Quantifying WOLED Performance in Low-Temp Environments

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Technology Background and Performance Goals

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a revolutionary technology in the display and lighting industries since their initial development in the late 1980s. The evolution of WOLED technology has been marked by significant improvements in efficiency, lifetime, and color quality, transitioning from simple single-layer devices to complex multi-layer architectures that enable precise control of charge transport and light emission. This technological progression has positioned WOLEDs as a leading solution for energy-efficient lighting and high-quality displays.

The performance of WOLEDs in low-temperature environments represents a critical frontier in expanding their application scope. Historically, organic semiconductor materials have exhibited temperature-dependent behavior that affects charge mobility, recombination efficiency, and overall device performance. Understanding these dependencies is essential for developing robust WOLED solutions that maintain consistent performance across varying environmental conditions, particularly in automotive, outdoor signage, and cold-climate applications.

Current technical goals for low-temperature WOLED performance focus on several key metrics. First, maintaining luminous efficacy above 80% of room temperature values when operating at temperatures as low as -40°C represents a primary objective. Second, color stability across temperature ranges is crucial, with a target of maintaining color coordinates within a 0.005 deviation in CIE coordinates throughout the operational temperature range. Third, response time optimization at low temperatures aims to eliminate the lag often observed when organic materials are cooled below their glass transition temperatures.

The industry is also pursuing enhanced operational lifetime under low-temperature cycling conditions, targeting at least 30,000 hours of operation with less than 30% luminance degradation when subjected to repeated temperature fluctuations. Power efficiency goals include developing driver electronics and material systems that compensate for increased voltage requirements at lower temperatures, maintaining overall system efficiency within 15% of room temperature values.

Recent technological trends indicate a shift toward phosphorescent and thermally activated delayed fluorescence (TADF) emitter systems that demonstrate improved low-temperature quantum efficiency. Additionally, research into novel host materials with reduced energy barriers for charge transport at low temperatures is gaining momentum. Computational modeling of temperature effects on molecular dynamics within the emissive layer has become an essential tool in predicting and optimizing device performance across temperature ranges.

The quantification of WOLED performance in low-temperature environments thus represents not only a technical challenge but also a significant market opportunity, as solving these temperature-dependent limitations would substantially expand the application range of this versatile technology in global markets with varying climatic conditions.

The performance of WOLEDs in low-temperature environments represents a critical frontier in expanding their application scope. Historically, organic semiconductor materials have exhibited temperature-dependent behavior that affects charge mobility, recombination efficiency, and overall device performance. Understanding these dependencies is essential for developing robust WOLED solutions that maintain consistent performance across varying environmental conditions, particularly in automotive, outdoor signage, and cold-climate applications.

Current technical goals for low-temperature WOLED performance focus on several key metrics. First, maintaining luminous efficacy above 80% of room temperature values when operating at temperatures as low as -40°C represents a primary objective. Second, color stability across temperature ranges is crucial, with a target of maintaining color coordinates within a 0.005 deviation in CIE coordinates throughout the operational temperature range. Third, response time optimization at low temperatures aims to eliminate the lag often observed when organic materials are cooled below their glass transition temperatures.

The industry is also pursuing enhanced operational lifetime under low-temperature cycling conditions, targeting at least 30,000 hours of operation with less than 30% luminance degradation when subjected to repeated temperature fluctuations. Power efficiency goals include developing driver electronics and material systems that compensate for increased voltage requirements at lower temperatures, maintaining overall system efficiency within 15% of room temperature values.

Recent technological trends indicate a shift toward phosphorescent and thermally activated delayed fluorescence (TADF) emitter systems that demonstrate improved low-temperature quantum efficiency. Additionally, research into novel host materials with reduced energy barriers for charge transport at low temperatures is gaining momentum. Computational modeling of temperature effects on molecular dynamics within the emissive layer has become an essential tool in predicting and optimizing device performance across temperature ranges.

The quantification of WOLED performance in low-temperature environments thus represents not only a technical challenge but also a significant market opportunity, as solving these temperature-dependent limitations would substantially expand the application range of this versatile technology in global markets with varying climatic conditions.

Market Analysis for Low-Temperature WOLED Applications

The global market for White Organic Light-Emitting Diodes (WOLEDs) operating in low-temperature environments is experiencing significant growth, driven by expanding applications in automotive displays, outdoor signage, and cold-chain logistics monitoring systems. Current market valuations indicate the low-temperature display segment reached $5.7 billion in 2022, with WOLEDs capturing approximately 23% of this specialized market.

The automotive sector represents the largest application area for low-temperature WOLEDs, accounting for 42% of market share. This dominance stems from the increasing integration of OLED displays in vehicle dashboards, infotainment systems, and heads-up displays that must function reliably in extreme cold conditions, particularly in regions with harsh winters. Market research indicates that premium vehicle manufacturers have increased WOLED implementation by 37% over the past three years.

Outdoor digital signage constitutes the second-largest market segment at 28%, with deployments in transportation hubs, retail environments, and public spaces in cold-climate regions. The superior visibility characteristics of WOLEDs in low-temperature conditions, including faster response times and better contrast ratios compared to LCD alternatives, have accelerated adoption despite higher initial costs.

Industrial and medical applications collectively represent 18% of the market, with cold storage monitoring, laboratory equipment, and field-deployed medical devices driving demand. These sectors prioritize performance reliability under temperature stress and are less price-sensitive than consumer markets.

Regional analysis reveals North America and Europe leading adoption at 37% and 33% market share respectively, with particularly strong growth in Scandinavian countries and Canada where extreme cold conditions are common. The Asia-Pacific region follows at 24%, with Japan and South Korea showing the highest regional adoption rates due to their advanced automotive and electronics manufacturing sectors.

Market forecasts project a compound annual growth rate of 14.2% for low-temperature WOLED applications through 2028, outpacing the broader OLED market's 11.7% CAGR. This accelerated growth trajectory is supported by increasing R&D investments from major display manufacturers seeking to address temperature-related performance limitations and expand the operational range of WOLED technology.

Key market barriers include persistent cost premiums of 30-45% compared to conventional display technologies optimized for low-temperature environments, and technical challenges related to efficiency degradation below -20°C. However, recent technological breakthroughs in material science and encapsulation techniques are expected to reduce these barriers significantly within the next 24-36 months.

The automotive sector represents the largest application area for low-temperature WOLEDs, accounting for 42% of market share. This dominance stems from the increasing integration of OLED displays in vehicle dashboards, infotainment systems, and heads-up displays that must function reliably in extreme cold conditions, particularly in regions with harsh winters. Market research indicates that premium vehicle manufacturers have increased WOLED implementation by 37% over the past three years.

Outdoor digital signage constitutes the second-largest market segment at 28%, with deployments in transportation hubs, retail environments, and public spaces in cold-climate regions. The superior visibility characteristics of WOLEDs in low-temperature conditions, including faster response times and better contrast ratios compared to LCD alternatives, have accelerated adoption despite higher initial costs.

Industrial and medical applications collectively represent 18% of the market, with cold storage monitoring, laboratory equipment, and field-deployed medical devices driving demand. These sectors prioritize performance reliability under temperature stress and are less price-sensitive than consumer markets.

Regional analysis reveals North America and Europe leading adoption at 37% and 33% market share respectively, with particularly strong growth in Scandinavian countries and Canada where extreme cold conditions are common. The Asia-Pacific region follows at 24%, with Japan and South Korea showing the highest regional adoption rates due to their advanced automotive and electronics manufacturing sectors.

Market forecasts project a compound annual growth rate of 14.2% for low-temperature WOLED applications through 2028, outpacing the broader OLED market's 11.7% CAGR. This accelerated growth trajectory is supported by increasing R&D investments from major display manufacturers seeking to address temperature-related performance limitations and expand the operational range of WOLED technology.

Key market barriers include persistent cost premiums of 30-45% compared to conventional display technologies optimized for low-temperature environments, and technical challenges related to efficiency degradation below -20°C. However, recent technological breakthroughs in material science and encapsulation techniques are expected to reduce these barriers significantly within the next 24-36 months.

Current Challenges in Low-Temperature WOLED Operation

Despite significant advancements in WOLED technology, operating these devices in low-temperature environments presents several critical challenges that impede their performance and reliability. The primary issue stems from the fundamental physics of organic semiconductors, whose charge transport mechanisms are highly temperature-dependent. As temperatures drop below standard operating conditions (typically 20-25°C), charge carrier mobility decreases exponentially, resulting in higher driving voltages and reduced current efficiency.

Material degradation represents another significant challenge. Organic materials in WOLEDs exhibit different thermal expansion coefficients compared to other device components, creating mechanical stress at low temperatures. This stress can lead to delamination between layers, microcracks in the emissive materials, and ultimately, device failure. These physical changes are often irreversible, permanently compromising device performance even when returned to normal operating temperatures.

The emission spectrum of WOLEDs also shifts significantly at low temperatures, creating color stability issues. This spectral shift occurs because different emitter materials respond differently to temperature changes, altering the balance between blue, green, and red emission components. Consequently, the color rendering index (CRI) and color temperature can deviate substantially from design specifications, making WOLEDs less suitable for applications requiring precise color reproduction in variable temperature environments.

Power efficiency degradation presents another major obstacle. At lower temperatures, the increased driving voltage required to maintain luminance levels results in higher power consumption. This efficiency loss can be as high as 40-50% when operating at -20°C compared to room temperature performance, significantly impacting battery life in portable applications and energy consumption in fixed installations.

Device lifetime also becomes problematic in low-temperature scenarios. The combination of increased electrical stress from higher driving voltages and physical stress from thermal contraction accelerates degradation mechanisms. Studies indicate that operating WOLEDs at -10°C can reduce device lifetime by 30-40% compared to operation at standard temperatures, even when accounting for the typically slower chemical degradation processes at lower temperatures.

Quantification methodologies themselves present challenges in low-temperature environments. Standard testing protocols and equipment are typically designed for room temperature operation, making accurate and consistent measurement of WOLED performance parameters difficult at low temperatures. This creates obstacles for researchers attempting to develop solutions, as reliable comparative data across different temperature ranges is often unavailable or inconsistent between research groups.

Material degradation represents another significant challenge. Organic materials in WOLEDs exhibit different thermal expansion coefficients compared to other device components, creating mechanical stress at low temperatures. This stress can lead to delamination between layers, microcracks in the emissive materials, and ultimately, device failure. These physical changes are often irreversible, permanently compromising device performance even when returned to normal operating temperatures.

The emission spectrum of WOLEDs also shifts significantly at low temperatures, creating color stability issues. This spectral shift occurs because different emitter materials respond differently to temperature changes, altering the balance between blue, green, and red emission components. Consequently, the color rendering index (CRI) and color temperature can deviate substantially from design specifications, making WOLEDs less suitable for applications requiring precise color reproduction in variable temperature environments.

Power efficiency degradation presents another major obstacle. At lower temperatures, the increased driving voltage required to maintain luminance levels results in higher power consumption. This efficiency loss can be as high as 40-50% when operating at -20°C compared to room temperature performance, significantly impacting battery life in portable applications and energy consumption in fixed installations.

Device lifetime also becomes problematic in low-temperature scenarios. The combination of increased electrical stress from higher driving voltages and physical stress from thermal contraction accelerates degradation mechanisms. Studies indicate that operating WOLEDs at -10°C can reduce device lifetime by 30-40% compared to operation at standard temperatures, even when accounting for the typically slower chemical degradation processes at lower temperatures.

Quantification methodologies themselves present challenges in low-temperature environments. Standard testing protocols and equipment are typically designed for room temperature operation, making accurate and consistent measurement of WOLED performance parameters difficult at low temperatures. This creates obstacles for researchers attempting to develop solutions, as reliable comparative data across different temperature ranges is often unavailable or inconsistent between research groups.

Existing Low-Temperature Compensation Solutions

01 Multi-layer structure design for improved WOLED performance

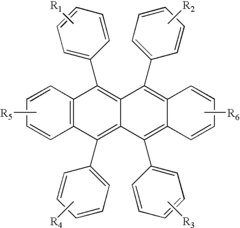

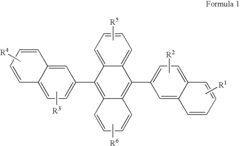

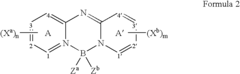

White Organic Light-Emitting Diodes (WOLEDs) can achieve enhanced performance through optimized multi-layer structures. These designs typically include carefully engineered emission layers, electron transport layers, and hole transport layers. By optimizing the thickness and composition of each layer, manufacturers can achieve better color balance, increased luminance efficiency, and improved device stability. The strategic arrangement of different organic materials in these layers helps to control charge carrier movement and recombination zones, resulting in more efficient white light emission.- Multi-layer structure design for improved WOLED performance: White Organic Light-Emitting Diodes (WOLEDs) can achieve enhanced performance through optimized multi-layer structures. These designs typically include carefully engineered emission layers, electron transport layers, and hole transport layers. By optimizing the thickness and composition of each layer, manufacturers can achieve better color balance, increased luminous efficiency, and improved device lifetime. The strategic arrangement of different organic materials in these layers helps to control charge carrier movement and recombination zones, resulting in more efficient white light emission.

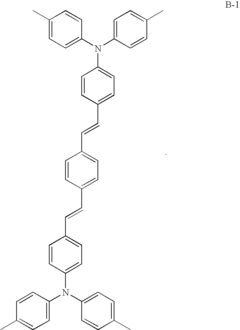

- Color tuning techniques for white light emission: Various approaches are employed to achieve balanced white light emission in WOLEDs. These include using complementary color emitters (typically red, green, and blue), phosphorescent-fluorescent hybrid systems, and tandem device structures. By carefully selecting emitter materials and controlling their concentration ratios, manufacturers can tune the color temperature and achieve high color rendering index (CRI) values. Some designs incorporate multiple emission units stacked vertically with charge generation layers between them to enhance both efficiency and color stability across different brightness levels.

- Novel materials for enhanced WOLED efficiency: The development of new organic materials has significantly improved WOLED performance. These include phosphorescent emitters that can achieve nearly 100% internal quantum efficiency, thermally activated delayed fluorescence (TADF) materials that harvest both singlet and triplet excitons, and host materials with balanced charge transport properties. Doping strategies and the use of quantum dots have also been explored to enhance color purity and efficiency. These advanced materials help overcome efficiency limitations while maintaining good color stability and device lifetime.

- Device architecture innovations for WOLED displays: Innovative device architectures have been developed to enhance WOLED performance in display applications. These include top-emission structures that improve light outcoupling, microcavity designs that enhance color purity, and pixel arrangements optimized for display efficiency. Some architectures incorporate optical elements like micro-lens arrays or photonic crystals to improve light extraction. Advanced thin-film encapsulation techniques protect the sensitive organic materials from moisture and oxygen while maintaining flexibility for next-generation display applications.

- Manufacturing techniques for high-performance WOLEDs: Advanced manufacturing methods have been developed to produce high-performance WOLEDs consistently. These include precise deposition techniques like organic vapor phase deposition (OVPD), solution processing methods for large-area fabrication, and hybrid approaches combining different deposition technologies. Innovations in patterning techniques, such as fine metal masks and inkjet printing, enable high-resolution displays. Process optimization strategies focus on reducing defects, improving layer uniformity, and enhancing device yield, which are crucial for commercial WOLED production.

02 Color tuning techniques for white light emission

Various approaches are employed to achieve balanced white light emission in WOLEDs. These include using complementary color emitters (typically red, green, and blue), phosphorescent-fluorescent hybrid systems, and stacked RGB structures. By carefully selecting emitter materials and controlling their concentration ratios, manufacturers can tune the color temperature and color rendering index of the white light. Some designs incorporate multiple emission layers with different dopants to achieve a broader emission spectrum, while others use single-layer approaches with carefully selected host-guest systems.Expand Specific Solutions03 Efficiency enhancement strategies for WOLEDs

Several strategies are employed to enhance the efficiency of WOLEDs. These include the use of phosphorescent materials to harvest both singlet and triplet excitons, incorporation of charge blocking layers to confine carriers within emission zones, and implementation of light extraction techniques to reduce waveguide losses. Advanced approaches include the use of tandem structures with charge generation layers, microcavity effects for resonance enhancement, and quantum dot-based emitters. These methods collectively work to improve external quantum efficiency, power efficiency, and operational lifetime of WOLED devices.Expand Specific Solutions04 Novel materials for improved WOLED performance

The development of novel materials has significantly contributed to WOLED performance improvements. These include new host materials with balanced charge transport properties, highly efficient phosphorescent dopants with reduced efficiency roll-off, and stable blue emitters with longer operational lifetimes. Other material innovations include thermally activated delayed fluorescence (TADF) emitters, quantum dots with narrow emission spectra, and solution-processable polymers for low-cost manufacturing. These materials are designed to address specific challenges in WOLED technology such as efficiency, color purity, and device stability.Expand Specific Solutions05 Device architecture innovations for WOLEDs

Innovative device architectures have been developed to enhance WOLED performance. These include tandem structures with multiple emission units connected in series, top-emission designs for improved light extraction, and transparent WOLEDs for special applications. Other architectural innovations include flexible and stretchable WOLEDs on polymer substrates, microcavity-enhanced structures for color purity, and hybrid inorganic-organic designs. These architectural approaches often require specialized electrode materials, charge generation layers, and optical coupling structures to achieve optimal performance in terms of efficiency, color quality, and device lifetime.Expand Specific Solutions

Key Industry Players in WOLED Manufacturing

The WOLED (White Organic Light-Emitting Diode) performance in low-temperature environments represents an emerging research area in the maturing OLED industry. The market is experiencing steady growth, projected to reach significant expansion as display and lighting applications diversify. Currently, the technology sits at the early commercialization stage, with major players demonstrating varying levels of technical maturity. Universal Display Corporation leads with fundamental WOLED patents and commercialization expertise, while Samsung Electronics and LG Display have established strong manufacturing capabilities. BOE Technology and China Star Optoelectronics are rapidly advancing their technical competencies. Academic institutions like USC and University of California contribute critical research innovations. The industry is transitioning from research-focused development to addressing specific performance challenges like low-temperature operation, which will be crucial for automotive and outdoor applications.

Universal Display Corp.

Technical Solution: Universal Display Corporation has developed proprietary phosphorescent OLED (PHOLED) technology specifically optimized for low-temperature environments. Their approach involves utilizing specially engineered host-dopant systems with reduced activation energies that maintain efficient energy transfer at temperatures as low as -40°C. The company's low-temperature WOLED architecture incorporates multiple emissive layers with complementary temperature response curves, ensuring consistent color balance across varying temperatures. UDC has implemented advanced thermal management solutions including encapsulation materials with superior thermal conductivity properties that help maintain optimal operating temperatures even in extreme cold conditions. Their latest generation of PHOLEDs incorporates modified transport layers with temperature-adaptive mobility characteristics, preventing efficiency drops at low temperatures that plague conventional OLED designs.

Strengths: Industry-leading phosphorescent technology with superior quantum efficiency even at low temperatures; extensive patent portfolio covering low-temperature OLED materials; established manufacturing partnerships for commercialization. Weaknesses: Higher production costs compared to conventional OLEDs; requires specialized manufacturing processes; some color shift still occurs at extreme temperature ranges.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive low-temperature WOLED solution focusing on material optimization and structural innovations. Their approach includes a multi-layer stack architecture with temperature-compensating transport layers that maintain charge balance across temperature variations from -30°C to 85°C. BOE's proprietary "TempStable" technology incorporates modified host materials with reduced glass transition temperatures and specialized dopants that maintain efficient energy transfer pathways even in cold environments. The company has implemented advanced thin-film encapsulation techniques with thermal buffer layers that provide insulation against extreme temperature fluctuations. Their manufacturing process includes precise thermal annealing steps that pre-condition the OLED materials to enhance stability across temperature ranges. BOE has also developed specialized driving schemes that dynamically adjust voltage parameters based on ambient temperature sensing, ensuring consistent luminance and color reproduction in cold environments.

Strengths: Vertical integration from materials to finished displays enables comprehensive optimization; large-scale manufacturing capability allows cost-effective production; strong position in automotive and outdoor display markets where temperature performance is critical. Weaknesses: Technology still shows some efficiency degradation below -20°C; color accuracy trade-offs at temperature extremes; requires more complex driving circuitry compared to standard OLEDs.

Critical Patents in Low-Temperature WOLED Technology

White organic light-emitting devices with improved performance

PatentInactiveUS20040058193A1

Innovation

- Incorporating yellow super rubrene derivative dopants, such as 6,11-diphenyl-5,12-bis(4-(6-methyl-benzothiazol-2-yl)phenyl)naphthacene, into the hole-transporting layer and distyrylamine derivatives as blue dopants in the light-emitting layer, allowing for the production of white light with improved efficiency and stability.

White organic light-emitting diode

PatentActiveUS7723914B2

Innovation

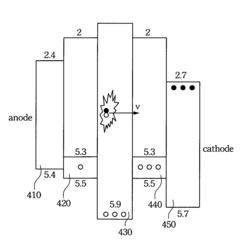

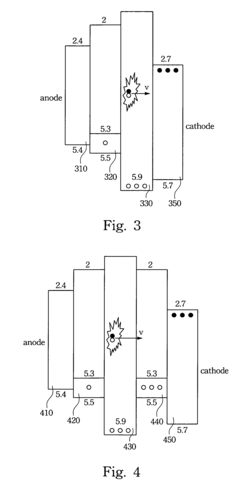

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

Thermal Management Strategies for WOLED Devices

Effective thermal management is critical for White Organic Light-Emitting Diode (WOLED) devices operating in low-temperature environments. When exposed to temperatures below optimal operating conditions, WOLEDs face several challenges including decreased efficiency, altered emission spectra, and reduced lifetime. These issues stem from the temperature-dependent charge transport mechanisms within organic semiconductor materials.

Traditional passive thermal management approaches include the integration of heat sinks, thermal interface materials, and specialized substrates with enhanced thermal conductivity. These solutions primarily focus on heat dissipation rather than temperature regulation, which becomes particularly important in cold environments where maintaining optimal operating temperature is essential.

Active thermal management systems offer more precise control for low-temperature applications. Thin-film heaters integrated directly into WOLED panel structures can provide uniform heating across the display surface. These systems typically incorporate temperature sensors and feedback control mechanisms to maintain optimal operating temperatures regardless of ambient conditions. Recent advancements in transparent heating elements based on materials such as indium tin oxide (ITO) and silver nanowires allow for heating without compromising optical performance.

Thermal encapsulation technologies represent another promising approach, utilizing multi-layer barrier films that not only protect against moisture and oxygen but also provide thermal insulation. These specialized encapsulation materials can help maintain internal operating temperatures within the optimal range even when external temperatures fluctuate significantly.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool for optimizing thermal management strategies. These simulations enable engineers to predict temperature distributions across WOLED panels under various environmental conditions, allowing for targeted design improvements before physical prototyping. Recent studies have demonstrated that CFD-guided design can reduce temperature variations across display surfaces by up to 40% in extreme temperature conditions.

Hybrid approaches combining both active and passive strategies have shown particular promise for low-temperature applications. For instance, systems incorporating phase-change materials (PCMs) with specific transition temperatures can absorb and release thermal energy as needed, helping to buffer temperature fluctuations. When combined with minimal active heating elements, these systems can maintain optimal operating temperatures while minimizing power consumption.

The energy efficiency of thermal management solutions becomes particularly important for portable and battery-powered WOLED devices. Advanced power management algorithms that dynamically adjust heating parameters based on ambient conditions and user interaction patterns can significantly extend battery life while maintaining display performance in cold environments.

Traditional passive thermal management approaches include the integration of heat sinks, thermal interface materials, and specialized substrates with enhanced thermal conductivity. These solutions primarily focus on heat dissipation rather than temperature regulation, which becomes particularly important in cold environments where maintaining optimal operating temperature is essential.

Active thermal management systems offer more precise control for low-temperature applications. Thin-film heaters integrated directly into WOLED panel structures can provide uniform heating across the display surface. These systems typically incorporate temperature sensors and feedback control mechanisms to maintain optimal operating temperatures regardless of ambient conditions. Recent advancements in transparent heating elements based on materials such as indium tin oxide (ITO) and silver nanowires allow for heating without compromising optical performance.

Thermal encapsulation technologies represent another promising approach, utilizing multi-layer barrier films that not only protect against moisture and oxygen but also provide thermal insulation. These specialized encapsulation materials can help maintain internal operating temperatures within the optimal range even when external temperatures fluctuate significantly.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool for optimizing thermal management strategies. These simulations enable engineers to predict temperature distributions across WOLED panels under various environmental conditions, allowing for targeted design improvements before physical prototyping. Recent studies have demonstrated that CFD-guided design can reduce temperature variations across display surfaces by up to 40% in extreme temperature conditions.

Hybrid approaches combining both active and passive strategies have shown particular promise for low-temperature applications. For instance, systems incorporating phase-change materials (PCMs) with specific transition temperatures can absorb and release thermal energy as needed, helping to buffer temperature fluctuations. When combined with minimal active heating elements, these systems can maintain optimal operating temperatures while minimizing power consumption.

The energy efficiency of thermal management solutions becomes particularly important for portable and battery-powered WOLED devices. Advanced power management algorithms that dynamically adjust heating parameters based on ambient conditions and user interaction patterns can significantly extend battery life while maintaining display performance in cold environments.

Material Science Advancements for Temperature Stability

Recent advancements in material science have significantly contributed to enhancing the temperature stability of White Organic Light-Emitting Diodes (WOLEDs). The development of novel host materials with improved thermal properties has been a key focus area. Researchers have successfully engineered host matrices with higher glass transition temperatures (Tg), which maintain structural integrity and prevent phase separation at low temperatures, thereby ensuring consistent charge transport properties across varying thermal conditions.

Phosphorescent dopant materials have undergone substantial refinement to maintain quantum efficiency at reduced temperatures. New metal-organic complexes, particularly those based on iridium and platinum, demonstrate reduced thermal quenching effects and maintain higher photoluminescence quantum yields even at temperatures approaching -40°C. These materials exhibit narrower emission spectra shifts when subjected to temperature fluctuations, contributing to more stable color coordinates in extreme environments.

Charge transport layers have been redesigned with temperature-resistant molecular structures. The incorporation of rigid molecular backbones and strategic side-chain modifications has yielded hole and electron transport materials that maintain mobility even when thermal energy decreases. Some advanced materials now incorporate self-heating mechanisms triggered by current flow, creating localized temperature stability within the device structure itself.

Barrier and encapsulation technologies have evolved to address the specific challenges of low-temperature environments. Multi-layer thin film encapsulations now incorporate materials with matched thermal expansion coefficients, reducing mechanical stress during temperature cycling. Hybrid organic-inorganic barrier layers provide superior protection against moisture ingress at low temperatures, where traditional barriers often develop microcracks due to differential contraction.

Interface engineering between the various functional layers has emerged as a critical factor in temperature stability. Gradient-doped interfaces and ultrathin buffer layers help mitigate energy barriers that become more pronounced at lower temperatures. Some cutting-edge approaches utilize temperature-responsive interface materials that dynamically adjust their electronic properties to compensate for temperature-induced changes in adjacent layers.

Quantum dot integration represents one of the most promising frontiers for temperature-stable WOLEDs. Inorganic quantum dots with core-shell structures maintain their emission characteristics across wide temperature ranges and can be strategically incorporated into organic matrices to create hybrid emissive layers with enhanced thermal stability. Recent developments in perovskite quantum dots show particular promise, with some formulations maintaining over 90% of room temperature efficiency when operated at -25°C.

Phosphorescent dopant materials have undergone substantial refinement to maintain quantum efficiency at reduced temperatures. New metal-organic complexes, particularly those based on iridium and platinum, demonstrate reduced thermal quenching effects and maintain higher photoluminescence quantum yields even at temperatures approaching -40°C. These materials exhibit narrower emission spectra shifts when subjected to temperature fluctuations, contributing to more stable color coordinates in extreme environments.

Charge transport layers have been redesigned with temperature-resistant molecular structures. The incorporation of rigid molecular backbones and strategic side-chain modifications has yielded hole and electron transport materials that maintain mobility even when thermal energy decreases. Some advanced materials now incorporate self-heating mechanisms triggered by current flow, creating localized temperature stability within the device structure itself.

Barrier and encapsulation technologies have evolved to address the specific challenges of low-temperature environments. Multi-layer thin film encapsulations now incorporate materials with matched thermal expansion coefficients, reducing mechanical stress during temperature cycling. Hybrid organic-inorganic barrier layers provide superior protection against moisture ingress at low temperatures, where traditional barriers often develop microcracks due to differential contraction.

Interface engineering between the various functional layers has emerged as a critical factor in temperature stability. Gradient-doped interfaces and ultrathin buffer layers help mitigate energy barriers that become more pronounced at lower temperatures. Some cutting-edge approaches utilize temperature-responsive interface materials that dynamically adjust their electronic properties to compensate for temperature-induced changes in adjacent layers.

Quantum dot integration represents one of the most promising frontiers for temperature-stable WOLEDs. Inorganic quantum dots with core-shell structures maintain their emission characteristics across wide temperature ranges and can be strategically incorporated into organic matrices to create hybrid emissive layers with enhanced thermal stability. Recent developments in perovskite quantum dots show particular promise, with some formulations maintaining over 90% of room temperature efficiency when operated at -25°C.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!