significantly reducing component wear and extending system life [14]. BASF's synthetic package includes advanced oxidation inhibitors that prevent fluid breakdown under high temperatures and pressures, maintaining performance over extended periods [16]. Additionally, their additives are designed to be compatible with a variety of elastomers used in power steering systems, preventing seal degradation and fluid leakage [18].

Strengths: Comprehensive performance enhancement, excellent wear protection, and long-term stability. Weaknesses: May require specialized blending equipment and potentially higher raw material costs.

Core Innovations in Synthetic Additive Technology

Power steering fluid additive

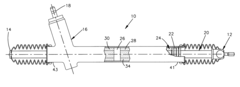

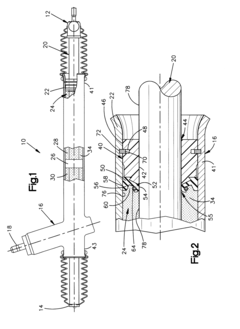

PatentInactiveUS6503871B2

Innovation

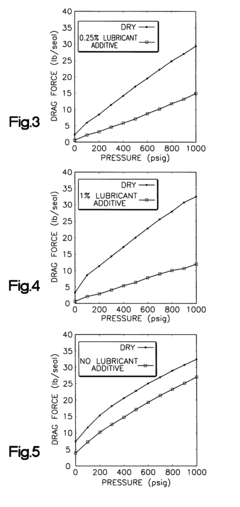

- A power steering fluid comprising a base oil and a metal-free lubricant additive, specifically a fatty acid salt of a secondary amine, which reduces interfacial surface tension and effectively lubricates the seals and metal racks, reducing friction and noise.

Power steering fluid with wide performance range

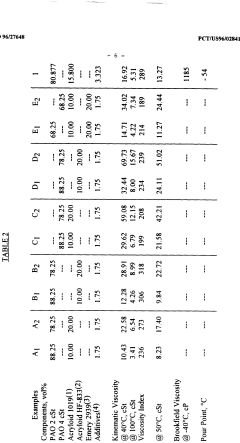

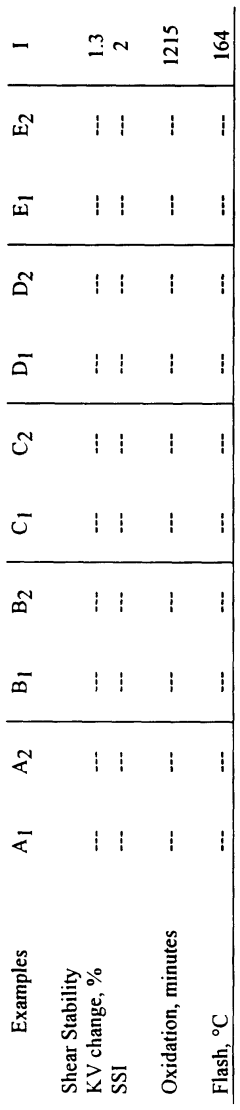

PatentWO1996027648A1

Innovation

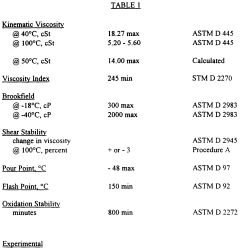

- A power steering fluid comprising 75-85 vol% poly alpha olefin (PAO 2) and 14-18 vol% polymethacrylate with a weight average molecular weight of 50,000 to 300,000, along with conventional additives, is developed to achieve kinematic viscosities of 5.2-5.6 cSt @ 100°C, 14 cSt max @ 50°C, and a viscosity index of 245 minimum, while maintaining shear stability, pour point, and oxidation stability.

Environmental Impact of Synthetic Power Steering Fluids

The environmental impact of synthetic power steering fluids is a critical consideration in the automotive industry's pursuit of sustainability. These fluids, enhanced with synthetic additives, offer improved efficiency and performance but also raise concerns about their ecological footprint. The production of synthetic power steering fluids involves complex chemical processes that may contribute to greenhouse gas emissions and resource depletion. However, their extended lifespan and improved efficiency can potentially offset these initial environmental costs over time.

One of the primary environmental benefits of synthetic power steering fluids is their longevity. Compared to conventional mineral-based fluids, synthetic variants typically last significantly longer, reducing the frequency of fluid changes and disposal. This extended service life translates to fewer waste products entering the environment and decreased demand for raw materials in fluid production. Additionally, the improved thermal stability of synthetic fluids helps maintain optimal performance under extreme conditions, potentially reducing energy consumption in power steering systems.

However, the disposal of used synthetic power steering fluids presents environmental challenges. These fluids often contain additives that can be harmful to ecosystems if not properly managed. Improper disposal can lead to soil and water contamination, affecting both terrestrial and aquatic life. To mitigate these risks, stringent recycling and disposal protocols are essential, requiring specialized facilities and processes to handle these synthetic fluids safely.

The manufacturing process of synthetic additives for power steering fluids also warrants environmental scrutiny. While these additives enhance fluid efficiency, their production may involve energy-intensive processes and the use of potentially hazardous chemicals. Balancing the environmental costs of production against the long-term benefits of improved fluid performance is crucial in assessing the overall ecological impact.

Advancements in green chemistry are driving the development of more environmentally friendly synthetic additives. Researchers are exploring bio-based alternatives and less toxic formulations that maintain high performance while reducing environmental risks. These innovations aim to create power steering fluids that are not only more efficient but also more sustainable throughout their lifecycle.

The automotive industry's shift towards electric vehicles (EVs) is also influencing the environmental considerations of power steering fluids. As EVs become more prevalent, the demand for traditional hydraulic power steering systems may decrease, potentially reducing the overall environmental impact of power steering fluids. However, this transition also highlights the need for continued research into sustainable fluid technologies for the remaining hydraulic systems and emerging electric power steering solutions.

One of the primary environmental benefits of synthetic power steering fluids is their longevity. Compared to conventional mineral-based fluids, synthetic variants typically last significantly longer, reducing the frequency of fluid changes and disposal. This extended service life translates to fewer waste products entering the environment and decreased demand for raw materials in fluid production. Additionally, the improved thermal stability of synthetic fluids helps maintain optimal performance under extreme conditions, potentially reducing energy consumption in power steering systems.

However, the disposal of used synthetic power steering fluids presents environmental challenges. These fluids often contain additives that can be harmful to ecosystems if not properly managed. Improper disposal can lead to soil and water contamination, affecting both terrestrial and aquatic life. To mitigate these risks, stringent recycling and disposal protocols are essential, requiring specialized facilities and processes to handle these synthetic fluids safely.

The manufacturing process of synthetic additives for power steering fluids also warrants environmental scrutiny. While these additives enhance fluid efficiency, their production may involve energy-intensive processes and the use of potentially hazardous chemicals. Balancing the environmental costs of production against the long-term benefits of improved fluid performance is crucial in assessing the overall ecological impact.

Advancements in green chemistry are driving the development of more environmentally friendly synthetic additives. Researchers are exploring bio-based alternatives and less toxic formulations that maintain high performance while reducing environmental risks. These innovations aim to create power steering fluids that are not only more efficient but also more sustainable throughout their lifecycle.

The automotive industry's shift towards electric vehicles (EVs) is also influencing the environmental considerations of power steering fluids. As EVs become more prevalent, the demand for traditional hydraulic power steering systems may decrease, potentially reducing the overall environmental impact of power steering fluids. However, this transition also highlights the need for continued research into sustainable fluid technologies for the remaining hydraulic systems and emerging electric power steering solutions.

Cost-Benefit Analysis of Enhanced Power Steering Fluids

The cost-benefit analysis of enhanced power steering fluids is a crucial consideration for automotive manufacturers and consumers alike. Synthetic additives in power steering fluids offer significant improvements in efficiency, but these benefits come at a price. To fully understand the economic implications, it is essential to examine both the costs and advantages associated with these enhanced fluids.

From a cost perspective, enhanced power steering fluids with synthetic additives are typically more expensive than traditional mineral-based fluids. The production process for synthetic additives involves complex chemical engineering, resulting in higher manufacturing costs. These increased expenses are often passed on to consumers, leading to a higher initial purchase price for enhanced fluids.

However, the benefits of using enhanced power steering fluids can potentially offset the higher upfront costs. Synthetic additives improve the fluid's thermal stability, reducing breakdown and extending the fluid's lifespan. This longevity translates to less frequent fluid changes, potentially lowering long-term maintenance costs for vehicle owners.

Enhanced fluids also offer improved performance across a wider temperature range. This characteristic is particularly valuable in extreme climates, where traditional fluids may become less effective. The consistent performance can lead to reduced wear on power steering components, potentially extending the life of the system and reducing repair costs over time.

Another significant benefit is the improved energy efficiency of power steering systems using enhanced fluids. Synthetic additives can reduce friction and improve fluid flow, resulting in smoother operation and potentially lower fuel consumption. While the fuel savings may be modest on an individual basis, they can accumulate to significant amounts across large fleets or over the lifetime of a vehicle.

From an environmental perspective, the use of enhanced power steering fluids can contribute to reduced waste. The extended lifespan of these fluids means fewer oil changes and less fluid disposal, aligning with sustainability goals and potentially reducing environmental compliance costs for businesses.

For automotive manufacturers, the decision to use enhanced power steering fluids in their vehicles involves balancing increased production costs against potential warranty savings and improved customer satisfaction. The enhanced durability and performance of these fluids may lead to fewer warranty claims related to power steering issues, potentially offsetting the higher initial costs.

In conclusion, while enhanced power steering fluids with synthetic additives come with higher upfront costs, their long-term benefits in terms of reduced maintenance, improved performance, and potential energy savings can provide a favorable cost-benefit ratio. The decision to use these fluids should be based on a comprehensive analysis of vehicle usage patterns, environmental conditions, and long-term ownership costs.

From a cost perspective, enhanced power steering fluids with synthetic additives are typically more expensive than traditional mineral-based fluids. The production process for synthetic additives involves complex chemical engineering, resulting in higher manufacturing costs. These increased expenses are often passed on to consumers, leading to a higher initial purchase price for enhanced fluids.

However, the benefits of using enhanced power steering fluids can potentially offset the higher upfront costs. Synthetic additives improve the fluid's thermal stability, reducing breakdown and extending the fluid's lifespan. This longevity translates to less frequent fluid changes, potentially lowering long-term maintenance costs for vehicle owners.

Enhanced fluids also offer improved performance across a wider temperature range. This characteristic is particularly valuable in extreme climates, where traditional fluids may become less effective. The consistent performance can lead to reduced wear on power steering components, potentially extending the life of the system and reducing repair costs over time.

Another significant benefit is the improved energy efficiency of power steering systems using enhanced fluids. Synthetic additives can reduce friction and improve fluid flow, resulting in smoother operation and potentially lower fuel consumption. While the fuel savings may be modest on an individual basis, they can accumulate to significant amounts across large fleets or over the lifetime of a vehicle.

From an environmental perspective, the use of enhanced power steering fluids can contribute to reduced waste. The extended lifespan of these fluids means fewer oil changes and less fluid disposal, aligning with sustainability goals and potentially reducing environmental compliance costs for businesses.

For automotive manufacturers, the decision to use enhanced power steering fluids in their vehicles involves balancing increased production costs against potential warranty savings and improved customer satisfaction. The enhanced durability and performance of these fluids may lead to fewer warranty claims related to power steering issues, potentially offsetting the higher initial costs.

In conclusion, while enhanced power steering fluids with synthetic additives come with higher upfront costs, their long-term benefits in terms of reduced maintenance, improved performance, and potential energy savings can provide a favorable cost-benefit ratio. The decision to use these fluids should be based on a comprehensive analysis of vehicle usage patterns, environmental conditions, and long-term ownership costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!