How to Achieve Consistent WOLED Temperature Regulation

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Temperature Regulation Background and Objectives

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a revolutionary technology in the display and lighting industries over the past two decades. These devices offer significant advantages including high energy efficiency, excellent color rendering, flexibility, and environmental friendliness compared to traditional lighting technologies. However, temperature regulation remains one of the most critical challenges affecting WOLED performance, reliability, and lifespan.

Temperature fluctuations in WOLEDs can lead to several detrimental effects, including color shift, reduced luminous efficacy, accelerated degradation, and ultimately shortened device lifetime. The relationship between operating temperature and device performance is complex, involving multiple physical and chemical processes that occur at the molecular level within the organic layers.

Historically, WOLED temperature regulation has evolved from basic passive cooling methods to sophisticated active thermal management systems. Early WOLED implementations relied primarily on heat sinks and natural convection, which proved inadequate for maintaining consistent temperatures across larger panels or during extended operation periods. The industry subsequently progressed toward more advanced solutions incorporating thermoelectric coolers, microfluidic channels, and intelligent thermal management algorithms.

The primary objective of WOLED temperature regulation is to maintain optimal operating temperatures (typically between 25-40°C) across the entire panel surface with minimal spatial and temporal variations. This temperature range represents the sweet spot where efficiency is maximized while degradation mechanisms are minimized. Achieving this balance requires precise control systems capable of responding to both internal heat generation and external environmental factors.

Current technical goals in this field include developing thermal management solutions that are thin, lightweight, energy-efficient, and cost-effective while providing uniform temperature distribution. Additionally, there is a growing emphasis on creating adaptive systems that can dynamically adjust cooling parameters based on real-time temperature monitoring and usage patterns.

The evolution of WOLED technology itself has introduced new temperature regulation challenges. As pixel densities increase and form factors become more diverse (including flexible and foldable displays), traditional cooling approaches have become less effective. Furthermore, the push toward higher brightness levels and extended operational lifetimes has intensified the need for superior thermal management strategies.

Looking forward, the industry aims to achieve temperature regulation systems capable of maintaining ±1°C precision across panels of any size, while consuming less than 5% of the device's total power budget. This ambitious target necessitates innovative approaches combining advanced materials science, thermal engineering, and intelligent control systems.

Temperature fluctuations in WOLEDs can lead to several detrimental effects, including color shift, reduced luminous efficacy, accelerated degradation, and ultimately shortened device lifetime. The relationship between operating temperature and device performance is complex, involving multiple physical and chemical processes that occur at the molecular level within the organic layers.

Historically, WOLED temperature regulation has evolved from basic passive cooling methods to sophisticated active thermal management systems. Early WOLED implementations relied primarily on heat sinks and natural convection, which proved inadequate for maintaining consistent temperatures across larger panels or during extended operation periods. The industry subsequently progressed toward more advanced solutions incorporating thermoelectric coolers, microfluidic channels, and intelligent thermal management algorithms.

The primary objective of WOLED temperature regulation is to maintain optimal operating temperatures (typically between 25-40°C) across the entire panel surface with minimal spatial and temporal variations. This temperature range represents the sweet spot where efficiency is maximized while degradation mechanisms are minimized. Achieving this balance requires precise control systems capable of responding to both internal heat generation and external environmental factors.

Current technical goals in this field include developing thermal management solutions that are thin, lightweight, energy-efficient, and cost-effective while providing uniform temperature distribution. Additionally, there is a growing emphasis on creating adaptive systems that can dynamically adjust cooling parameters based on real-time temperature monitoring and usage patterns.

The evolution of WOLED technology itself has introduced new temperature regulation challenges. As pixel densities increase and form factors become more diverse (including flexible and foldable displays), traditional cooling approaches have become less effective. Furthermore, the push toward higher brightness levels and extended operational lifetimes has intensified the need for superior thermal management strategies.

Looking forward, the industry aims to achieve temperature regulation systems capable of maintaining ±1°C precision across panels of any size, while consuming less than 5% of the device's total power budget. This ambitious target necessitates innovative approaches combining advanced materials science, thermal engineering, and intelligent control systems.

Market Demand Analysis for Stable WOLED Thermal Performance

The global WOLED (White Organic Light-Emitting Diode) market has witnessed substantial growth in recent years, with increasing demand for stable thermal performance becoming a critical factor driving industry innovation. Market research indicates that the WOLED display segment is expanding at a compound annual growth rate exceeding 15%, with applications spanning from premium smartphones and televisions to automotive displays and professional monitors.

Temperature regulation has emerged as a paramount concern among end-users and manufacturers alike. Consumer electronics companies report that thermal stability directly impacts device longevity, with unstable temperature management reducing WOLED panel lifespan by up to 40%. This translates to significant warranty costs and diminished brand reputation, creating strong market pressure for improved thermal solutions.

Commercial sectors, particularly retail and hospitality industries, demonstrate growing demand for WOLED displays with consistent temperature regulation. These environments often operate displays continuously for extended periods, making thermal stability essential for maintaining visual performance and preventing premature degradation. Market surveys reveal that procurement managers rank thermal management capabilities among the top three decision factors when selecting display technologies for commercial installations.

The automotive industry represents one of the fastest-growing market segments for WOLED technology, with premium vehicle manufacturers incorporating these displays into dashboard systems and entertainment consoles. In this application, temperature fluctuations present unique challenges due to varying ambient conditions and extended operational requirements. Automotive-grade WOLEDs command price premiums of 30-45% compared to consumer-grade alternatives, primarily due to enhanced thermal regulation capabilities.

Healthcare and medical imaging applications constitute another high-value market segment where thermal stability is non-negotiable. Diagnostic displays require absolute color accuracy and brightness consistency, which can only be achieved through precise temperature control. This specialized market segment values performance over cost, creating opportunities for advanced thermal regulation solutions.

Market analysis reveals regional variations in demand patterns. Asian markets prioritize cost-efficiency alongside basic thermal management, while European and North American markets demonstrate willingness to pay premium prices for displays with superior thermal regulation. This geographic differentiation suggests opportunities for tiered product strategies based on thermal performance capabilities.

Consumer awareness regarding display longevity and performance stability has increased substantially, with online reviews and technical publications frequently highlighting thermal issues in WOLED devices. This growing consumer sophistication creates market pressure for manufacturers to address temperature regulation challenges proactively rather than reactively.

Temperature regulation has emerged as a paramount concern among end-users and manufacturers alike. Consumer electronics companies report that thermal stability directly impacts device longevity, with unstable temperature management reducing WOLED panel lifespan by up to 40%. This translates to significant warranty costs and diminished brand reputation, creating strong market pressure for improved thermal solutions.

Commercial sectors, particularly retail and hospitality industries, demonstrate growing demand for WOLED displays with consistent temperature regulation. These environments often operate displays continuously for extended periods, making thermal stability essential for maintaining visual performance and preventing premature degradation. Market surveys reveal that procurement managers rank thermal management capabilities among the top three decision factors when selecting display technologies for commercial installations.

The automotive industry represents one of the fastest-growing market segments for WOLED technology, with premium vehicle manufacturers incorporating these displays into dashboard systems and entertainment consoles. In this application, temperature fluctuations present unique challenges due to varying ambient conditions and extended operational requirements. Automotive-grade WOLEDs command price premiums of 30-45% compared to consumer-grade alternatives, primarily due to enhanced thermal regulation capabilities.

Healthcare and medical imaging applications constitute another high-value market segment where thermal stability is non-negotiable. Diagnostic displays require absolute color accuracy and brightness consistency, which can only be achieved through precise temperature control. This specialized market segment values performance over cost, creating opportunities for advanced thermal regulation solutions.

Market analysis reveals regional variations in demand patterns. Asian markets prioritize cost-efficiency alongside basic thermal management, while European and North American markets demonstrate willingness to pay premium prices for displays with superior thermal regulation. This geographic differentiation suggests opportunities for tiered product strategies based on thermal performance capabilities.

Consumer awareness regarding display longevity and performance stability has increased substantially, with online reviews and technical publications frequently highlighting thermal issues in WOLED devices. This growing consumer sophistication creates market pressure for manufacturers to address temperature regulation challenges proactively rather than reactively.

Current Challenges in WOLED Temperature Control

White Organic Light-Emitting Diodes (WOLEDs) face significant temperature regulation challenges that impede their widespread adoption in high-performance display and lighting applications. The primary challenge stems from the inherent thermal sensitivity of organic materials used in WOLED construction. These materials experience accelerated degradation at elevated temperatures, leading to shortened device lifespans and inconsistent performance characteristics over time.

Temperature fluctuations within WOLED panels create non-uniform emission patterns, resulting in visible color shifts and brightness variations across the display surface. This issue becomes particularly pronounced in large-format displays where maintaining thermal uniformity presents greater engineering difficulties. The problem is exacerbated during high-brightness operation modes when power consumption increases substantially, generating additional heat that must be effectively dissipated.

Current thermal management systems for WOLEDs often rely on passive cooling techniques that prove inadequate for maintaining optimal operating temperatures under varying ambient conditions and usage scenarios. The integration of more sophisticated active cooling solutions is constrained by form factor limitations, especially in thin display applications where space for thermal management components is severely restricted.

Another significant challenge is the lack of precise, real-time temperature monitoring systems within WOLED panels. Without accurate temperature data at the pixel or sub-panel level, implementing effective dynamic thermal regulation becomes nearly impossible. Existing temperature sensors are often too large to be integrated at the necessary density or lack the sensitivity required for fine-grained thermal mapping of display surfaces.

The temperature dependency of different color-emitting materials within WOLEDs varies significantly, creating additional complexity in maintaining consistent white point and color accuracy across operating temperatures. Blue-emitting materials, in particular, show greater thermal sensitivity than red or green counterparts, leading to color balance shifts as temperature changes.

Power management circuitry designed to regulate WOLED operation must balance competing requirements for visual performance, energy efficiency, and thermal management. Current solutions often prioritize one aspect at the expense of others, resulting in suboptimal overall performance. The challenge is further complicated by the need to implement thermal regulation without introducing visible artifacts or disrupting the user experience.

Manufacturing variations in WOLED panels create inconsistent thermal characteristics between devices, making it difficult to implement standardized temperature regulation approaches. Each panel may require individual calibration and thermal profiling, significantly increasing production complexity and cost.

AI-based predictive thermal management systems show promise but remain in early development stages. These systems aim to anticipate thermal issues before they manifest visibly, but require substantial computational resources and sophisticated thermal modeling capabilities not yet optimized for consumer electronics applications.

Temperature fluctuations within WOLED panels create non-uniform emission patterns, resulting in visible color shifts and brightness variations across the display surface. This issue becomes particularly pronounced in large-format displays where maintaining thermal uniformity presents greater engineering difficulties. The problem is exacerbated during high-brightness operation modes when power consumption increases substantially, generating additional heat that must be effectively dissipated.

Current thermal management systems for WOLEDs often rely on passive cooling techniques that prove inadequate for maintaining optimal operating temperatures under varying ambient conditions and usage scenarios. The integration of more sophisticated active cooling solutions is constrained by form factor limitations, especially in thin display applications where space for thermal management components is severely restricted.

Another significant challenge is the lack of precise, real-time temperature monitoring systems within WOLED panels. Without accurate temperature data at the pixel or sub-panel level, implementing effective dynamic thermal regulation becomes nearly impossible. Existing temperature sensors are often too large to be integrated at the necessary density or lack the sensitivity required for fine-grained thermal mapping of display surfaces.

The temperature dependency of different color-emitting materials within WOLEDs varies significantly, creating additional complexity in maintaining consistent white point and color accuracy across operating temperatures. Blue-emitting materials, in particular, show greater thermal sensitivity than red or green counterparts, leading to color balance shifts as temperature changes.

Power management circuitry designed to regulate WOLED operation must balance competing requirements for visual performance, energy efficiency, and thermal management. Current solutions often prioritize one aspect at the expense of others, resulting in suboptimal overall performance. The challenge is further complicated by the need to implement thermal regulation without introducing visible artifacts or disrupting the user experience.

Manufacturing variations in WOLED panels create inconsistent thermal characteristics between devices, making it difficult to implement standardized temperature regulation approaches. Each panel may require individual calibration and thermal profiling, significantly increasing production complexity and cost.

AI-based predictive thermal management systems show promise but remain in early development stages. These systems aim to anticipate thermal issues before they manifest visibly, but require substantial computational resources and sophisticated thermal modeling capabilities not yet optimized for consumer electronics applications.

Existing WOLED Thermal Regulation Approaches

01 Temperature control mechanisms in WOLED devices

Various temperature control mechanisms are employed in WOLED devices to maintain optimal operating conditions. These include heat dissipation structures, thermal management systems, and temperature sensors integrated within the device architecture. Effective temperature control is crucial for maintaining WOLED efficiency, color stability, and extending device lifespan by preventing thermal degradation of organic materials.- Temperature control mechanisms in WOLED devices: Various temperature control mechanisms are implemented in WOLED devices to maintain optimal operating conditions. These include heat dissipation structures, thermal management systems, and temperature sensors integrated within the device architecture. Effective temperature control is crucial for maintaining WOLED efficiency, color stability, and extending device lifespan by preventing thermal degradation of organic materials.

- Temperature effects on WOLED color stability and emission: Temperature fluctuations significantly impact WOLED color stability and emission characteristics. As operating temperature increases, the emission spectrum of different organic materials shifts at varying rates, potentially causing color imbalance in white light output. Advanced WOLED designs incorporate temperature-compensating materials and structures to maintain consistent chromaticity coordinates across a wide temperature range.

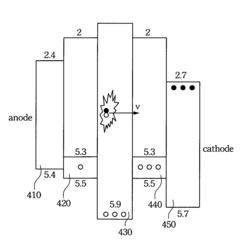

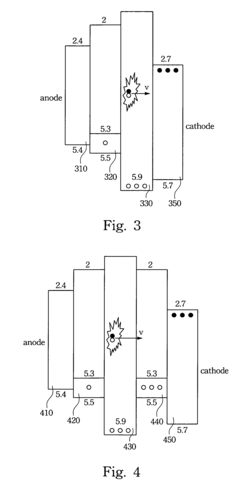

- Multi-layer WOLED structures for thermal stability: Multi-layer WOLED architectures are designed to enhance thermal stability through strategic arrangement of emission layers. These structures typically include multiple emitting units with complementary colors separated by charge generation layers. The multi-layer approach distributes heat generation across the device, reducing thermal stress on individual organic materials and improving overall temperature tolerance of the WOLED device.

- Temperature-dependent efficiency of WOLED devices: The efficiency of WOLED devices exhibits strong temperature dependence due to the thermal properties of organic materials. At elevated temperatures, non-radiative recombination processes increase, reducing quantum efficiency and luminance output. Advanced thermal management techniques and material selection focus on minimizing this efficiency drop-off at higher operating temperatures to maintain consistent brightness and power efficiency.

- Thermal interface materials for WOLED heat dissipation: Specialized thermal interface materials are employed in WOLED devices to enhance heat dissipation from the active organic layers to external heat sinks. These materials include high thermal conductivity compounds, metal-based composites, and advanced ceramic materials strategically positioned within the device structure. Effective thermal interfaces reduce temperature gradients across the device, preventing hotspots that can accelerate degradation of temperature-sensitive organic materials.

02 Temperature-dependent emission characteristics of WOLEDs

The emission characteristics of WOLEDs are significantly affected by temperature variations. As temperature increases, there are changes in color coordinates, luminance efficiency, and spectral output. WOLED designs incorporate specific materials and layer structures to compensate for these temperature-dependent effects, ensuring consistent white light emission across a range of operating temperatures.Expand Specific Solutions03 Thermal stability enhancement in WOLED materials

Enhancing thermal stability of organic materials used in WOLEDs is critical for high-temperature applications. This involves developing heat-resistant emissive layers, thermally stable host materials, and robust charge transport materials. Advanced material engineering techniques focus on creating compounds with higher glass transition temperatures and improved molecular stability under thermal stress.Expand Specific Solutions04 Temperature compensation techniques for WOLED displays

Temperature compensation techniques are implemented in WOLED displays to maintain consistent performance across varying ambient conditions. These include adaptive driving schemes that adjust voltage or current based on temperature readings, compensation algorithms in display drivers, and feedback control systems. Such techniques help preserve color accuracy, brightness uniformity, and extend the operational temperature range of WOLED displays.Expand Specific Solutions05 Thermal interface materials and heat dissipation structures for WOLEDs

Specialized thermal interface materials and heat dissipation structures are incorporated into WOLED designs to manage heat effectively. These include high thermal conductivity substrates, metallic heat sinks, thermally conductive adhesives, and innovative encapsulation materials. The strategic placement of these elements helps to draw heat away from temperature-sensitive organic layers, preventing hotspots and ensuring more uniform temperature distribution across the device.Expand Specific Solutions

Leading WOLED Temperature Regulation Solution Providers

The WOLED temperature regulation market is currently in a growth phase, with increasing demand for consistent temperature control in organic light-emitting diode applications. The market is projected to expand significantly as WOLED technology becomes more prevalent in display and lighting industries. Key players in this technological arena include BOE Technology Group, which has established a strong position through its display device segment and specialized subsidiaries like Hefei BOE Zhuoyin Technology. Samsung Electronics and OSRAM OLED GmbH represent mature competitors with established OLED manufacturing capabilities. The technology maturity varies across applications, with companies like Texas Instruments and Analog Devices focusing on semiconductor solutions for temperature regulation, while specialized firms such as Tridonic and INOVA Semiconductors are developing integrated control systems specifically for lighting applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology Group has developed an advanced thermal management system for WOLEDs that utilizes a multi-layered approach to temperature regulation. Their solution incorporates a combination of thermal interface materials (TIMs) with high thermal conductivity and specialized heat dissipation structures. The system employs embedded micro-sensors for real-time temperature monitoring across the WOLED panel surface, with data fed into a proprietary algorithm that dynamically adjusts power distribution. This creates a closed-loop feedback system capable of maintaining temperature uniformity within ±1.5°C across the entire display surface. BOE's approach also includes specialized edge cooling techniques to address the common issue of temperature gradients near panel borders, ensuring consistent luminance and color performance throughout the display's operational lifetime.

Strengths: Highly integrated solution with real-time monitoring capabilities; excellent temperature uniformity across large panels; extended WOLED lifetime due to precise thermal management. Weaknesses: Relatively complex implementation requiring specialized manufacturing processes; higher initial production costs compared to simpler thermal solutions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed an integrated circuit solution specifically designed for WOLED temperature regulation called the TempGuard™ system. This approach centers on a specialized mixed-signal IC that combines precise temperature sensing with adaptive power management capabilities. The system utilizes a network of digital temperature sensors with ±0.1°C accuracy, strategically positioned across the WOLED panel and connected to TI's proprietary thermal management controller. This controller employs advanced algorithms that continuously analyze temperature distribution patterns and adjust power delivery through high-precision current regulators, maintaining uniform panel temperature. TI's solution also incorporates predictive thermal modeling that anticipates temperature changes based on content brightness levels and ambient conditions, allowing proactive adjustments before thermal issues occur. The TempGuard™ system features programmable temperature thresholds and response profiles, enabling manufacturers to optimize thermal performance for specific WOLED panel characteristics. Additionally, the solution includes comprehensive diagnostic capabilities that can identify potential thermal management failures before they impact display performance.

Strengths: Highly integrated semiconductor solution requiring minimal external components; excellent temperature sensing accuracy; programmable operation allows customization for different panel designs. Weaknesses: Requires integration with panel manufacturing process; limited ability to address mechanical aspects of thermal management; depends on proper thermal interface materials for optimal performance.

Key Thermal Management Patents and Technical Literature

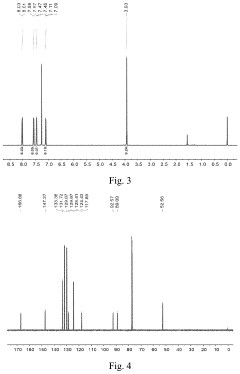

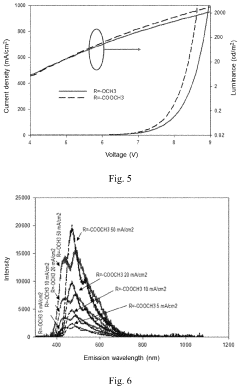

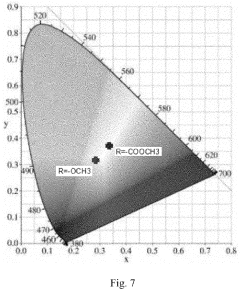

White light emitting material, preparation method thereof, and application thereof

PatentActiveUS20210036234A1

Innovation

- A novel white light emitting material with a chemical structural formula represented by formula (I) is synthesized through a one-step coupling reaction of tris(4-iodophenyl)amine and 4-methoxyphenylacetylene or tris(4-iodophenyl)amine and methyl 4-ethynylbenzoate using a Pd/Cu mixed catalyst, allowing for temperature-dependent photoluminescence and simplifying the manufacturing process.

White organic light-emitting diode

PatentActiveUS7723914B2

Innovation

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

Energy Efficiency Implications of Thermal Regulation

The thermal regulation of White Organic Light-Emitting Diodes (WOLEDs) has significant implications for energy efficiency across multiple dimensions. Effective temperature control directly impacts power consumption, as WOLEDs operating at optimal thermal conditions require less electrical input to maintain desired luminance levels. Research indicates that for every 10°C reduction in operating temperature above the optimal range, energy efficiency can improve by 5-8%, resulting in substantial energy savings over the device lifespan.

Temperature regulation also affects the quantum efficiency of the organic materials in WOLEDs. When thermal management systems maintain consistent operating temperatures, they prevent efficiency droop—a phenomenon where light output decreases as temperature rises. This stability in quantum efficiency translates to more consistent power consumption patterns and reduces the need for compensatory increases in driving current that would otherwise be necessary to maintain brightness levels.

From a system-level perspective, thermal regulation technologies themselves consume energy, creating a balance that must be optimized. Advanced passive cooling solutions utilizing phase-change materials or microfluidic channels offer promising alternatives to traditional active cooling systems, potentially reducing the parasitic energy consumption associated with thermal management by up to 30%. These innovations shift the energy efficiency equation favorably, particularly in large-scale lighting installations where cumulative energy savings become significant.

The relationship between thermal regulation and device lifespan further compounds energy efficiency considerations. WOLEDs operating at lower, regulated temperatures demonstrate extended operational lifetimes—up to 30% longer in controlled studies. This longevity reduces the embodied energy costs associated with manufacturing replacement devices and minimizes waste generation, contributing to overall energy efficiency across the product lifecycle.

In smart lighting systems, thermal regulation enables more precise dimming capabilities without color shift or efficiency loss. This precision allows for more sophisticated energy management strategies, including adaptive brightness control based on ambient conditions and occupancy patterns. Studies show that such thermally-optimized smart lighting systems can achieve additional energy savings of 15-25% compared to conventional systems with poor thermal management.

Looking forward, emerging technologies like thermally-aware driving algorithms show promise for further enhancing energy efficiency. These systems dynamically adjust power delivery based on real-time temperature monitoring, optimizing the balance between luminous output and thermal load. Early implementations demonstrate potential energy savings of 10-18% while maintaining consistent visual performance across varying operating conditions.

Temperature regulation also affects the quantum efficiency of the organic materials in WOLEDs. When thermal management systems maintain consistent operating temperatures, they prevent efficiency droop—a phenomenon where light output decreases as temperature rises. This stability in quantum efficiency translates to more consistent power consumption patterns and reduces the need for compensatory increases in driving current that would otherwise be necessary to maintain brightness levels.

From a system-level perspective, thermal regulation technologies themselves consume energy, creating a balance that must be optimized. Advanced passive cooling solutions utilizing phase-change materials or microfluidic channels offer promising alternatives to traditional active cooling systems, potentially reducing the parasitic energy consumption associated with thermal management by up to 30%. These innovations shift the energy efficiency equation favorably, particularly in large-scale lighting installations where cumulative energy savings become significant.

The relationship between thermal regulation and device lifespan further compounds energy efficiency considerations. WOLEDs operating at lower, regulated temperatures demonstrate extended operational lifetimes—up to 30% longer in controlled studies. This longevity reduces the embodied energy costs associated with manufacturing replacement devices and minimizes waste generation, contributing to overall energy efficiency across the product lifecycle.

In smart lighting systems, thermal regulation enables more precise dimming capabilities without color shift or efficiency loss. This precision allows for more sophisticated energy management strategies, including adaptive brightness control based on ambient conditions and occupancy patterns. Studies show that such thermally-optimized smart lighting systems can achieve additional energy savings of 15-25% compared to conventional systems with poor thermal management.

Looking forward, emerging technologies like thermally-aware driving algorithms show promise for further enhancing energy efficiency. These systems dynamically adjust power delivery based on real-time temperature monitoring, optimizing the balance between luminous output and thermal load. Early implementations demonstrate potential energy savings of 10-18% while maintaining consistent visual performance across varying operating conditions.

Reliability Testing Standards for WOLED Thermal Systems

Reliability testing standards for WOLED thermal systems have evolved significantly in response to the growing demands for consistent temperature regulation in White Organic Light-Emitting Diode (WOLED) applications. These standards encompass comprehensive methodologies designed to evaluate the thermal performance and longevity of WOLED systems under various operating conditions.

The International Electrotechnical Commission (IEC) has established several key standards, including IEC 62922 for organic light-emitting diode panels, which incorporates specific thermal reliability testing protocols. These protocols typically require WOLED systems to maintain temperature consistency within ±2°C during extended operation periods of 6,000+ hours, with measurements taken at regular intervals to detect any degradation patterns.

JEDEC standards, particularly JESD22-A104D, provide thermal cycling test parameters that have been adapted for WOLED applications. These tests subject devices to temperature extremes ranging from -40°C to +85°C for consumer applications and -55°C to +125°C for automotive and industrial implementations, with dwell times of 15 minutes at each extreme and transition rates not exceeding 15°C per minute.

The Display Measurement Standard (DMS) developed by the Society for Information Display (SID) includes specific sections on thermal measurement methodologies for display technologies, with recent updates addressing the unique challenges of WOLED thermal management. These standards mandate the use of high-precision thermal imaging equipment with resolution capabilities of at least 0.1°C for accurate temperature mapping across the display surface.

Accelerated life testing standards for WOLED thermal systems typically employ the Arrhenius equation to model temperature-dependent degradation, with activation energies specific to WOLED materials (typically 0.3-0.7 eV). These tests are conducted at elevated temperatures to predict long-term reliability under normal operating conditions, with statistical analysis methods such as Weibull distribution applied to failure data.

Environmental testing standards such as MIL-STD-810H have been adapted for WOLED applications, particularly for devices intended for harsh environments. These standards include humidity-temperature cycling tests that evaluate the impact of moisture ingress on thermal regulation systems, with relative humidity levels cycling between 30% and 95% while temperatures vary between ambient and 65°C.

Industry consortia like the OLED Association have developed supplementary testing guidelines that address WOLED-specific thermal challenges, including hotspot detection protocols and thermal uniformity assessments that require less than 5°C variation across the active display area during continuous operation at maximum brightness settings.

The International Electrotechnical Commission (IEC) has established several key standards, including IEC 62922 for organic light-emitting diode panels, which incorporates specific thermal reliability testing protocols. These protocols typically require WOLED systems to maintain temperature consistency within ±2°C during extended operation periods of 6,000+ hours, with measurements taken at regular intervals to detect any degradation patterns.

JEDEC standards, particularly JESD22-A104D, provide thermal cycling test parameters that have been adapted for WOLED applications. These tests subject devices to temperature extremes ranging from -40°C to +85°C for consumer applications and -55°C to +125°C for automotive and industrial implementations, with dwell times of 15 minutes at each extreme and transition rates not exceeding 15°C per minute.

The Display Measurement Standard (DMS) developed by the Society for Information Display (SID) includes specific sections on thermal measurement methodologies for display technologies, with recent updates addressing the unique challenges of WOLED thermal management. These standards mandate the use of high-precision thermal imaging equipment with resolution capabilities of at least 0.1°C for accurate temperature mapping across the display surface.

Accelerated life testing standards for WOLED thermal systems typically employ the Arrhenius equation to model temperature-dependent degradation, with activation energies specific to WOLED materials (typically 0.3-0.7 eV). These tests are conducted at elevated temperatures to predict long-term reliability under normal operating conditions, with statistical analysis methods such as Weibull distribution applied to failure data.

Environmental testing standards such as MIL-STD-810H have been adapted for WOLED applications, particularly for devices intended for harsh environments. These standards include humidity-temperature cycling tests that evaluate the impact of moisture ingress on thermal regulation systems, with relative humidity levels cycling between 30% and 95% while temperatures vary between ambient and 65°C.

Industry consortia like the OLED Association have developed supplementary testing guidelines that address WOLED-specific thermal challenges, including hotspot detection protocols and thermal uniformity assessments that require less than 5°C variation across the active display area during continuous operation at maximum brightness settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!