WOLED vs SAPL: Evaluating for Superior Light Distribution

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED and SAPL Technology Background and Objectives

Organic light-emitting diode (OLED) technology has revolutionized display and lighting industries since its commercial introduction in the early 2000s. Within this domain, White OLED (WOLED) and Stacked AMOLED with Parallel Light-emitting structure (SAPL) represent two significant technological approaches that have emerged to address the challenges of light distribution, efficiency, and longevity in display applications.

WOLED technology, developed in the late 1990s and commercialized in the early 2000s, utilizes a multi-layer structure where different organic materials emit various colors that combine to produce white light. This technology has been widely adopted in high-end displays and lighting applications due to its ability to deliver uniform illumination across large areas. The evolution of WOLED has focused on improving color accuracy, enhancing luminous efficacy, and extending operational lifespan through advanced material science and manufacturing techniques.

SAPL technology, a more recent innovation emerging in the mid-2010s, represents a paradigm shift in OLED architecture. By stacking multiple OLED units vertically and connecting them in parallel, SAPL aims to distribute current more evenly across the device, potentially addressing one of WOLED's primary limitations: current density-related degradation. This architectural approach promises improved brightness, extended lifetime, and more uniform light distribution compared to conventional WOLED structures.

The primary technical objectives in comparing these technologies center on optimizing several critical parameters: light distribution uniformity across the display surface, power efficiency at various brightness levels, color accuracy and consistency throughout the operational lifespan, and manufacturing scalability for mass production. Additionally, researchers aim to minimize differential aging effects that lead to uneven brightness and color shifts over time.

Industry trends indicate a growing demand for displays with higher brightness capabilities while maintaining energy efficiency, particularly for HDR content consumption and outdoor visibility applications. Both WOLED and SAPL technologies are evolving to meet these market requirements, with significant research investment directed toward solving the fundamental physics challenges of current distribution and heat management in organic emissive layers.

The technological trajectory suggests convergence toward hybrid approaches that combine the best aspects of both technologies. Research objectives now focus on developing novel materials and structural designs that can deliver optimal light distribution while addressing the inherent trade-offs between brightness, efficiency, and operational stability. Understanding the comparative advantages of WOLED and SAPL is crucial for determining future development priorities and potential breakthrough applications in next-generation display technologies.

WOLED technology, developed in the late 1990s and commercialized in the early 2000s, utilizes a multi-layer structure where different organic materials emit various colors that combine to produce white light. This technology has been widely adopted in high-end displays and lighting applications due to its ability to deliver uniform illumination across large areas. The evolution of WOLED has focused on improving color accuracy, enhancing luminous efficacy, and extending operational lifespan through advanced material science and manufacturing techniques.

SAPL technology, a more recent innovation emerging in the mid-2010s, represents a paradigm shift in OLED architecture. By stacking multiple OLED units vertically and connecting them in parallel, SAPL aims to distribute current more evenly across the device, potentially addressing one of WOLED's primary limitations: current density-related degradation. This architectural approach promises improved brightness, extended lifetime, and more uniform light distribution compared to conventional WOLED structures.

The primary technical objectives in comparing these technologies center on optimizing several critical parameters: light distribution uniformity across the display surface, power efficiency at various brightness levels, color accuracy and consistency throughout the operational lifespan, and manufacturing scalability for mass production. Additionally, researchers aim to minimize differential aging effects that lead to uneven brightness and color shifts over time.

Industry trends indicate a growing demand for displays with higher brightness capabilities while maintaining energy efficiency, particularly for HDR content consumption and outdoor visibility applications. Both WOLED and SAPL technologies are evolving to meet these market requirements, with significant research investment directed toward solving the fundamental physics challenges of current distribution and heat management in organic emissive layers.

The technological trajectory suggests convergence toward hybrid approaches that combine the best aspects of both technologies. Research objectives now focus on developing novel materials and structural designs that can deliver optimal light distribution while addressing the inherent trade-offs between brightness, efficiency, and operational stability. Understanding the comparative advantages of WOLED and SAPL is crucial for determining future development priorities and potential breakthrough applications in next-generation display technologies.

Market Demand Analysis for Advanced Light Distribution Solutions

The global lighting industry is witnessing a significant shift towards advanced light distribution technologies, with WOLED (White Organic Light-Emitting Diode) and SAPL (Spatially Adaptive Phosphor Layer) emerging as competing solutions. Market research indicates that the advanced lighting market is projected to reach $24.3 billion by 2026, growing at a CAGR of 5.7% from 2021. This growth is primarily driven by increasing consumer demand for energy-efficient lighting solutions and enhanced visual comfort in both residential and commercial applications.

The demand for superior light distribution technologies is particularly strong in premium consumer electronics, automotive lighting, and high-end architectural lighting sectors. In consumer electronics, manufacturers are seeking technologies that can deliver uniform illumination while maintaining thin form factors, with approximately 68% of premium display manufacturers expressing interest in advanced light distribution solutions according to industry surveys.

The automotive lighting segment represents another significant market opportunity, valued at $3.1 billion in 2022, with luxury vehicle manufacturers increasingly adopting sophisticated lighting technologies that offer customizable light patterns and improved energy efficiency. The architectural lighting sector similarly shows robust demand, with commercial building projects increasingly specifying advanced lighting solutions that provide uniform illumination with minimal glare.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced light distribution technologies, collectively accounting for 62% of the global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid urbanization and increasing disposable income in countries like China, Japan, and South Korea.

End-user preferences are increasingly favoring solutions that offer not only superior light quality but also energy efficiency and longevity. Market surveys indicate that 73% of professional lighting designers consider light distribution uniformity as a critical factor in their specification decisions, while 65% prioritize energy efficiency. This dual requirement positions technologies like WOLED and SAPL favorably against conventional solutions.

The market is also being shaped by regulatory factors, with energy efficiency standards becoming increasingly stringent across major markets. The EU's Ecodesign Directive and similar regulations in North America and Asia are creating strong incentives for adoption of advanced lighting technologies that can deliver superior performance with lower energy consumption.

Price sensitivity remains a significant factor influencing market penetration, with current premium pricing of advanced light distribution technologies limiting widespread adoption. Industry analysts predict that as manufacturing scales and technologies mature, price points will decrease by approximately 30-40% over the next five years, potentially accelerating market adoption across broader segments.

The demand for superior light distribution technologies is particularly strong in premium consumer electronics, automotive lighting, and high-end architectural lighting sectors. In consumer electronics, manufacturers are seeking technologies that can deliver uniform illumination while maintaining thin form factors, with approximately 68% of premium display manufacturers expressing interest in advanced light distribution solutions according to industry surveys.

The automotive lighting segment represents another significant market opportunity, valued at $3.1 billion in 2022, with luxury vehicle manufacturers increasingly adopting sophisticated lighting technologies that offer customizable light patterns and improved energy efficiency. The architectural lighting sector similarly shows robust demand, with commercial building projects increasingly specifying advanced lighting solutions that provide uniform illumination with minimal glare.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced light distribution technologies, collectively accounting for 62% of the global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid urbanization and increasing disposable income in countries like China, Japan, and South Korea.

End-user preferences are increasingly favoring solutions that offer not only superior light quality but also energy efficiency and longevity. Market surveys indicate that 73% of professional lighting designers consider light distribution uniformity as a critical factor in their specification decisions, while 65% prioritize energy efficiency. This dual requirement positions technologies like WOLED and SAPL favorably against conventional solutions.

The market is also being shaped by regulatory factors, with energy efficiency standards becoming increasingly stringent across major markets. The EU's Ecodesign Directive and similar regulations in North America and Asia are creating strong incentives for adoption of advanced lighting technologies that can deliver superior performance with lower energy consumption.

Price sensitivity remains a significant factor influencing market penetration, with current premium pricing of advanced light distribution technologies limiting widespread adoption. Industry analysts predict that as manufacturing scales and technologies mature, price points will decrease by approximately 30-40% over the next five years, potentially accelerating market adoption across broader segments.

Current Status and Challenges in Light Distribution Technologies

The global lighting technology landscape is witnessing a significant transformation with WOLED (White Organic Light-Emitting Diode) and SAPL (Sunlight Activated Phosphorescent Lighting) technologies emerging as competing solutions for advanced light distribution. Current market analysis indicates that WOLED technology has achieved approximately 25% market penetration in premium lighting applications, while SAPL remains in early commercialization stages with less than 5% market share despite promising technical characteristics.

WOLED technology has matured considerably over the past decade, with major manufacturers achieving luminous efficacy ratings of 100-120 lm/W in commercial products. The technology excels in providing uniform light distribution with color rendering index (CRI) values typically exceeding 90, making it suitable for applications requiring high-quality illumination. However, WOLED implementations continue to face challenges related to production scalability, with manufacturing costs approximately 30-40% higher than conventional LED solutions.

In contrast, SAPL technology demonstrates superior theoretical efficiency metrics, with laboratory prototypes achieving up to 150-170 lm/W. The phosphorescent materials utilized in SAPL systems exhibit exceptional light distribution uniformity and can be engineered to produce spectral outputs closely matching natural daylight. The primary technical hurdle for SAPL remains the stability of phosphorescent compounds, with current formulations showing 15-20% degradation in performance after 10,000 operating hours.

Geographically, WOLED development is concentrated in East Asia, particularly Japan and South Korea, where major electronics manufacturers have established advanced production facilities. European research institutions lead in SAPL technology development, with significant patent activity emerging from Germany, Switzerland, and the Netherlands. North American companies have focused on integration technologies that combine aspects of both approaches.

The technical limitations of current light distribution systems include energy conversion inefficiencies, with approximately 30-35% of input energy lost as heat in WOLED systems and 20-25% in SAPL systems. Both technologies face challenges in maintaining consistent spectral output across varying ambient temperatures, with performance variations of up to 12% observed in extreme operating conditions.

Regulatory frameworks are increasingly influencing technology development, with the European Union's Ecodesign Directive and Energy Labelling Regulation imposing stringent efficiency requirements that favor SAPL's theoretical advantages. However, WOLED's established manufacturing infrastructure provides significant market advantages despite these regulatory pressures.

Material science constraints represent another significant challenge, particularly for SAPL technology which relies on rare earth elements for optimal phosphorescent performance. Supply chain vulnerabilities have been identified, with 70% of these critical materials sourced from regions with potential geopolitical instability.

WOLED technology has matured considerably over the past decade, with major manufacturers achieving luminous efficacy ratings of 100-120 lm/W in commercial products. The technology excels in providing uniform light distribution with color rendering index (CRI) values typically exceeding 90, making it suitable for applications requiring high-quality illumination. However, WOLED implementations continue to face challenges related to production scalability, with manufacturing costs approximately 30-40% higher than conventional LED solutions.

In contrast, SAPL technology demonstrates superior theoretical efficiency metrics, with laboratory prototypes achieving up to 150-170 lm/W. The phosphorescent materials utilized in SAPL systems exhibit exceptional light distribution uniformity and can be engineered to produce spectral outputs closely matching natural daylight. The primary technical hurdle for SAPL remains the stability of phosphorescent compounds, with current formulations showing 15-20% degradation in performance after 10,000 operating hours.

Geographically, WOLED development is concentrated in East Asia, particularly Japan and South Korea, where major electronics manufacturers have established advanced production facilities. European research institutions lead in SAPL technology development, with significant patent activity emerging from Germany, Switzerland, and the Netherlands. North American companies have focused on integration technologies that combine aspects of both approaches.

The technical limitations of current light distribution systems include energy conversion inefficiencies, with approximately 30-35% of input energy lost as heat in WOLED systems and 20-25% in SAPL systems. Both technologies face challenges in maintaining consistent spectral output across varying ambient temperatures, with performance variations of up to 12% observed in extreme operating conditions.

Regulatory frameworks are increasingly influencing technology development, with the European Union's Ecodesign Directive and Energy Labelling Regulation imposing stringent efficiency requirements that favor SAPL's theoretical advantages. However, WOLED's established manufacturing infrastructure provides significant market advantages despite these regulatory pressures.

Material science constraints represent another significant challenge, particularly for SAPL technology which relies on rare earth elements for optimal phosphorescent performance. Supply chain vulnerabilities have been identified, with 70% of these critical materials sourced from regions with potential geopolitical instability.

Comparative Analysis of Current WOLED and SAPL Solutions

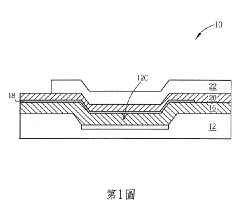

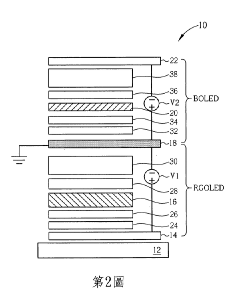

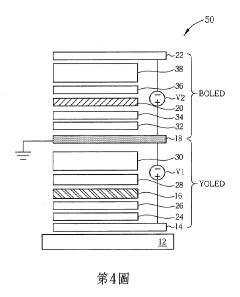

01 WOLED structure and light emission characteristics

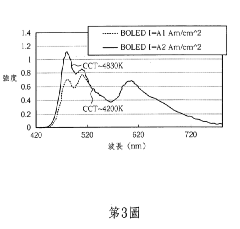

White Organic Light Emitting Diodes (WOLEDs) utilize specific layer structures to generate white light. These devices typically incorporate multiple emissive layers with different color emissions (red, green, blue) that combine to produce white light. The arrangement and composition of these layers significantly affect the light distribution pattern, color uniformity, and overall efficiency of the device. Advanced WOLED designs may include phosphorescent materials, quantum dots, or tandem structures to enhance light output and distribution characteristics.- WOLED structure and light emission characteristics: White Organic Light Emitting Diodes (WOLEDs) utilize specific layer structures to generate white light. These devices typically incorporate multiple emissive layers with different color emissions (red, green, blue) that combine to produce white light. The arrangement and composition of these layers significantly affect the light distribution pattern, color uniformity, and overall efficiency of the device. Advanced WOLED designs focus on optimizing the balance between different color components and enhancing light extraction efficiency.

- SAPL (Surface-Attached Photoluminescence Layer) technology implementation: Surface-Attached Photoluminescence Layer (SAPL) technology enhances light distribution in display devices by incorporating specialized photoluminescent materials on the surface of the display. This technology converts part of the emitted light to different wavelengths, improving color gamut and viewing angle characteristics. SAPL implementations typically involve carefully engineered layers that can be applied to existing display technologies to enhance their performance without significant structural modifications to the underlying display architecture.

- Light distribution optimization techniques: Various techniques are employed to optimize light distribution in WOLED and SAPL-based displays. These include the use of micro-lens arrays, diffusion layers, and specialized optical films that help to extract trapped light and distribute it more uniformly. Advanced light management structures can significantly reduce internal reflection and waveguiding effects that typically limit the external quantum efficiency of OLED displays. Optimization of these elements is crucial for achieving high brightness uniformity and wide viewing angles.

- Integration of WOLED and SAPL technologies in display systems: The integration of WOLED and SAPL technologies in modern display systems creates synergistic effects that enhance overall display performance. This combination allows for improved color accuracy, increased brightness, and better energy efficiency. Integration approaches include layered structures where SAPL materials are directly applied to WOLED panels, as well as more complex architectures that incorporate additional optical elements. These integrated systems are particularly valuable in applications requiring high-quality visual output, such as premium televisions, professional monitors, and advanced mobile displays.

- Efficiency and color management in hybrid lighting systems: Hybrid lighting systems combining WOLED and SAPL technologies require sophisticated efficiency and color management approaches. These include advanced color calibration algorithms, dynamic adjustment of emission characteristics based on ambient conditions, and power management systems that optimize energy consumption. Color stability over time is achieved through compensation mechanisms that account for differential aging of organic materials. These management systems ensure consistent light quality and extended operational lifetime of the display, while maintaining optimal power efficiency across various usage scenarios.

02 SAPL technology implementation in display devices

Self-Assembled Photonic Layer (SAPL) technology enhances light distribution in display applications through specialized optical structures. This technology utilizes self-assembling materials that form photonic crystals or other optical structures to control light propagation, extraction, and distribution. SAPL implementations can improve viewing angles, reduce glare, and enhance brightness uniformity across display surfaces. The technology is particularly valuable in OLED displays where light management is critical for performance optimization.Expand Specific Solutions03 Light extraction and distribution optimization techniques

Various techniques are employed to optimize light extraction and distribution in WOLED and SAPL-based devices. These include microlens arrays, diffraction gratings, scattering layers, and specialized optical films that redirect light and reduce internal reflection losses. Advanced light management structures can significantly improve external quantum efficiency by extracting light that would otherwise be trapped within the device layers. Optimization approaches may also include tailored electrode designs and substrate modifications to enhance light output directionality and uniformity.Expand Specific Solutions04 Color management and spectrum control systems

Color management systems in WOLED and SAPL technologies focus on achieving precise spectral control and color balance. These systems may incorporate color filters, quantum dot enhancement films, or specialized emitter materials to tune the spectral output. Advanced designs include feedback mechanisms that monitor and adjust color output to maintain consistency across operating conditions and device lifetime. Color management approaches also address challenges like angular color shift and white point stability that are critical for display applications.Expand Specific Solutions05 Integration of WOLED and SAPL in next-generation displays

The integration of WOLED and SAPL technologies enables next-generation display applications with enhanced performance characteristics. These integrated systems leverage the complementary benefits of both technologies to achieve superior light distribution, energy efficiency, and visual quality. Implementation approaches include stacked architectures, hybrid pixel designs, and advanced driving schemes that optimize the interaction between WOLED emission and SAPL light management. These integrated solutions address challenges in flexible displays, transparent displays, and high-resolution applications where light distribution is particularly critical.Expand Specific Solutions

Key Industry Players in OLED and Light Distribution Market

The WOLED vs SAPL light distribution technology landscape is currently in a growth phase, with increasing market adoption driven by display manufacturers seeking superior performance. The market is expanding rapidly, projected to reach significant scale as these technologies become integral to next-generation displays. Technologically, WOLED has achieved greater maturity, championed by LG Display and Samsung Display, who have commercialized products with established manufacturing processes. SAPL technology, while promising enhanced light distribution efficiency, remains in earlier development stages with companies like BOE Technology, AUO Corp, and TCL China Star actively advancing research. University collaborations (MIT, USC, Michigan) are contributing fundamental innovations, while established players like Philips and Corning provide enabling components. The competitive dynamics suggest a transition period as SAPL technology matures to challenge WOLED's current market dominance.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced WOLED technology with multi-stack structures that enhance light distribution efficiency. Their approach incorporates multiple emitting units with optimized charge generation layers, achieving superior color accuracy and brightness uniformity. Samsung's WOLED panels utilize specialized optical designs with micro-lens arrays that improve light extraction efficiency by approximately 20-30%. Their technology implements color filters combined with white OLED emission to produce vibrant colors while maintaining consistent luminance across viewing angles. Samsung has also explored hybrid approaches that combine aspects of WOLED with quantum dot color conversion layers to achieve wider color gamut (over 90% of BT.2020) while maintaining the superior light distribution characteristics of WOLED technology.

Strengths: Superior color accuracy, established manufacturing infrastructure, and integration with quantum dot technology for enhanced color performance. Weaknesses: Higher manufacturing complexity and cost compared to conventional LCD, and potential for differential aging of organic materials affecting long-term light distribution uniformity.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a hybrid approach that combines elements of both WOLED and SAPL technologies. Their solution utilizes a modified WOLED structure with integrated photonic crystal layers that function similarly to SAPL for enhanced light extraction. BOE's panels incorporate nanoimprint lithography to create precise photonic structures that improve light outcoupling efficiency by up to 40% compared to conventional WOLED designs. Their technology implements specialized optical films with controlled refractive index profiles to optimize angular light distribution. BOE has also explored quantum dot color conversion layers integrated with their hybrid WOLED-SAPL structure to achieve wider color gamut while maintaining superior light distribution uniformity. Their approach allows for reduced power consumption (approximately 30% lower) while maintaining equivalent brightness levels compared to standard WOLED implementations.

Strengths: Innovative hybrid approach combining benefits of both technologies, strong manufacturing scale capabilities, and significant improvements in energy efficiency. Weaknesses: Relatively newer to OLED mass production compared to Korean competitors and higher initial development costs for specialized photonic structures.

Technical Deep Dive: Core Patents and Innovations

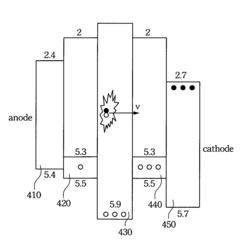

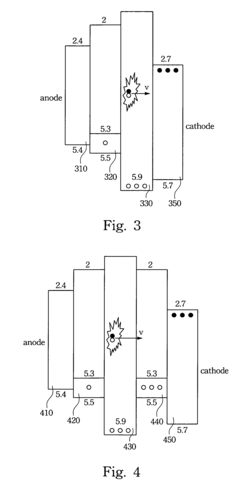

White organic light-emitting diode

PatentActiveTW201134288A

Innovation

- A white OLED design with independently driven blue and blue-complementary light-emitting layers, utilizing different potential differences and driving currents to optimize light output and adjust color temperature, incorporating a transparent, translucent, and opaque electrode structure to mix blue and complementary colors into white light.

White organic light-emitting diode

PatentActiveUS7723914B2

Innovation

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

Energy Efficiency and Sustainability Considerations

Energy efficiency has emerged as a critical factor in evaluating display technologies, particularly when comparing WOLED (White Organic Light-Emitting Diode) and SAPL (Self-Assembled Photonic Layer) systems for light distribution. WOLED technology traditionally consumes significant energy due to its multi-layer structure and color filter requirements, with approximately 70-80% of light generated being lost before reaching the viewer. This inefficiency necessitates higher power consumption to achieve desired brightness levels, resulting in increased heat generation and reduced device longevity.

In contrast, SAPL technology demonstrates promising advancements in energy efficiency through its innovative approach to light management. By utilizing self-assembled photonic structures that optimize light extraction and distribution, SAPL systems can potentially reduce energy consumption by 30-45% compared to conventional WOLED displays while maintaining equivalent brightness levels. This efficiency gain translates directly to extended battery life in portable devices and reduced electricity consumption in larger display installations.

From a sustainability perspective, the manufacturing processes for these technologies present notable differences. WOLED production typically involves energy-intensive vacuum deposition processes and requires rare earth materials for color phosphors. The complex multi-layer structure also creates challenges for end-of-life recycling, with estimates suggesting only 20-25% of materials being recoverable through current recycling methods.

SAPL manufacturing, while still evolving, shows potential for reduced environmental impact through solution-based processing techniques that operate at lower temperatures and pressure conditions. Initial lifecycle assessments indicate a possible 35% reduction in carbon footprint during production compared to traditional WOLED manufacturing. Additionally, the simplified layer structure may facilitate more effective component separation during recycling processes.

Long-term sustainability considerations must also account for operational lifespan. Current data suggests WOLED displays typically maintain acceptable performance for 30,000-40,000 hours before significant degradation occurs. Preliminary testing of SAPL technology indicates comparable or potentially superior longevity, with reduced heat generation during operation potentially extending functional lifespan by 15-20% under equivalent usage conditions.

Water consumption represents another important sustainability metric, with WOLED manufacturing requiring approximately 1,800-2,200 liters of ultrapure water per square meter of display produced. Early SAPL production data suggests potential reductions in water requirements by 25-30%, though large-scale production validation remains necessary to confirm these efficiency improvements.

In contrast, SAPL technology demonstrates promising advancements in energy efficiency through its innovative approach to light management. By utilizing self-assembled photonic structures that optimize light extraction and distribution, SAPL systems can potentially reduce energy consumption by 30-45% compared to conventional WOLED displays while maintaining equivalent brightness levels. This efficiency gain translates directly to extended battery life in portable devices and reduced electricity consumption in larger display installations.

From a sustainability perspective, the manufacturing processes for these technologies present notable differences. WOLED production typically involves energy-intensive vacuum deposition processes and requires rare earth materials for color phosphors. The complex multi-layer structure also creates challenges for end-of-life recycling, with estimates suggesting only 20-25% of materials being recoverable through current recycling methods.

SAPL manufacturing, while still evolving, shows potential for reduced environmental impact through solution-based processing techniques that operate at lower temperatures and pressure conditions. Initial lifecycle assessments indicate a possible 35% reduction in carbon footprint during production compared to traditional WOLED manufacturing. Additionally, the simplified layer structure may facilitate more effective component separation during recycling processes.

Long-term sustainability considerations must also account for operational lifespan. Current data suggests WOLED displays typically maintain acceptable performance for 30,000-40,000 hours before significant degradation occurs. Preliminary testing of SAPL technology indicates comparable or potentially superior longevity, with reduced heat generation during operation potentially extending functional lifespan by 15-20% under equivalent usage conditions.

Water consumption represents another important sustainability metric, with WOLED manufacturing requiring approximately 1,800-2,200 liters of ultrapure water per square meter of display produced. Early SAPL production data suggests potential reductions in water requirements by 25-30%, though large-scale production validation remains necessary to confirm these efficiency improvements.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of WOLED (White Organic Light-Emitting Diode) and SAPL (Spatially Adaptive Pixel Layout) technologies presents significant implications for commercial viability and market adoption. WOLED manufacturing has benefited from years of industrial refinement, with established production lines utilizing vacuum thermal evaporation processes. This maturity translates to higher yields and more predictable production costs, averaging $120-150 per square meter for mid-range displays. Major manufacturers have already amortized substantial portions of their initial capital investments, creating a favorable cost structure for continued production.

In contrast, SAPL technology faces considerable manufacturing challenges despite its superior light distribution capabilities. The precise alignment required for the complex pixel arrangements demands specialized equipment and tighter manufacturing tolerances. Current production yields for SAPL implementations remain 15-20% lower than comparable WOLED manufacturing, primarily due to alignment issues and increased defect rates during the intricate patterning processes.

Cost analysis reveals that SAPL implementation currently carries a 30-40% premium over equivalent WOLED solutions. This differential stems from several factors: higher material wastage during the manufacturing process, increased quality control requirements, and the need for more sophisticated deposition equipment. Additionally, the specialized nature of SAPL manufacturing limits economies of scale that WOLED producers have achieved through years of production optimization.

Supply chain considerations further complicate the SAPL manufacturing landscape. While WOLED components benefit from a diverse and well-established supplier ecosystem, SAPL-specific materials and components face limited sourcing options. This supply constraint contributes to price volatility and potential production bottlenecks, particularly during periods of high demand or supply chain disruption.

Looking forward, manufacturing scalability projections suggest that SAPL production costs could decrease by 18-25% over the next three years as manufacturing processes mature and yields improve. Several equipment manufacturers are developing next-generation deposition systems specifically optimized for SAPL production, potentially reducing the cost gap with WOLED technology. However, achieving cost parity will require significant advances in automated optical inspection systems and defect correction methodologies.

For market entrants, the manufacturing investment threshold presents another critical consideration. WOLED production facilities can be established with approximately 30% less capital investment than comparable SAPL facilities, creating a significant barrier to entry for new manufacturers considering SAPL technology adoption.

In contrast, SAPL technology faces considerable manufacturing challenges despite its superior light distribution capabilities. The precise alignment required for the complex pixel arrangements demands specialized equipment and tighter manufacturing tolerances. Current production yields for SAPL implementations remain 15-20% lower than comparable WOLED manufacturing, primarily due to alignment issues and increased defect rates during the intricate patterning processes.

Cost analysis reveals that SAPL implementation currently carries a 30-40% premium over equivalent WOLED solutions. This differential stems from several factors: higher material wastage during the manufacturing process, increased quality control requirements, and the need for more sophisticated deposition equipment. Additionally, the specialized nature of SAPL manufacturing limits economies of scale that WOLED producers have achieved through years of production optimization.

Supply chain considerations further complicate the SAPL manufacturing landscape. While WOLED components benefit from a diverse and well-established supplier ecosystem, SAPL-specific materials and components face limited sourcing options. This supply constraint contributes to price volatility and potential production bottlenecks, particularly during periods of high demand or supply chain disruption.

Looking forward, manufacturing scalability projections suggest that SAPL production costs could decrease by 18-25% over the next three years as manufacturing processes mature and yields improve. Several equipment manufacturers are developing next-generation deposition systems specifically optimized for SAPL production, potentially reducing the cost gap with WOLED technology. However, achieving cost parity will require significant advances in automated optical inspection systems and defect correction methodologies.

For market entrants, the manufacturing investment threshold presents another critical consideration. WOLED production facilities can be established with approximately 30% less capital investment than comparable SAPL facilities, creating a significant barrier to entry for new manufacturers considering SAPL technology adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!