Test WOLED Under Dynamic Stress for Stability Insights

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Dynamic Stress Testing Background and Objectives

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a pivotal technology in the display and lighting industries over the past two decades. These devices offer superior color rendering, energy efficiency, and form factor advantages compared to traditional lighting technologies. However, the long-term stability of WOLEDs remains a critical challenge that limits their widespread commercial adoption, particularly in applications requiring extended operational lifetimes.

Dynamic stress testing represents a methodological advancement beyond conventional static testing protocols. While static testing evaluates device performance under constant operating conditions, dynamic stress testing subjects WOLEDs to varying electrical and environmental parameters that more accurately simulate real-world usage scenarios. This approach provides deeper insights into degradation mechanisms that may not manifest under static conditions.

The evolution of WOLED technology has progressed through several generations, from early phosphorescent emitters to more recent hybrid and TADF (Thermally Activated Delayed Fluorescence) systems. Each iteration has improved efficiency and color quality, but stability issues persist across all variants. Understanding how these different WOLED architectures respond to dynamic stress conditions is essential for developing more robust devices.

Current stability assessment methods primarily focus on accelerated aging under constant current or brightness conditions. These approaches, while standardized, fail to capture the complex degradation patterns that occur during actual device operation, where brightness levels, ambient temperatures, and usage patterns fluctuate continuously. The technical objective of dynamic stress testing is to bridge this gap between laboratory evaluation and real-world performance.

Recent research indicates that transient electrical stresses, such as voltage spikes and current fluctuations, can trigger unique degradation pathways in organic semiconductor materials. These pathways include charge trapping, interfacial degradation, and molecular reorganization that may not be activated under static testing conditions. By systematically investigating these phenomena through dynamic stress protocols, we aim to develop comprehensive stability models that can predict device lifetime more accurately.

The ultimate goal of this technical investigation is threefold: first, to establish standardized dynamic stress testing protocols that can be widely adopted by the industry; second, to identify the fundamental physical and chemical mechanisms responsible for WOLED degradation under variable operating conditions; and third, to leverage these insights to design more stable device architectures and materials that can withstand the demands of commercial applications.

This research aligns with the broader industry trend toward more reliable and longer-lasting organic electronic devices, addressing a key barrier to market expansion for WOLED technology in premium display products and specialized lighting applications where performance consistency is paramount.

Dynamic stress testing represents a methodological advancement beyond conventional static testing protocols. While static testing evaluates device performance under constant operating conditions, dynamic stress testing subjects WOLEDs to varying electrical and environmental parameters that more accurately simulate real-world usage scenarios. This approach provides deeper insights into degradation mechanisms that may not manifest under static conditions.

The evolution of WOLED technology has progressed through several generations, from early phosphorescent emitters to more recent hybrid and TADF (Thermally Activated Delayed Fluorescence) systems. Each iteration has improved efficiency and color quality, but stability issues persist across all variants. Understanding how these different WOLED architectures respond to dynamic stress conditions is essential for developing more robust devices.

Current stability assessment methods primarily focus on accelerated aging under constant current or brightness conditions. These approaches, while standardized, fail to capture the complex degradation patterns that occur during actual device operation, where brightness levels, ambient temperatures, and usage patterns fluctuate continuously. The technical objective of dynamic stress testing is to bridge this gap between laboratory evaluation and real-world performance.

Recent research indicates that transient electrical stresses, such as voltage spikes and current fluctuations, can trigger unique degradation pathways in organic semiconductor materials. These pathways include charge trapping, interfacial degradation, and molecular reorganization that may not be activated under static testing conditions. By systematically investigating these phenomena through dynamic stress protocols, we aim to develop comprehensive stability models that can predict device lifetime more accurately.

The ultimate goal of this technical investigation is threefold: first, to establish standardized dynamic stress testing protocols that can be widely adopted by the industry; second, to identify the fundamental physical and chemical mechanisms responsible for WOLED degradation under variable operating conditions; and third, to leverage these insights to design more stable device architectures and materials that can withstand the demands of commercial applications.

This research aligns with the broader industry trend toward more reliable and longer-lasting organic electronic devices, addressing a key barrier to market expansion for WOLED technology in premium display products and specialized lighting applications where performance consistency is paramount.

Market Demand Analysis for Stable WOLED Technologies

The global market for White Organic Light-Emitting Diodes (WOLEDs) has experienced substantial growth in recent years, driven primarily by increasing adoption in high-end displays and lighting applications. Market research indicates that the OLED display market is projected to reach $48.8 billion by 2026, with WOLEDs representing a significant segment of this market. The compound annual growth rate (CAGR) for WOLED technology specifically is estimated at 15.2% between 2021 and 2026, outpacing many other display technologies.

Consumer electronics manufacturers are increasingly demanding WOLED solutions with enhanced stability profiles, as device longevity has become a critical differentiator in premium product segments. Smartphone manufacturers report that display lifetime and consistent performance are among the top five features consumers consider when making purchasing decisions. This trend is particularly pronounced in the high-end market, where consumers expect devices to maintain visual quality for 3+ years of regular use.

The automotive industry represents an emerging high-value market for WOLED technology, with projected integration in 30% of premium vehicles by 2025. However, this application demands exceptional stability under variable temperature conditions and continuous operation, creating specific requirements for stress testing methodologies that can accurately predict performance in real-world scenarios.

Commercial and residential lighting sectors are also driving demand for stable WOLED solutions, with energy efficiency regulations in major markets like the EU, North America, and Asia-Pacific regions incentivizing the adoption of long-lasting OLED lighting. The lighting market specifically values stability under dynamic power conditions, as fixtures experience frequent on-off cycles and variable brightness settings.

Industry surveys reveal that manufacturers are willing to pay a 20-30% premium for WOLED components that demonstrate superior stability under dynamic stress conditions, highlighting the economic value of advanced testing methodologies. This premium is justified by reduced warranty claims and enhanced brand reputation for end-product manufacturers.

The development of international standards for WOLED stability testing is currently underway, with major industry consortiums working to establish unified testing protocols. This standardization effort reflects market recognition that current static testing methods inadequately predict real-world performance, creating opportunities for testing innovations that better simulate dynamic usage patterns.

Healthcare displays, aerospace instrumentation, and other mission-critical applications represent specialized market segments with exceptionally stringent stability requirements, where performance degradation can have serious consequences. These niche markets, while smaller in volume, offer higher margins and are willing to invest significantly in advanced stability testing and validation.

Consumer electronics manufacturers are increasingly demanding WOLED solutions with enhanced stability profiles, as device longevity has become a critical differentiator in premium product segments. Smartphone manufacturers report that display lifetime and consistent performance are among the top five features consumers consider when making purchasing decisions. This trend is particularly pronounced in the high-end market, where consumers expect devices to maintain visual quality for 3+ years of regular use.

The automotive industry represents an emerging high-value market for WOLED technology, with projected integration in 30% of premium vehicles by 2025. However, this application demands exceptional stability under variable temperature conditions and continuous operation, creating specific requirements for stress testing methodologies that can accurately predict performance in real-world scenarios.

Commercial and residential lighting sectors are also driving demand for stable WOLED solutions, with energy efficiency regulations in major markets like the EU, North America, and Asia-Pacific regions incentivizing the adoption of long-lasting OLED lighting. The lighting market specifically values stability under dynamic power conditions, as fixtures experience frequent on-off cycles and variable brightness settings.

Industry surveys reveal that manufacturers are willing to pay a 20-30% premium for WOLED components that demonstrate superior stability under dynamic stress conditions, highlighting the economic value of advanced testing methodologies. This premium is justified by reduced warranty claims and enhanced brand reputation for end-product manufacturers.

The development of international standards for WOLED stability testing is currently underway, with major industry consortiums working to establish unified testing protocols. This standardization effort reflects market recognition that current static testing methods inadequately predict real-world performance, creating opportunities for testing innovations that better simulate dynamic usage patterns.

Healthcare displays, aerospace instrumentation, and other mission-critical applications represent specialized market segments with exceptionally stringent stability requirements, where performance degradation can have serious consequences. These niche markets, while smaller in volume, offer higher margins and are willing to invest significantly in advanced stability testing and validation.

Current WOLED Stability Challenges and Limitations

Despite significant advancements in WOLED (White Organic Light-Emitting Diode) technology, stability remains a critical challenge that impedes broader commercial adoption. Current WOLEDs exhibit several stability limitations that become particularly evident under dynamic stress conditions, which more accurately reflect real-world usage scenarios than static testing protocols.

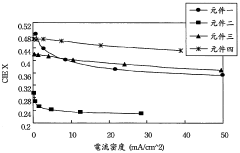

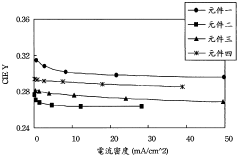

The primary stability challenge facing WOLEDs is differential aging of the various emissive components. Blue emitters typically degrade faster than red and green counterparts, leading to color shift over time. This differential degradation is exacerbated under dynamic operating conditions where voltage and current fluctuations occur frequently, causing unpredictable shifts in color coordinates and luminance efficiency.

Thermal instability presents another significant limitation. During operation, WOLEDs generate considerable heat, particularly at high brightness levels. This thermal stress accelerates molecular degradation processes within the organic layers, including morphological changes, interfacial degradation, and chemical decomposition. Dynamic stress testing reveals that temperature fluctuations, rather than constant elevated temperatures, may trigger more severe degradation mechanisms through repeated expansion and contraction cycles.

Moisture and oxygen sensitivity continue to plague WOLED technology. Even with advanced encapsulation techniques, gradual ingress of environmental contaminants remains problematic. Under dynamic stress conditions, the mechanical strain from thermal cycling can compromise encapsulation integrity, accelerating degradation through oxidation and hydrolysis of the organic materials.

Interface stability between different functional layers represents another critical limitation. Current WOLED architectures rely on multiple interfaces between charge transport layers, host materials, and emissive dopants. These interfaces are particularly vulnerable to electrochemical reactions under fluctuating electrical fields, leading to increased charge trapping sites and non-radiative recombination centers.

Driving circuit interactions also present challenges for WOLED stability. Modern display applications require complex driving schemes with varying duty cycles and brightness levels. Current compensation circuits cannot fully account for the non-linear aging characteristics of WOLEDs under dynamic stress conditions, resulting in uneven pixel aging across display panels.

Manufacturing inconsistencies further compound stability issues. Variations in layer thickness, dopant concentration, and material purity introduce unpredictable degradation patterns that become more pronounced under dynamic operating conditions. These manufacturing tolerances make it difficult to develop universal stability models and compensation algorithms.

The lack of standardized dynamic stress testing protocols represents a significant gap in current WOLED development. Most stability assessments rely on accelerated aging under constant current conditions, which fails to capture the complex degradation mechanisms triggered by real-world usage patterns involving brightness changes, on-off cycling, and varying ambient conditions.

The primary stability challenge facing WOLEDs is differential aging of the various emissive components. Blue emitters typically degrade faster than red and green counterparts, leading to color shift over time. This differential degradation is exacerbated under dynamic operating conditions where voltage and current fluctuations occur frequently, causing unpredictable shifts in color coordinates and luminance efficiency.

Thermal instability presents another significant limitation. During operation, WOLEDs generate considerable heat, particularly at high brightness levels. This thermal stress accelerates molecular degradation processes within the organic layers, including morphological changes, interfacial degradation, and chemical decomposition. Dynamic stress testing reveals that temperature fluctuations, rather than constant elevated temperatures, may trigger more severe degradation mechanisms through repeated expansion and contraction cycles.

Moisture and oxygen sensitivity continue to plague WOLED technology. Even with advanced encapsulation techniques, gradual ingress of environmental contaminants remains problematic. Under dynamic stress conditions, the mechanical strain from thermal cycling can compromise encapsulation integrity, accelerating degradation through oxidation and hydrolysis of the organic materials.

Interface stability between different functional layers represents another critical limitation. Current WOLED architectures rely on multiple interfaces between charge transport layers, host materials, and emissive dopants. These interfaces are particularly vulnerable to electrochemical reactions under fluctuating electrical fields, leading to increased charge trapping sites and non-radiative recombination centers.

Driving circuit interactions also present challenges for WOLED stability. Modern display applications require complex driving schemes with varying duty cycles and brightness levels. Current compensation circuits cannot fully account for the non-linear aging characteristics of WOLEDs under dynamic stress conditions, resulting in uneven pixel aging across display panels.

Manufacturing inconsistencies further compound stability issues. Variations in layer thickness, dopant concentration, and material purity introduce unpredictable degradation patterns that become more pronounced under dynamic operating conditions. These manufacturing tolerances make it difficult to develop universal stability models and compensation algorithms.

The lack of standardized dynamic stress testing protocols represents a significant gap in current WOLED development. Most stability assessments rely on accelerated aging under constant current conditions, which fails to capture the complex degradation mechanisms triggered by real-world usage patterns involving brightness changes, on-off cycling, and varying ambient conditions.

Current Dynamic Stress Testing Methodologies

01 Material composition for improved WOLED stability

Specific material compositions can significantly enhance the stability of White Organic Light-Emitting Diodes. These include optimized combinations of host materials, dopants, and transport layers that reduce degradation mechanisms. Advanced materials such as phosphorescent compounds, metal complexes, and specially designed polymers can extend device lifetime while maintaining color balance and efficiency. The selection of materials with compatible energy levels and appropriate molecular structures helps prevent phase separation and chemical degradation during operation.- Material composition for improved WOLED stability: Various material compositions can enhance the stability of White Organic Light-Emitting Diodes. These include specific host materials, dopants, and emissive layer structures that minimize degradation mechanisms. Optimized combinations of red, green, and blue emitters with appropriate energy levels can reduce energy transfer issues and improve operational lifetime. Certain phosphorescent and fluorescent materials show superior stability characteristics when properly integrated into the device structure.

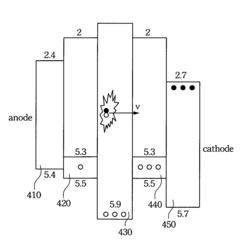

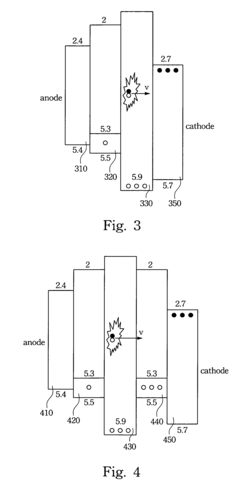

- Multi-layer structure design for WOLED stability: The arrangement and design of multiple layers in WOLEDs significantly impact device stability. Implementing buffer layers between emissive regions can prevent exciton quenching and charge accumulation at interfaces. Optimized thickness ratios between different functional layers help balance charge transport and recombination. Tandem structures with intermediate connecting layers can distribute electrical stress and extend device lifetime while maintaining color stability over time.

- Charge transport optimization for stable WOLEDs: Enhancing charge transport properties is crucial for WOLED stability. This involves designing electron and hole transport layers with balanced mobility and appropriate energy levels to ensure uniform charge distribution. Incorporating charge blocking layers prevents leakage of carriers and confines excitons within the emissive region. Gradient-doped transport layers can reduce driving voltage and operational stress, leading to improved device longevity and consistent luminance output.

- Thermal stability enhancement techniques: Thermal management is essential for WOLED stability as heat generation during operation accelerates degradation. Implementing materials with high glass transition temperatures improves resistance to morphological changes under thermal stress. Heat-dissipating structures and substrates with good thermal conductivity help maintain lower operating temperatures. Thermally activated delayed fluorescence (TADF) materials can provide efficient emission while generating less heat, contributing to extended device lifetime.

- Encapsulation and moisture barrier technologies: Protection from environmental factors is critical for WOLED stability. Advanced encapsulation techniques using multi-layer barriers prevent oxygen and moisture penetration that would otherwise cause rapid degradation of organic materials. Thin-film encapsulation with alternating organic and inorganic layers provides effective protection while maintaining device flexibility. Edge sealing technologies prevent lateral diffusion of contaminants, while getter materials incorporated into the package actively absorb residual moisture and impurities.

02 Multi-layer structure design for WOLED stability

The architecture of WOLED devices plays a crucial role in their operational stability. Multi-layer structures with carefully designed emission layers, electron/hole transport layers, and blocking layers can distribute electrical stress and heat more evenly throughout the device. Tandem structures with multiple emission units connected by charge generation layers show improved stability by reducing current density while maintaining brightness. Optimized layer thicknesses and interface engineering between organic layers help prevent degradation mechanisms and extend device lifetime.Expand Specific Solutions03 Color stability enhancement techniques

Maintaining color stability over the lifetime of WOLEDs is essential for display and lighting applications. Various approaches include using complementary emitters with similar degradation rates, implementing color compensation algorithms, and developing feedback systems that adjust driving conditions based on color shift detection. Advanced color mixing strategies with multiple emissive layers or carefully selected dopant combinations help maintain the white point even as individual emitters degrade at different rates. Encapsulation techniques that prevent differential degradation of color components also contribute to long-term color stability.Expand Specific Solutions04 Thermal management for WOLED stability

Effective thermal management is critical for enhancing WOLED stability as heat accelerates degradation mechanisms. Designs incorporating heat dissipation structures, thermally conductive substrates, and optimized device geometries help reduce operating temperatures. Advanced thermal interface materials between the OLED panel and heat sinks improve heat transfer efficiency. Active cooling systems and thermal management algorithms that adjust driving conditions based on temperature monitoring can prevent hotspots and thermal runaway, significantly extending device lifetime under high-brightness operation conditions.Expand Specific Solutions05 Encapsulation and barrier technologies

Protection from environmental factors such as moisture and oxygen is essential for WOLED stability. Advanced encapsulation technologies including thin-film encapsulation with alternating organic/inorganic layers, edge sealing techniques, and getter materials that absorb contaminants significantly extend device lifetime. Hybrid barrier films combining different materials with complementary properties provide superior protection while maintaining flexibility. Novel approaches using atomic layer deposition create ultra-thin yet highly effective barrier layers that prevent degradation without compromising optical properties or adding significant thickness to the device.Expand Specific Solutions

Key Industry Players in WOLED Development

The WOLED stability testing market is currently in a growth phase, with increasing demand for reliable testing methodologies as OLED technology matures. The competitive landscape features a mix of established electronics manufacturers, research institutions, and specialized testing companies. Wuhan China Star Optoelectronics emerges as a key player with significant panel production capacity, while academic institutions like Tokyo Institute of Technology and MIT contribute valuable research insights. The technology maturity varies across applications, with companies like AUDI AG and GlobalFoundries representing different implementation stages. The market is characterized by collaboration between industry and academia, with testing protocols becoming increasingly standardized as WOLED applications expand beyond displays into automotive and industrial sectors.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has established a comprehensive WOLED dynamic stress testing program that combines electrical, optical, and thermal characterization under variable operating conditions. Their approach utilizes custom-designed test chambers that enable precise control of environmental factors (temperature, humidity, ambient light) while applying programmed electrical stress patterns. The research team has developed specialized imaging techniques that allow for spatial mapping of degradation across WOLED panels during dynamic operation, revealing how non-uniform current distribution affects device stability. Their methodology includes frequency-dependent impedance spectroscopy synchronized with optical measurements to correlate electrical characteristics with light emission properties under stress. The university has made significant contributions to understanding how dynamic driving affects different layers within the WOLED stack, particularly focusing on the interaction between charge transport layers and emissive materials during current transients. Their research has demonstrated that certain dynamic driving schemes can actually improve device stability compared to DC operation by allowing for partial recovery of degraded sites during low-current periods.

Strengths: Holistic approach combining multiple characterization techniques; spatial resolution capabilities that identify non-uniform degradation patterns; innovative findings regarding potential stability benefits of specific dynamic driving schemes. Weaknesses: Complex multi-parameter testing approach may be challenging to standardize across the industry; specialized equipment requirements may limit widespread adoption of testing methodologies.

Wuhan China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: Wuhan China Star Optoelectronics has developed a comprehensive WOLED (White Organic Light-Emitting Diode) dynamic stress testing platform that combines electrical, thermal, and optical stress factors to evaluate device stability. Their approach utilizes accelerated aging protocols with variable current densities (30-90 mA/cm²) and elevated temperatures (40-85°C) while continuously monitoring luminance decay, voltage shift, and color coordinates. The company employs a proprietary algorithm that correlates dynamic stress test results with predicted lifetime performance, allowing for rapid assessment of material combinations and device architectures. Their testing methodology includes intermittent recovery periods to simulate real-world usage patterns and evaluate the reversible and irreversible degradation mechanisms in WOLED panels. This approach has enabled them to develop more stable blue emitter systems that traditionally represent the weakest link in WOLED longevity.

Strengths: Comprehensive multi-factor stress testing that closely simulates real-world usage conditions; proprietary predictive algorithms that accelerate development cycles; specialized expertise in blue emitter stability which is critical for WOLED longevity. Weaknesses: Testing methodology may be optimized for their specific panel designs and materials, potentially limiting applicability to other WOLED architectures; resource-intensive testing protocols require significant equipment investment.

Critical Technical Innovations in WOLED Stability

White organic light-emitting diode

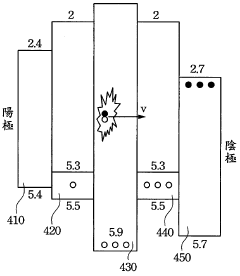

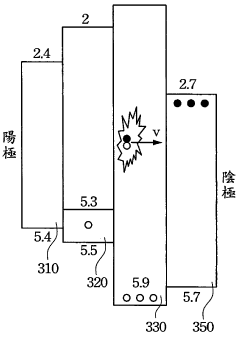

PatentActiveUS7723914B2

Innovation

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

White organic light emitting diode

PatentInactiveTW200708189A

Innovation

- A symmetrical WOLED structure is introduced with symmetrical light-emitting layers flanking a middle emitting layer, compensating for reduced luminescence in one layer by increasing luminescence in the other, thereby stabilizing light emission across varying voltages.

Reliability Standards and Certification Requirements

The reliability of WOLED (White Organic Light-Emitting Diode) technology must adhere to stringent industry standards and certification requirements to ensure market acceptance and long-term performance. Currently, several key standards govern WOLED reliability testing under dynamic stress conditions, including the International Electrotechnical Commission (IEC) 62341 series specifically for OLED displays and the JEDEC JESD22 standards for electronic component reliability.

For consumer electronics applications, WOLED displays must typically meet a minimum lifetime of 30,000-50,000 hours with less than 50% luminance degradation under normal operating conditions. More demanding applications such as automotive displays require certification under AEC-Q200 standards, which mandate reliability under extreme temperature cycling (-40°C to 85°C) and high humidity conditions (85% RH at 85°C).

Dynamic stress testing protocols for WOLEDs generally include accelerated aging tests that simulate real-world usage patterns. These tests must follow standardized procedures such as those outlined in VESA's Display Measurement Standard, which specifies precise methodologies for measuring display performance under various conditions. The ISO 9241-307 standard additionally provides guidelines for ergonomic requirements and evaluation methods for electronic visual displays.

Certification bodies like UL (Underwriters Laboratories) and TÜV require WOLED manufacturers to demonstrate compliance with safety standards including UL 8752 for organic light-emitting diode displays and IEC 61747 for liquid crystal and solid-state display devices. These certifications evaluate not only performance stability but also safety aspects under electrical, thermal, and mechanical stress conditions.

For dynamic stress testing specifically, manufacturers must implement test protocols that simulate varying brightness levels, on-off cycling, and different content patterns. The IDMS (Information Display Measurements Standard) provides specific test patterns and measurement methodologies that have become industry benchmarks for evaluating display stability under dynamic operating conditions.

Emerging standards are beginning to address the unique challenges of flexible and foldable WOLED displays, with organizations like the Flexible Display Center developing specialized reliability metrics for bendable displays. These include cycle testing requirements of 100,000 to 200,000 folds without significant performance degradation for consumer-grade flexible displays.

Compliance with these standards not only ensures product reliability but also facilitates global market access, as many regions have adopted these international standards as part of their regulatory frameworks for electronic displays and lighting products.

For consumer electronics applications, WOLED displays must typically meet a minimum lifetime of 30,000-50,000 hours with less than 50% luminance degradation under normal operating conditions. More demanding applications such as automotive displays require certification under AEC-Q200 standards, which mandate reliability under extreme temperature cycling (-40°C to 85°C) and high humidity conditions (85% RH at 85°C).

Dynamic stress testing protocols for WOLEDs generally include accelerated aging tests that simulate real-world usage patterns. These tests must follow standardized procedures such as those outlined in VESA's Display Measurement Standard, which specifies precise methodologies for measuring display performance under various conditions. The ISO 9241-307 standard additionally provides guidelines for ergonomic requirements and evaluation methods for electronic visual displays.

Certification bodies like UL (Underwriters Laboratories) and TÜV require WOLED manufacturers to demonstrate compliance with safety standards including UL 8752 for organic light-emitting diode displays and IEC 61747 for liquid crystal and solid-state display devices. These certifications evaluate not only performance stability but also safety aspects under electrical, thermal, and mechanical stress conditions.

For dynamic stress testing specifically, manufacturers must implement test protocols that simulate varying brightness levels, on-off cycling, and different content patterns. The IDMS (Information Display Measurements Standard) provides specific test patterns and measurement methodologies that have become industry benchmarks for evaluating display stability under dynamic operating conditions.

Emerging standards are beginning to address the unique challenges of flexible and foldable WOLED displays, with organizations like the Flexible Display Center developing specialized reliability metrics for bendable displays. These include cycle testing requirements of 100,000 to 200,000 folds without significant performance degradation for consumer-grade flexible displays.

Compliance with these standards not only ensures product reliability but also facilitates global market access, as many regions have adopted these international standards as part of their regulatory frameworks for electronic displays and lighting products.

Environmental Impact of WOLED Manufacturing Processes

The manufacturing processes of White Organic Light-Emitting Diodes (WOLEDs) involve several stages that can have significant environmental implications. The production of WOLED panels requires various chemicals, including heavy metals, organic compounds, and solvents, many of which are potentially hazardous to the environment if not properly managed. Particularly concerning are the perfluorinated compounds (PFCs) used in certain manufacturing steps, which have high global warming potentials and long atmospheric lifetimes.

Energy consumption represents another major environmental concern in WOLED manufacturing. The production facilities operate continuously and require substantial electricity for processes such as vapor deposition, encapsulation, and quality control testing. This energy demand contributes significantly to the carbon footprint of WOLED devices, especially when power is sourced from fossil fuel-based electricity grids.

Water usage in WOLED manufacturing is also considerable, primarily for cleaning processes and cooling systems. The wastewater generated often contains trace amounts of organic solvents and metal particles that require specialized treatment before discharge. Studies indicate that a typical WOLED manufacturing facility may consume between 5-10 million gallons of water annually, depending on production capacity and efficiency measures implemented.

Waste generation presents additional environmental challenges. The manufacturing yield for high-performance WOLEDs used in dynamic stress testing applications typically ranges from 70-85%, meaning that 15-30% of materials become waste. This includes substrate materials, partially completed panels that fail quality checks, and chemical waste from various production stages. The disposal or recycling of these materials requires careful management to prevent environmental contamination.

Recent advancements in green manufacturing techniques are beginning to address these environmental concerns. Closed-loop solvent recovery systems can recapture and purify up to 90% of solvents used in production. Water recycling technologies have demonstrated potential to reduce freshwater consumption by 40-60% in newer facilities. Additionally, some manufacturers have begun implementing renewable energy sources to power their production lines, with several major WOLED producers committing to 100% renewable energy targets by 2030.

When conducting dynamic stress testing for WOLED stability insights, researchers must also consider the environmental impact of the testing procedures themselves. Accelerated aging tests often require continuous operation of multiple panels under various stress conditions, consuming significant energy over extended periods. The development of more efficient testing protocols that can deliver equivalent stability insights with reduced environmental impact represents an important area for future research and development.

Energy consumption represents another major environmental concern in WOLED manufacturing. The production facilities operate continuously and require substantial electricity for processes such as vapor deposition, encapsulation, and quality control testing. This energy demand contributes significantly to the carbon footprint of WOLED devices, especially when power is sourced from fossil fuel-based electricity grids.

Water usage in WOLED manufacturing is also considerable, primarily for cleaning processes and cooling systems. The wastewater generated often contains trace amounts of organic solvents and metal particles that require specialized treatment before discharge. Studies indicate that a typical WOLED manufacturing facility may consume between 5-10 million gallons of water annually, depending on production capacity and efficiency measures implemented.

Waste generation presents additional environmental challenges. The manufacturing yield for high-performance WOLEDs used in dynamic stress testing applications typically ranges from 70-85%, meaning that 15-30% of materials become waste. This includes substrate materials, partially completed panels that fail quality checks, and chemical waste from various production stages. The disposal or recycling of these materials requires careful management to prevent environmental contamination.

Recent advancements in green manufacturing techniques are beginning to address these environmental concerns. Closed-loop solvent recovery systems can recapture and purify up to 90% of solvents used in production. Water recycling technologies have demonstrated potential to reduce freshwater consumption by 40-60% in newer facilities. Additionally, some manufacturers have begun implementing renewable energy sources to power their production lines, with several major WOLED producers committing to 100% renewable energy targets by 2030.

When conducting dynamic stress testing for WOLED stability insights, researchers must also consider the environmental impact of the testing procedures themselves. Accelerated aging tests often require continuous operation of multiple panels under various stress conditions, consuming significant energy over extended periods. The development of more efficient testing protocols that can deliver equivalent stability insights with reduced environmental impact represents an important area for future research and development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!