Power Steering Fluid's Role in Enhancing Vehicle Maneuverability

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking. The need for easier vehicle control led to the development of hydraulic power steering systems in the 1950s.

Hydraulic power steering marked a revolutionary change in vehicle maneuverability. This system utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. The power steering fluid, typically a mineral oil-based or synthetic hydraulic fluid, played a crucial role in transmitting power and reducing steering effort. This innovation greatly enhanced driving comfort and safety, particularly for larger vehicles.

As automotive technology advanced, electronic power steering (EPS) systems emerged in the 1990s. EPS replaced the hydraulic pump with an electric motor, eliminating the need for traditional power steering fluid. This transition offered several advantages, including improved fuel efficiency, reduced maintenance, and more precise steering control. The evolution of EPS systems has continued, with advancements in sensor technology and control algorithms further enhancing vehicle responsiveness and driver feedback.

In recent years, the focus has shifted towards integrating power steering systems with advanced driver assistance systems (ADAS) and autonomous driving technologies. This integration has led to the development of steer-by-wire systems, which completely eliminate the mechanical connection between the steering wheel and the wheels, relying entirely on electronic controls and actuators.

The role of power steering fluid has also evolved alongside these technological advancements. While traditional hydraulic systems still rely on power steering fluid, modern fluids have been engineered to provide improved performance, longevity, and compatibility with various materials used in steering components. In hybrid systems that combine hydraulic and electric elements, specialized fluids have been developed to meet the unique requirements of these configurations.

Looking towards the future, the evolution of power steering technology is likely to continue in the direction of increased electrification and integration with autonomous driving systems. While the use of traditional power steering fluid may decrease in newer vehicle models, its importance in maintaining and enhancing vehicle maneuverability in existing hydraulic and hybrid systems remains significant. The ongoing research and development in this field promise to deliver even more sophisticated steering solutions, further improving vehicle handling, safety, and overall driving experience.

Hydraulic power steering marked a revolutionary change in vehicle maneuverability. This system utilized a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. The power steering fluid, typically a mineral oil-based or synthetic hydraulic fluid, played a crucial role in transmitting power and reducing steering effort. This innovation greatly enhanced driving comfort and safety, particularly for larger vehicles.

As automotive technology advanced, electronic power steering (EPS) systems emerged in the 1990s. EPS replaced the hydraulic pump with an electric motor, eliminating the need for traditional power steering fluid. This transition offered several advantages, including improved fuel efficiency, reduced maintenance, and more precise steering control. The evolution of EPS systems has continued, with advancements in sensor technology and control algorithms further enhancing vehicle responsiveness and driver feedback.

In recent years, the focus has shifted towards integrating power steering systems with advanced driver assistance systems (ADAS) and autonomous driving technologies. This integration has led to the development of steer-by-wire systems, which completely eliminate the mechanical connection between the steering wheel and the wheels, relying entirely on electronic controls and actuators.

The role of power steering fluid has also evolved alongside these technological advancements. While traditional hydraulic systems still rely on power steering fluid, modern fluids have been engineered to provide improved performance, longevity, and compatibility with various materials used in steering components. In hybrid systems that combine hydraulic and electric elements, specialized fluids have been developed to meet the unique requirements of these configurations.

Looking towards the future, the evolution of power steering technology is likely to continue in the direction of increased electrification and integration with autonomous driving systems. While the use of traditional power steering fluid may decrease in newer vehicle models, its importance in maintaining and enhancing vehicle maneuverability in existing hydraulic and hybrid systems remains significant. The ongoing research and development in this field promise to deliver even more sophisticated steering solutions, further improving vehicle handling, safety, and overall driving experience.

Market Demand Analysis

The market demand for power steering fluid and its role in enhancing vehicle maneuverability has been steadily growing, driven by several key factors in the automotive industry. As vehicles become more sophisticated and consumers expect higher levels of performance and comfort, the importance of efficient power steering systems has increased significantly.

The global power steering fluid market has shown robust growth in recent years, with a compound annual growth rate (CAGR) projected to remain strong through the next decade. This growth is primarily attributed to the rising production of vehicles worldwide, particularly in emerging economies where automotive ownership is rapidly expanding. Additionally, the increasing average age of vehicles in developed markets has led to a surge in demand for aftermarket power steering fluid replacements and maintenance services.

Consumer preferences have shifted towards vehicles that offer smoother handling and improved maneuverability, especially in urban environments where tight parking spaces and congested roads are common. This trend has pushed automakers to focus on enhancing steering systems, with power steering fluid playing a crucial role in achieving these improvements. The market has also seen a growing demand for high-performance power steering fluids that can withstand extreme temperatures and provide longer-lasting protection for steering components.

Environmental concerns and regulatory pressures have influenced the power steering fluid market as well. There is an increasing demand for eco-friendly and biodegradable power steering fluids that minimize environmental impact in case of leaks or during disposal. This has led to innovations in fluid formulations, with manufacturers developing synthetic and semi-synthetic options that offer improved performance and sustainability.

The commercial vehicle segment has emerged as a significant driver of market growth for power steering fluids. With the expansion of e-commerce and logistics industries, there has been a surge in demand for light and heavy-duty commercial vehicles. These vehicles often operate under more demanding conditions and require high-quality power steering fluids to maintain optimal performance and extend the lifespan of steering components.

Technological advancements in vehicle design, such as the integration of electric power steering systems, have also impacted the power steering fluid market. While these systems reduce the overall demand for traditional hydraulic fluids, they have created new opportunities for specialized fluids designed for hybrid and electric power steering systems. This shift has prompted fluid manufacturers to invest in research and development to meet the evolving needs of modern vehicle architectures.

The aftermarket segment continues to be a substantial contributor to the power steering fluid market. As vehicle owners become more aware of the importance of regular maintenance in prolonging vehicle life and ensuring safety, there has been an uptick in demand for high-quality power steering fluids in the retail and service sectors. This trend is further supported by the growing do-it-yourself (DIY) culture among car enthusiasts, who seek premium products for their vehicles.

The global power steering fluid market has shown robust growth in recent years, with a compound annual growth rate (CAGR) projected to remain strong through the next decade. This growth is primarily attributed to the rising production of vehicles worldwide, particularly in emerging economies where automotive ownership is rapidly expanding. Additionally, the increasing average age of vehicles in developed markets has led to a surge in demand for aftermarket power steering fluid replacements and maintenance services.

Consumer preferences have shifted towards vehicles that offer smoother handling and improved maneuverability, especially in urban environments where tight parking spaces and congested roads are common. This trend has pushed automakers to focus on enhancing steering systems, with power steering fluid playing a crucial role in achieving these improvements. The market has also seen a growing demand for high-performance power steering fluids that can withstand extreme temperatures and provide longer-lasting protection for steering components.

Environmental concerns and regulatory pressures have influenced the power steering fluid market as well. There is an increasing demand for eco-friendly and biodegradable power steering fluids that minimize environmental impact in case of leaks or during disposal. This has led to innovations in fluid formulations, with manufacturers developing synthetic and semi-synthetic options that offer improved performance and sustainability.

The commercial vehicle segment has emerged as a significant driver of market growth for power steering fluids. With the expansion of e-commerce and logistics industries, there has been a surge in demand for light and heavy-duty commercial vehicles. These vehicles often operate under more demanding conditions and require high-quality power steering fluids to maintain optimal performance and extend the lifespan of steering components.

Technological advancements in vehicle design, such as the integration of electric power steering systems, have also impacted the power steering fluid market. While these systems reduce the overall demand for traditional hydraulic fluids, they have created new opportunities for specialized fluids designed for hybrid and electric power steering systems. This shift has prompted fluid manufacturers to invest in research and development to meet the evolving needs of modern vehicle architectures.

The aftermarket segment continues to be a substantial contributor to the power steering fluid market. As vehicle owners become more aware of the importance of regular maintenance in prolonging vehicle life and ensuring safety, there has been an uptick in demand for high-quality power steering fluids in the retail and service sectors. This trend is further supported by the growing do-it-yourself (DIY) culture among car enthusiasts, who seek premium products for their vehicles.

Current Fluid Challenges

Power steering fluid plays a crucial role in enhancing vehicle maneuverability, but it faces several challenges in modern automotive systems. One of the primary issues is fluid degradation over time, which can lead to reduced performance and potential system failure. As vehicles are designed to last longer, the fluid must maintain its properties for extended periods, often in harsh operating conditions.

Temperature fluctuations pose another significant challenge. Power steering fluid must maintain consistent viscosity across a wide range of temperatures, from cold starts to high-heat situations during prolonged operation. Extreme temperatures can cause the fluid to become too thick or thin, affecting steering responsiveness and potentially damaging system components.

Contamination is a persistent problem in power steering systems. Debris from wear and tear of internal components can accumulate in the fluid, leading to increased friction and accelerated wear. Modern fluids must incorporate advanced filtration properties to mitigate this issue and extend the life of steering components.

The increasing adoption of electric power steering systems has created new challenges for fluid technology. While these systems generally require less fluid, they often operate at higher temperatures and pressures, demanding fluids with enhanced thermal stability and load-carrying capacity.

Environmental concerns have also impacted power steering fluid development. There is a growing need for biodegradable and environmentally friendly fluids that maintain performance standards while reducing the ecological impact of leaks or disposal.

Compatibility issues arise as manufacturers use a variety of materials in power steering systems. Fluids must be formulated to work harmoniously with different types of seals, hoses, and metal alloys without causing degradation or chemical reactions that could compromise system integrity.

The trend towards longer service intervals has put additional pressure on fluid longevity. Manufacturers are seeking fluids that can maintain their properties for extended periods, reducing the need for frequent changes and lowering maintenance costs for vehicle owners.

Noise reduction is another area of focus in power steering fluid development. As vehicles become quieter overall, the hydraulic noise from power steering systems becomes more noticeable. Fluids must be designed to minimize cavitation and reduce operational noise without sacrificing performance.

Lastly, the push for improved fuel efficiency has led to the need for lower viscosity fluids that can reduce power consumption while still providing adequate protection and performance. Balancing these requirements presents a significant challenge for fluid engineers and chemists.

Temperature fluctuations pose another significant challenge. Power steering fluid must maintain consistent viscosity across a wide range of temperatures, from cold starts to high-heat situations during prolonged operation. Extreme temperatures can cause the fluid to become too thick or thin, affecting steering responsiveness and potentially damaging system components.

Contamination is a persistent problem in power steering systems. Debris from wear and tear of internal components can accumulate in the fluid, leading to increased friction and accelerated wear. Modern fluids must incorporate advanced filtration properties to mitigate this issue and extend the life of steering components.

The increasing adoption of electric power steering systems has created new challenges for fluid technology. While these systems generally require less fluid, they often operate at higher temperatures and pressures, demanding fluids with enhanced thermal stability and load-carrying capacity.

Environmental concerns have also impacted power steering fluid development. There is a growing need for biodegradable and environmentally friendly fluids that maintain performance standards while reducing the ecological impact of leaks or disposal.

Compatibility issues arise as manufacturers use a variety of materials in power steering systems. Fluids must be formulated to work harmoniously with different types of seals, hoses, and metal alloys without causing degradation or chemical reactions that could compromise system integrity.

The trend towards longer service intervals has put additional pressure on fluid longevity. Manufacturers are seeking fluids that can maintain their properties for extended periods, reducing the need for frequent changes and lowering maintenance costs for vehicle owners.

Noise reduction is another area of focus in power steering fluid development. As vehicles become quieter overall, the hydraulic noise from power steering systems becomes more noticeable. Fluids must be designed to minimize cavitation and reduce operational noise without sacrificing performance.

Lastly, the push for improved fuel efficiency has led to the need for lower viscosity fluids that can reduce power consumption while still providing adequate protection and performance. Balancing these requirements presents a significant challenge for fluid engineers and chemists.

Existing Fluid Solutions

01 Fluid composition for power steering systems

Specialized fluid compositions are developed to enhance the maneuverability of power steering systems. These fluids are designed to maintain optimal viscosity under various temperature conditions, reduce friction, and improve overall system performance. The compositions may include additives to prevent corrosion, reduce wear, and extend the lifespan of power steering components.- Fluid composition for power steering systems: Specialized fluid compositions are developed to enhance the maneuverability of power steering systems. These fluids are designed to maintain optimal viscosity, reduce friction, and improve overall system performance under various operating conditions.

- Hydraulic control mechanisms for power steering: Advanced hydraulic control mechanisms are implemented to improve the responsiveness and precision of power steering systems. These mechanisms often include specialized valves, pumps, and flow control devices to optimize fluid distribution and pressure regulation.

- Electronic power steering fluid management: Integration of electronic controls in power steering fluid systems enhances maneuverability by dynamically adjusting fluid pressure and flow based on driving conditions. This approach often involves sensors, actuators, and sophisticated control algorithms.

- Power steering pump design improvements: Innovative pump designs are developed to optimize fluid delivery and pressure control in power steering systems. These designs focus on improving efficiency, reducing noise, and enhancing overall system performance and maneuverability.

- Fluid circulation and cooling systems: Advanced fluid circulation and cooling systems are implemented to maintain optimal fluid temperature and properties during operation. These systems help prevent fluid degradation and ensure consistent power steering performance and maneuverability across various driving conditions.

02 Hydraulic control systems for power steering

Advanced hydraulic control systems are implemented to improve the maneuverability of power steering. These systems may include pressure-sensitive valves, flow control mechanisms, and feedback loops to optimize steering response. The design of these systems aims to provide smooth and precise steering control while minimizing energy loss.Expand Specific Solutions03 Power steering pump design

Innovative power steering pump designs are developed to enhance fluid delivery and overall system maneuverability. These pumps may incorporate features such as variable displacement, pressure-sensitive flow control, and noise reduction mechanisms. The goal is to provide efficient and responsive steering assistance while minimizing power consumption.Expand Specific Solutions04 Integration of electronic controls in power steering systems

Electronic control systems are integrated into power steering systems to improve maneuverability and responsiveness. These systems may include sensors to detect vehicle speed, steering angle, and driver input, allowing for adaptive steering assistance. The electronic controls can adjust fluid pressure and flow based on driving conditions, enhancing overall steering performance.Expand Specific Solutions05 Steering column and gear mechanisms

Advancements in steering column and gear mechanisms contribute to improved power steering fluid maneuverability. These developments may include optimized gear ratios, reduced friction in steering linkages, and enhanced sealing to prevent fluid leaks. The design of these components aims to maximize the efficiency of power steering fluid transmission and overall system performance.Expand Specific Solutions

Key Industry Players

The power steering fluid market is in a mature stage, with a steady global demand driven by the automotive industry. The market size is substantial, reflecting the widespread adoption of power steering systems in vehicles worldwide. Technologically, power steering fluid systems are well-established, but innovations continue to emerge, focusing on enhancing efficiency and environmental sustainability. Key players like GM Global Technology Operations, JTEKT Corp., and Hitachi Ltd. are at the forefront of these advancements, leveraging their extensive automotive expertise. Companies such as Eaton Corp. and ZF Friedrichshafen AG are also significant contributors, developing advanced fluid formulations and integrated steering systems to improve vehicle maneuverability and performance.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced power steering fluid system that enhances vehicle maneuverability through a combination of innovative technologies. Their system utilizes a high-performance fluid with optimized viscosity characteristics, allowing for smoother and more responsive steering across a wide range of operating temperatures[1]. The fluid is designed to work in conjunction with GM's electric power steering systems, which use sensors and electronic controls to adjust steering assist based on vehicle speed and driver input[2]. This integration allows for variable assist levels, providing easier steering at low speeds for parking maneuvers while maintaining a firmer feel at higher speeds for improved stability. GM has also incorporated a self-cleaning filtration system that extends the life of the power steering fluid and components, reducing maintenance requirements[3].

Strengths: Improved responsiveness and adaptability to driving conditions, reduced maintenance, and seamless integration with electric power steering systems. Weaknesses: May require specialized fluid, potentially higher initial cost compared to traditional systems.

JTEKT Corp.

Technical Solution: JTEKT has pioneered a next-generation power steering fluid technology that significantly enhances vehicle maneuverability. Their system employs a synthetic, high-performance fluid with advanced additives that reduce friction and wear within the steering mechanism[1]. This fluid works in tandem with JTEKT's innovative variable-assist power steering pump, which adjusts fluid pressure based on steering input and vehicle speed[2]. The system also incorporates a thermal management module that maintains optimal fluid viscosity across a wide temperature range, ensuring consistent steering performance in diverse climates[3]. JTEKT's fluid formulation includes nano-scale particles that fill microscopic imperfections in metal surfaces, further reducing friction and improving overall steering efficiency[4].

Strengths: Exceptional friction reduction, improved steering efficiency, and consistent performance across various temperatures. Weaknesses: Potentially higher cost due to advanced formulation, may require specialized handling during maintenance.

Fluid Innovation Analysis

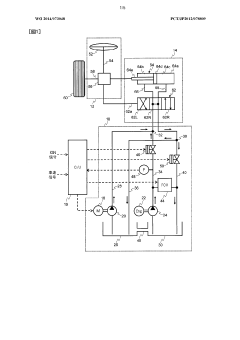

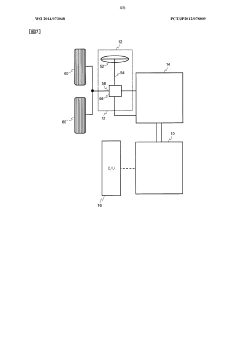

Power steering apparatus, and method of supplying operating oil for same

PatentWO2014073048A1

Innovation

- A power steering system incorporating an electric motor-driven first hydraulic pump and an engine-driven second hydraulic pump, with a control device that adjusts the flow rates of hydraulic fluid supplied by both pumps based on vehicle operating state to optimize hydraulic pressure assistance.

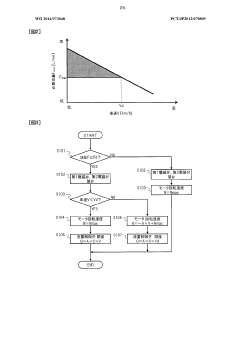

Power steering system for vehicles

PatentWO1991006462A1

Innovation

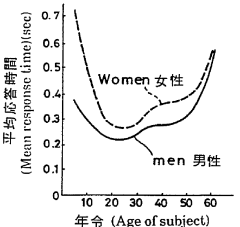

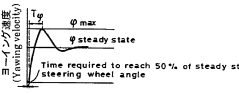

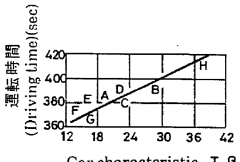

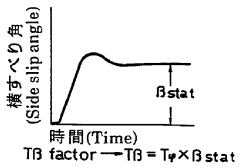

- The implementation of a pressure oil setting valve in the hydraulic piping upstream of the directional control valve, which injects compensatory pressure oil during steering wheel engagement and retraction, and a reaction force regulating valve that adjusts steering force based on vehicle speed, reduces phase lag without increasing gain, enhancing steering response and compensating for driver physiological differences.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and use of power steering fluids in modern vehicles. As governments worldwide increasingly focus on reducing environmental impact and promoting sustainability, the automotive industry faces stringent requirements for the composition and disposal of power steering fluids.

One of the primary concerns addressed by environmental regulations is the toxicity of power steering fluids. Traditional mineral-based fluids often contain harmful substances that can pose risks to ecosystems if leaked or improperly disposed of. In response, regulations have been implemented to limit the use of toxic components and promote the development of more environmentally friendly alternatives.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential in this regard. It requires manufacturers to assess and manage the risks associated with chemicals used in their products, including power steering fluids. This has led to the phasing out of certain hazardous substances and the adoption of safer alternatives.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the proper disposal of power steering fluids under the Resource Conservation and Recovery Act (RCRA). These regulations classify used power steering fluid as a hazardous waste, mandating specific handling and disposal procedures to prevent environmental contamination.

The push for environmental sustainability has also driven innovation in power steering fluid technology. Manufacturers are increasingly developing biodegradable and non-toxic formulations that maintain performance while reducing environmental impact. These eco-friendly fluids often utilize synthetic esters or vegetable-based oils, which offer improved biodegradability compared to traditional mineral-based fluids.

Regulations have also focused on improving the longevity and efficiency of power steering systems to reduce fluid consumption and waste. This has led to the development of more durable fluids with extended service life, as well as the implementation of sealed power steering systems that require less frequent fluid changes.

Furthermore, environmental regulations have spurred research into alternative power steering technologies that reduce or eliminate the need for hydraulic fluids altogether. Electric power steering systems, for instance, have gained popularity partly due to their environmental benefits, as they do not require traditional power steering fluid.

As environmental concerns continue to grow, it is likely that regulations governing power steering fluids will become even more stringent. This ongoing regulatory pressure will undoubtedly drive further innovation in fluid formulations and steering system design, ultimately leading to more environmentally friendly and sustainable solutions for enhancing vehicle maneuverability.

One of the primary concerns addressed by environmental regulations is the toxicity of power steering fluids. Traditional mineral-based fluids often contain harmful substances that can pose risks to ecosystems if leaked or improperly disposed of. In response, regulations have been implemented to limit the use of toxic components and promote the development of more environmentally friendly alternatives.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential in this regard. It requires manufacturers to assess and manage the risks associated with chemicals used in their products, including power steering fluids. This has led to the phasing out of certain hazardous substances and the adoption of safer alternatives.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the proper disposal of power steering fluids under the Resource Conservation and Recovery Act (RCRA). These regulations classify used power steering fluid as a hazardous waste, mandating specific handling and disposal procedures to prevent environmental contamination.

The push for environmental sustainability has also driven innovation in power steering fluid technology. Manufacturers are increasingly developing biodegradable and non-toxic formulations that maintain performance while reducing environmental impact. These eco-friendly fluids often utilize synthetic esters or vegetable-based oils, which offer improved biodegradability compared to traditional mineral-based fluids.

Regulations have also focused on improving the longevity and efficiency of power steering systems to reduce fluid consumption and waste. This has led to the development of more durable fluids with extended service life, as well as the implementation of sealed power steering systems that require less frequent fluid changes.

Furthermore, environmental regulations have spurred research into alternative power steering technologies that reduce or eliminate the need for hydraulic fluids altogether. Electric power steering systems, for instance, have gained popularity partly due to their environmental benefits, as they do not require traditional power steering fluid.

As environmental concerns continue to grow, it is likely that regulations governing power steering fluids will become even more stringent. This ongoing regulatory pressure will undoubtedly drive further innovation in fluid formulations and steering system design, ultimately leading to more environmentally friendly and sustainable solutions for enhancing vehicle maneuverability.

Safety Considerations

Safety considerations are paramount when discussing power steering fluid's role in enhancing vehicle maneuverability. The proper maintenance and use of power steering fluid directly impact the safety of drivers, passengers, and other road users. One of the primary safety concerns is the potential for power steering system failure due to low fluid levels or contaminated fluid. Such failures can lead to sudden loss of steering control, especially at low speeds or during parking maneuvers, increasing the risk of accidents.

Regular inspection and maintenance of power steering fluid levels are crucial for preventing unexpected steering difficulties. Low fluid levels can cause increased friction and wear on steering components, potentially leading to system damage and compromised vehicle control. Additionally, contaminated or degraded fluid may not provide adequate lubrication and hydraulic pressure, further jeopardizing steering performance and safety.

The choice of power steering fluid also plays a significant role in safety considerations. Using the wrong type of fluid can cause seal degradation, leading to leaks and potential system failure. It's essential to use manufacturer-recommended fluids to ensure optimal performance and longevity of the power steering system. Some modern vehicles use electric power steering systems, which eliminate the need for hydraulic fluid but introduce new safety considerations related to electrical and software components.

Environmental factors can also impact the safety aspects of power steering fluid. Extreme temperatures, both hot and cold, can affect fluid viscosity and performance. In cold climates, power steering fluid with appropriate cold-weather properties is crucial to maintain steering responsiveness. Conversely, in hot environments, fluid breakdown can occur more rapidly, necessitating more frequent fluid changes to maintain safe steering operation.

The disposal of used power steering fluid presents another safety consideration. Improper disposal can lead to environmental contamination, posing risks to wildlife and human health. Safe handling and disposal practices are essential to mitigate these risks. Additionally, the potential for fluid leaks during vehicle operation or maintenance activities requires careful attention to prevent slips and falls, as well as environmental contamination.

In the context of vehicle design and manufacturing, the integration of power steering systems and fluid selection must undergo rigorous safety testing and comply with regulatory standards. This includes crash testing to ensure that power steering components and fluid reservoirs maintain integrity during collisions, minimizing the risk of fluid loss or system failure in accident scenarios.

Regular inspection and maintenance of power steering fluid levels are crucial for preventing unexpected steering difficulties. Low fluid levels can cause increased friction and wear on steering components, potentially leading to system damage and compromised vehicle control. Additionally, contaminated or degraded fluid may not provide adequate lubrication and hydraulic pressure, further jeopardizing steering performance and safety.

The choice of power steering fluid also plays a significant role in safety considerations. Using the wrong type of fluid can cause seal degradation, leading to leaks and potential system failure. It's essential to use manufacturer-recommended fluids to ensure optimal performance and longevity of the power steering system. Some modern vehicles use electric power steering systems, which eliminate the need for hydraulic fluid but introduce new safety considerations related to electrical and software components.

Environmental factors can also impact the safety aspects of power steering fluid. Extreme temperatures, both hot and cold, can affect fluid viscosity and performance. In cold climates, power steering fluid with appropriate cold-weather properties is crucial to maintain steering responsiveness. Conversely, in hot environments, fluid breakdown can occur more rapidly, necessitating more frequent fluid changes to maintain safe steering operation.

The disposal of used power steering fluid presents another safety consideration. Improper disposal can lead to environmental contamination, posing risks to wildlife and human health. Safe handling and disposal practices are essential to mitigate these risks. Additionally, the potential for fluid leaks during vehicle operation or maintenance activities requires careful attention to prevent slips and falls, as well as environmental contamination.

In the context of vehicle design and manufacturing, the integration of power steering systems and fluid selection must undergo rigorous safety testing and comply with regulatory standards. This includes crash testing to ensure that power steering components and fluid reservoirs maintain integrity during collisions, minimizing the risk of fluid loss or system failure in accident scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!