WOLED vs N-Doped LCD: Which Offers Better Display Resolution?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED and N-Doped LCD Technology Evolution and Objectives

Display technology has undergone significant evolution since the introduction of cathode ray tubes in the early 20th century. The journey from CRT to LCD, LED, OLED, and now advanced variants like WOLED (White Organic Light Emitting Diode) and N-Doped LCD represents a continuous pursuit of higher resolution, better color accuracy, and improved energy efficiency. These technological advancements have been driven by increasing consumer demands for immersive visual experiences across various devices, from smartphones to large-format displays.

WOLED technology emerged as an evolution of traditional OLED displays around 2012, pioneered by LG Display. Unlike conventional RGB OLED displays that use separate red, green, and blue subpixels, WOLED utilizes a white OLED layer combined with color filters. This architecture offers manufacturing advantages while maintaining many benefits of OLED technology, such as perfect blacks and wide viewing angles. The technology has steadily improved, with pixel densities increasing from approximately 100 PPI (pixels per inch) to over 300 PPI in premium television displays.

N-Doped LCD technology represents a more recent innovation in liquid crystal displays, introduced commercially around 2018. This technology incorporates negative dielectric anisotropy liquid crystals doped with specific compounds to enhance switching speeds and viewing angles. The evolution of LCD technology has been remarkable, from early TN (Twisted Nematic) panels to IPS (In-Plane Switching), and now to advanced variants like N-Doped LCDs that aim to address traditional LCD limitations while maintaining cost advantages.

Resolution capabilities have been a central focus in the development trajectory of both technologies. WOLED displays initially struggled with subpixel arrangements that limited effective resolution, but innovations in pixel structure and driving methods have significantly improved their performance. Similarly, N-Doped LCD technology has evolved to support higher refresh rates and pixel densities that were previously unattainable with conventional LCD technology.

The primary technical objective in comparing WOLED and N-Doped LCD technologies is to determine which can deliver superior display resolution while balancing other critical factors such as power consumption, manufacturing scalability, and cost-effectiveness. Resolution is not merely about pixel count but encompasses aspects like effective resolution, subpixel arrangement, contrast ratio, and motion clarity—all of which contribute to perceived image quality.

Secondary objectives include evaluating the technologies' potential for further advancement, identifying their fundamental physical limitations, and assessing their suitability for different application scenarios ranging from mobile devices to large-format displays. Understanding these factors is crucial for predicting which technology might dominate specific market segments in the coming years.

WOLED technology emerged as an evolution of traditional OLED displays around 2012, pioneered by LG Display. Unlike conventional RGB OLED displays that use separate red, green, and blue subpixels, WOLED utilizes a white OLED layer combined with color filters. This architecture offers manufacturing advantages while maintaining many benefits of OLED technology, such as perfect blacks and wide viewing angles. The technology has steadily improved, with pixel densities increasing from approximately 100 PPI (pixels per inch) to over 300 PPI in premium television displays.

N-Doped LCD technology represents a more recent innovation in liquid crystal displays, introduced commercially around 2018. This technology incorporates negative dielectric anisotropy liquid crystals doped with specific compounds to enhance switching speeds and viewing angles. The evolution of LCD technology has been remarkable, from early TN (Twisted Nematic) panels to IPS (In-Plane Switching), and now to advanced variants like N-Doped LCDs that aim to address traditional LCD limitations while maintaining cost advantages.

Resolution capabilities have been a central focus in the development trajectory of both technologies. WOLED displays initially struggled with subpixel arrangements that limited effective resolution, but innovations in pixel structure and driving methods have significantly improved their performance. Similarly, N-Doped LCD technology has evolved to support higher refresh rates and pixel densities that were previously unattainable with conventional LCD technology.

The primary technical objective in comparing WOLED and N-Doped LCD technologies is to determine which can deliver superior display resolution while balancing other critical factors such as power consumption, manufacturing scalability, and cost-effectiveness. Resolution is not merely about pixel count but encompasses aspects like effective resolution, subpixel arrangement, contrast ratio, and motion clarity—all of which contribute to perceived image quality.

Secondary objectives include evaluating the technologies' potential for further advancement, identifying their fundamental physical limitations, and assessing their suitability for different application scenarios ranging from mobile devices to large-format displays. Understanding these factors is crucial for predicting which technology might dominate specific market segments in the coming years.

Display Resolution Market Demands and Consumer Preferences

The display resolution market has witnessed significant evolution over the past decade, driven primarily by consumer demand for more immersive viewing experiences across multiple device categories. Market research indicates that consumers increasingly prioritize higher resolution displays when making purchasing decisions for smartphones, televisions, and computer monitors. This trend is particularly pronounced in premium market segments, where resolution has become a key differentiating factor alongside color accuracy and refresh rates.

Consumer preferences regarding display resolution vary significantly across different device categories. For smartphones, the transition from HD to Full HD and now to Quad HD and even 4K displays reflects consumers' desire for sharper text and more detailed images on increasingly larger screen sizes. In the television sector, 4K has become the new standard, with 8K beginning to penetrate the ultra-premium segment despite limited native content availability.

Professional users in fields such as graphic design, video editing, and medical imaging demonstrate distinct resolution requirements compared to general consumers. These professionals often prioritize resolution precision and color accuracy over other display features, creating a specialized market segment with higher willingness to pay for superior display technologies.

Regional variations in display resolution preferences are notable, with developed markets in North America, Europe, and East Asia showing stronger demand for higher resolution displays across all device categories. Emerging markets typically demonstrate a more price-sensitive approach, with resolution becoming a secondary consideration after affordability.

The relationship between perceived resolution quality and actual pixel density follows a non-linear pattern. Research shows diminishing returns in consumer satisfaction as pixel density increases beyond certain thresholds, which vary by viewing distance and screen size. This phenomenon has important implications for manufacturers deciding between WOLED and N-Doped LCD technologies, as the resolution advantages of either technology must be balanced against cost considerations and other performance metrics.

Energy efficiency has emerged as an increasingly important factor influencing consumer preferences, particularly for mobile devices where battery life remains a critical concern. Display technologies that can deliver higher resolutions without proportional increases in power consumption gain competitive advantage in consumer perception and purchasing decisions.

Consumer preferences regarding display resolution vary significantly across different device categories. For smartphones, the transition from HD to Full HD and now to Quad HD and even 4K displays reflects consumers' desire for sharper text and more detailed images on increasingly larger screen sizes. In the television sector, 4K has become the new standard, with 8K beginning to penetrate the ultra-premium segment despite limited native content availability.

Professional users in fields such as graphic design, video editing, and medical imaging demonstrate distinct resolution requirements compared to general consumers. These professionals often prioritize resolution precision and color accuracy over other display features, creating a specialized market segment with higher willingness to pay for superior display technologies.

Regional variations in display resolution preferences are notable, with developed markets in North America, Europe, and East Asia showing stronger demand for higher resolution displays across all device categories. Emerging markets typically demonstrate a more price-sensitive approach, with resolution becoming a secondary consideration after affordability.

The relationship between perceived resolution quality and actual pixel density follows a non-linear pattern. Research shows diminishing returns in consumer satisfaction as pixel density increases beyond certain thresholds, which vary by viewing distance and screen size. This phenomenon has important implications for manufacturers deciding between WOLED and N-Doped LCD technologies, as the resolution advantages of either technology must be balanced against cost considerations and other performance metrics.

Energy efficiency has emerged as an increasingly important factor influencing consumer preferences, particularly for mobile devices where battery life remains a critical concern. Display technologies that can deliver higher resolutions without proportional increases in power consumption gain competitive advantage in consumer perception and purchasing decisions.

Current Technical Limitations and Challenges in Display Technologies

Despite significant advancements in display technology, both WOLED and N-Doped LCD face distinct technical limitations that impact their resolution capabilities. WOLED (White Organic Light Emitting Diode) displays struggle with sub-pixel degradation over time, particularly with blue OLED materials showing faster deterioration rates than red and green counterparts. This uneven aging process leads to color shifts and reduced resolution clarity after extended usage periods, presenting a significant challenge for long-term display quality maintenance.

Resolution limitations in WOLED displays are further complicated by manufacturing constraints. The current vapor deposition processes used for OLED production face yield challenges when attempting to achieve ultra-high pixel densities beyond 1000 PPI (pixels per inch), particularly in larger display formats. The precision required for depositing organic materials at increasingly smaller scales introduces variability that can compromise resolution consistency across the display surface.

N-Doped LCD technology, while offering improvements over traditional LCD displays, confronts its own set of technical hurdles. The liquid crystal alignment stability in N-Doped configurations remains problematic under varying temperature conditions, causing potential resolution degradation in extreme environmental settings. This temperature sensitivity can result in inconsistent pixel response times across the display, affecting perceived resolution quality particularly during the display of high-motion content.

Response time limitations represent another critical challenge for N-Doped LCD technology. Despite improvements through negative doping techniques, these displays still exhibit slower pixel transition speeds compared to WOLED, resulting in motion blur that effectively reduces perceived resolution during dynamic content playback. This limitation becomes particularly evident in applications requiring rapid screen updates such as gaming or fast-motion video.

Power efficiency presents contrasting challenges for both technologies. WOLED displays require complex power management systems to maintain consistent brightness across varying content types without compromising resolution, while N-Doped LCDs struggle with backlight uniformity issues that can affect perceived resolution quality, especially in high-contrast scenes. The power requirements for maintaining optimal resolution performance impact device design considerations, particularly for mobile applications.

Manufacturing scalability poses different constraints for each technology. WOLED fabrication faces yield challenges at larger sizes while maintaining high pixel densities, whereas N-Doped LCD production confronts difficulties in achieving consistent doping concentrations across large panels, leading to potential resolution uniformity issues. These manufacturing limitations directly impact production costs and market accessibility of high-resolution implementations of both technologies.

Viewing angle performance presents another resolution-related challenge, with WOLED offering superior off-axis resolution consistency compared to N-Doped LCD, which still exhibits some degree of color and contrast shifting when viewed from extreme angles, effectively reducing the perceived resolution quality for multiple viewers.

Resolution limitations in WOLED displays are further complicated by manufacturing constraints. The current vapor deposition processes used for OLED production face yield challenges when attempting to achieve ultra-high pixel densities beyond 1000 PPI (pixels per inch), particularly in larger display formats. The precision required for depositing organic materials at increasingly smaller scales introduces variability that can compromise resolution consistency across the display surface.

N-Doped LCD technology, while offering improvements over traditional LCD displays, confronts its own set of technical hurdles. The liquid crystal alignment stability in N-Doped configurations remains problematic under varying temperature conditions, causing potential resolution degradation in extreme environmental settings. This temperature sensitivity can result in inconsistent pixel response times across the display, affecting perceived resolution quality particularly during the display of high-motion content.

Response time limitations represent another critical challenge for N-Doped LCD technology. Despite improvements through negative doping techniques, these displays still exhibit slower pixel transition speeds compared to WOLED, resulting in motion blur that effectively reduces perceived resolution during dynamic content playback. This limitation becomes particularly evident in applications requiring rapid screen updates such as gaming or fast-motion video.

Power efficiency presents contrasting challenges for both technologies. WOLED displays require complex power management systems to maintain consistent brightness across varying content types without compromising resolution, while N-Doped LCDs struggle with backlight uniformity issues that can affect perceived resolution quality, especially in high-contrast scenes. The power requirements for maintaining optimal resolution performance impact device design considerations, particularly for mobile applications.

Manufacturing scalability poses different constraints for each technology. WOLED fabrication faces yield challenges at larger sizes while maintaining high pixel densities, whereas N-Doped LCD production confronts difficulties in achieving consistent doping concentrations across large panels, leading to potential resolution uniformity issues. These manufacturing limitations directly impact production costs and market accessibility of high-resolution implementations of both technologies.

Viewing angle performance presents another resolution-related challenge, with WOLED offering superior off-axis resolution consistency compared to N-Doped LCD, which still exhibits some degree of color and contrast shifting when viewed from extreme angles, effectively reducing the perceived resolution quality for multiple viewers.

Comparative Analysis of WOLED and N-Doped LCD Resolution Solutions

01 WOLED technology for high-resolution displays

White Organic Light Emitting Diode (WOLED) technology enables high-resolution displays with improved color accuracy and brightness. These displays utilize white light emission from organic materials that is filtered through color filters to produce vibrant images. WOLED technology offers advantages such as better power efficiency, wider viewing angles, and thinner form factors compared to traditional LCD displays, making it suitable for high-resolution applications.- WOLED technology for high-resolution displays: White Organic Light Emitting Diode (WOLED) technology enables high-resolution displays with superior color reproduction and contrast ratios. These displays utilize white light emission from organic materials combined with color filters to produce vibrant images. WOLED technology offers advantages such as thin form factors, energy efficiency, and excellent viewing angles, making it suitable for high-resolution applications in various electronic devices.

- N-Doped LCD display technology advancements: N-Doped Liquid Crystal Display (LCD) technology represents an advancement in traditional LCD displays by incorporating nitrogen-doped materials to improve performance characteristics. This technology enhances electron mobility, resulting in faster response times and better image quality. N-Doped LCDs offer improved brightness, contrast ratios, and power efficiency compared to conventional LCD displays, while maintaining compatibility with existing manufacturing processes.

- Display resolution enhancement techniques: Various techniques are employed to enhance display resolution in both WOLED and LCD technologies. These include pixel arrangement optimization, sub-pixel rendering, and advanced driving schemes. Resolution enhancement methods improve perceived image quality by increasing pixel density, reducing artifacts, and enhancing sharpness. These techniques enable displays to achieve higher effective resolutions without significantly increasing manufacturing costs or power consumption.

- Integration of WOLED and LCD technologies: Hybrid display solutions that integrate aspects of both WOLED and LCD technologies offer unique advantages. These hybrid displays combine the high contrast and color reproduction of WOLED with the established manufacturing processes of LCD technology. Integration approaches include using WOLED backlighting for LCD panels or creating composite display structures. These hybrid solutions aim to deliver superior image quality while addressing limitations of each individual technology.

- Power efficiency and thermal management in high-resolution displays: High-resolution WOLED and N-Doped LCD displays require sophisticated power efficiency and thermal management solutions. Advanced driving circuits, dynamic brightness control, and selective pixel activation help reduce power consumption while maintaining image quality. Thermal management techniques include heat dissipation structures, temperature sensors, and adaptive brightness algorithms that prevent overheating during extended operation. These approaches extend device lifespan and improve user experience in high-resolution display applications.

02 N-Doped LCD display technology advancements

N-Doped Liquid Crystal Display (LCD) technology incorporates nitrogen-doped materials to enhance display performance. This technology improves electron mobility and conductivity in the display components, resulting in faster response times and better image quality. N-Doped LCDs offer improved resolution capabilities while maintaining energy efficiency, making them suitable for various applications from mobile devices to large-format displays.Expand Specific Solutions03 Display resolution enhancement techniques

Various techniques are employed to enhance display resolution in both WOLED and LCD technologies. These include pixel arrangement optimization, sub-pixel rendering, and advanced driving schemes that effectively increase the perceived resolution. Additional methods involve sophisticated image processing algorithms that improve clarity and sharpness, allowing displays to achieve higher effective resolution without increasing the physical pixel count.Expand Specific Solutions04 Hybrid display technologies combining WOLED and LCD elements

Hybrid display technologies combine elements of both WOLED and LCD to leverage the advantages of each. These displays may use WOLED backlighting with LCD color filtering or incorporate both technologies in different parts of the display. The hybrid approach allows for improved contrast ratios, better color reproduction, and enhanced resolution while optimizing power consumption, resulting in displays with superior visual performance.Expand Specific Solutions05 Advanced pixel structures for high-resolution displays

Innovative pixel structures are developed to achieve higher resolution in display technologies. These include specialized arrangements of sub-pixels, novel electrode designs, and advanced thin-film transistor (TFT) configurations. Such structures enable more precise control of light emission or transmission, resulting in displays with higher pixel density, improved color accuracy, and enhanced overall visual quality for both WOLED and N-Doped LCD technologies.Expand Specific Solutions

Major Manufacturers and Competitive Landscape in Display Industry

The WOLED vs N-Doped LCD display technology landscape is currently in a transitional phase, with the market expanding rapidly as demand for high-resolution displays grows across consumer electronics. The global display market is valued at approximately $150 billion, with both technologies competing for market share. WOLED technology, championed by LG Display and Samsung Display, offers superior contrast ratios and color accuracy, while N-Doped LCD, advanced by BOE Technology and TCL China Star Optoelectronics, provides cost advantages with improving performance metrics. Technical maturity varies, with WOLED showing advantages in premium segments while N-Doped LCD dominates mid-range applications. Research collaborations between display manufacturers and institutions like University of Washington and USC are accelerating innovations in both technologies.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed both OLED and advanced LCD technologies, positioning themselves as a versatile display manufacturer addressing resolution challenges from multiple angles. Their OLED technology focuses on flexible and rigid displays with pixel densities exceeding 400 PPI for mobile applications. For their LCD technology, BOE has pioneered Advanced Super Dimension Switch (ADS) panels, a proprietary version of N-Doped LCD technology that improves viewing angles and contrast ratios. BOE's high-resolution LCD panels implement oxide semiconductor TFTs with negative doping to enhance electron mobility, achieving response times as low as 5ms. Their latest Mini-LED backlit LCDs feature over 1000 dimming zones in premium models, significantly improving contrast performance. BOE has successfully manufactured 8K resolution displays (7680×4320) using both technologies, with their LCD panels achieving brightness levels up to 1500 nits while maintaining power efficiency through advanced backlight control algorithms and negative-doped transistor designs that reduce power leakage.

Strengths: Versatility in offering both technologies; competitive manufacturing costs; higher brightness capabilities in their LCD lineup; and strong scaling capabilities for various device sizes from smartphones to large TVs. Weaknesses: Their OLED technology lags behind industry leaders in efficiency and color volume; their LCD technology, while advanced, still suffers from fundamental contrast limitations compared to self-emissive displays; and resolution improvements come with increased power consumption in both technologies.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed their proprietary H-IPS Pro technology, an advanced implementation of N-Doped LCD that focuses on achieving OLED-competitive resolution and image quality. Their panels utilize negative-doped oxide semiconductors in the TFT layer, improving electron mobility and enabling faster pixel response times of approximately 4ms. TCL's advanced LCD technology incorporates quantum dot enhancement films that expand the color gamut to 97% of the DCI-P3 standard. Their Mini-LED backlight technology, branded as OD Zero, places thousands of mini-LED sources directly against the LCD panel without an optical distance gap, allowing for more precise local dimming with over 1500 control zones in premium models. This approach enables contrast ratios exceeding 2000:1 while maintaining brightness levels up to 1800 nits for HDR content. TCL CSOT has achieved 8K resolution (7680×4320) in their high-end displays with pixel densities over 100 PPI for large format displays, utilizing advanced sub-pixel rendering techniques to enhance perceived resolution.

Strengths: Significantly higher brightness capabilities than WOLED; excellent color performance through quantum dot enhancement; no risk of burn-in; longer theoretical lifespan; and more affordable manufacturing process allowing for better price-to-performance ratio. Weaknesses: Cannot achieve the perfect blacks of WOLED technology; limited viewing angles compared to OLED displays; some blooming effects remain despite advanced local dimming; and higher power consumption when displaying bright content across the entire screen.

Key Patents and Technical Innovations in Display Resolution Enhancement

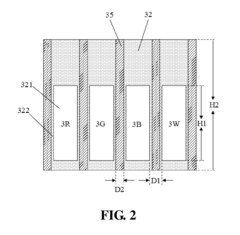

Woled display apparatus

PatentWO2017201777A1

Innovation

- Introducing a light purification layer with specific absorption wavelengths into the WOLED display device can selectively absorb red, green, and blue light to reduce its half-peak width, improve the filtering effect of the color filter layer, and enhance the red, green, and blue light The luminous purity of the three primary colors, thereby expanding the color gamut.

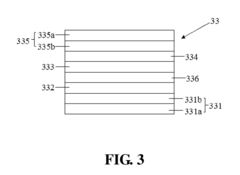

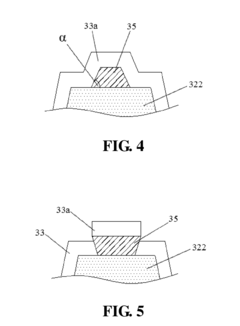

Woled display panel and display device

PatentInactiveUS20190013370A1

Innovation

- A WOLED display panel design featuring a thin film transistor array substrate with a color filter layer and a light emitting structure layer, including a protruding insulating post spacer with a trapezoid or inverted trapezoid cross-section and a convex bend portion in the organic light emitting layer, which increases the transverse travel path of holes and reduces leakage current between sub-pixels.

Power Efficiency and Battery Life Considerations

Power efficiency represents a critical differentiating factor between WOLED and N-Doped LCD technologies, directly impacting device battery life and operational costs. WOLED displays demonstrate superior power efficiency in most usage scenarios, particularly when displaying darker content. This efficiency stems from WOLED's fundamental operating principle: pixels emit light only when needed, with black pixels consuming virtually no power. In contrast, N-Doped LCD technology requires constant backlighting regardless of content, though N-Doping innovations have significantly improved energy efficiency compared to traditional LCD panels.

Quantitative analysis reveals that WOLED displays typically consume 30-40% less power than even advanced N-Doped LCDs when displaying mixed content. This efficiency gap widens to 60-70% for predominantly dark interfaces. However, the efficiency advantage narrows or even reverses when displaying predominantly white or very bright content, where N-Doped LCDs can demonstrate comparable or slightly better power consumption metrics.

Battery life implications are substantial, particularly for mobile devices. Smartphones and tablets equipped with WOLED technology generally deliver 2-4 hours of additional screen-on time compared to equivalent N-Doped LCD devices under typical usage patterns. This translates to approximately 20-30% longer overall battery life, a significant competitive advantage in consumer electronics markets where battery performance remains a key purchasing consideration.

Temperature management also factors into the efficiency equation. WOLED displays generate less heat during operation, reducing energy lost as thermal waste and minimizing the power requirements for device cooling systems. This creates a positive feedback loop for efficiency, particularly in compact devices where thermal management presents significant engineering challenges.

Recent advancements in both technologies continue to narrow the efficiency gap. N-Doped LCD manufacturers have implemented sophisticated local dimming technologies and improved transmittance rates, while WOLED developers have addressed efficiency degradation issues at high brightness levels. These parallel innovation paths suggest continued competition in the power efficiency domain, though WOLED maintains a structural advantage for most consumer applications.

For enterprise deployment scenarios, the cumulative energy consumption difference between these technologies translates to meaningful operational cost variations at scale. Organizations deploying thousands of displays can realize substantial energy savings by selecting the technology best aligned with their specific usage patterns and content requirements.

Quantitative analysis reveals that WOLED displays typically consume 30-40% less power than even advanced N-Doped LCDs when displaying mixed content. This efficiency gap widens to 60-70% for predominantly dark interfaces. However, the efficiency advantage narrows or even reverses when displaying predominantly white or very bright content, where N-Doped LCDs can demonstrate comparable or slightly better power consumption metrics.

Battery life implications are substantial, particularly for mobile devices. Smartphones and tablets equipped with WOLED technology generally deliver 2-4 hours of additional screen-on time compared to equivalent N-Doped LCD devices under typical usage patterns. This translates to approximately 20-30% longer overall battery life, a significant competitive advantage in consumer electronics markets where battery performance remains a key purchasing consideration.

Temperature management also factors into the efficiency equation. WOLED displays generate less heat during operation, reducing energy lost as thermal waste and minimizing the power requirements for device cooling systems. This creates a positive feedback loop for efficiency, particularly in compact devices where thermal management presents significant engineering challenges.

Recent advancements in both technologies continue to narrow the efficiency gap. N-Doped LCD manufacturers have implemented sophisticated local dimming technologies and improved transmittance rates, while WOLED developers have addressed efficiency degradation issues at high brightness levels. These parallel innovation paths suggest continued competition in the power efficiency domain, though WOLED maintains a structural advantage for most consumer applications.

For enterprise deployment scenarios, the cumulative energy consumption difference between these technologies translates to meaningful operational cost variations at scale. Organizations deploying thousands of displays can realize substantial energy savings by selecting the technology best aligned with their specific usage patterns and content requirements.

Manufacturing Cost Analysis and Scalability Assessment

The manufacturing cost structure of WOLED and N-Doped LCD technologies reveals significant differences that impact their market positioning and adoption rates. WOLED manufacturing requires specialized vacuum deposition equipment and precise control of organic material layers, resulting in higher initial capital expenditure. The complex multi-layer structure of WOLED panels, particularly for RGB subpixel arrangements, demands sophisticated production techniques that currently limit yield rates to 70-85% for high-resolution displays, substantially affecting unit economics.

In contrast, N-Doped LCD manufacturing leverages existing LCD production infrastructure with modifications to incorporate negative dielectric anisotropy materials. This adaptation of established manufacturing lines represents a 15-30% lower initial investment compared to new WOLED facilities. The manufacturing process for N-Doped LCD also demonstrates better scalability for larger panel sizes, with production yields averaging 85-92% across various resolution specifications.

Material costs present another critical differential factor. WOLED panels require rare organic compounds and precious metals for electron transport layers, with material costs accounting for approximately 35-45% of total production expenses. N-Doped LCD technology utilizes more readily available materials, with liquid crystal compounds and color filters representing only 20-30% of total production costs.

Energy consumption during manufacturing favors N-Doped LCD, which requires approximately 30% less energy than WOLED production processes. This efficiency translates to lower operational costs and reduced carbon footprint, an increasingly important consideration for manufacturers facing environmental regulations and sustainability targets.

Scalability assessment indicates that N-Doped LCD technology offers superior advantages for mass production scenarios. Current production lines can be modified to accommodate N-Doped technology with minimal disruption, enabling manufacturers to maintain production continuity while upgrading capabilities. WOLED manufacturing, while improving, still faces challenges in scaling to Gen 10.5+ substrate sizes without significant yield penalties.

Long-term cost projection models suggest that while WOLED manufacturing costs may decrease by 18-25% over the next five years through process optimization and economies of scale, N-Doped LCD is expected to maintain its cost advantage for at least the medium term, particularly for displays below premium price points. This cost differential will likely continue to influence market segmentation, with WOLED targeting premium applications where performance justifies higher costs, and N-Doped LCD dominating mid-range and mass-market segments.

In contrast, N-Doped LCD manufacturing leverages existing LCD production infrastructure with modifications to incorporate negative dielectric anisotropy materials. This adaptation of established manufacturing lines represents a 15-30% lower initial investment compared to new WOLED facilities. The manufacturing process for N-Doped LCD also demonstrates better scalability for larger panel sizes, with production yields averaging 85-92% across various resolution specifications.

Material costs present another critical differential factor. WOLED panels require rare organic compounds and precious metals for electron transport layers, with material costs accounting for approximately 35-45% of total production expenses. N-Doped LCD technology utilizes more readily available materials, with liquid crystal compounds and color filters representing only 20-30% of total production costs.

Energy consumption during manufacturing favors N-Doped LCD, which requires approximately 30% less energy than WOLED production processes. This efficiency translates to lower operational costs and reduced carbon footprint, an increasingly important consideration for manufacturers facing environmental regulations and sustainability targets.

Scalability assessment indicates that N-Doped LCD technology offers superior advantages for mass production scenarios. Current production lines can be modified to accommodate N-Doped technology with minimal disruption, enabling manufacturers to maintain production continuity while upgrading capabilities. WOLED manufacturing, while improving, still faces challenges in scaling to Gen 10.5+ substrate sizes without significant yield penalties.

Long-term cost projection models suggest that while WOLED manufacturing costs may decrease by 18-25% over the next five years through process optimization and economies of scale, N-Doped LCD is expected to maintain its cost advantage for at least the medium term, particularly for displays below premium price points. This cost differential will likely continue to influence market segmentation, with WOLED targeting premium applications where performance justifies higher costs, and N-Doped LCD dominating mid-range and mass-market segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!