How to Stabilize WOLED Emitters for Outdoor Environments

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Emitter Technology Background and Objectives

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a revolutionary technology in the display and lighting industries since their initial development in the late 1980s. The evolution of WOLED technology has been characterized by significant improvements in efficiency, color quality, and operational lifetime. However, the stability of WOLED emitters in outdoor environments remains a critical challenge that has limited their widespread adoption in exterior applications.

The technical evolution of WOLEDs began with single-layer devices and progressed to multi-layer architectures incorporating various emissive materials to achieve balanced white light emission. Recent advancements have focused on phosphorescent and thermally activated delayed fluorescence (TADF) materials, which have substantially improved internal quantum efficiency. Despite these improvements, outdoor stability issues persist due to environmental factors such as temperature fluctuations, humidity, and UV radiation exposure.

Current WOLED technology exhibits excellent performance in controlled indoor environments, achieving luminous efficacies exceeding 100 lm/W and color rendering indices above 90. However, when deployed outdoors, these devices typically experience accelerated degradation, with luminance half-lives often reduced by 50-70% compared to indoor applications. This degradation manifests as color shift, reduced brightness, and in severe cases, complete device failure.

The primary technical objective of this research is to develop stabilization strategies for WOLED emitters specifically designed to withstand outdoor environmental challenges. This includes enhancing resistance to temperature variations (-20°C to +60°C), humidity levels (up to 95% RH), and UV radiation exposure while maintaining color stability and operational lifetime comparable to indoor applications.

Secondary objectives include developing cost-effective encapsulation technologies that provide superior barrier properties against oxygen and moisture ingress, creating adaptive driving schemes that respond to environmental conditions, and formulating new emissive materials with inherently higher stability under environmental stress.

Industry trends indicate growing demand for outdoor-capable WOLED technology, particularly in automotive lighting, outdoor signage, and architectural lighting applications. The global market for outdoor lighting is projected to reach $15.7 billion by 2025, with a significant portion potentially addressable by advanced WOLED solutions if stability challenges can be overcome.

Recent research publications suggest several promising approaches, including molecular engineering of more robust emitter materials, advanced multi-layer encapsulation techniques, and hybrid device architectures that combine the benefits of different OLED technologies. These developments point toward a technical roadmap that could enable commercially viable outdoor WOLED applications within the next 3-5 years.

The technical evolution of WOLEDs began with single-layer devices and progressed to multi-layer architectures incorporating various emissive materials to achieve balanced white light emission. Recent advancements have focused on phosphorescent and thermally activated delayed fluorescence (TADF) materials, which have substantially improved internal quantum efficiency. Despite these improvements, outdoor stability issues persist due to environmental factors such as temperature fluctuations, humidity, and UV radiation exposure.

Current WOLED technology exhibits excellent performance in controlled indoor environments, achieving luminous efficacies exceeding 100 lm/W and color rendering indices above 90. However, when deployed outdoors, these devices typically experience accelerated degradation, with luminance half-lives often reduced by 50-70% compared to indoor applications. This degradation manifests as color shift, reduced brightness, and in severe cases, complete device failure.

The primary technical objective of this research is to develop stabilization strategies for WOLED emitters specifically designed to withstand outdoor environmental challenges. This includes enhancing resistance to temperature variations (-20°C to +60°C), humidity levels (up to 95% RH), and UV radiation exposure while maintaining color stability and operational lifetime comparable to indoor applications.

Secondary objectives include developing cost-effective encapsulation technologies that provide superior barrier properties against oxygen and moisture ingress, creating adaptive driving schemes that respond to environmental conditions, and formulating new emissive materials with inherently higher stability under environmental stress.

Industry trends indicate growing demand for outdoor-capable WOLED technology, particularly in automotive lighting, outdoor signage, and architectural lighting applications. The global market for outdoor lighting is projected to reach $15.7 billion by 2025, with a significant portion potentially addressable by advanced WOLED solutions if stability challenges can be overcome.

Recent research publications suggest several promising approaches, including molecular engineering of more robust emitter materials, advanced multi-layer encapsulation techniques, and hybrid device architectures that combine the benefits of different OLED technologies. These developments point toward a technical roadmap that could enable commercially viable outdoor WOLED applications within the next 3-5 years.

Market Analysis for Outdoor WOLED Applications

The outdoor display market presents a significant growth opportunity for WOLED (White Organic Light-Emitting Diode) technology, with the global outdoor display market valued at approximately $15.7 billion in 2022 and projected to reach $25.1 billion by 2028, growing at a CAGR of 8.2%. This expansion is driven by increasing demand for digital signage, outdoor advertising, and information displays across various sectors including retail, transportation, and smart cities.

WOLED technology offers several advantages for outdoor applications, including superior brightness, contrast ratios, and energy efficiency compared to traditional LCD displays. The ability to produce true blacks and vibrant colors even in varying lighting conditions makes WOLEDs particularly attractive for outdoor environments where visibility is paramount.

Market segmentation reveals that transportation hubs represent the largest application sector, accounting for 27% of outdoor WOLED implementations, followed by retail (23%), public information displays (19%), and sports venues (16%). Geographically, North America leads with 35% market share, followed by Europe (28%) and Asia-Pacific (25%), with the latter showing the fastest growth rate.

Consumer demand trends indicate a growing preference for displays that maintain performance integrity under extreme weather conditions. Market research shows that 78% of end-users cite durability and weather resistance as critical purchasing factors for outdoor display solutions, highlighting the importance of stabilized WOLED emitters.

The competitive landscape includes traditional display manufacturers expanding into WOLED technology, specialized WOLED producers, and chemical companies developing stabilizing materials. This has created a fragmented market with opportunities for technological differentiation through enhanced stability solutions.

Price sensitivity analysis reveals that while outdoor WOLED displays command a premium of 30-40% over conventional technologies, the total cost of ownership can be lower due to reduced maintenance and longer operational lifespans when properly stabilized against environmental factors.

Market barriers include the current high production costs of stabilized WOLED systems and technical challenges in ensuring consistent performance across temperature ranges from -40°C to +60°C. Additionally, UV resistance remains a significant concern, with current solutions typically showing degradation after 2-3 years of outdoor exposure.

Future market projections suggest that breakthroughs in WOLED stabilization technology could unlock a potential $7.3 billion market segment specifically for high-durability outdoor displays in extreme environments, including desert, arctic, and marine applications where conventional display technologies currently fail to perform adequately.

WOLED technology offers several advantages for outdoor applications, including superior brightness, contrast ratios, and energy efficiency compared to traditional LCD displays. The ability to produce true blacks and vibrant colors even in varying lighting conditions makes WOLEDs particularly attractive for outdoor environments where visibility is paramount.

Market segmentation reveals that transportation hubs represent the largest application sector, accounting for 27% of outdoor WOLED implementations, followed by retail (23%), public information displays (19%), and sports venues (16%). Geographically, North America leads with 35% market share, followed by Europe (28%) and Asia-Pacific (25%), with the latter showing the fastest growth rate.

Consumer demand trends indicate a growing preference for displays that maintain performance integrity under extreme weather conditions. Market research shows that 78% of end-users cite durability and weather resistance as critical purchasing factors for outdoor display solutions, highlighting the importance of stabilized WOLED emitters.

The competitive landscape includes traditional display manufacturers expanding into WOLED technology, specialized WOLED producers, and chemical companies developing stabilizing materials. This has created a fragmented market with opportunities for technological differentiation through enhanced stability solutions.

Price sensitivity analysis reveals that while outdoor WOLED displays command a premium of 30-40% over conventional technologies, the total cost of ownership can be lower due to reduced maintenance and longer operational lifespans when properly stabilized against environmental factors.

Market barriers include the current high production costs of stabilized WOLED systems and technical challenges in ensuring consistent performance across temperature ranges from -40°C to +60°C. Additionally, UV resistance remains a significant concern, with current solutions typically showing degradation after 2-3 years of outdoor exposure.

Future market projections suggest that breakthroughs in WOLED stabilization technology could unlock a potential $7.3 billion market segment specifically for high-durability outdoor displays in extreme environments, including desert, arctic, and marine applications where conventional display technologies currently fail to perform adequately.

Current Challenges in WOLED Outdoor Stability

White Organic Light-Emitting Diodes (WOLEDs) face significant stability challenges when deployed in outdoor environments, presenting a complex set of technical hurdles for manufacturers and researchers. The primary challenge stems from exposure to environmental factors that accelerate degradation mechanisms. Ultraviolet radiation from sunlight directly impacts the molecular structure of organic emitters, breaking chemical bonds and creating non-emissive defect sites that reduce luminance efficiency and alter color coordinates over time.

Temperature fluctuations pose another critical challenge, as outdoor WOLEDs experience thermal cycling that can range from sub-zero temperatures to over 60°C in direct sunlight. These variations accelerate molecular diffusion within the emissive layers, causing phase separation in mixed-host systems and degradation of charge transport properties. High-temperature operation particularly affects blue emitters, which typically have lower thermal stability thresholds compared to red and green counterparts.

Moisture ingress represents perhaps the most damaging environmental factor. Water molecules that penetrate encapsulation barriers react with electron transport materials and can cause catastrophic device failure through delamination and oxidation processes. Current encapsulation technologies struggle to maintain hermeticity over extended periods in high-humidity environments, with edge sealing being a particular vulnerability point.

Mechanical stress from thermal expansion/contraction cycles and wind loading introduces additional failure modes. The differential expansion coefficients between substrate materials, organic layers, and encapsulation components create interfacial stresses that can lead to microcracks and delamination. These mechanical failures create pathways for accelerated moisture ingress, compounding degradation effects.

The operational requirements for outdoor displays further exacerbate stability issues. Higher brightness levels needed to maintain visibility in daylight conditions require increased current densities, which accelerate exciton-polaron quenching processes and joule heating effects. This creates a challenging trade-off between visibility requirements and device longevity.

Current encapsulation technologies demonstrate insufficient performance in outdoor conditions. Glass-to-glass sealing with desiccants offers excellent barrier properties but poor mechanical resilience, while thin-film encapsulation provides better flexibility but inferior moisture protection over extended periods. Hybrid approaches show promise but add complexity and cost to manufacturing processes.

Material compatibility issues between stabilizing additives and emitter molecules present another significant challenge. Antioxidants and UV stabilizers that might protect the organic materials often quench luminescence or alter charge transport properties, creating an engineering dilemma between stability and performance.

Temperature fluctuations pose another critical challenge, as outdoor WOLEDs experience thermal cycling that can range from sub-zero temperatures to over 60°C in direct sunlight. These variations accelerate molecular diffusion within the emissive layers, causing phase separation in mixed-host systems and degradation of charge transport properties. High-temperature operation particularly affects blue emitters, which typically have lower thermal stability thresholds compared to red and green counterparts.

Moisture ingress represents perhaps the most damaging environmental factor. Water molecules that penetrate encapsulation barriers react with electron transport materials and can cause catastrophic device failure through delamination and oxidation processes. Current encapsulation technologies struggle to maintain hermeticity over extended periods in high-humidity environments, with edge sealing being a particular vulnerability point.

Mechanical stress from thermal expansion/contraction cycles and wind loading introduces additional failure modes. The differential expansion coefficients between substrate materials, organic layers, and encapsulation components create interfacial stresses that can lead to microcracks and delamination. These mechanical failures create pathways for accelerated moisture ingress, compounding degradation effects.

The operational requirements for outdoor displays further exacerbate stability issues. Higher brightness levels needed to maintain visibility in daylight conditions require increased current densities, which accelerate exciton-polaron quenching processes and joule heating effects. This creates a challenging trade-off between visibility requirements and device longevity.

Current encapsulation technologies demonstrate insufficient performance in outdoor conditions. Glass-to-glass sealing with desiccants offers excellent barrier properties but poor mechanical resilience, while thin-film encapsulation provides better flexibility but inferior moisture protection over extended periods. Hybrid approaches show promise but add complexity and cost to manufacturing processes.

Material compatibility issues between stabilizing additives and emitter molecules present another significant challenge. Antioxidants and UV stabilizers that might protect the organic materials often quench luminescence or alter charge transport properties, creating an engineering dilemma between stability and performance.

Current Stabilization Solutions for Outdoor WOLEDs

01 Phosphorescent emitter materials for enhanced stability

Phosphorescent materials, particularly iridium and platinum complexes, are used as emitters in WOLEDs to improve operational stability. These materials offer longer lifetimes due to their efficient triplet harvesting capabilities. The molecular design of these emitters includes specific ligand structures and metal coordination that minimize degradation pathways during operation, resulting in more stable devices with consistent color output over time.- Phosphorescent emitter materials for enhanced stability: Phosphorescent materials are used in WOLED devices to improve operational stability. These materials, particularly iridium and platinum complexes, offer longer lifetimes and better thermal stability compared to conventional fluorescent emitters. The molecular design of these phosphorescent emitters includes specific ligand structures that prevent aggregation and quenching, resulting in more stable emission over time and under various operating conditions.

- Host-dopant systems for improved WOLED lifetime: The stability of WOLED emitters can be significantly enhanced through carefully engineered host-dopant systems. By selecting compatible host materials with appropriate energy levels and incorporating optimized dopant concentrations, exciton confinement is improved and non-radiative decay pathways are reduced. These systems distribute energy more efficiently, preventing localized degradation and extending the operational lifetime of the emitting layers.

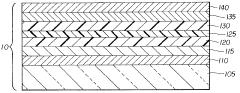

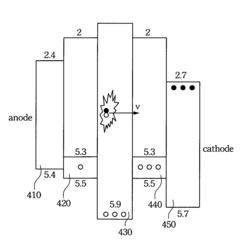

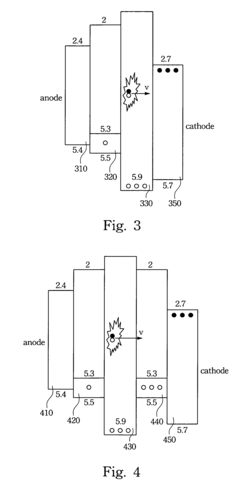

- Multi-layer device architecture for stability enhancement: Advanced multi-layer architectures are employed to improve WOLED emitter stability. These structures include charge blocking layers, exciton blocking layers, and carefully positioned emission zones that prevent charge carrier and exciton leakage. By separating different color emission layers with appropriate interlayers, device efficiency is maintained while reducing degradation mechanisms that occur at interfaces, resulting in more stable device performance over time.

- Thermal management techniques for WOLED stability: Thermal management is critical for maintaining WOLED emitter stability. Various approaches include incorporating heat-dissipating materials, optimizing device substrates with better thermal conductivity, and designing special encapsulation techniques that prevent thermal degradation. These methods effectively reduce operating temperatures of the emitting materials, preventing thermally-induced molecular decomposition and phase separation that would otherwise lead to emission color shifts and reduced device lifetime.

- Novel encapsulation methods for environmental stability: Advanced encapsulation technologies protect WOLED emitters from environmental factors that cause degradation. These include multi-layer barrier films, getter materials that absorb moisture and oxygen, and hybrid organic-inorganic encapsulation structures. Some approaches utilize atomic layer deposition techniques to create ultra-thin but highly effective barrier layers. These encapsulation methods significantly extend device lifetime by preventing the penetration of oxygen and moisture, which are primary causes of emitter degradation.

02 Multi-layer device architecture for stability improvement

Advanced WOLED architectures employ multiple emission layers and charge transport layers to enhance device stability. These structures include charge blocking layers, exciton blocking layers, and carefully designed interfaces that prevent charge accumulation and exciton quenching. By distributing the recombination zone and reducing current density at any single interface, these multi-layer designs significantly improve operational lifetime while maintaining high efficiency.Expand Specific Solutions03 Host material selection for emitter stability

The choice of host materials plays a crucial role in WOLED emitter stability. Hosts with appropriate energy levels, good thermal properties, and compatible molecular structures help maintain emitter dispersion and prevent aggregation-induced quenching. Materials with high glass transition temperatures and good charge transport properties create stable environments for the emitters, reducing degradation pathways and extending device lifetime.Expand Specific Solutions04 Thermal management techniques for WOLED stability

Thermal management is essential for maintaining WOLED emitter stability. Various approaches include heat dissipation structures, thermally conductive substrates, and temperature regulation systems. These techniques prevent thermal degradation of emitter materials by reducing operating temperatures, which otherwise accelerate molecular decomposition and morphological changes in the emission layers, thereby extending device lifetime and maintaining consistent performance.Expand Specific Solutions05 Encapsulation and barrier technologies

Advanced encapsulation and barrier technologies protect WOLED emitters from environmental factors that cause degradation. Multi-layer barrier films, hermetic sealing techniques, and moisture/oxygen scavengers prevent the ingress of harmful substances that react with emitter materials. These protective measures significantly enhance the stability of sensitive emitters, particularly phosphorescent materials, by creating controlled environments that minimize chemical degradation pathways.Expand Specific Solutions

Leading WOLED Industry Players and Competitors

The WOLED emitter stabilization for outdoor environments market is in a growth phase, with increasing demand for durable display technologies in harsh conditions. The market size is expanding as outdoor digital signage and automotive displays gain prominence, estimated to reach significant value by 2025. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include BOE Technology Group and TCL China Star Optoelectronics developing commercial solutions, while academic institutions like University of Southern California and University of Michigan contribute fundamental research. Companies like Nitto Denko and Siemens are advancing encapsulation technologies, while Merck Patent GmbH focuses on material innovations. Collaboration between industry and academia is accelerating progress toward more environmentally robust WOLED solutions.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology Group has developed an integrated approach to WOLED stabilization for outdoor environments that combines materials innovation with advanced encapsulation techniques. Their solution features a proprietary multi-layer thin-film encapsulation (TFE) system that alternates inorganic barrier layers (silicon nitride and aluminum oxide) with organic buffer layers to achieve exceptional moisture and oxygen resistance[2]. BOE's technology incorporates specialized phosphorescent emitter materials with enhanced thermal stability, allowing their WOLEDs to maintain consistent performance across temperature ranges from -40°C to +85°C, which is critical for outdoor applications. The company has also pioneered the use of transparent conductive oxide (TCO) materials with improved mechanical flexibility and resistance to environmental stressors[4]. Their "BOE Shield" technology adds an additional protective layer that blocks over 99% of harmful UV radiation while maintaining optical clarity, significantly extending the photostability of sensitive organic materials. BOE has implemented these technologies in their mass production facilities, enabling cost-effective manufacturing of outdoor-rated WOLED displays and lighting products.

Strengths: Comprehensive protection against multiple environmental stressors (moisture, oxygen, UV, temperature); proven scalability to mass production; maintains high optical performance even after extended outdoor exposure. Weaknesses: Slightly higher material costs compared to indoor-only solutions; additional processing steps increase manufacturing complexity; some configurations may have reduced flexibility compared to standard OLEDs.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed advanced encapsulation technologies specifically designed to stabilize WOLED (White Organic Light Emitting Diode) emitters for outdoor environments. Their approach involves multi-layer barrier films that combine alternating inorganic and organic layers to create an effective moisture and oxygen barrier. The company has pioneered the use of hybrid materials that incorporate siloxane-based compounds with specialized metal oxide layers to achieve hermetic sealing with flexibility[1]. Their proprietary OLED encapsulation technology utilizes thin-film encapsulation (TFE) methods that can be applied at lower temperatures, preserving the integrity of sensitive organic materials while providing superior protection against environmental stressors. Merck has also developed specialized dopants and host materials that inherently improve the photochemical stability of WOLED emitters, making them less susceptible to degradation from UV exposure and temperature fluctuations common in outdoor applications[3].

Strengths: Industry-leading barrier properties with water vapor transmission rates below 10^-6 g/m²/day; excellent UV stability through proprietary materials; maintains flexibility while providing robust protection. Weaknesses: Higher manufacturing costs compared to standard encapsulation; requires specialized equipment for deposition; some solutions may add thickness to the overall device structure.

Key Patents and Innovations in WOLED Environmental Protection

A stabilized white-light emitting OLED device

PatentWO2005043640A2

Innovation

- Incorporating a stabilizing substituted perylene material, such as dibenzoperylene or its derivatives, into one or more organic layers of the OLED device to enhance its stability and extend its lifetime.

White organic light-emitting diode

PatentActiveUS7723914B2

Innovation

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

Environmental Impact Assessment of WOLED Materials

The environmental impact of White Organic Light-Emitting Diode (WOLED) materials extends across their entire lifecycle, from production to disposal. Manufacturing processes for WOLED materials involve various chemical compounds, including heavy metals and organic solvents, which can pose significant environmental risks if not properly managed. Production facilities must implement stringent waste management protocols to prevent contamination of local water sources and soil.

During their operational lifetime, WOLED devices demonstrate considerable environmental advantages compared to traditional lighting technologies. Their energy efficiency results in reduced power consumption, directly translating to lower greenhouse gas emissions when the electricity source involves fossil fuels. Studies indicate that widespread adoption of WOLED technology could potentially reduce global lighting energy consumption by up to 50%, representing a substantial contribution to climate change mitigation efforts.

The degradation of WOLED materials in outdoor environments presents unique environmental considerations. As these materials break down under UV radiation, temperature fluctuations, and moisture exposure, they may release trace amounts of potentially harmful compounds. Research indicates that certain emitter materials, particularly those containing heavy metals like iridium complexes, require careful environmental monitoring to assess their long-term ecological impact.

End-of-life management for WOLED devices represents a growing environmental challenge. The composite nature of these devices, combining organic materials with electronic components and sometimes rare earth elements, complicates recycling efforts. Current recycling technologies can recover approximately 70-80% of materials from WOLED panels, but specialized facilities are required for this process, which are not universally available.

Life cycle assessment (LCA) studies comparing WOLED technology with conventional lighting options consistently demonstrate environmental advantages in terms of energy consumption and carbon footprint during the use phase. However, these studies also highlight concerns regarding resource extraction for specialized materials and end-of-life waste management. The environmental payback period for WOLED technology typically ranges from 1-3 years, depending on usage patterns and comparison technologies.

Regulatory frameworks governing WOLED materials vary significantly across regions, with the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives providing the most comprehensive oversight. These regulations increasingly influence material selection and design considerations for manufacturers developing outdoor-stable WOLED emitters, driving innovation toward more environmentally benign alternatives.

During their operational lifetime, WOLED devices demonstrate considerable environmental advantages compared to traditional lighting technologies. Their energy efficiency results in reduced power consumption, directly translating to lower greenhouse gas emissions when the electricity source involves fossil fuels. Studies indicate that widespread adoption of WOLED technology could potentially reduce global lighting energy consumption by up to 50%, representing a substantial contribution to climate change mitigation efforts.

The degradation of WOLED materials in outdoor environments presents unique environmental considerations. As these materials break down under UV radiation, temperature fluctuations, and moisture exposure, they may release trace amounts of potentially harmful compounds. Research indicates that certain emitter materials, particularly those containing heavy metals like iridium complexes, require careful environmental monitoring to assess their long-term ecological impact.

End-of-life management for WOLED devices represents a growing environmental challenge. The composite nature of these devices, combining organic materials with electronic components and sometimes rare earth elements, complicates recycling efforts. Current recycling technologies can recover approximately 70-80% of materials from WOLED panels, but specialized facilities are required for this process, which are not universally available.

Life cycle assessment (LCA) studies comparing WOLED technology with conventional lighting options consistently demonstrate environmental advantages in terms of energy consumption and carbon footprint during the use phase. However, these studies also highlight concerns regarding resource extraction for specialized materials and end-of-life waste management. The environmental payback period for WOLED technology typically ranges from 1-3 years, depending on usage patterns and comparison technologies.

Regulatory frameworks governing WOLED materials vary significantly across regions, with the European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives providing the most comprehensive oversight. These regulations increasingly influence material selection and design considerations for manufacturers developing outdoor-stable WOLED emitters, driving innovation toward more environmentally benign alternatives.

Durability Testing Methodologies for Outdoor WOLED Systems

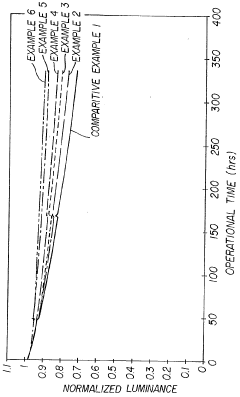

Durability testing methodologies for outdoor WOLED systems require comprehensive protocols that account for the unique challenges these displays face in variable environmental conditions. The primary testing framework must include accelerated aging tests that simulate prolonged exposure to UV radiation, which is particularly damaging to organic materials in WOLEDs. These tests typically employ specialized UV chambers where samples are subjected to concentrated UV exposure equivalent to several years of outdoor deployment within weeks or months of testing.

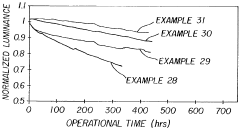

Temperature cycling tests represent another critical component, as outdoor WOLEDs experience significant thermal stress from day-night transitions and seasonal variations. Standard methodologies involve rapid cycling between extreme temperatures (-40°C to +85°C) while monitoring luminance, color accuracy, and power efficiency degradation. The industry standard typically requires 1,000 cycles without significant performance deterioration for outdoor-rated systems.

Humidity resistance testing is equally important, with condensation cycling tests exposing WOLED panels to alternating high humidity and drying periods. This methodology reveals potential delamination issues, encapsulation failures, and moisture ingress points that may compromise device longevity. The IEC 60068-2-30 standard provides a baseline framework that has been adapted specifically for WOLED applications.

Mechanical durability assessments focus on vibration resistance and impact testing, simulating conditions such as wind loads, transportation stress, and potential impacts from debris. These tests employ standardized equipment that applies controlled forces while monitoring for pixel failures, connection integrity, and structural damage to the display assembly.

Integrated environmental testing combines multiple stressors simultaneously, more accurately reflecting real-world conditions. This approach has gained prominence as research has demonstrated that sequential testing often fails to identify failure modes that emerge from the interaction of multiple environmental factors. For example, the combination of UV exposure and humidity cycling has been shown to accelerate degradation pathways not observed when these factors are tested separately.

Emerging methodologies now incorporate real-time monitoring systems that collect performance data throughout the testing process, enabling the development of predictive models for WOLED degradation. These models correlate accelerated test results with real-world performance, allowing manufacturers to estimate display lifetime under specific deployment conditions with greater accuracy. This approach has significantly improved the reliability of durability predictions, reducing the gap between laboratory testing and field performance.

Temperature cycling tests represent another critical component, as outdoor WOLEDs experience significant thermal stress from day-night transitions and seasonal variations. Standard methodologies involve rapid cycling between extreme temperatures (-40°C to +85°C) while monitoring luminance, color accuracy, and power efficiency degradation. The industry standard typically requires 1,000 cycles without significant performance deterioration for outdoor-rated systems.

Humidity resistance testing is equally important, with condensation cycling tests exposing WOLED panels to alternating high humidity and drying periods. This methodology reveals potential delamination issues, encapsulation failures, and moisture ingress points that may compromise device longevity. The IEC 60068-2-30 standard provides a baseline framework that has been adapted specifically for WOLED applications.

Mechanical durability assessments focus on vibration resistance and impact testing, simulating conditions such as wind loads, transportation stress, and potential impacts from debris. These tests employ standardized equipment that applies controlled forces while monitoring for pixel failures, connection integrity, and structural damage to the display assembly.

Integrated environmental testing combines multiple stressors simultaneously, more accurately reflecting real-world conditions. This approach has gained prominence as research has demonstrated that sequential testing often fails to identify failure modes that emerge from the interaction of multiple environmental factors. For example, the combination of UV exposure and humidity cycling has been shown to accelerate degradation pathways not observed when these factors are tested separately.

Emerging methodologies now incorporate real-time monitoring systems that collect performance data throughout the testing process, enabling the development of predictive models for WOLED degradation. These models correlate accelerated test results with real-world performance, allowing manufacturers to estimate display lifetime under specific deployment conditions with greater accuracy. This approach has significantly improved the reliability of durability predictions, reducing the gap between laboratory testing and field performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!