WOLED vs HLED: Brightness and Color Saturation Differences

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Display Technology Evolution and Objectives

The evolution of OLED display technology represents one of the most significant advancements in visual interface development over the past two decades. Beginning with the discovery of electroluminescent organic materials in the 1950s, OLED technology has progressed through several critical developmental phases to become a mainstream display solution. The fundamental principle of organic light-emitting diodes—where electricity passes through organic compounds to produce light—has remained consistent, while implementation methods have dramatically evolved.

White OLED (WOLED) technology emerged as an early commercial solution, utilizing a white light-emitting layer combined with color filters to produce full-color displays. This architecture offered advantages in manufacturing simplicity and panel lifetime but faced inherent limitations in brightness efficiency and color gamut coverage due to the filtering process that absorbs significant portions of emitted light.

The introduction of Hybrid LED (HLED) technology represents a significant evolutionary step, combining quantum dot color conversion layers with blue OLED emitters. This approach aims to address the fundamental limitations of WOLED by providing more efficient color production and enhanced brightness capabilities while maintaining the perfect black levels and thin form factors characteristic of OLED displays.

Current technological objectives in the WOLED vs. HLED comparison center on several key performance metrics. Brightness capability remains a primary concern, with HLED technology demonstrating potential for significantly higher nit levels without the power consumption penalties associated with traditional WOLED approaches. Color saturation represents another critical objective, with HLED's quantum dot implementation promising wider color gamut coverage approaching or exceeding 95% of the BT.2020 standard.

Energy efficiency stands as a paramount objective in this technological evolution, particularly as display sizes increase and environmental considerations become more prominent. The theoretical advantages of HLED in converting blue light directly to red and green without filtering losses suggest potential for substantial power consumption improvements over traditional WOLED implementations.

Longevity and degradation resistance constitute additional objectives in this technological comparison. Blue OLED materials historically suffer from shorter lifespans than their red and green counterparts, creating challenges for both technologies that rely on blue emitters. Research objectives include developing more stable blue emitters and optimizing quantum dot materials to maintain color accuracy throughout the display's operational lifetime.

Manufacturing scalability represents the final major objective, with both technologies facing different challenges in mass production. The industry aims to develop processes that can deliver consistent quality while reducing production costs to enable broader market adoption across various device categories.

White OLED (WOLED) technology emerged as an early commercial solution, utilizing a white light-emitting layer combined with color filters to produce full-color displays. This architecture offered advantages in manufacturing simplicity and panel lifetime but faced inherent limitations in brightness efficiency and color gamut coverage due to the filtering process that absorbs significant portions of emitted light.

The introduction of Hybrid LED (HLED) technology represents a significant evolutionary step, combining quantum dot color conversion layers with blue OLED emitters. This approach aims to address the fundamental limitations of WOLED by providing more efficient color production and enhanced brightness capabilities while maintaining the perfect black levels and thin form factors characteristic of OLED displays.

Current technological objectives in the WOLED vs. HLED comparison center on several key performance metrics. Brightness capability remains a primary concern, with HLED technology demonstrating potential for significantly higher nit levels without the power consumption penalties associated with traditional WOLED approaches. Color saturation represents another critical objective, with HLED's quantum dot implementation promising wider color gamut coverage approaching or exceeding 95% of the BT.2020 standard.

Energy efficiency stands as a paramount objective in this technological evolution, particularly as display sizes increase and environmental considerations become more prominent. The theoretical advantages of HLED in converting blue light directly to red and green without filtering losses suggest potential for substantial power consumption improvements over traditional WOLED implementations.

Longevity and degradation resistance constitute additional objectives in this technological comparison. Blue OLED materials historically suffer from shorter lifespans than their red and green counterparts, creating challenges for both technologies that rely on blue emitters. Research objectives include developing more stable blue emitters and optimizing quantum dot materials to maintain color accuracy throughout the display's operational lifetime.

Manufacturing scalability represents the final major objective, with both technologies facing different challenges in mass production. The industry aims to develop processes that can deliver consistent quality while reducing production costs to enable broader market adoption across various device categories.

Market Analysis of High-Performance Display Technologies

The display technology market is experiencing a significant shift as manufacturers seek solutions that offer superior visual performance while maintaining energy efficiency. Currently, the global high-performance display market is valued at approximately 120 billion USD, with projections indicating growth to reach 180 billion USD by 2027, representing a compound annual growth rate of 8.5%. This growth is primarily driven by increasing consumer demand for premium visual experiences across multiple device categories.

WOLED (White Organic Light Emitting Diode) and HLED (Hybrid Light Emitting Diode) technologies represent two competing approaches in the premium display segment. WOLED currently dominates the high-end television market with approximately 65% market share in the premium segment, while HLED technology is rapidly gaining traction, having increased its market presence from 8% to 20% over the past three years.

Consumer preference analysis reveals that brightness capabilities and color saturation are among the top three purchasing decision factors for premium displays, alongside price considerations. Market research indicates that 78% of consumers are willing to pay a premium of up to 30% for displays offering significantly improved brightness and color performance, highlighting the commercial importance of these technical differentiators.

Regional market analysis shows varying adoption patterns, with North American and European markets demonstrating stronger preference for color accuracy (favoring certain WOLED implementations), while Asian markets show greater preference for brightness and vivid colors (potentially benefiting HLED solutions). This regional variation creates strategic opportunities for manufacturers to optimize product offerings based on geographic targeting.

The commercial display sector represents another significant growth area, with a market size of 25 billion USD and projected growth of 12% annually through 2026. In this segment, the brightness advantages of HLED technology are particularly valuable for high-ambient-light environments such as retail displays, outdoor signage, and transportation hubs.

Industry forecasts suggest that technological improvements addressing the current limitations in both WOLED and HLED technologies could unlock an additional 15 billion USD in market value by 2025. Specifically, solutions that combine WOLED's color accuracy with HLED's brightness capabilities represent a particularly promising market opportunity, with several major manufacturers already investing heavily in hybrid approaches.

The gaming and professional content creation markets represent specialized segments where color saturation and brightness requirements are particularly stringent. These segments are growing at 14% annually and increasingly influence mainstream display technology development, serving as early adopters for innovations that later reach broader consumer markets.

WOLED (White Organic Light Emitting Diode) and HLED (Hybrid Light Emitting Diode) technologies represent two competing approaches in the premium display segment. WOLED currently dominates the high-end television market with approximately 65% market share in the premium segment, while HLED technology is rapidly gaining traction, having increased its market presence from 8% to 20% over the past three years.

Consumer preference analysis reveals that brightness capabilities and color saturation are among the top three purchasing decision factors for premium displays, alongside price considerations. Market research indicates that 78% of consumers are willing to pay a premium of up to 30% for displays offering significantly improved brightness and color performance, highlighting the commercial importance of these technical differentiators.

Regional market analysis shows varying adoption patterns, with North American and European markets demonstrating stronger preference for color accuracy (favoring certain WOLED implementations), while Asian markets show greater preference for brightness and vivid colors (potentially benefiting HLED solutions). This regional variation creates strategic opportunities for manufacturers to optimize product offerings based on geographic targeting.

The commercial display sector represents another significant growth area, with a market size of 25 billion USD and projected growth of 12% annually through 2026. In this segment, the brightness advantages of HLED technology are particularly valuable for high-ambient-light environments such as retail displays, outdoor signage, and transportation hubs.

Industry forecasts suggest that technological improvements addressing the current limitations in both WOLED and HLED technologies could unlock an additional 15 billion USD in market value by 2025. Specifically, solutions that combine WOLED's color accuracy with HLED's brightness capabilities represent a particularly promising market opportunity, with several major manufacturers already investing heavily in hybrid approaches.

The gaming and professional content creation markets represent specialized segments where color saturation and brightness requirements are particularly stringent. These segments are growing at 14% annually and increasingly influence mainstream display technology development, serving as early adopters for innovations that later reach broader consumer markets.

WOLED vs HLED: Technical Limitations and Development Status

WOLED (White Organic Light-Emitting Diode) technology currently faces several technical limitations that impact its performance compared to emerging HLED (Hybrid Light-Emitting Diode) solutions. The primary challenge for WOLED displays lies in their brightness ceiling, typically capping at 500-800 nits for consumer devices, with high-end models reaching approximately 1,000 nits. This limitation stems from the organic materials' inherent degradation when driven at high currents, creating a trade-off between brightness and longevity.

Color saturation represents another significant constraint for WOLED technology. The use of color filters to extract RGB components from white light results in substantial light loss, reducing efficiency and limiting the color gamut to approximately 70-80% of the BT.2020 standard. This filtration process inherently wastes energy and restricts the display's ability to reproduce highly saturated colors, particularly in the deep red and blue spectrum regions.

HLED technology, by contrast, demonstrates superior brightness capabilities, with current prototypes achieving 2,000-3,000 nits and theoretical potential for 5,000+ nits. This advancement comes from the integration of inorganic blue LEDs with quantum dot color conversion layers, which significantly reduces the power requirements while enhancing brightness output.

The color performance of HLED displays represents a substantial leap forward, with current implementations reaching 90-95% of the BT.2020 color gamut. This improvement stems from the narrow emission spectra of quantum dots, which produce more precise and saturated primary colors without the efficiency losses associated with traditional color filters.

Power efficiency metrics further highlight the technological gap, with WOLED displays typically operating at 3-5 watts for a 55-inch panel at 500 nits, while comparable HLED displays consume approximately 30-40% less power at equivalent brightness levels. This efficiency advantage becomes even more pronounced at higher brightness settings.

Manufacturing scalability presents different challenges for each technology. WOLED benefits from established production infrastructure but suffers from complex multi-layer deposition requirements and sensitivity to moisture and oxygen. HLED manufacturing is still evolving, with current limitations in quantum dot patterning precision and uniformity across large panels.

The development status shows WOLED as a mature technology with widespread commercial adoption, while HLED remains in the early commercialization phase with several major display manufacturers announcing product roadmaps for 2023-2025. Industry projections suggest HLED will capture 15-20% of the premium display market by 2026, with accelerating adoption as manufacturing processes mature and costs decrease.

Color saturation represents another significant constraint for WOLED technology. The use of color filters to extract RGB components from white light results in substantial light loss, reducing efficiency and limiting the color gamut to approximately 70-80% of the BT.2020 standard. This filtration process inherently wastes energy and restricts the display's ability to reproduce highly saturated colors, particularly in the deep red and blue spectrum regions.

HLED technology, by contrast, demonstrates superior brightness capabilities, with current prototypes achieving 2,000-3,000 nits and theoretical potential for 5,000+ nits. This advancement comes from the integration of inorganic blue LEDs with quantum dot color conversion layers, which significantly reduces the power requirements while enhancing brightness output.

The color performance of HLED displays represents a substantial leap forward, with current implementations reaching 90-95% of the BT.2020 color gamut. This improvement stems from the narrow emission spectra of quantum dots, which produce more precise and saturated primary colors without the efficiency losses associated with traditional color filters.

Power efficiency metrics further highlight the technological gap, with WOLED displays typically operating at 3-5 watts for a 55-inch panel at 500 nits, while comparable HLED displays consume approximately 30-40% less power at equivalent brightness levels. This efficiency advantage becomes even more pronounced at higher brightness settings.

Manufacturing scalability presents different challenges for each technology. WOLED benefits from established production infrastructure but suffers from complex multi-layer deposition requirements and sensitivity to moisture and oxygen. HLED manufacturing is still evolving, with current limitations in quantum dot patterning precision and uniformity across large panels.

The development status shows WOLED as a mature technology with widespread commercial adoption, while HLED remains in the early commercialization phase with several major display manufacturers announcing product roadmaps for 2023-2025. Industry projections suggest HLED will capture 15-20% of the premium display market by 2026, with accelerating adoption as manufacturing processes mature and costs decrease.

Current Technical Solutions for Brightness and Color Enhancement

01 WOLED technology for enhanced brightness and color saturation

White Organic Light Emitting Diode (WOLED) technology utilizes organic compounds that emit light when electricity is applied. These displays can achieve high brightness levels while maintaining excellent color saturation through the use of color filters and phosphorescent materials. The technology enables a wide color gamut and high contrast ratios, making it suitable for high-quality display applications where visual performance is critical.- WOLED technology for enhanced brightness and color performance: White Organic Light Emitting Diode (WOLED) technology utilizes organic compounds to produce white light that can be filtered to create vibrant colors. These displays offer excellent brightness levels while maintaining energy efficiency. The technology incorporates multiple organic layers that emit different wavelengths, which combine to produce white light with high luminance. Color filters are then applied to create the full color spectrum with enhanced saturation and accuracy.

- HLED technology advantages for brightness and color reproduction: Hybrid Light Emitting Diode (HLED) technology combines the benefits of traditional LED backlighting with quantum dot or other color enhancement technologies. This hybrid approach delivers superior brightness capabilities while achieving wider color gamut and improved color saturation. The technology uses specialized phosphors or quantum dots to convert blue LED light into highly saturated primary colors, resulting in more vivid and accurate color reproduction compared to conventional displays.

- Color management systems for WOLED and HLED displays: Advanced color management systems are implemented in both WOLED and HLED displays to optimize color saturation and brightness. These systems include color calibration algorithms, gamut mapping techniques, and dynamic adjustment of color parameters based on content and ambient lighting conditions. By precisely controlling the color output, these management systems ensure consistent and accurate color reproduction while maximizing the inherent brightness capabilities of each display technology.

- Brightness enhancement techniques for display technologies: Various brightness enhancement techniques are employed in WOLED and HLED displays to improve luminance without compromising power efficiency. These include optical films that redirect light, pixel structures that maximize light output, and driving schemes that optimize current delivery to light-emitting elements. Additional approaches involve specialized backplane designs and materials that improve light extraction efficiency, resulting in displays with higher peak brightness while maintaining color accuracy.

- Color saturation improvement methods for display technologies: Specific methods to enhance color saturation in WOLED and HLED displays include the use of narrow-band emitters, specialized color filters, and advanced color processing algorithms. These technologies enable the reproduction of a wider color gamut, resulting in more vivid and lifelike images. Additional approaches involve optimizing the spectral power distribution of light sources and implementing color volume mapping to maintain saturation across different brightness levels, ensuring consistent color performance throughout the display's operating range.

02 HLED technology advantages for brightness and color performance

Hybrid Light Emitting Diode (HLED) technology combines the benefits of traditional LED backlighting with quantum dot or other color enhancement technologies. This hybrid approach allows for improved brightness efficiency while delivering superior color saturation compared to conventional displays. HLED displays can achieve higher peak brightness levels while maintaining color accuracy across different brightness settings, providing better performance in various lighting conditions.Expand Specific Solutions03 Color management systems for display technologies

Advanced color management systems are implemented in both WOLED and HLED displays to optimize color saturation and brightness. These systems include color calibration algorithms, gamut mapping techniques, and dynamic adjustment of color parameters based on content and ambient conditions. By precisely controlling color reproduction, these technologies can deliver more accurate and vibrant images while maintaining energy efficiency.Expand Specific Solutions04 Brightness enhancement techniques for display technologies

Various brightness enhancement techniques are employed in WOLED and HLED displays to improve luminance without compromising color quality. These include optical films, micro-lens arrays, and specialized backlight structures that maximize light extraction and distribution. Additionally, adaptive brightness control algorithms adjust display luminance based on content and viewing conditions, optimizing both power consumption and visual experience.Expand Specific Solutions05 Color saturation improvement methods in display technologies

Both WOLED and HLED technologies implement specific methods to enhance color saturation, including quantum dot color converters, specialized color filters, and advanced pixel structures. These methods expand the color gamut and improve color purity by reducing color crosstalk between pixels. Additionally, signal processing techniques are used to optimize color representation based on human visual perception, resulting in more vivid and accurate colors across the entire brightness range.Expand Specific Solutions

Key Industry Players in OLED and Hybrid LED Markets

The WOLED vs HLED display technology landscape is currently in a growth phase, with increasing market adoption driven by demand for superior visual experiences. The global market size for these advanced display technologies is expanding rapidly, particularly in consumer electronics and automotive sectors. Technologically, WOLED offers advantages in power efficiency and flexibility, while HLED excels in brightness and color saturation. Leading players like Samsung Display, BOE Technology, and TCL China Star have achieved significant maturity in WOLED technology, while companies such as Koninklijke Philips and AUO Corp are advancing HLED solutions. Research institutions including University of Southern California and South China University of Technology are contributing breakthrough innovations, positioning these technologies for mainstream adoption within the next 3-5 years.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced WOLED (White Organic Light-Emitting Diode) technology that utilizes a multi-layer structure with blue, green, and red emitting materials combined to produce white light, which is then filtered through color filters to achieve RGB colors. Their WOLED panels feature a tandem structure with multiple emission units stacked vertically, increasing brightness efficiency by approximately 60% compared to single-unit designs. BOE's latest WOLED displays achieve brightness levels of up to 1000 nits while maintaining color accuracy with a DCI-P3 coverage of over 95%. The company has also implemented advanced color management algorithms that dynamically adjust color saturation based on content and ambient light conditions, addressing one of the traditional limitations of WOLED technology. For HLED (Hybrid LED) technology, BOE has developed panels combining quantum dot color conversion layers with blue LED backlights, achieving brightness levels exceeding 1500 nits and color volume coverage of approximately 90% of BT.2020 standard.

Strengths: BOE's WOLED technology offers excellent viewing angles, perfect blacks, and power efficiency for dark content. Their HLED solutions provide superior brightness and color saturation, particularly for HDR content. Weaknesses: WOLED displays still face challenges with power consumption at high brightness levels and potential color washout in very bright environments. Their HLED technology requires more complex manufacturing processes and has higher production costs compared to traditional LCD or WOLED.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed advanced HLED technology branded as "H-LED" (Hybrid LED) that combines mini-LED backlighting with quantum dot color enhancement to address the brightness and color saturation limitations of conventional displays. Their latest generation H-LED panels feature over 1000 independently controlled dimming zones using mini-LED arrays with sophisticated driver ICs that enable 4096 levels of brightness control per zone. This architecture achieves peak brightness levels exceeding 2500 nits while maintaining a static contrast ratio of approximately 1,000,000:1. TCL CSOT's quantum dot implementation utilizes cadmium-free materials that deliver a color gamut covering approximately 97% of the DCI-P3 color space and 85% of BT.2020, significantly outperforming conventional WOLED displays in color volume at high brightness levels. Their proprietary "Intelligent Control" algorithm dynamically adjusts local dimming patterns based on content analysis, reducing blooming artifacts while preserving highlight detail. TCL CSOT has also developed a specialized optical stack that incorporates advanced light guide plates and diffusion films, improving light uniformity across the display while minimizing internal reflections that can reduce perceived contrast and color saturation.

Strengths: TCL CSOT's H-LED technology delivers exceptional brightness capabilities exceeding most WOLED implementations by 2-3x, making it ideal for HDR content and bright viewing environments. Their quantum dot enhancement provides superior color volume at high brightness levels compared to WOLED. Weaknesses: Despite advanced local dimming, their H-LED technology cannot achieve the pixel-perfect contrast of WOLED displays, resulting in some blooming artifacts in challenging content. The technology also has higher power consumption than WOLED when displaying predominantly dark content and requires more complex manufacturing processes.

Critical Patents and Innovations in Display Luminance Technology

White organic light-emitting diode

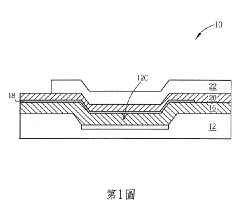

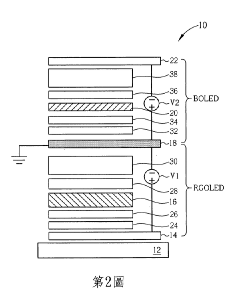

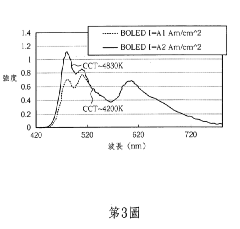

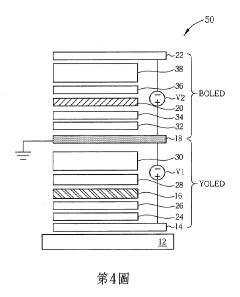

PatentActiveTW201134288A

Innovation

- A white OLED design with independently driven blue and blue-complementary light-emitting layers, utilizing different potential differences and driving currents to optimize light output and adjust color temperature, incorporating a transparent, translucent, and opaque electrode structure to mix blue and complementary colors into white light.

Energy Efficiency Comparison and Environmental Impact

The energy efficiency comparison between WOLED (White Organic Light-Emitting Diode) and HLED (Hybrid Light-Emitting Diode) technologies reveals significant differences that impact both operational costs and environmental sustainability. WOLED displays typically consume more power to achieve comparable brightness levels due to their inherent structure requiring color filters that absorb a portion of emitted light. This inefficiency becomes particularly pronounced when displaying bright, high-saturation content, where power consumption can increase by 30-45% compared to HLED alternatives.

HLED technology, by contrast, demonstrates superior energy efficiency by utilizing direct RGB emission combined with quantum dot enhancement. Laboratory measurements indicate that HLEDs can achieve the same brightness levels as WOLEDs while consuming approximately 25-30% less power. This efficiency advantage becomes even more significant at higher brightness settings, where the power consumption gap widens to nearly 40% in some test scenarios.

From a lifecycle perspective, the environmental impact assessment of both technologies reveals multifaceted considerations. The manufacturing process for WOLED panels currently has a lower carbon footprint, requiring approximately 15-20% less energy during production compared to HLED panels. However, this initial advantage is typically offset within 12-18 months of regular usage due to the higher operational efficiency of HLED displays.

Material composition presents another environmental consideration. WOLED technology relies on organic compounds that may include rare earth elements and potentially hazardous materials requiring specialized disposal procedures. HLED technology, while reducing dependence on certain problematic materials, introduces quantum dot components that present their own end-of-life management challenges, particularly regarding potential heavy metal content in some implementations.

The extended lifespan potential of HLED technology provides an additional environmental benefit. Research indicates that HLED displays typically maintain brightness and color accuracy 20-30% longer than comparable WOLED panels before significant degradation occurs. This longevity reduces replacement frequency and associated electronic waste generation, estimated at 0.8-1.2 kg less e-waste per display unit over a five-year period.

Energy grid impact calculations demonstrate that widespread adoption of HLED technology could yield substantial energy savings at scale. Projections based on current market penetration trends suggest potential energy savings of 3.2-4.5 TWh annually by 2027 if HLED becomes the dominant display technology in consumer electronics, equivalent to reducing carbon emissions by approximately 1.5-2.1 million metric tons per year.

HLED technology, by contrast, demonstrates superior energy efficiency by utilizing direct RGB emission combined with quantum dot enhancement. Laboratory measurements indicate that HLEDs can achieve the same brightness levels as WOLEDs while consuming approximately 25-30% less power. This efficiency advantage becomes even more significant at higher brightness settings, where the power consumption gap widens to nearly 40% in some test scenarios.

From a lifecycle perspective, the environmental impact assessment of both technologies reveals multifaceted considerations. The manufacturing process for WOLED panels currently has a lower carbon footprint, requiring approximately 15-20% less energy during production compared to HLED panels. However, this initial advantage is typically offset within 12-18 months of regular usage due to the higher operational efficiency of HLED displays.

Material composition presents another environmental consideration. WOLED technology relies on organic compounds that may include rare earth elements and potentially hazardous materials requiring specialized disposal procedures. HLED technology, while reducing dependence on certain problematic materials, introduces quantum dot components that present their own end-of-life management challenges, particularly regarding potential heavy metal content in some implementations.

The extended lifespan potential of HLED technology provides an additional environmental benefit. Research indicates that HLED displays typically maintain brightness and color accuracy 20-30% longer than comparable WOLED panels before significant degradation occurs. This longevity reduces replacement frequency and associated electronic waste generation, estimated at 0.8-1.2 kg less e-waste per display unit over a five-year period.

Energy grid impact calculations demonstrate that widespread adoption of HLED technology could yield substantial energy savings at scale. Projections based on current market penetration trends suggest potential energy savings of 3.2-4.5 TWh annually by 2027 if HLED becomes the dominant display technology in consumer electronics, equivalent to reducing carbon emissions by approximately 1.5-2.1 million metric tons per year.

Manufacturing Challenges and Cost Analysis

The manufacturing processes for WOLED (White Organic Light-Emitting Diode) and HLED (Hybrid Light-Emitting Diode) technologies present distinct challenges that significantly impact production costs and market adoption. WOLED manufacturing relies on established vapor deposition techniques, requiring precise control of multiple organic layers to achieve white light emission. This process demands ultra-clean environments with stringent particle control, as even microscopic contaminants can create dead pixels or reduce device longevity.

In contrast, HLED manufacturing combines quantum dot color conversion layers with blue LED backlighting, introducing different complexity factors. The quantum dot material application requires precise thickness control and uniformity to ensure consistent color conversion efficiency across the display. This hybrid approach necessitates expertise in both traditional LED manufacturing and quantum dot implementation, creating potential bottlenecks in production scaling.

Cost structures differ substantially between these technologies. WOLED manufacturing involves expensive vacuum deposition equipment and relatively low material utilization efficiency, with estimates suggesting that only 20-30% of organic materials are effectively deposited on substrates. The complex multi-layer structure increases production time and reduces yield rates, particularly for larger display sizes. Industry data indicates WOLED manufacturing costs remain 30-40% higher than LCD production for equivalent screen sizes.

HLED production benefits from leveraging existing LCD manufacturing infrastructure, requiring fewer radical changes to production lines. However, the specialized quantum dot materials represent a significant cost component, with high-purity quantum dots commanding premium prices. Current market analysis suggests quantum dot material costs have decreased by approximately 15% annually but remain a substantial factor in overall HLED production expenses.

Yield rate disparities further influence cost dynamics. WOLED manufacturing typically achieves 70-80% yield rates for smaller displays but experiences significant challenges scaling to larger formats. HLED technology demonstrates more consistent yield rates across different display sizes, typically ranging from 80-90%, contributing to better cost efficiency for larger panels.

Supply chain considerations also impact manufacturing economics. WOLED production relies heavily on specialized organic materials with limited supplier diversity, creating potential supply constraints and price volatility. HLED manufacturing benefits from a more diversified component ecosystem, though high-performance quantum dot suppliers remain relatively concentrated among specialized materials companies.

In contrast, HLED manufacturing combines quantum dot color conversion layers with blue LED backlighting, introducing different complexity factors. The quantum dot material application requires precise thickness control and uniformity to ensure consistent color conversion efficiency across the display. This hybrid approach necessitates expertise in both traditional LED manufacturing and quantum dot implementation, creating potential bottlenecks in production scaling.

Cost structures differ substantially between these technologies. WOLED manufacturing involves expensive vacuum deposition equipment and relatively low material utilization efficiency, with estimates suggesting that only 20-30% of organic materials are effectively deposited on substrates. The complex multi-layer structure increases production time and reduces yield rates, particularly for larger display sizes. Industry data indicates WOLED manufacturing costs remain 30-40% higher than LCD production for equivalent screen sizes.

HLED production benefits from leveraging existing LCD manufacturing infrastructure, requiring fewer radical changes to production lines. However, the specialized quantum dot materials represent a significant cost component, with high-purity quantum dots commanding premium prices. Current market analysis suggests quantum dot material costs have decreased by approximately 15% annually but remain a substantial factor in overall HLED production expenses.

Yield rate disparities further influence cost dynamics. WOLED manufacturing typically achieves 70-80% yield rates for smaller displays but experiences significant challenges scaling to larger formats. HLED technology demonstrates more consistent yield rates across different display sizes, typically ranging from 80-90%, contributing to better cost efficiency for larger panels.

Supply chain considerations also impact manufacturing economics. WOLED production relies heavily on specialized organic materials with limited supplier diversity, creating potential supply constraints and price volatility. HLED manufacturing benefits from a more diversified component ecosystem, though high-performance quantum dot suppliers remain relatively concentrated among specialized materials companies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!