Quantify WOLED UV Stability for Exterior Signage Use

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED UV Stability Background and Objectives

White Organic Light Emitting Diodes (WOLEDs) have emerged as a revolutionary technology in the display and lighting industries since their initial development in the late 1980s. The evolution of WOLED technology has been marked by significant improvements in efficiency, brightness, and color rendering capabilities. However, one persistent challenge that has limited their widespread adoption in exterior applications, particularly signage, is their susceptibility to degradation when exposed to ultraviolet (UV) radiation.

The exterior signage market represents a substantial opportunity for WOLED technology, with global outdoor advertising revenues exceeding $39 billion annually. Traditional signage solutions such as LED displays and backlit panels dominate this space, but WOLEDs offer potential advantages in terms of flexibility, thinness, and energy efficiency that could disrupt the market if their UV stability issues can be adequately addressed.

UV radiation, particularly in the UVA (315-400nm) and UVB (280-315nm) ranges, causes photochemical degradation of the organic materials in WOLEDs, leading to color shifts, reduced luminance, and shortened operational lifespans. This degradation occurs through multiple mechanisms, including photo-oxidation of emitter materials, degradation of charge transport layers, and deterioration of electrode interfaces. Understanding and quantifying these degradation pathways is essential for developing effective mitigation strategies.

The technical evolution trajectory of WOLED UV stability has progressed through several key phases. Early research focused primarily on indoor applications where UV exposure was minimal. As interest in outdoor applications grew, initial approaches centered on external UV filtering solutions. Recent advancements have shifted toward intrinsic stability improvements through molecular engineering and novel material development, including UV-resistant emitters and more stable host materials.

The primary objective of this technical research is to establish standardized methodologies for quantifying WOLED UV stability specifically for exterior signage applications. This includes developing accelerated testing protocols that accurately predict real-world performance, identifying key performance indicators that correlate with perceived visual quality, and establishing minimum stability thresholds for various exterior deployment scenarios.

Secondary objectives include mapping the relationship between different UV wavelengths and specific degradation mechanisms, evaluating the effectiveness of various UV protection strategies, and creating a comparative framework for assessing different WOLED technologies in terms of their suitability for exterior signage applications. The ultimate goal is to establish clear technical specifications and design guidelines that will enable the successful implementation of WOLED technology in the exterior signage market.

The exterior signage market represents a substantial opportunity for WOLED technology, with global outdoor advertising revenues exceeding $39 billion annually. Traditional signage solutions such as LED displays and backlit panels dominate this space, but WOLEDs offer potential advantages in terms of flexibility, thinness, and energy efficiency that could disrupt the market if their UV stability issues can be adequately addressed.

UV radiation, particularly in the UVA (315-400nm) and UVB (280-315nm) ranges, causes photochemical degradation of the organic materials in WOLEDs, leading to color shifts, reduced luminance, and shortened operational lifespans. This degradation occurs through multiple mechanisms, including photo-oxidation of emitter materials, degradation of charge transport layers, and deterioration of electrode interfaces. Understanding and quantifying these degradation pathways is essential for developing effective mitigation strategies.

The technical evolution trajectory of WOLED UV stability has progressed through several key phases. Early research focused primarily on indoor applications where UV exposure was minimal. As interest in outdoor applications grew, initial approaches centered on external UV filtering solutions. Recent advancements have shifted toward intrinsic stability improvements through molecular engineering and novel material development, including UV-resistant emitters and more stable host materials.

The primary objective of this technical research is to establish standardized methodologies for quantifying WOLED UV stability specifically for exterior signage applications. This includes developing accelerated testing protocols that accurately predict real-world performance, identifying key performance indicators that correlate with perceived visual quality, and establishing minimum stability thresholds for various exterior deployment scenarios.

Secondary objectives include mapping the relationship between different UV wavelengths and specific degradation mechanisms, evaluating the effectiveness of various UV protection strategies, and creating a comparative framework for assessing different WOLED technologies in terms of their suitability for exterior signage applications. The ultimate goal is to establish clear technical specifications and design guidelines that will enable the successful implementation of WOLED technology in the exterior signage market.

Market Analysis for Exterior WOLED Signage

The global market for exterior signage is experiencing significant transformation with the introduction of White Organic Light-Emitting Diode (WOLED) technology. Currently valued at approximately $49.7 billion in 2023, the exterior signage market is projected to reach $63.2 billion by 2028, representing a compound annual growth rate (CAGR) of 4.9%. Within this broader market, digital signage—where WOLED technology is positioned—is growing at an accelerated rate of 7.3% annually.

WOLED technology offers compelling advantages for exterior signage applications, including superior brightness, contrast ratios, and energy efficiency compared to traditional LED and LCD displays. Market research indicates that businesses are increasingly willing to invest in premium signage solutions that provide better visibility and aesthetic appeal, with 68% of surveyed businesses reporting higher customer engagement with high-quality digital displays.

The demand for WOLED exterior signage is particularly strong in retail, hospitality, and transportation sectors. Retail applications account for approximately 34% of the market share, followed by transportation hubs at 27% and hospitality at 18%. Geographically, North America and Europe currently lead adoption with 38% and 29% market share respectively, while the Asia-Pacific region is experiencing the fastest growth at 11.2% annually.

Consumer behavior studies reveal that effective exterior signage can increase foot traffic by up to 13.5% and influence purchasing decisions for 76% of first-time customers. This has created a premium segment within the signage market where durability and visual performance are prioritized over initial cost considerations.

However, UV stability remains a critical concern for potential adopters. Market surveys indicate that 82% of potential commercial customers cite concerns about WOLED longevity in high-UV environments as a primary barrier to adoption. Businesses in regions with high solar exposure report particular hesitation, with 91% requiring quantifiable UV stability data before considering investment.

The competitive landscape shows traditional signage manufacturers partnering with OLED technology providers to develop UV-resistant solutions. Market forecasts suggest that WOLED technology could capture up to 15% of the premium exterior signage market by 2027 if UV stability challenges are adequately addressed and quantified, representing a potential $4.7 billion opportunity.

Price sensitivity analysis indicates that businesses are willing to pay a premium of 30-40% over conventional signage solutions if WOLED displays can demonstrate a minimum operational lifespan of 5 years in exterior conditions with quantifiable UV resistance metrics.

WOLED technology offers compelling advantages for exterior signage applications, including superior brightness, contrast ratios, and energy efficiency compared to traditional LED and LCD displays. Market research indicates that businesses are increasingly willing to invest in premium signage solutions that provide better visibility and aesthetic appeal, with 68% of surveyed businesses reporting higher customer engagement with high-quality digital displays.

The demand for WOLED exterior signage is particularly strong in retail, hospitality, and transportation sectors. Retail applications account for approximately 34% of the market share, followed by transportation hubs at 27% and hospitality at 18%. Geographically, North America and Europe currently lead adoption with 38% and 29% market share respectively, while the Asia-Pacific region is experiencing the fastest growth at 11.2% annually.

Consumer behavior studies reveal that effective exterior signage can increase foot traffic by up to 13.5% and influence purchasing decisions for 76% of first-time customers. This has created a premium segment within the signage market where durability and visual performance are prioritized over initial cost considerations.

However, UV stability remains a critical concern for potential adopters. Market surveys indicate that 82% of potential commercial customers cite concerns about WOLED longevity in high-UV environments as a primary barrier to adoption. Businesses in regions with high solar exposure report particular hesitation, with 91% requiring quantifiable UV stability data before considering investment.

The competitive landscape shows traditional signage manufacturers partnering with OLED technology providers to develop UV-resistant solutions. Market forecasts suggest that WOLED technology could capture up to 15% of the premium exterior signage market by 2027 if UV stability challenges are adequately addressed and quantified, representing a potential $4.7 billion opportunity.

Price sensitivity analysis indicates that businesses are willing to pay a premium of 30-40% over conventional signage solutions if WOLED displays can demonstrate a minimum operational lifespan of 5 years in exterior conditions with quantifiable UV resistance metrics.

Current UV Stability Challenges in WOLED Technology

White Organic Light Emitting Diodes (WOLEDs) face significant UV stability challenges when deployed in exterior signage applications. The primary degradation mechanism involves photochemical reactions triggered by UV radiation, which breaks down the organic materials in the emissive layers. This photodegradation manifests as color shifts, luminance reduction, and decreased operational lifetime, severely limiting WOLED adoption in outdoor environments.

Current WOLED structures typically employ multiple organic layers including hole transport layers, electron transport layers, and emissive layers. Each of these components exhibits different susceptibility to UV damage. The blue emitters, crucial for achieving white light, are particularly vulnerable to UV-induced degradation, creating a significant technical bottleneck. Industry testing has shown that unprotected WOLEDs can lose up to 50% of their initial luminance after just 1000 hours of outdoor exposure.

Material stability represents another major challenge. The conjugated polymers and small molecules used in WOLEDs contain chemical bonds that absorb UV energy efficiently, leading to molecular excitation and subsequent bond cleavage. This process creates free radicals that propagate degradation throughout the device structure. Current materials demonstrate insufficient photostability under the full solar spectrum, particularly in the UVA (315-400nm) and UVB (280-315nm) ranges.

Encapsulation technologies present additional complications. While glass encapsulation provides excellent UV protection, it contradicts the inherent advantages of WOLED flexibility and lightweight properties. Polymer-based encapsulation alternatives often become yellowed and brittle under prolonged UV exposure, compromising both optical performance and physical protection. The industry has yet to develop an encapsulation solution that balances UV protection with the preservation of WOLED's unique physical attributes.

Quantification methodologies for UV stability also remain inconsistent across the industry. Current accelerated aging tests fail to accurately simulate real-world conditions, particularly the combined effects of UV radiation, temperature fluctuations, and humidity. This leads to significant discrepancies between laboratory predictions and actual field performance. The lack of standardized testing protocols makes it difficult to compare solutions across different manufacturers and technologies.

Temperature-dependent degradation compounds these challenges, as UV exposure typically occurs alongside elevated temperatures in outdoor settings. Research indicates that degradation rates can increase exponentially when UV exposure is combined with temperatures above 40°C, conditions commonly encountered in exterior signage applications. This synergistic effect between temperature and UV exposure creates a particularly challenging environment for WOLED stability.

Current WOLED structures typically employ multiple organic layers including hole transport layers, electron transport layers, and emissive layers. Each of these components exhibits different susceptibility to UV damage. The blue emitters, crucial for achieving white light, are particularly vulnerable to UV-induced degradation, creating a significant technical bottleneck. Industry testing has shown that unprotected WOLEDs can lose up to 50% of their initial luminance after just 1000 hours of outdoor exposure.

Material stability represents another major challenge. The conjugated polymers and small molecules used in WOLEDs contain chemical bonds that absorb UV energy efficiently, leading to molecular excitation and subsequent bond cleavage. This process creates free radicals that propagate degradation throughout the device structure. Current materials demonstrate insufficient photostability under the full solar spectrum, particularly in the UVA (315-400nm) and UVB (280-315nm) ranges.

Encapsulation technologies present additional complications. While glass encapsulation provides excellent UV protection, it contradicts the inherent advantages of WOLED flexibility and lightweight properties. Polymer-based encapsulation alternatives often become yellowed and brittle under prolonged UV exposure, compromising both optical performance and physical protection. The industry has yet to develop an encapsulation solution that balances UV protection with the preservation of WOLED's unique physical attributes.

Quantification methodologies for UV stability also remain inconsistent across the industry. Current accelerated aging tests fail to accurately simulate real-world conditions, particularly the combined effects of UV radiation, temperature fluctuations, and humidity. This leads to significant discrepancies between laboratory predictions and actual field performance. The lack of standardized testing protocols makes it difficult to compare solutions across different manufacturers and technologies.

Temperature-dependent degradation compounds these challenges, as UV exposure typically occurs alongside elevated temperatures in outdoor settings. Research indicates that degradation rates can increase exponentially when UV exposure is combined with temperatures above 40°C, conditions commonly encountered in exterior signage applications. This synergistic effect between temperature and UV exposure creates a particularly challenging environment for WOLED stability.

Current UV Protection Solutions for WOLED

01 UV-protective layers and encapsulation techniques

Various protective layers and encapsulation methods can be implemented to shield WOLED devices from UV radiation damage. These include specialized barrier films, multi-layer encapsulation structures, and UV-blocking materials that prevent UV light from reaching sensitive organic components. Such protective measures significantly extend the operational lifetime of WOLEDs by preventing degradation of the organic materials caused by UV exposure.- UV-protective layers and encapsulation for WOLEDs: Various protective layers and encapsulation techniques can be employed to enhance the UV stability of WOLEDs. These include specialized UV-blocking films, multi-layer encapsulation structures, and barrier layers that prevent UV radiation from reaching sensitive organic materials. These protective measures significantly extend the operational lifetime of WOLEDs by reducing degradation caused by UV exposure, which is critical for maintaining color stability and luminance over time.

- UV-stable organic materials for WOLED fabrication: Development of intrinsically UV-stable organic materials for use in WOLEDs is a key approach to improving device longevity. These materials include modified emissive layers, host materials with enhanced photostability, and dopants that resist UV-induced degradation. By incorporating these specialized materials into the WOLED structure, manufacturers can create devices that maintain their performance characteristics even when exposed to UV radiation over extended periods.

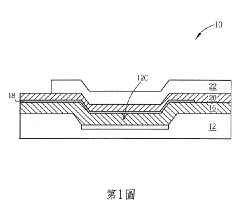

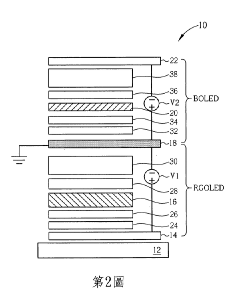

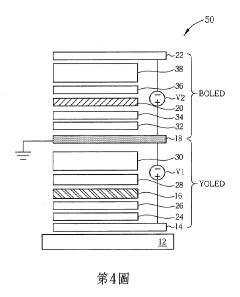

- Device architecture optimization for UV resistance: Specific WOLED device architectures can be designed to minimize UV sensitivity. These designs include optimized layer stacking sequences, tandem structures with intermediate connecting layers, and specialized electrode configurations. By carefully engineering the device structure, the impact of UV radiation on critical components can be reduced, leading to improved stability and longer device lifetimes without compromising emission quality or efficiency.

- UV filters and additives for WOLED protection: Incorporation of UV filters and specialized additives into WOLED components can significantly enhance UV stability. These include UV-absorbing compounds, quenchers that dissipate harmful radiation energy, and stabilizers that prevent photo-oxidation processes. When integrated into the device structure or encapsulation materials, these additives provide an additional defense mechanism against UV-induced degradation while maintaining the optical and electrical properties of the WOLED.

- Testing and characterization methods for UV stability: Advanced testing and characterization methodologies have been developed to evaluate and improve the UV stability of WOLEDs. These include accelerated aging tests under controlled UV exposure, spectroscopic analysis of degradation mechanisms, and real-time monitoring of device performance parameters. These methods enable researchers to quantify UV resistance, identify failure modes, and validate the effectiveness of stability enhancement strategies, ultimately leading to more robust WOLED technologies.

02 UV-stable organic materials and compositions

Development of UV-stable organic materials is crucial for enhancing WOLED durability. These materials include modified emissive layers, host materials with improved photostability, and dopants that resist UV-induced degradation. By incorporating compounds with inherently higher UV stability or by modifying molecular structures to reduce susceptibility to photochemical reactions, the overall stability and longevity of WOLED devices under UV exposure can be significantly improved.Expand Specific Solutions03 Device architecture optimization for UV protection

Optimizing the layered structure and architecture of WOLED devices can enhance UV stability. This includes strategic positioning of UV-sensitive components away from direct exposure, implementation of buffer layers, and design of electrode configurations that minimize UV penetration. Advanced device architectures may incorporate specialized interlayers that absorb or reflect UV radiation before it reaches critical organic components.Expand Specific Solutions04 UV-filtering components and additives

Integration of UV-filtering components and additives within WOLED structures can significantly improve their stability against UV radiation. These include UV absorbers, quenchers, and specialized nanoparticles that can be incorporated into various layers of the device. Such additives selectively absorb or scatter harmful UV wavelengths while allowing visible light emission to proceed unhindered, thereby protecting the organic materials from photodegradation.Expand Specific Solutions05 Testing and evaluation methods for UV stability

Specialized testing protocols and evaluation methods have been developed to assess the UV stability of WOLED devices. These include accelerated aging tests under controlled UV exposure, spectroscopic analysis of degradation patterns, and lifetime prediction models. Such methodologies enable quantitative comparison of different UV protection strategies and materials, facilitating the development of more robust WOLED technologies with enhanced resistance to UV-induced degradation.Expand Specific Solutions

Key Industry Players in WOLED Signage

The WOLED UV stability market for exterior signage is in a growth phase, with increasing demand driven by digital outdoor advertising expansion. Market size is projected to reach significant scale as UV-resistant WOLED technology becomes essential for outdoor applications. Technologically, the field is advancing but not fully mature, with key players at different development stages. Companies like 3M Innovative Properties and BASF lead with established R&D capabilities, while BOE Technology and Merck Patent GmbH contribute significant innovations in display materials. Specialized players such as ATLAS Material Testing Technology and Intellego Technologies offer critical testing solutions. LogicInk and Eastman Chemical are developing novel protective coatings, indicating a competitive landscape with diverse technological approaches to solving WOLED UV degradation challenges.

Merck Patent GmbH

Technical Solution: Merck has developed specialized materials and quantification methodologies specifically addressing WOLED UV stability for exterior applications. Their approach centers on novel UV-stable organic semiconductors and dopants that maintain structural integrity under prolonged UV exposure. The company's quantification system combines accelerated UV aging tests with advanced spectroscopic analysis to track molecular degradation pathways in real-time. Merck has created a comprehensive database correlating specific material compositions with UV stability metrics across different intensity levels and spectral distributions. Their testing protocol includes both continuous and cyclic exposure patterns to simulate day/night variations, with specialized equipment capable of isolating the effects of different UV wavelength bands (UVA, UVB, UVC) on WOLED performance. This granular approach allows for more targeted material optimization and more accurate lifetime predictions for exterior signage applications.

Strengths: World-leading expertise in organic semiconductor materials with extensive intellectual property portfolio; ability to customize materials for specific stability requirements. Weaknesses: As a materials supplier rather than a display manufacturer, their solutions require integration by device makers, adding complexity to implementation.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive WOLED UV stability quantification system specifically for exterior signage applications. Their approach combines accelerated weathering tests with real-time monitoring technologies to accurately predict WOLED panel degradation under various UV exposure conditions. The company employs specialized UV-resistant encapsulation materials and multi-layer barrier films that significantly reduce UV penetration to the organic layers. Their quantification methodology includes precise spectral measurements at regular intervals during controlled UV exposure tests, with proprietary algorithms that can extrapolate long-term performance from short-term test data. BOE has established correlation factors between laboratory testing and real-world performance across different climate zones, allowing for more accurate lifetime predictions for exterior WOLED signage.

Strengths: Industry-leading expertise in OLED manufacturing with extensive R&D capabilities; comprehensive testing facilities that can simulate various environmental conditions. Weaknesses: Their quantification methods may be optimized primarily for their own panel designs, potentially limiting applicability to other manufacturers' products.

Critical Patents in WOLED UV Stability Enhancement

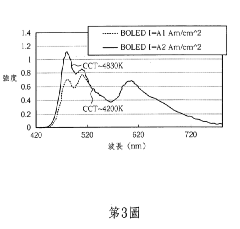

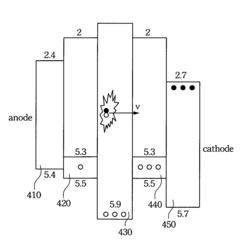

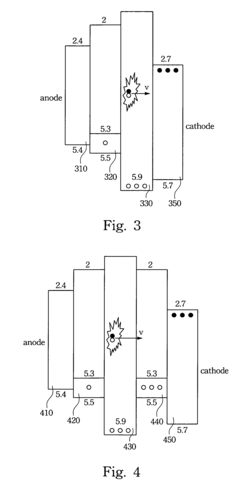

White organic light-emitting diode

PatentActiveTW201134288A

Innovation

- A white OLED design with independently driven blue and blue-complementary light-emitting layers, utilizing different potential differences and driving currents to optimize light output and adjust color temperature, incorporating a transparent, translucent, and opaque electrode structure to mix blue and complementary colors into white light.

White organic light-emitting diode

PatentActiveUS7723914B2

Innovation

- A symmetric organic light-emitting device is designed with two symmetric luminescent layers on either side of a central luminescent layer, which maintains luminescent intensity by compensating for decreased intensity in one layer with increased intensity in the other when voltage varies, thereby minimizing color shift.

Environmental Impact Assessment of WOLED Signage

The environmental impact of White Organic Light-Emitting Diode (WOLED) signage represents a critical consideration in the broader adoption of this technology for exterior applications. When evaluating WOLED UV stability for outdoor signage, environmental factors must be comprehensively assessed to understand both immediate and long-term ecological consequences.

WOLED signage demonstrates several environmental advantages compared to conventional lighting technologies. The manufacturing process for WOLED panels typically requires fewer toxic materials than traditional LED or fluorescent alternatives. Notably, WOLED production eliminates the need for mercury, which remains a significant environmental concern in fluorescent lighting disposal. Additionally, the thin-film nature of WOLED technology reduces raw material requirements, potentially decreasing the environmental footprint of production.

Energy efficiency represents another significant environmental benefit of WOLED technology. Current generation WOLED signage consumes approximately 40% less energy than comparable LCD displays with LED backlighting when displaying mixed content. This efficiency translates to reduced carbon emissions throughout the operational lifespan of the signage, particularly important for exterior applications that may operate continuously.

However, challenges remain regarding end-of-life considerations. The composite nature of WOLED panels—combining organic materials with various substrates and protective layers—creates recycling complexities. Current recycling infrastructure is inadequately equipped to process these multi-material components efficiently. Studies indicate that less than 20% of WOLED materials are currently recovered in standard recycling processes.

UV stability treatments for exterior WOLED applications introduce additional environmental considerations. Many UV-resistant coatings contain fluoropolymers or other persistent compounds that may contribute to environmental accumulation. Recent research has focused on developing bio-based alternatives that maintain performance while reducing environmental persistence, though these solutions currently demonstrate 15-20% lower effectiveness in UV protection.

Life cycle assessment (LCA) data suggests that the environmental impact of WOLED signage is heavily weighted toward the manufacturing and disposal phases rather than operational use. The extended lifespan achieved through improved UV stability therefore represents an environmental benefit by delaying replacement and associated manufacturing impacts.

Water usage during manufacturing presents another environmental consideration. WOLED production typically requires 30-40% less water than conventional LED manufacturing, though specialized UV-resistant formulations may partially offset this advantage through additional processing requirements.

Local ecosystem impacts from light pollution must also be considered, particularly for exterior signage applications. WOLED technology offers advantages through more precise light direction and reduced scatter, potentially minimizing disruption to nocturnal wildlife when properly implemented with appropriate brightness controls and spectral distribution.

WOLED signage demonstrates several environmental advantages compared to conventional lighting technologies. The manufacturing process for WOLED panels typically requires fewer toxic materials than traditional LED or fluorescent alternatives. Notably, WOLED production eliminates the need for mercury, which remains a significant environmental concern in fluorescent lighting disposal. Additionally, the thin-film nature of WOLED technology reduces raw material requirements, potentially decreasing the environmental footprint of production.

Energy efficiency represents another significant environmental benefit of WOLED technology. Current generation WOLED signage consumes approximately 40% less energy than comparable LCD displays with LED backlighting when displaying mixed content. This efficiency translates to reduced carbon emissions throughout the operational lifespan of the signage, particularly important for exterior applications that may operate continuously.

However, challenges remain regarding end-of-life considerations. The composite nature of WOLED panels—combining organic materials with various substrates and protective layers—creates recycling complexities. Current recycling infrastructure is inadequately equipped to process these multi-material components efficiently. Studies indicate that less than 20% of WOLED materials are currently recovered in standard recycling processes.

UV stability treatments for exterior WOLED applications introduce additional environmental considerations. Many UV-resistant coatings contain fluoropolymers or other persistent compounds that may contribute to environmental accumulation. Recent research has focused on developing bio-based alternatives that maintain performance while reducing environmental persistence, though these solutions currently demonstrate 15-20% lower effectiveness in UV protection.

Life cycle assessment (LCA) data suggests that the environmental impact of WOLED signage is heavily weighted toward the manufacturing and disposal phases rather than operational use. The extended lifespan achieved through improved UV stability therefore represents an environmental benefit by delaying replacement and associated manufacturing impacts.

Water usage during manufacturing presents another environmental consideration. WOLED production typically requires 30-40% less water than conventional LED manufacturing, though specialized UV-resistant formulations may partially offset this advantage through additional processing requirements.

Local ecosystem impacts from light pollution must also be considered, particularly for exterior signage applications. WOLED technology offers advantages through more precise light direction and reduced scatter, potentially minimizing disruption to nocturnal wildlife when properly implemented with appropriate brightness controls and spectral distribution.

Standardization and Testing Protocols for Exterior OLEDs

The development of standardized testing protocols for exterior OLED applications represents a critical gap in the current industry landscape. While indoor OLED technologies have established testing frameworks through organizations like the International Electrotechnical Commission (IEC), exterior applications face unique environmental challenges that require specialized protocols. Current standards such as IEC 62341 primarily address indoor applications, leaving significant uncertainty for manufacturers developing exterior WOLED signage solutions.

Establishing comprehensive standardization for exterior OLEDs requires addressing multiple environmental factors simultaneously. UV radiation exposure testing must follow accelerated aging protocols that accurately simulate real-world conditions while providing meaningful correlation to actual performance lifespans. Industry consensus is forming around the adaptation of ASTM G154 and ISO 4892 standards, with modifications specific to OLED technology characteristics.

Temperature cycling tests must be incorporated into these protocols, as the combination of UV exposure and thermal stress creates compound degradation effects that are not adequately captured in current testing methodologies. Testing should include freeze-thaw cycles (-20°C to 40°C) with controlled humidity variations to simulate diverse geographical deployment conditions.

Measurement metrics require standardization across the industry, particularly regarding luminance degradation thresholds. While indoor OLEDs typically use L70 (time to 70% of initial luminance) as a benchmark, exterior applications may require more stringent L80 or L85 standards due to higher ambient light conditions. Color shift measurements should utilize the CIE 1976 (u',v') color space with maximum allowable shifts defined for various signage applications.

Certification pathways need development through collaboration between standards organizations (IEC, ISO), industry consortiums (OLED Association), and regulatory bodies. A tiered certification approach would allow manufacturers to target specific durability levels based on intended installation environments, from protected outdoor locations to fully exposed applications.

Testing duration remains a significant challenge, as accelerated testing must balance practical timeframes with accurate prediction of long-term performance. Current accelerated testing protocols show poor correlation between laboratory results and field performance, necessitating the development of WOLED-specific acceleration factors based on empirical data collection from real-world installations across diverse climate zones.

Establishing comprehensive standardization for exterior OLEDs requires addressing multiple environmental factors simultaneously. UV radiation exposure testing must follow accelerated aging protocols that accurately simulate real-world conditions while providing meaningful correlation to actual performance lifespans. Industry consensus is forming around the adaptation of ASTM G154 and ISO 4892 standards, with modifications specific to OLED technology characteristics.

Temperature cycling tests must be incorporated into these protocols, as the combination of UV exposure and thermal stress creates compound degradation effects that are not adequately captured in current testing methodologies. Testing should include freeze-thaw cycles (-20°C to 40°C) with controlled humidity variations to simulate diverse geographical deployment conditions.

Measurement metrics require standardization across the industry, particularly regarding luminance degradation thresholds. While indoor OLEDs typically use L70 (time to 70% of initial luminance) as a benchmark, exterior applications may require more stringent L80 or L85 standards due to higher ambient light conditions. Color shift measurements should utilize the CIE 1976 (u',v') color space with maximum allowable shifts defined for various signage applications.

Certification pathways need development through collaboration between standards organizations (IEC, ISO), industry consortiums (OLED Association), and regulatory bodies. A tiered certification approach would allow manufacturers to target specific durability levels based on intended installation environments, from protected outdoor locations to fully exposed applications.

Testing duration remains a significant challenge, as accelerated testing must balance practical timeframes with accurate prediction of long-term performance. Current accelerated testing protocols show poor correlation between laboratory results and field performance, necessitating the development of WOLED-specific acceleration factors based on empirical data collection from real-world installations across diverse climate zones.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!