How to Evaluate WOLED Degradation under Stress Tests

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Degradation Testing Background and Objectives

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a pivotal technology in the display and lighting industries over the past two decades. These devices offer superior color rendering, flexibility, and energy efficiency compared to traditional lighting technologies. However, the degradation of WOLEDs under various operational conditions remains a significant challenge that impacts their commercial viability and long-term performance reliability.

The evolution of WOLED technology has progressed through several generations, from early phosphorescent materials to the current state-of-the-art hybrid architectures combining fluorescent and phosphorescent emitters. Throughout this evolution, understanding degradation mechanisms has been crucial for advancing device lifetimes from mere hours to tens of thousands of hours in commercial applications.

Stress testing methodologies for WOLEDs have similarly evolved from basic constant-current aging tests to sophisticated accelerated lifetime testing protocols that incorporate multiple environmental and operational stressors. These methodologies aim to predict real-world performance and identify failure modes that might not be apparent under standard operating conditions.

The primary technical objectives of WOLED degradation evaluation include quantifying luminance decay rates, color shift trajectories, and voltage drift under various stress conditions. Additionally, researchers seek to establish correlations between accelerated testing results and real-world performance, enabling more accurate lifetime predictions for commercial products.

Current industry standards for WOLED testing, such as those established by the International Electrotechnical Commission (IEC) and the Society for Information Display (SID), provide frameworks for evaluation but often lag behind the rapid technological advancements in the field. This creates a need for more adaptive and comprehensive testing methodologies.

The scientific understanding of degradation mechanisms has advanced significantly, identifying key processes such as exciton-polaron annihilation, chemical degradation of emitter molecules, and interfacial instabilities. These insights have informed both material development strategies and device architecture optimizations aimed at enhancing operational stability.

Looking forward, the technical goals for WOLED degradation testing include developing non-invasive in-situ monitoring techniques, establishing more accurate acceleration factors for lifetime prediction, and creating standardized protocols that account for the increasing complexity of multi-emitter systems. These advancements will be essential for supporting the next generation of WOLED applications in flexible displays, automotive lighting, and healthcare technologies.

The evolution of WOLED technology has progressed through several generations, from early phosphorescent materials to the current state-of-the-art hybrid architectures combining fluorescent and phosphorescent emitters. Throughout this evolution, understanding degradation mechanisms has been crucial for advancing device lifetimes from mere hours to tens of thousands of hours in commercial applications.

Stress testing methodologies for WOLEDs have similarly evolved from basic constant-current aging tests to sophisticated accelerated lifetime testing protocols that incorporate multiple environmental and operational stressors. These methodologies aim to predict real-world performance and identify failure modes that might not be apparent under standard operating conditions.

The primary technical objectives of WOLED degradation evaluation include quantifying luminance decay rates, color shift trajectories, and voltage drift under various stress conditions. Additionally, researchers seek to establish correlations between accelerated testing results and real-world performance, enabling more accurate lifetime predictions for commercial products.

Current industry standards for WOLED testing, such as those established by the International Electrotechnical Commission (IEC) and the Society for Information Display (SID), provide frameworks for evaluation but often lag behind the rapid technological advancements in the field. This creates a need for more adaptive and comprehensive testing methodologies.

The scientific understanding of degradation mechanisms has advanced significantly, identifying key processes such as exciton-polaron annihilation, chemical degradation of emitter molecules, and interfacial instabilities. These insights have informed both material development strategies and device architecture optimizations aimed at enhancing operational stability.

Looking forward, the technical goals for WOLED degradation testing include developing non-invasive in-situ monitoring techniques, establishing more accurate acceleration factors for lifetime prediction, and creating standardized protocols that account for the increasing complexity of multi-emitter systems. These advancements will be essential for supporting the next generation of WOLED applications in flexible displays, automotive lighting, and healthcare technologies.

Market Requirements for WOLED Reliability Assessment

The WOLED (White Organic Light-Emitting Diode) display market has witnessed substantial growth in recent years, with increasing adoption in premium televisions, smartphones, and other high-end display applications. This market expansion has intensified the demand for comprehensive reliability assessment protocols, particularly for evaluating WOLED degradation under various stress conditions.

Display manufacturers require standardized testing methodologies that can accurately predict the operational lifespan of WOLED panels in real-world usage scenarios. Current market data indicates that consumers expect premium WOLED displays to maintain consistent performance for at least 30,000 hours of operation, with minimal color shift and luminance degradation. This expectation creates significant pressure on manufacturers to develop robust reliability assessment frameworks.

The automotive industry represents an emerging market segment with particularly stringent reliability requirements. WOLED displays in automotive applications must withstand extreme temperature variations, high humidity, and constant vibration while maintaining performance integrity over extended periods. Testing protocols must therefore simulate these conditions to provide meaningful reliability data.

Commercial display applications, including digital signage and professional monitors, demand assessment methodologies focused on burn-in resistance and performance stability under continuous operation. These sectors require accelerated testing protocols that can reliably predict long-term degradation patterns within reasonable testing timeframes.

Consumer electronics manufacturers have expressed the need for reliability assessment standards that address specific degradation mechanisms, including differential aging of various color components, which leads to color shift over time. The market increasingly demands quantitative metrics for color stability, with tolerance thresholds becoming more stringent as WOLED technology matures.

From a competitive standpoint, manufacturers require testing methodologies that can differentiate their products based on reliability performance. This has created demand for assessment protocols that not only identify potential failure modes but also quantify reliability advantages in terms meaningful to consumers, such as "years of typical use" rather than abstract technical specifications.

The medical and aerospace sectors represent specialized market segments with extreme reliability requirements. These applications demand customized stress testing protocols that can verify WOLED performance under unique environmental conditions, including radiation exposure and rapid pressure changes.

Market research indicates growing consumer awareness regarding display longevity, with reliability increasingly becoming a key purchasing consideration alongside traditional metrics like resolution and color accuracy. This trend underscores the commercial importance of developing comprehensive, standardized approaches to WOLED degradation assessment under various stress conditions.

Display manufacturers require standardized testing methodologies that can accurately predict the operational lifespan of WOLED panels in real-world usage scenarios. Current market data indicates that consumers expect premium WOLED displays to maintain consistent performance for at least 30,000 hours of operation, with minimal color shift and luminance degradation. This expectation creates significant pressure on manufacturers to develop robust reliability assessment frameworks.

The automotive industry represents an emerging market segment with particularly stringent reliability requirements. WOLED displays in automotive applications must withstand extreme temperature variations, high humidity, and constant vibration while maintaining performance integrity over extended periods. Testing protocols must therefore simulate these conditions to provide meaningful reliability data.

Commercial display applications, including digital signage and professional monitors, demand assessment methodologies focused on burn-in resistance and performance stability under continuous operation. These sectors require accelerated testing protocols that can reliably predict long-term degradation patterns within reasonable testing timeframes.

Consumer electronics manufacturers have expressed the need for reliability assessment standards that address specific degradation mechanisms, including differential aging of various color components, which leads to color shift over time. The market increasingly demands quantitative metrics for color stability, with tolerance thresholds becoming more stringent as WOLED technology matures.

From a competitive standpoint, manufacturers require testing methodologies that can differentiate their products based on reliability performance. This has created demand for assessment protocols that not only identify potential failure modes but also quantify reliability advantages in terms meaningful to consumers, such as "years of typical use" rather than abstract technical specifications.

The medical and aerospace sectors represent specialized market segments with extreme reliability requirements. These applications demand customized stress testing protocols that can verify WOLED performance under unique environmental conditions, including radiation exposure and rapid pressure changes.

Market research indicates growing consumer awareness regarding display longevity, with reliability increasingly becoming a key purchasing consideration alongside traditional metrics like resolution and color accuracy. This trend underscores the commercial importance of developing comprehensive, standardized approaches to WOLED degradation assessment under various stress conditions.

Current Challenges in WOLED Stress Testing

Despite significant advancements in WOLED technology, stress testing methodologies face several critical challenges that impede accurate evaluation of degradation mechanisms. The primary obstacle lies in the complex multi-layer structure of WOLEDs, which makes isolating specific degradation pathways extremely difficult. When multiple emissive layers experience simultaneous degradation under stress conditions, determining the primary failure mechanism becomes a sophisticated analytical problem requiring advanced characterization techniques.

Temperature control presents another significant challenge during accelerated stress testing. The relationship between temperature and degradation follows non-linear patterns, making extrapolation from high-temperature test data to normal operating conditions problematic. Additionally, maintaining uniform temperature distribution across test samples is technically demanding, as even minor temperature variations can lead to inconsistent degradation patterns that compromise test validity.

The industry also struggles with standardization issues in stress testing protocols. Different manufacturers employ varied methodologies, driving conditions, and evaluation metrics, making cross-comparison of results nearly impossible. This lack of standardized approaches creates significant barriers to establishing universal reliability benchmarks and hampers collaborative research efforts across the WOLED ecosystem.

Accurately simulating real-world usage patterns represents another formidable challenge. Laboratory stress tests typically apply constant current or brightness levels, whereas actual device usage involves dynamic content with varying pixel intensities. This discrepancy leads to potential misalignment between laboratory predictions and real-world performance, particularly for display applications where content varies significantly over the device lifetime.

The time-scaling problem further complicates WOLED evaluation, as accelerated tests must compress years of operational degradation into weeks or days of testing. Current mathematical models for extrapolating long-term performance from short-term data contain significant uncertainties, especially when accounting for multiple simultaneous degradation mechanisms with different acceleration factors.

Measurement precision issues also plague WOLED stress testing. Subtle color shifts and efficiency losses require extremely sensitive instrumentation, while ensuring measurement consistency throughout extended test periods presents significant technical challenges. Even minor calibration drifts in testing equipment can lead to erroneous conclusions about degradation rates and mechanisms.

Finally, correlating electrical parameters with optical performance degradation remains problematic. While electrical measurements provide convenient in-situ monitoring, establishing reliable relationships between electrical shifts and the resulting changes in brightness, color coordinates, and spectral distribution requires sophisticated modeling that is not yet fully developed in the industry.

Temperature control presents another significant challenge during accelerated stress testing. The relationship between temperature and degradation follows non-linear patterns, making extrapolation from high-temperature test data to normal operating conditions problematic. Additionally, maintaining uniform temperature distribution across test samples is technically demanding, as even minor temperature variations can lead to inconsistent degradation patterns that compromise test validity.

The industry also struggles with standardization issues in stress testing protocols. Different manufacturers employ varied methodologies, driving conditions, and evaluation metrics, making cross-comparison of results nearly impossible. This lack of standardized approaches creates significant barriers to establishing universal reliability benchmarks and hampers collaborative research efforts across the WOLED ecosystem.

Accurately simulating real-world usage patterns represents another formidable challenge. Laboratory stress tests typically apply constant current or brightness levels, whereas actual device usage involves dynamic content with varying pixel intensities. This discrepancy leads to potential misalignment between laboratory predictions and real-world performance, particularly for display applications where content varies significantly over the device lifetime.

The time-scaling problem further complicates WOLED evaluation, as accelerated tests must compress years of operational degradation into weeks or days of testing. Current mathematical models for extrapolating long-term performance from short-term data contain significant uncertainties, especially when accounting for multiple simultaneous degradation mechanisms with different acceleration factors.

Measurement precision issues also plague WOLED stress testing. Subtle color shifts and efficiency losses require extremely sensitive instrumentation, while ensuring measurement consistency throughout extended test periods presents significant technical challenges. Even minor calibration drifts in testing equipment can lead to erroneous conclusions about degradation rates and mechanisms.

Finally, correlating electrical parameters with optical performance degradation remains problematic. While electrical measurements provide convenient in-situ monitoring, establishing reliable relationships between electrical shifts and the resulting changes in brightness, color coordinates, and spectral distribution requires sophisticated modeling that is not yet fully developed in the industry.

Standard Protocols for WOLED Stress Testing

01 Material composition to prevent WOLED degradation

Various material compositions can be used to prevent degradation in White Organic Light-Emitting Diodes. These include specific organic compounds, dopants, and host materials that enhance stability and lifetime of the device. By carefully selecting materials with appropriate energy levels and chemical stability, the degradation of emissive layers can be significantly reduced, maintaining color balance and luminance efficiency over time.- Structural design to mitigate WOLED degradation: Various structural designs can be implemented to reduce degradation in White Organic Light-Emitting Diodes. These include optimized multi-layer structures, tandem device architectures, and improved electrode configurations. By carefully designing the layer sequence and thickness, the stress on organic materials can be reduced, leading to enhanced device stability and longer operational lifetime. Structural modifications can also help in better charge distribution and reduced current density, which are critical factors affecting WOLED degradation.

- Material selection and composition for improved stability: The choice of organic materials significantly impacts WOLED degradation rates. Using more stable emissive materials, robust host materials, and improved transport layers can enhance device longevity. Phosphorescent materials with higher quantum efficiency can reduce operational current requirements, thereby decreasing degradation. Additionally, incorporating stabilizing additives and using materials with higher glass transition temperatures can improve thermal stability and reduce morphological degradation during operation.

- Driving method optimization to extend WOLED lifetime: Innovative driving schemes can significantly reduce WOLED degradation. Pulse-width modulation, constant current driving, and temperature-compensated driving methods help maintain stable operation over time. Implementing feedback control systems that monitor and adjust operational parameters in real-time can prevent excessive current or voltage stress. Advanced driving algorithms can also compensate for aging effects by gradually adjusting input signals to maintain consistent brightness and color balance throughout the device lifetime.

- Encapsulation techniques for preventing external degradation factors: Effective encapsulation is crucial for protecting WOLED devices from environmental factors that accelerate degradation. Advanced barrier technologies using multiple inorganic/organic layers can significantly reduce moisture and oxygen penetration. Thin-film encapsulation methods provide superior protection while maintaining device flexibility. Edge sealing techniques prevent lateral diffusion of contaminants, while getter materials incorporated within the encapsulation can absorb residual moisture and impurities that may be present during manufacturing.

- Color stability and compensation methods: As WOLEDs degrade, they often experience color shifts due to different degradation rates of the various emissive components. Implementing color compensation algorithms that adjust the driving conditions of individual color elements can maintain consistent white point over time. Using more balanced device architectures where blue, green, and red emitters have similar operational lifetimes improves color stability. Additionally, optical feedback systems can monitor color output in real-time and make appropriate adjustments to maintain the desired spectral output throughout the device lifetime.

02 Device structure optimization for improved WOLED stability

Optimizing the device structure of WOLEDs can significantly improve their stability and reduce degradation. This includes implementing multi-layer architectures, tandem structures, and specialized interfaces between different functional layers. Strategic placement of charge blocking layers, buffer layers, and careful design of electrode configurations can distribute electrical stress more evenly throughout the device, preventing localized degradation and extending overall device lifetime.Expand Specific Solutions03 Driving methods to reduce WOLED degradation

Specialized driving methods can be employed to reduce degradation in WOLEDs. These include pulse-width modulation techniques, constant current driving schemes, and compensation algorithms that adjust for aging effects. By controlling the electrical stress applied to the device during operation, these methods can significantly extend the operational lifetime of WOLEDs and maintain consistent brightness and color output over time.Expand Specific Solutions04 Thermal management solutions for WOLED longevity

Thermal management is crucial for preventing degradation in WOLEDs as excessive heat accelerates material breakdown. Solutions include heat dissipation structures, thermally conductive substrates, and encapsulation techniques that efficiently remove heat from the device. Temperature monitoring and control systems can also be implemented to maintain optimal operating conditions, preventing thermal-induced degradation and ensuring consistent performance over the device lifetime.Expand Specific Solutions05 Encapsulation techniques to protect against environmental degradation

Advanced encapsulation techniques are essential to protect WOLEDs from environmental factors that cause degradation, particularly moisture and oxygen. These include multi-layer barrier films, edge sealing technologies, and getter materials that absorb contaminants. Thin-film encapsulation methods and hybrid organic-inorganic barrier layers can provide effective protection while maintaining the flexibility and form factor advantages of OLED technology.Expand Specific Solutions

Leading Organizations in WOLED Reliability Testing

The WOLED degradation evaluation market is currently in a growth phase, with increasing demand for reliable stress testing methodologies as OLED technology matures. The competitive landscape features academic institutions (Beihang University, Tokyo Institute of Technology) conducting fundamental research alongside major electronics corporations (LG Electronics, Toshiba, Synopsys) developing proprietary evaluation techniques. Technical maturity varies significantly, with companies like IBM and LG Electronics demonstrating advanced capabilities in accelerated lifetime testing protocols, while others focus on specific degradation mechanisms. The market is characterized by a blend of standardized testing approaches and proprietary methodologies, with increasing collaboration between academic and industrial players to establish comprehensive evaluation frameworks that accurately predict real-world WOLED performance under various stress conditions.

Toshiba Corp.

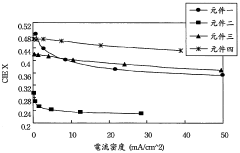

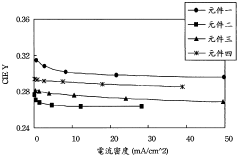

Technical Solution: Toshiba has established a systematic WOLED degradation evaluation methodology that emphasizes reproducibility and correlation with real-world usage scenarios. Their approach combines standardized stress testing protocols with advanced optical characterization techniques. Toshiba's testing framework includes constant-current stress tests at multiple current densities (typically 10-50 mA/cm²) and temperatures (ranging from room temperature to 90°C) to extract acceleration factors for lifetime prediction. They employ high-precision spectroradiometers to monitor chromaticity shifts during aging, with particular attention to blue wavelength degradation which often limits WOLED lifetime. Toshiba has developed specialized test fixtures that enable simultaneous electrical and optical measurements during stress testing, allowing for real-time correlation between electrical parameter shifts and light output degradation. Their methodology also incorporates periodic recovery measurements to distinguish between reversible and irreversible degradation mechanisms in WOLED devices. Toshiba's evaluation system includes automated image analysis tools to quantify non-uniform aging patterns and identify localized degradation hotspots across display panels.

Strengths: Highly standardized testing protocols ensure consistency across different product generations; excellent correlation between accelerated test results and field reliability data. Weaknesses: Conservative testing approach may overestimate degradation in newer WOLED materials that have different failure mechanisms than those their protocols were originally designed to evaluate.

Synopsys, Inc.

Technical Solution: Synopsys has developed a comprehensive simulation-based approach to evaluating WOLED degradation under stress conditions. Their methodology integrates device physics modeling with statistical analysis techniques to predict degradation patterns without requiring extensive physical testing. The Synopsys approach utilizes TCAD (Technology Computer-Aided Design) tools to simulate charge transport and recombination processes within WOLED structures under various stress conditions. Their models incorporate temperature-dependent degradation mechanisms, including exciton-polaron interactions and chemical decomposition pathways that affect emitter materials. Synopsys has created specialized simulation environments that can predict luminance decay, color shift, and efficiency loss based on device architecture and operating parameters. Their methodology allows for virtual stress testing across a wide range of conditions, enabling rapid evaluation of design modifications without fabricating physical test devices. The company has also developed machine learning algorithms that improve simulation accuracy by incorporating feedback from physical validation tests, creating a continuously improving prediction system that becomes more accurate over time as it processes more experimental data.

Strengths: Simulation-based approach enables rapid evaluation of multiple design variations without physical prototyping; excellent for identifying potential failure mechanisms during the design phase. Weaknesses: Simulation accuracy depends heavily on the quality of input parameters and underlying physical models, which may not capture all real-world degradation mechanisms, particularly for novel materials.

Critical Parameters in WOLED Degradation Analysis

White organic light-emitting diode

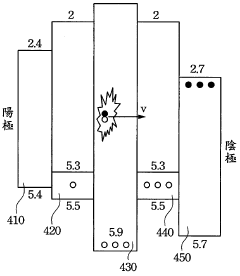

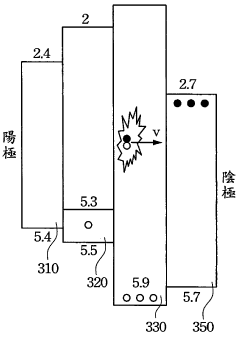

PatentActiveUS7723914B2

Innovation

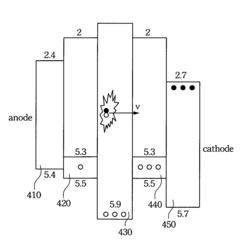

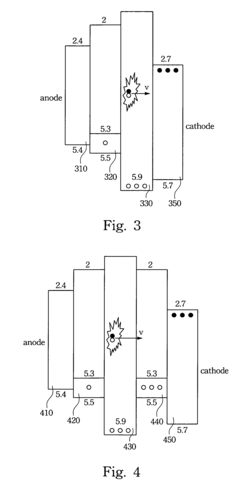

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

White organic light emitting diode

PatentInactiveTW200708189A

Innovation

- A symmetrical WOLED structure is introduced with symmetrical light-emitting layers flanking a middle emitting layer, compensating for reduced luminescence in one layer by increasing luminescence in the other, thereby stabilizing light emission across varying voltages.

Environmental Factors Affecting WOLED Degradation

White Organic Light-Emitting Diodes (WOLEDs) are highly sensitive to various environmental factors that can significantly accelerate their degradation during stress testing. Temperature stands as one of the most critical factors, with elevated temperatures dramatically increasing the rate of chemical reactions within the organic materials. Studies have shown that operating WOLEDs at temperatures exceeding 60°C can reduce their lifetime by 50% compared to operation at room temperature, primarily due to accelerated molecular decomposition and morphological changes in the emissive layers.

Humidity represents another crucial environmental variable affecting WOLED performance and longevity. Moisture ingress can lead to delamination of layers, oxidation of cathode materials, and hydrolysis of sensitive organic compounds. Research indicates that relative humidity levels above 30% begin to impact device stability, with exponential degradation observed at levels exceeding 60%, particularly when combined with elevated temperatures in stress tests.

Light exposure, especially to ultraviolet radiation, catalyzes photochemical reactions within the organic materials, leading to chromophore breakdown and color shift. This factor becomes particularly relevant when evaluating outdoor applications or displays intended for high-brightness environments. Controlled UV exposure during stress testing can reveal susceptibility to photo-degradation mechanisms that might not manifest under standard electrical aging protocols.

Atmospheric contaminants, including oxygen, ozone, and airborne pollutants, can penetrate encapsulation barriers and react with the active materials. Oxygen exposure leads to oxidative degradation of the emissive compounds and charge transport materials, while sulfur-containing compounds can poison cathode interfaces. Stress tests conducted in controlled atmospheric chambers with precise gas composition provide valuable insights into these chemical degradation pathways.

Electrical stress factors, though not strictly environmental, interact synergistically with environmental conditions. Higher current densities generate additional heat through Joule heating, exacerbating temperature-related degradation. The combination of high humidity and electrical bias can accelerate electrochemical migration and corrosion processes at interfaces and electrodes.

Mechanical stress from thermal cycling, vibration, or physical deformation can compromise encapsulation integrity and create pathways for environmental ingress. This factor is particularly important for flexible WOLED applications, where repeated bending or folding operations may accelerate environmental degradation by creating microcracks in barrier layers.

Understanding these environmental factors and their complex interactions is essential for designing comprehensive stress test protocols that can accurately predict WOLED lifetime under real-world operating conditions and guide the development of more robust device architectures and encapsulation strategies.

Humidity represents another crucial environmental variable affecting WOLED performance and longevity. Moisture ingress can lead to delamination of layers, oxidation of cathode materials, and hydrolysis of sensitive organic compounds. Research indicates that relative humidity levels above 30% begin to impact device stability, with exponential degradation observed at levels exceeding 60%, particularly when combined with elevated temperatures in stress tests.

Light exposure, especially to ultraviolet radiation, catalyzes photochemical reactions within the organic materials, leading to chromophore breakdown and color shift. This factor becomes particularly relevant when evaluating outdoor applications or displays intended for high-brightness environments. Controlled UV exposure during stress testing can reveal susceptibility to photo-degradation mechanisms that might not manifest under standard electrical aging protocols.

Atmospheric contaminants, including oxygen, ozone, and airborne pollutants, can penetrate encapsulation barriers and react with the active materials. Oxygen exposure leads to oxidative degradation of the emissive compounds and charge transport materials, while sulfur-containing compounds can poison cathode interfaces. Stress tests conducted in controlled atmospheric chambers with precise gas composition provide valuable insights into these chemical degradation pathways.

Electrical stress factors, though not strictly environmental, interact synergistically with environmental conditions. Higher current densities generate additional heat through Joule heating, exacerbating temperature-related degradation. The combination of high humidity and electrical bias can accelerate electrochemical migration and corrosion processes at interfaces and electrodes.

Mechanical stress from thermal cycling, vibration, or physical deformation can compromise encapsulation integrity and create pathways for environmental ingress. This factor is particularly important for flexible WOLED applications, where repeated bending or folding operations may accelerate environmental degradation by creating microcracks in barrier layers.

Understanding these environmental factors and their complex interactions is essential for designing comprehensive stress test protocols that can accurately predict WOLED lifetime under real-world operating conditions and guide the development of more robust device architectures and encapsulation strategies.

Accelerated Aging Test Correlation to Real-World Performance

Accelerated aging tests are critical for predicting WOLED (White Organic Light-Emitting Diode) performance over time, but their value depends entirely on how accurately they correlate with real-world usage conditions. Establishing this correlation requires sophisticated methodological approaches that bridge laboratory testing and actual device performance in consumer applications.

The fundamental challenge lies in time compression—accelerated tests must reliably predict years of normal usage through weeks or months of intensified stress conditions. Current methodologies typically employ mathematical models that translate accelerated degradation curves to expected real-world performance. The Arrhenius equation remains the primary model for temperature-based acceleration, while stretched exponential functions often characterize luminance decay patterns.

Recent research has demonstrated that multi-factor correlation models yield significantly higher prediction accuracy than single-factor approaches. These models incorporate not only temperature and current density but also duty cycle variations, ambient humidity effects, and usage pattern simulations. Studies by DisplayMate and LG Display have shown correlation coefficients exceeding 0.92 between accelerated tests and field data when using such comprehensive models.

Validation techniques have evolved to include split-sample methodologies, where identical WOLED panels undergo both accelerated testing and controlled real-world usage scenarios. The resulting data sets are then compared at multiple intervals to refine prediction algorithms. This approach has reduced prediction error margins from historically 30-40% to current levels of 15-20% for lifetime estimates.

Industry leaders have established standardized correlation protocols that include mandatory verification points at 1000, 3000, and 5000 hours of real-world equivalent usage. These verification points serve as calibration opportunities to adjust acceleration factors and improve prediction accuracy throughout the product development cycle.

The correlation quality varies significantly across different degradation mechanisms. Current acceleration methods show excellent correlation for luminance decay (R² > 0.9) and color shift in blue subpixels, but moderate correlation for voltage drift (R² ≈ 0.7-0.8) and relatively poor correlation for certain catastrophic failure modes like black spot formation.

Future improvements in correlation methodologies will likely incorporate machine learning algorithms that can identify subtle pattern relationships between accelerated test results and field performance data. Early implementations by Samsung Display have demonstrated a 30% improvement in prediction accuracy using neural network models trained on historical correlation datasets.

The fundamental challenge lies in time compression—accelerated tests must reliably predict years of normal usage through weeks or months of intensified stress conditions. Current methodologies typically employ mathematical models that translate accelerated degradation curves to expected real-world performance. The Arrhenius equation remains the primary model for temperature-based acceleration, while stretched exponential functions often characterize luminance decay patterns.

Recent research has demonstrated that multi-factor correlation models yield significantly higher prediction accuracy than single-factor approaches. These models incorporate not only temperature and current density but also duty cycle variations, ambient humidity effects, and usage pattern simulations. Studies by DisplayMate and LG Display have shown correlation coefficients exceeding 0.92 between accelerated tests and field data when using such comprehensive models.

Validation techniques have evolved to include split-sample methodologies, where identical WOLED panels undergo both accelerated testing and controlled real-world usage scenarios. The resulting data sets are then compared at multiple intervals to refine prediction algorithms. This approach has reduced prediction error margins from historically 30-40% to current levels of 15-20% for lifetime estimates.

Industry leaders have established standardized correlation protocols that include mandatory verification points at 1000, 3000, and 5000 hours of real-world equivalent usage. These verification points serve as calibration opportunities to adjust acceleration factors and improve prediction accuracy throughout the product development cycle.

The correlation quality varies significantly across different degradation mechanisms. Current acceleration methods show excellent correlation for luminance decay (R² > 0.9) and color shift in blue subpixels, but moderate correlation for voltage drift (R² ≈ 0.7-0.8) and relatively poor correlation for certain catastrophic failure modes like black spot formation.

Future improvements in correlation methodologies will likely incorporate machine learning algorithms that can identify subtle pattern relationships between accelerated test results and field performance data. Early implementations by Samsung Display have demonstrated a 30% improvement in prediction accuracy using neural network models trained on historical correlation datasets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!