WOLED vs LCoS: Application Fit for High-Color Display

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED and LCoS Display Technology Evolution

The evolution of display technologies has been marked by continuous innovation aimed at achieving higher resolution, better color reproduction, and improved energy efficiency. WOLED (White Organic Light Emitting Diode) and LCoS (Liquid Crystal on Silicon) represent two distinct approaches that have emerged as significant players in the high-color display market.

WOLED technology evolved from the broader OLED family, which began commercial development in the late 1990s. The key breakthrough came in the early 2000s when researchers developed white OLED structures that could emit full-spectrum light through color filters. By 2010, WOLED had matured sufficiently for implementation in premium television displays, with companies like LG Display pioneering large-scale production techniques that overcame earlier manufacturing challenges.

LCoS technology traces its roots to the 1970s when liquid crystal research intersected with semiconductor manufacturing. However, it wasn't until the 1990s that practical LCoS displays became feasible. The technology underwent significant refinement in the early 2000s, particularly in addressing issues related to pixel density and response time. By 2005, LCoS had established itself as a viable solution for projection systems, with continuous improvements in resolution and color accuracy following throughout the 2010s.

The technological trajectories of these display technologies have been shaped by different market demands. WOLED development has been primarily driven by the consumer television market, with emphasis on achieving perfect blacks, wide viewing angles, and thin form factors. This has led to innovations in manufacturing processes, particularly in depositing organic materials uniformly over large areas.

LCoS evolution, conversely, has been influenced by the projection and near-eye display markets, focusing on miniaturization, high pixel density, and optical efficiency. This has resulted in advancements in silicon backplane design and liquid crystal alignment technologies.

Recent years have seen both technologies reach new milestones. WOLED has achieved significant improvements in energy efficiency and lifetime, addressing historical limitations. Meanwhile, LCoS has seen dramatic increases in resolution and refresh rates, making it increasingly suitable for augmented reality applications.

The convergence of these evolutionary paths has created interesting competitive dynamics in markets like head-mounted displays, where both technologies offer distinct advantages. WOLED provides superior contrast and form factor, while LCoS excels in brightness and power efficiency for certain implementations.

Understanding this technological evolution provides crucial context for evaluating the application fit of each technology in current and future high-color display applications, highlighting how their respective development histories have shaped their current capabilities and limitations.

WOLED technology evolved from the broader OLED family, which began commercial development in the late 1990s. The key breakthrough came in the early 2000s when researchers developed white OLED structures that could emit full-spectrum light through color filters. By 2010, WOLED had matured sufficiently for implementation in premium television displays, with companies like LG Display pioneering large-scale production techniques that overcame earlier manufacturing challenges.

LCoS technology traces its roots to the 1970s when liquid crystal research intersected with semiconductor manufacturing. However, it wasn't until the 1990s that practical LCoS displays became feasible. The technology underwent significant refinement in the early 2000s, particularly in addressing issues related to pixel density and response time. By 2005, LCoS had established itself as a viable solution for projection systems, with continuous improvements in resolution and color accuracy following throughout the 2010s.

The technological trajectories of these display technologies have been shaped by different market demands. WOLED development has been primarily driven by the consumer television market, with emphasis on achieving perfect blacks, wide viewing angles, and thin form factors. This has led to innovations in manufacturing processes, particularly in depositing organic materials uniformly over large areas.

LCoS evolution, conversely, has been influenced by the projection and near-eye display markets, focusing on miniaturization, high pixel density, and optical efficiency. This has resulted in advancements in silicon backplane design and liquid crystal alignment technologies.

Recent years have seen both technologies reach new milestones. WOLED has achieved significant improvements in energy efficiency and lifetime, addressing historical limitations. Meanwhile, LCoS has seen dramatic increases in resolution and refresh rates, making it increasingly suitable for augmented reality applications.

The convergence of these evolutionary paths has created interesting competitive dynamics in markets like head-mounted displays, where both technologies offer distinct advantages. WOLED provides superior contrast and form factor, while LCoS excels in brightness and power efficiency for certain implementations.

Understanding this technological evolution provides crucial context for evaluating the application fit of each technology in current and future high-color display applications, highlighting how their respective development histories have shaped their current capabilities and limitations.

Market Demand Analysis for High-Color Display Solutions

The high-color display market has witnessed substantial growth in recent years, driven by increasing consumer demand for superior visual experiences across multiple application domains. Current market analysis indicates that the global high-color display market is projected to grow at a compound annual growth rate of 15% through 2028, with particularly strong demand emerging in premium consumer electronics, professional content creation, and specialized industrial applications.

Consumer electronics represents the largest segment for high-color display technologies, with smartphone manufacturers increasingly adopting advanced display solutions to differentiate their flagship products. The premium television market has similarly embraced high-color technologies, with consumers demonstrating willingness to pay premium prices for enhanced color accuracy and wider color gamuts. Market research indicates that devices featuring high-color displays command price premiums of 20-30% compared to standard display alternatives.

Professional markets, including content creation, medical imaging, and scientific visualization, constitute a smaller but higher-margin segment. These professional users require exceptional color accuracy, consistency, and reproduction capabilities that both WOLED and LCoS technologies can potentially address. The professional display market segment is growing at 18% annually, outpacing the broader display market.

Emerging application areas are creating new market opportunities for high-color display technologies. Augmented reality (AR) and virtual reality (VR) headsets require compact, high-resolution displays with excellent color reproduction capabilities. The automotive industry is increasingly incorporating advanced display technologies in dashboard systems and entertainment consoles, with premium manufacturers emphasizing color accuracy as a differentiating feature.

Regional analysis reveals that North America and Asia-Pacific dominate the high-color display market, with Europe showing accelerated adoption rates. China has emerged as both a major consumer market and manufacturing hub for display technologies, with significant investments in domestic production capabilities for both WOLED and LCoS technologies.

Market research indicates diverging consumer preferences across different application domains. For large-format displays like televisions and monitors, consumers prioritize color accuracy, viewing angles, and energy efficiency—attributes where WOLED technology demonstrates particular strengths. For projection systems and near-eye displays, the high pixel density, fast response times, and compact form factors of LCoS technology align well with market requirements.

Industry forecasts suggest that the market will continue to fragment based on specific application requirements rather than consolidating around a single display technology. This trend indicates potential complementary market positions for WOLED and LCoS technologies, with each addressing distinct segments of the high-color display ecosystem based on their respective technical advantages and limitations.

Consumer electronics represents the largest segment for high-color display technologies, with smartphone manufacturers increasingly adopting advanced display solutions to differentiate their flagship products. The premium television market has similarly embraced high-color technologies, with consumers demonstrating willingness to pay premium prices for enhanced color accuracy and wider color gamuts. Market research indicates that devices featuring high-color displays command price premiums of 20-30% compared to standard display alternatives.

Professional markets, including content creation, medical imaging, and scientific visualization, constitute a smaller but higher-margin segment. These professional users require exceptional color accuracy, consistency, and reproduction capabilities that both WOLED and LCoS technologies can potentially address. The professional display market segment is growing at 18% annually, outpacing the broader display market.

Emerging application areas are creating new market opportunities for high-color display technologies. Augmented reality (AR) and virtual reality (VR) headsets require compact, high-resolution displays with excellent color reproduction capabilities. The automotive industry is increasingly incorporating advanced display technologies in dashboard systems and entertainment consoles, with premium manufacturers emphasizing color accuracy as a differentiating feature.

Regional analysis reveals that North America and Asia-Pacific dominate the high-color display market, with Europe showing accelerated adoption rates. China has emerged as both a major consumer market and manufacturing hub for display technologies, with significant investments in domestic production capabilities for both WOLED and LCoS technologies.

Market research indicates diverging consumer preferences across different application domains. For large-format displays like televisions and monitors, consumers prioritize color accuracy, viewing angles, and energy efficiency—attributes where WOLED technology demonstrates particular strengths. For projection systems and near-eye displays, the high pixel density, fast response times, and compact form factors of LCoS technology align well with market requirements.

Industry forecasts suggest that the market will continue to fragment based on specific application requirements rather than consolidating around a single display technology. This trend indicates potential complementary market positions for WOLED and LCoS technologies, with each addressing distinct segments of the high-color display ecosystem based on their respective technical advantages and limitations.

Technical Challenges in WOLED and LCoS Implementation

Despite the promising capabilities of both WOLED and LCoS technologies for high-color displays, their implementation faces several significant technical challenges that must be addressed for optimal performance and market viability.

WOLED (White Organic Light-Emitting Diode) technology confronts material stability issues as a primary challenge. The organic compounds used in blue OLED emitters typically degrade faster than red and green counterparts, leading to color shift over time and reduced display lifespan. This differential aging creates particular difficulties in maintaining consistent white point and color accuracy throughout the display's operational life.

Manufacturing complexity presents another substantial hurdle for WOLED implementation. The production process requires precise deposition of multiple organic layers with thickness tolerances measured in nanometers. This precision requirement leads to lower yield rates and increased production costs, especially for larger display sizes. Additionally, the need for hermetic sealing to protect organic materials from oxygen and moisture adds further manufacturing complexity.

Power efficiency remains problematic for WOLED displays, particularly in mobile applications. While WOLED offers better efficiency than traditional LCD technology, the color filter layer necessary for creating RGB subpixels from white light reduces overall light transmission, requiring higher power consumption to maintain brightness levels comparable to direct RGB OLED solutions.

For LCoS (Liquid Crystal on Silicon) technology, the primary challenge lies in miniaturization while maintaining optical performance. As pixel sizes decrease to improve resolution, diffraction effects become more pronounced, potentially limiting contrast ratio and image quality. The small pixel pitch also creates challenges in maintaining uniform liquid crystal alignment across the display surface.

Thermal management represents a significant issue for LCoS implementations. The concentrated light sources required for projection systems generate substantial heat that must be dissipated effectively to prevent damage to the liquid crystal layer and silicon backplane. This thermal challenge becomes particularly acute in compact designs for wearable displays or mobile projection systems.

Response time limitations affect LCoS performance in high-frame-rate applications. While faster than many LCD technologies, LCoS still exhibits switching times that can cause motion blur in rapidly changing content. This limitation becomes particularly noticeable in AR/VR applications where low latency is critical for user experience and comfort.

Both technologies also face integration challenges when implemented in complex display systems. WOLED requires sophisticated thin-film transistor backplanes for precise current control, while LCoS systems demand precise optical alignment of multiple components including polarizers, beam splitters, and projection lenses. These integration requirements increase manufacturing complexity and potential points of failure.

WOLED (White Organic Light-Emitting Diode) technology confronts material stability issues as a primary challenge. The organic compounds used in blue OLED emitters typically degrade faster than red and green counterparts, leading to color shift over time and reduced display lifespan. This differential aging creates particular difficulties in maintaining consistent white point and color accuracy throughout the display's operational life.

Manufacturing complexity presents another substantial hurdle for WOLED implementation. The production process requires precise deposition of multiple organic layers with thickness tolerances measured in nanometers. This precision requirement leads to lower yield rates and increased production costs, especially for larger display sizes. Additionally, the need for hermetic sealing to protect organic materials from oxygen and moisture adds further manufacturing complexity.

Power efficiency remains problematic for WOLED displays, particularly in mobile applications. While WOLED offers better efficiency than traditional LCD technology, the color filter layer necessary for creating RGB subpixels from white light reduces overall light transmission, requiring higher power consumption to maintain brightness levels comparable to direct RGB OLED solutions.

For LCoS (Liquid Crystal on Silicon) technology, the primary challenge lies in miniaturization while maintaining optical performance. As pixel sizes decrease to improve resolution, diffraction effects become more pronounced, potentially limiting contrast ratio and image quality. The small pixel pitch also creates challenges in maintaining uniform liquid crystal alignment across the display surface.

Thermal management represents a significant issue for LCoS implementations. The concentrated light sources required for projection systems generate substantial heat that must be dissipated effectively to prevent damage to the liquid crystal layer and silicon backplane. This thermal challenge becomes particularly acute in compact designs for wearable displays or mobile projection systems.

Response time limitations affect LCoS performance in high-frame-rate applications. While faster than many LCD technologies, LCoS still exhibits switching times that can cause motion blur in rapidly changing content. This limitation becomes particularly noticeable in AR/VR applications where low latency is critical for user experience and comfort.

Both technologies also face integration challenges when implemented in complex display systems. WOLED requires sophisticated thin-film transistor backplanes for precise current control, while LCoS systems demand precise optical alignment of multiple components including polarizers, beam splitters, and projection lenses. These integration requirements increase manufacturing complexity and potential points of failure.

Current WOLED and LCoS Technical Architectures

01 WOLED structure and materials for high color display

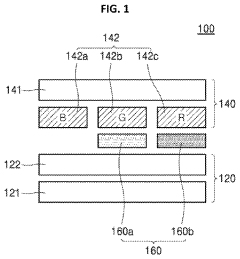

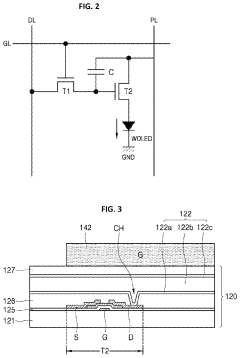

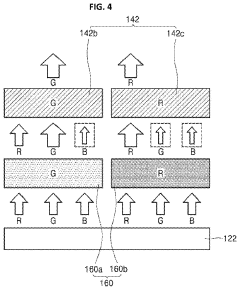

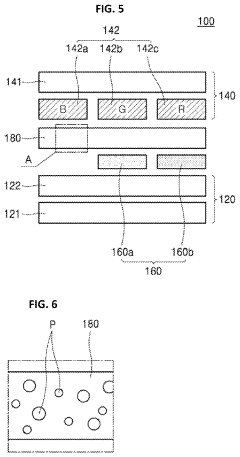

White Organic Light Emitting Diode (WOLED) technology utilizes specific organic materials and structures to produce high-quality white light that can be filtered for color displays. These displays incorporate multiple emitting layers with different colors (typically red, green, and blue) to generate white light with excellent color reproduction. The structure often includes phosphorescent materials to improve efficiency and color gamut, enabling high-color performance in display applications.- WOLED structure and materials for high color display: White organic light-emitting diodes (WOLEDs) can be designed with specific structures and materials to achieve high color gamut displays. These designs include multi-layer structures with different emitting materials that together produce white light with excellent color rendering. The combination of phosphorescent and fluorescent materials in WOLEDs can enhance color purity and efficiency, while specialized electrode configurations improve light extraction and color performance.

- LCoS display technology for high color reproduction: Liquid Crystal on Silicon (LCoS) technology utilizes reflective liquid crystal displays to achieve high color accuracy and resolution. LCoS displays incorporate specialized color filters and polarization techniques to enhance color reproduction. The reflective nature of LCoS allows for efficient light utilization, resulting in vibrant colors and high contrast ratios. Advanced LCoS designs include improved pixel structures and driving methods that minimize color distortion and maximize color gamut.

- Integration of WOLED and LCoS technologies: The combination of WOLED as a light source with LCoS as a modulation technology creates display systems with exceptional color performance. This integration leverages the high brightness and efficiency of WOLEDs with the high resolution and contrast capabilities of LCoS. Specialized optical designs ensure optimal light transmission from the WOLED source through the LCoS panel, while color management systems coordinate the technologies to achieve wide color gamut reproduction.

- Color enhancement techniques for display systems: Various color enhancement techniques can be applied to WOLED and LCoS display systems to expand their color gamut. These include quantum dot color conversion layers, specialized color filters, and advanced color management algorithms. Optical components such as dichroic filters and prisms can be used to separate and recombine light for improved color purity. Additionally, pixel-level color processing techniques can optimize the rendering of high dynamic range content with expanded color volume.

- Backplane and driving technologies for high color displays: Advanced backplane and driving technologies are essential for achieving high color performance in both WOLED and LCoS displays. These include thin-film transistor (TFT) arrays with high refresh rates and precise voltage control for accurate color reproduction. Compensation circuits can correct for non-uniformities in display panels, ensuring consistent color across the entire screen. Specialized driving schemes can reduce motion artifacts and color distortion, particularly in high frame rate applications requiring accurate color rendering.

02 LCoS (Liquid Crystal on Silicon) technology for high-resolution displays

LCoS technology combines liquid crystal and silicon semiconductor technology to create high-resolution reflective displays. These displays use silicon backplanes with liquid crystal layers to modulate light, offering advantages such as high pixel density, excellent contrast ratios, and superior color reproduction. LCoS displays are particularly effective for high-color applications due to their ability to precisely control light transmission and reflection, resulting in vibrant and accurate color representation.Expand Specific Solutions03 Color management and enhancement techniques

Various color management techniques are employed in WOLED and LCoS displays to achieve high color performance. These include color filters optimization, color conversion layers, and advanced color processing algorithms. Some displays incorporate quantum dot technology or specialized phosphors to expand the color gamut. Additional techniques involve color temperature adjustment, gamma correction, and dynamic color enhancement to improve color accuracy and vibrancy across different viewing conditions.Expand Specific Solutions04 Integration of WOLED and LCoS technologies

The integration of WOLED and LCoS technologies creates advanced display systems with exceptional color performance. WOLED provides the light source with broad spectrum white light, while LCoS technology modulates this light to create high-resolution images. This combination leverages the strengths of both technologies: WOLED's energy efficiency and color quality with LCoS's high resolution and contrast capabilities. The integration often involves specialized optical components and light management systems to optimize color reproduction and display performance.Expand Specific Solutions05 Backlight and optical systems for enhanced color display

Advanced backlight and optical systems are crucial for high-color performance in WOLED and LCoS displays. These systems include specialized light guides, diffusers, reflectors, and polarizers that optimize light distribution and color uniformity. Some designs incorporate micro-lens arrays or prism sheets to improve light efficiency and color purity. The optical path design minimizes light loss and color distortion, ensuring that the display delivers accurate and vibrant colors across the entire screen area.Expand Specific Solutions

Key Industry Players in Advanced Display Technologies

The WOLED vs LCoS display technology landscape is currently in a growth phase, with the global high-color display market expected to reach significant expansion by 2030. WOLED technology, championed by BOE Technology, LG Electronics, and TCL China Star, offers superior color reproduction but faces manufacturing complexity challenges. Meanwhile, LCoS technology, advanced by Himax Technologies, Nanjing Xinshiyuan Electronics, and II-VI Delaware, provides excellent resolution for AR/VR applications but with higher cost structures. The competitive dynamics are intensifying as Samsung and BOE invest heavily in WOLED manufacturing capabilities, while specialized players like OmniVision and Nanosys develop complementary technologies to enhance both platforms' performance in premium display applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed proprietary WOLED technology focusing on large-format displays with high color accuracy. Their approach utilizes a multi-layer OLED stack with specialized white light emission combined with color filters to achieve wide color gamut displays. BOE's implementation features a tandem OLED structure that stacks multiple emitting units to extend device lifetime and improve efficiency. Their panels achieve color gamut coverage of approximately 95% DCI-P3 and brightness levels of 800-1000 nits. BOE has also developed advanced thin-film encapsulation techniques to protect OLED materials from oxygen and moisture degradation, extending panel lifespan. For commercial applications, BOE has focused on premium television panels and high-end monitor displays, with recent expansion into flexible and transparent display applications using their WOLED technology[2][4]. Their manufacturing process employs 8.5 and 10.5 generation production lines for cost-effective large panel production.

Strengths: Cost-effective production of large-format displays; good color accuracy and wide viewing angles; flexible application potential including curved and foldable displays. Weaknesses: Lower peak brightness compared to quantum dot enhanced solutions; more limited production capacity for ultra-high-end displays; slightly higher power consumption than some competing WOLED implementations.

Himax Technologies, Inc.

Technical Solution: Himax Technologies has focused on developing advanced LCoS (Liquid Crystal on Silicon) display solutions for high-color applications, particularly in AR/VR and projection systems. Their LCoS technology utilizes silicon backplanes with liquid crystal layers to create high-resolution reflective displays. Himax's implementation features pixel sizes down to 3.6μm with fill factors exceeding 90%, enabling extremely high pixel densities (>4000 PPI) ideal for near-eye applications. Their color sequential LCoS displays can achieve refresh rates up to 240Hz with 24-bit color depth, producing over 16 million colors. Himax has developed proprietary driving schemes that reduce motion artifacts and color breakup effects common in field-sequential color systems. Their latest LCoS panels incorporate fast-switching liquid crystal materials with response times under 2ms and contrast ratios exceeding 2000:1. For commercial applications, Himax has targeted AR/VR headsets, head-up displays, and compact projection systems requiring high brightness and color accuracy[5][7].

Strengths: Extremely high resolution and pixel density ideal for near-eye displays; excellent power efficiency for portable applications; compact form factor enabling lightweight designs; no burn-in issues. Weaknesses: More complex optical systems required compared to direct-view displays; potential for color breakup artifacts in fast-moving content; lower contrast ratio compared to emissive display technologies like OLED.

Patent Landscape for High-Color Display Technologies

Organic light emitting diode (OLED) display device

PatentActiveUS11700753B2

Innovation

- Incorporating a quantum dot pattern between the thin film transistor substrate and the color filter substrate, and a silica aerogel film with excellent total reflection and scattering properties between the quantum dot pattern and the color filter, to reabsorb and reemit lost light.

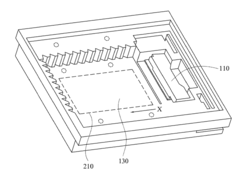

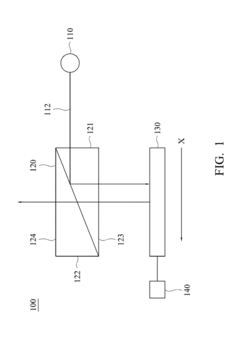

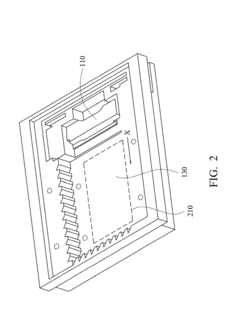

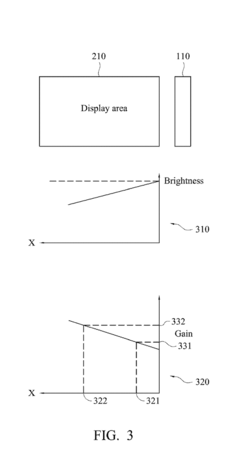

Liquid crystal on silicon display with brightness adjustment

PatentActiveUS20180018925A1

Innovation

- A gain control circuit is introduced to adjust brightness values based on their coordinates, using specific gain calculations and compensation values to ensure balanced light transmission to the LCoS panel, employing equations to adjust red, green, and blue brightness values accordingly.

Power Efficiency Comparison and Optimization

Power efficiency represents a critical factor in display technology selection, particularly when comparing WOLED (White Organic Light Emitting Diode) and LCoS (Liquid Crystal on Silicon) technologies for high-color display applications. WOLED displays demonstrate superior power efficiency in dark-content scenarios due to their emissive nature, where black pixels consume virtually no power. This characteristic makes WOLED particularly advantageous for mobile devices and applications with predominantly dark interfaces.

In contrast, LCoS systems require constant backlighting regardless of content brightness, resulting in relatively consistent power consumption across varying content. This technology utilizes polarized light that passes through liquid crystal cells and reflects off silicon backplanes, with power efficiency heavily dependent on the light source employed and optical path design.

Comparative measurements indicate that WOLED displays typically achieve 2-3 times better power efficiency than LCoS when displaying mixed content with significant dark areas. However, this advantage diminishes when displaying predominantly bright content, where the gap narrows considerably. Recent advancements in WOLED materials have yielded approximately 15% improvement in power efficiency over the past two years, while LCoS systems have seen modest gains through enhanced light source technologies and optical path optimizations.

Temperature sensitivity presents another dimension affecting power efficiency. WOLED displays maintain relatively stable power consumption across normal operating temperatures, whereas LCoS systems often require additional power for temperature control mechanisms to maintain optimal liquid crystal performance, particularly in extreme environments.

Several optimization strategies have emerged for both technologies. For WOLED, these include implementing more efficient OLED materials with higher quantum efficiency, utilizing advanced driving schemes that reduce power consumption during operation, and incorporating sophisticated power management algorithms. LCoS optimization approaches focus on developing more efficient light sources, improving optical path design to minimize light loss, and implementing dynamic backlighting control systems.

Future developments point toward hybrid solutions that leverage the strengths of both technologies. Research indicates potential for micro-LED backlighting in LCoS systems to significantly improve power efficiency, while WOLED panels continue to benefit from new material science breakthroughs that promise to extend their efficiency advantage while addressing historical limitations in brightness and longevity.

In contrast, LCoS systems require constant backlighting regardless of content brightness, resulting in relatively consistent power consumption across varying content. This technology utilizes polarized light that passes through liquid crystal cells and reflects off silicon backplanes, with power efficiency heavily dependent on the light source employed and optical path design.

Comparative measurements indicate that WOLED displays typically achieve 2-3 times better power efficiency than LCoS when displaying mixed content with significant dark areas. However, this advantage diminishes when displaying predominantly bright content, where the gap narrows considerably. Recent advancements in WOLED materials have yielded approximately 15% improvement in power efficiency over the past two years, while LCoS systems have seen modest gains through enhanced light source technologies and optical path optimizations.

Temperature sensitivity presents another dimension affecting power efficiency. WOLED displays maintain relatively stable power consumption across normal operating temperatures, whereas LCoS systems often require additional power for temperature control mechanisms to maintain optimal liquid crystal performance, particularly in extreme environments.

Several optimization strategies have emerged for both technologies. For WOLED, these include implementing more efficient OLED materials with higher quantum efficiency, utilizing advanced driving schemes that reduce power consumption during operation, and incorporating sophisticated power management algorithms. LCoS optimization approaches focus on developing more efficient light sources, improving optical path design to minimize light loss, and implementing dynamic backlighting control systems.

Future developments point toward hybrid solutions that leverage the strengths of both technologies. Research indicates potential for micro-LED backlighting in LCoS systems to significantly improve power efficiency, while WOLED panels continue to benefit from new material science breakthroughs that promise to extend their efficiency advantage while addressing historical limitations in brightness and longevity.

Form Factor and Integration Considerations

Form factor and integration considerations represent critical aspects when evaluating WOLED and LCoS technologies for high-color display applications. These factors significantly influence the adoption and implementation of these technologies across different use cases.

WOLED displays offer inherent advantages in form factor flexibility. Their self-emissive nature eliminates the need for backlighting systems, resulting in ultra-thin profiles that can be as slim as 2.57mm in commercial products. This thinness enables integration into space-constrained environments and supports the development of novel form factors including curved, rollable, and foldable displays. The lightweight nature of WOLED panels further enhances their integration potential in portable devices.

In contrast, LCoS technology presents more substantial form factor challenges. The projection-based system requires optical components including light sources, polarizers, and projection lenses, resulting in more complex and bulky implementations. Typical LCoS-based systems maintain a minimum depth of 15-30mm, limiting their application in ultra-thin devices. However, this limitation becomes less significant in fixed installation scenarios such as large venue displays or simulation environments.

Thermal management represents another crucial integration consideration. WOLED displays generate less heat compared to traditional LED displays but require careful thermal design to prevent pixel degradation. LCoS systems, particularly those using high-brightness light sources, generate considerable heat that necessitates active cooling solutions, adding complexity to the overall system design and potentially increasing noise levels.

Power consumption patterns differ significantly between these technologies. WOLED displays demonstrate pixel-level power efficiency that scales with content, consuming less power when displaying darker content. LCoS systems maintain relatively constant power requirements regardless of displayed content, as the light source operates continuously. This distinction makes WOLED particularly advantageous for battery-powered applications.

Integration with existing electronic ecosystems presents different challenges for each technology. WOLED displays utilize standardized display interfaces and can be driven by conventional display controllers. LCoS systems typically require specialized control electronics and optical alignment during integration, increasing implementation complexity and potentially limiting interchangeability between different system components.

Manufacturing scalability also influences integration considerations. WOLED panel production has achieved significant economies of scale, enabling cost-effective implementation across various device categories. LCoS manufacturing remains more specialized, with fewer suppliers and less standardization across component specifications, potentially complicating supply chain management for large-scale deployments.

WOLED displays offer inherent advantages in form factor flexibility. Their self-emissive nature eliminates the need for backlighting systems, resulting in ultra-thin profiles that can be as slim as 2.57mm in commercial products. This thinness enables integration into space-constrained environments and supports the development of novel form factors including curved, rollable, and foldable displays. The lightweight nature of WOLED panels further enhances their integration potential in portable devices.

In contrast, LCoS technology presents more substantial form factor challenges. The projection-based system requires optical components including light sources, polarizers, and projection lenses, resulting in more complex and bulky implementations. Typical LCoS-based systems maintain a minimum depth of 15-30mm, limiting their application in ultra-thin devices. However, this limitation becomes less significant in fixed installation scenarios such as large venue displays or simulation environments.

Thermal management represents another crucial integration consideration. WOLED displays generate less heat compared to traditional LED displays but require careful thermal design to prevent pixel degradation. LCoS systems, particularly those using high-brightness light sources, generate considerable heat that necessitates active cooling solutions, adding complexity to the overall system design and potentially increasing noise levels.

Power consumption patterns differ significantly between these technologies. WOLED displays demonstrate pixel-level power efficiency that scales with content, consuming less power when displaying darker content. LCoS systems maintain relatively constant power requirements regardless of displayed content, as the light source operates continuously. This distinction makes WOLED particularly advantageous for battery-powered applications.

Integration with existing electronic ecosystems presents different challenges for each technology. WOLED displays utilize standardized display interfaces and can be driven by conventional display controllers. LCoS systems typically require specialized control electronics and optical alignment during integration, increasing implementation complexity and potentially limiting interchangeability between different system components.

Manufacturing scalability also influences integration considerations. WOLED panel production has achieved significant economies of scale, enabling cost-effective implementation across various device categories. LCoS manufacturing remains more specialized, with fewer suppliers and less standardization across component specifications, potentially complicating supply chain management for large-scale deployments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!