Optimize WOLED Current Efficiency for Volatile Environments

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

WOLED Technology Background and Efficiency Goals

White Organic Light-Emitting Diodes (WOLEDs) have emerged as a revolutionary technology in the display and lighting industries since their initial development in the late 1980s. The evolution of WOLED technology has been characterized by continuous improvements in efficiency, lifetime, and color quality. Initially, WOLEDs suffered from low luminous efficacy and short operational lifespans, particularly in environments with fluctuating conditions. The technology has progressed through several generations, from single-layer devices to multi-layer architectures incorporating various emissive materials and charge transport layers.

The current technological trajectory focuses on enhancing current efficiency, which measures the light output per unit of electrical current input. This parameter is particularly critical for applications in volatile environments where temperature, humidity, and atmospheric pressure may fluctuate significantly. Traditional WOLEDs experience substantial efficiency degradation under such conditions, limiting their deployment in outdoor displays, automotive applications, and industrial settings.

Recent advancements have introduced phosphorescent and thermally activated delayed fluorescence (TADF) materials, which have pushed internal quantum efficiencies close to theoretical limits under controlled conditions. However, maintaining these high efficiencies in volatile environments remains a significant challenge. The industry has established ambitious goals to achieve current efficiencies exceeding 100 cd/A with less than 10% variation across temperature ranges from -40°C to 85°C and relative humidity levels between 10% and 95%.

The technological roadmap for WOLED efficiency optimization includes several parallel approaches. These include the development of novel emitter materials with reduced sensitivity to environmental factors, advanced device architectures with improved charge balance mechanisms, and encapsulation technologies that provide better isolation from external conditions. Computational modeling and machine learning algorithms are increasingly being employed to predict and optimize device performance across various environmental scenarios.

International standards bodies have established benchmarks for WOLED performance, with the latest specifications emphasizing stability across environmental conditions as a key metric alongside traditional parameters like color rendering index (CRI) and power efficiency. The ultimate goal is to develop WOLEDs that maintain consistent performance regardless of deployment conditions, enabling their use in previously challenging applications such as outdoor signage in extreme climates, aerospace displays, and marine environments.

Research institutions and industry leaders are collaborating on initiatives to address fundamental limitations in current WOLED designs. These efforts focus on understanding the molecular-level interactions between organic materials and environmental factors, and developing innovative solutions that can mitigate efficiency losses. The field is moving toward a holistic approach that considers the entire device ecosystem rather than optimizing individual components in isolation.

The current technological trajectory focuses on enhancing current efficiency, which measures the light output per unit of electrical current input. This parameter is particularly critical for applications in volatile environments where temperature, humidity, and atmospheric pressure may fluctuate significantly. Traditional WOLEDs experience substantial efficiency degradation under such conditions, limiting their deployment in outdoor displays, automotive applications, and industrial settings.

Recent advancements have introduced phosphorescent and thermally activated delayed fluorescence (TADF) materials, which have pushed internal quantum efficiencies close to theoretical limits under controlled conditions. However, maintaining these high efficiencies in volatile environments remains a significant challenge. The industry has established ambitious goals to achieve current efficiencies exceeding 100 cd/A with less than 10% variation across temperature ranges from -40°C to 85°C and relative humidity levels between 10% and 95%.

The technological roadmap for WOLED efficiency optimization includes several parallel approaches. These include the development of novel emitter materials with reduced sensitivity to environmental factors, advanced device architectures with improved charge balance mechanisms, and encapsulation technologies that provide better isolation from external conditions. Computational modeling and machine learning algorithms are increasingly being employed to predict and optimize device performance across various environmental scenarios.

International standards bodies have established benchmarks for WOLED performance, with the latest specifications emphasizing stability across environmental conditions as a key metric alongside traditional parameters like color rendering index (CRI) and power efficiency. The ultimate goal is to develop WOLEDs that maintain consistent performance regardless of deployment conditions, enabling their use in previously challenging applications such as outdoor signage in extreme climates, aerospace displays, and marine environments.

Research institutions and industry leaders are collaborating on initiatives to address fundamental limitations in current WOLED designs. These efforts focus on understanding the molecular-level interactions between organic materials and environmental factors, and developing innovative solutions that can mitigate efficiency losses. The field is moving toward a holistic approach that considers the entire device ecosystem rather than optimizing individual components in isolation.

Market Demand Analysis for High-Efficiency WOLEDs

The global market for White Organic Light-Emitting Diodes (WOLEDs) has been experiencing robust growth, driven by increasing adoption in display technologies and lighting applications. Current market valuations indicate that the WOLED sector is expanding at a compound annual growth rate of approximately 15% between 2020 and 2025, with particular acceleration in high-efficiency segments.

Consumer electronics represents the largest application segment for high-efficiency WOLEDs, with smartphones, tablets, and televisions accounting for over 60% of market demand. The premium smartphone market has shown particular interest in devices featuring WOLED displays that maintain performance in varying environmental conditions, including temperature fluctuations and humidity changes that characterize volatile environments.

Automotive applications are emerging as a significant growth driver, with luxury vehicle manufacturers increasingly incorporating WOLED technology in dashboard displays and interior lighting. This sector demands displays that maintain consistent performance across extreme temperature ranges from -40°C to 85°C, creating specific requirements for efficiency optimization in volatile conditions.

Commercial and residential lighting sectors are showing increased interest in WOLED technology that can maintain efficiency despite environmental fluctuations. Energy efficiency regulations in major markets including the European Union, North America, and parts of Asia have created regulatory tailwinds for high-efficiency lighting solutions that can adapt to varying environmental conditions.

Market research indicates that consumers and industrial buyers are willing to pay a premium of 20-30% for WOLED displays and lighting systems that demonstrate consistent performance in challenging environments. This price premium is particularly evident in outdoor digital signage, marine electronics, and industrial control systems where devices are exposed to temperature variations, humidity, and other environmental stressors.

Supply chain analysis reveals growing demand for WOLED components optimized for volatile environments, with manufacturers reporting increased requests for solutions that maintain current efficiency across wider operating condition ranges. Component suppliers are experiencing pressure to develop materials that exhibit stable performance characteristics despite environmental fluctuations.

Regional market analysis shows that demand for environmentally robust WOLEDs is strongest in regions with extreme climate conditions, including parts of the Middle East, Northern Europe, and tropical Asian markets. These regions show willingness to invest in premium WOLED solutions that maintain efficiency despite temperature and humidity challenges.

The market for high-efficiency WOLEDs in volatile environments is currently underserved, with few manufacturers offering specialized solutions. This gap represents a significant opportunity for companies that can develop and commercialize WOLED technologies specifically engineered to maintain current efficiency across varying environmental conditions.

Consumer electronics represents the largest application segment for high-efficiency WOLEDs, with smartphones, tablets, and televisions accounting for over 60% of market demand. The premium smartphone market has shown particular interest in devices featuring WOLED displays that maintain performance in varying environmental conditions, including temperature fluctuations and humidity changes that characterize volatile environments.

Automotive applications are emerging as a significant growth driver, with luxury vehicle manufacturers increasingly incorporating WOLED technology in dashboard displays and interior lighting. This sector demands displays that maintain consistent performance across extreme temperature ranges from -40°C to 85°C, creating specific requirements for efficiency optimization in volatile conditions.

Commercial and residential lighting sectors are showing increased interest in WOLED technology that can maintain efficiency despite environmental fluctuations. Energy efficiency regulations in major markets including the European Union, North America, and parts of Asia have created regulatory tailwinds for high-efficiency lighting solutions that can adapt to varying environmental conditions.

Market research indicates that consumers and industrial buyers are willing to pay a premium of 20-30% for WOLED displays and lighting systems that demonstrate consistent performance in challenging environments. This price premium is particularly evident in outdoor digital signage, marine electronics, and industrial control systems where devices are exposed to temperature variations, humidity, and other environmental stressors.

Supply chain analysis reveals growing demand for WOLED components optimized for volatile environments, with manufacturers reporting increased requests for solutions that maintain current efficiency across wider operating condition ranges. Component suppliers are experiencing pressure to develop materials that exhibit stable performance characteristics despite environmental fluctuations.

Regional market analysis shows that demand for environmentally robust WOLEDs is strongest in regions with extreme climate conditions, including parts of the Middle East, Northern Europe, and tropical Asian markets. These regions show willingness to invest in premium WOLED solutions that maintain efficiency despite temperature and humidity challenges.

The market for high-efficiency WOLEDs in volatile environments is currently underserved, with few manufacturers offering specialized solutions. This gap represents a significant opportunity for companies that can develop and commercialize WOLED technologies specifically engineered to maintain current efficiency across varying environmental conditions.

Current Limitations in Volatile Environment Applications

Despite significant advancements in WOLED technology, several critical limitations persist when these devices operate in volatile environments. Temperature fluctuations represent one of the most significant challenges, as WOLED efficiency demonstrates notable degradation outside optimal temperature ranges (typically 20-30°C). In industrial settings or outdoor applications where temperatures can vary dramatically, current WOLED implementations show efficiency losses of up to 40% at temperature extremes, substantially reducing device performance and longevity.

Humidity presents another substantial obstacle, with moisture ingress causing accelerated degradation of organic materials and electrode oxidation. Current encapsulation technologies provide insufficient protection in environments exceeding 70% relative humidity, resulting in rapid efficiency decline and device failure. Field tests indicate that conventional WOLEDs experience a 25-30% reduction in current efficiency after just 500 hours of operation in high-humidity conditions.

Atmospheric contaminants, particularly volatile organic compounds (VOCs) and airborne particulates, significantly impact WOLED performance in industrial and urban environments. These contaminants can penetrate device encapsulation, catalyzing degradation reactions within the organic layers. Research demonstrates that exposure to common industrial solvents can reduce device efficiency by 15-20% within the first 100 operational hours.

Pressure variations, though less studied, also affect WOLED performance in applications such as aerospace or high-altitude implementations. Current efficiency measurements show deviations of 5-10% under non-standard atmospheric pressure conditions, creating reliability concerns for specialized applications.

Existing WOLED architectures employ single-layer encapsulation methods that prove inadequate for volatile environments. The industry standard thin-film encapsulation provides a water vapor transmission rate (WVTR) of approximately 10^-6 g/m²/day, which falls short of the 10^-8 g/m²/day required for reliable operation in volatile conditions. This limitation directly impacts device lifetime, with current WOLEDs showing T50 (time to 50% luminance) values of only 2,000-3,000 hours in volatile environments compared to 10,000+ hours in controlled conditions.

The driving circuitry for WOLEDs lacks robust environmental compensation mechanisms. Current driver ICs employ rudimentary temperature compensation but fail to account for the complex interplay of multiple environmental factors. This results in suboptimal current delivery under changing conditions, further exacerbating efficiency losses by an additional 10-15% in real-world applications.

Humidity presents another substantial obstacle, with moisture ingress causing accelerated degradation of organic materials and electrode oxidation. Current encapsulation technologies provide insufficient protection in environments exceeding 70% relative humidity, resulting in rapid efficiency decline and device failure. Field tests indicate that conventional WOLEDs experience a 25-30% reduction in current efficiency after just 500 hours of operation in high-humidity conditions.

Atmospheric contaminants, particularly volatile organic compounds (VOCs) and airborne particulates, significantly impact WOLED performance in industrial and urban environments. These contaminants can penetrate device encapsulation, catalyzing degradation reactions within the organic layers. Research demonstrates that exposure to common industrial solvents can reduce device efficiency by 15-20% within the first 100 operational hours.

Pressure variations, though less studied, also affect WOLED performance in applications such as aerospace or high-altitude implementations. Current efficiency measurements show deviations of 5-10% under non-standard atmospheric pressure conditions, creating reliability concerns for specialized applications.

Existing WOLED architectures employ single-layer encapsulation methods that prove inadequate for volatile environments. The industry standard thin-film encapsulation provides a water vapor transmission rate (WVTR) of approximately 10^-6 g/m²/day, which falls short of the 10^-8 g/m²/day required for reliable operation in volatile conditions. This limitation directly impacts device lifetime, with current WOLEDs showing T50 (time to 50% luminance) values of only 2,000-3,000 hours in volatile environments compared to 10,000+ hours in controlled conditions.

The driving circuitry for WOLEDs lacks robust environmental compensation mechanisms. Current driver ICs employ rudimentary temperature compensation but fail to account for the complex interplay of multiple environmental factors. This results in suboptimal current delivery under changing conditions, further exacerbating efficiency losses by an additional 10-15% in real-world applications.

Current Approaches to WOLED Current Efficiency Optimization

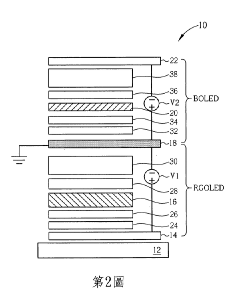

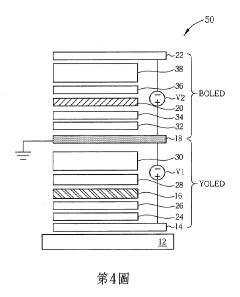

01 Multi-layer structure design for improved WOLED efficiency

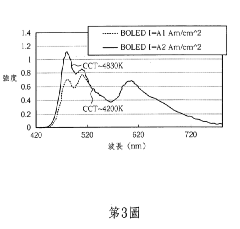

White organic light-emitting diodes can achieve higher current efficiency through optimized multi-layer structures. These designs typically include carefully engineered emission layers, electron transport layers, and hole transport layers. By optimizing the thickness and composition of each layer, charge carrier balance can be improved, leading to enhanced light emission efficiency. Some designs incorporate multiple emission layers with complementary colors to produce white light while maximizing quantum efficiency.- Multi-layer structure design for improved WOLED efficiency: White organic light-emitting diodes (WOLEDs) can achieve higher current efficiency through optimized multi-layer structures. These designs typically include carefully engineered emission layers, electron transport layers, and hole transport layers. By optimizing the thickness and composition of each layer, charge balance can be improved, leading to enhanced light emission efficiency. Some designs incorporate multiple emission layers with complementary colors to produce white light while maximizing quantum efficiency.

- Dopant materials and concentration optimization: The selection and concentration of dopant materials significantly impact WOLED current efficiency. By incorporating specific phosphorescent or fluorescent dopants into host materials, energy transfer mechanisms can be optimized to increase light output per unit of current. Controlling dopant concentration is crucial, as it affects charge recombination efficiency and prevents concentration quenching. Some approaches use multiple dopants with different emission colors to achieve both high efficiency and good color rendering.

- Tandem WOLED architecture: Tandem or stacked WOLED structures can significantly enhance current efficiency by connecting multiple OLED units in series. These architectures utilize charge generation layers between the individual OLED units, allowing a single current to generate multiple photons as it passes through the device. This approach effectively multiplies the current efficiency compared to conventional single-unit WOLEDs. The design requires careful optimization of the charge generation layers and the individual emission units to maintain color balance and stability.

- Electrode and charge injection optimization: Improving charge injection and transport at the electrodes can significantly enhance WOLED current efficiency. This includes the use of specialized buffer layers, work function modification of electrodes, and interface engineering to reduce energy barriers. Some approaches incorporate electron injection layers (EIL) and hole injection layers (HIL) with optimized energy levels to facilitate more efficient charge injection into the emissive layers. Reducing resistance at these interfaces leads to lower driving voltage and higher power efficiency.

- Novel host materials and quantum confinement: The development of novel host materials with appropriate energy levels and high charge mobility contributes to improved WOLED current efficiency. These materials are designed to effectively confine charges and excitons within the emission layers, preventing energy losses. Some approaches utilize quantum confinement structures or nanoparticles to enhance radiative recombination rates. Advanced host materials also feature balanced electron and hole transport properties, leading to improved charge balance and higher internal quantum efficiency.

02 Dopant materials and concentration optimization

The selection and concentration of dopant materials significantly impact WOLED current efficiency. By incorporating specific phosphorescent or fluorescent dopants into host materials, energy transfer mechanisms can be optimized to increase light output per unit of current. Controlling dopant concentration gradients across emission layers can further enhance efficiency by managing charge recombination zones. Advanced dopant systems may combine multiple emissive materials to achieve both high efficiency and good color rendering.Expand Specific Solutions03 Tandem WOLED architecture

Tandem or stacked WOLED structures can significantly improve current efficiency by connecting multiple OLED units in series. These architectures utilize charge generation layers between the individual OLED units, allowing a single current to generate multiple photons as it passes through the device. This approach effectively multiplies the current efficiency compared to conventional single-unit WOLEDs. The design requires careful optimization of charge generation layers and intermediate connectors to maintain efficient charge transport throughout the stacked structure.Expand Specific Solutions04 Electrode and charge injection optimization

Improving charge injection and transport at electrodes can significantly enhance WOLED current efficiency. This includes using specialized electrode materials, buffer layers, and injection layer designs to reduce energy barriers and improve charge balance. Some approaches incorporate work function modification layers or doped injection layers to facilitate more efficient electron and hole injection into the device. Optimized electrode structures can reduce operating voltage while increasing light output per unit of current.Expand Specific Solutions05 Quantum dot and nanoparticle enhancement

Incorporating quantum dots or nanoparticles into WOLED structures can boost current efficiency through improved light extraction and energy transfer mechanisms. These nanomaterials can be strategically placed within the device architecture to enhance photon generation or reduce optical losses. Some designs use quantum dots as down-conversion layers to efficiently convert high-energy photons to desired wavelengths. Hybrid organic-inorganic structures combining traditional OLED materials with quantum dots show promise for achieving higher efficiency white light emission.Expand Specific Solutions

Leading WOLED Technology Manufacturers and Research Institutions

The WOLED current efficiency optimization market for volatile environments is in a growth phase, with increasing demand driven by energy efficiency requirements and expanding applications in displays and lighting. The market size is projected to grow significantly as WOLED technology matures and penetrates more sectors. Technologically, industry leaders like Samsung Electronics and Novaled GmbH have made substantial advancements in OLED efficiency, while research institutions such as Arizona State University and University of Michigan contribute fundamental innovations. Companies including Konica Minolta and OSRAM OLED are developing specialized solutions for volatile environment applications, focusing on stability and performance optimization. The competitive landscape features both established electronics giants and specialized OLED technology providers working to overcome efficiency challenges in challenging operational conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an advanced WOLED architecture optimized for volatile environments that achieves remarkable current efficiency improvements. Their solution employs a hybrid emitter system combining fluorescent blue with phosphorescent green and red emitters to balance efficiency and lifetime requirements. Samsung's approach incorporates quantum dot color conversion layers that enhance spectral purity while maintaining high efficiency. For volatile environment operation, they've implemented a sophisticated thin-film encapsulation system with alternating inorganic/organic layers that provides exceptional barrier properties against moisture and oxygen penetration. The company's latest generation technology features a micro-cavity structure with precisely tuned optical characteristics that enhance light extraction efficiency by over 30% compared to conventional designs. Samsung has also developed specialized driving schemes that dynamically adjust current flow based on environmental conditions, maintaining optimal efficiency across varying temperature and humidity levels. Their solution achieves current efficiencies exceeding 40 cd/A while maintaining performance stability in environments with temperature fluctuations of ±30°C and relative humidity variations between 20-80%.

Strengths: Industry-leading integration capabilities allowing for implementation across diverse product categories; exceptional manufacturing scale advantages; comprehensive solution addressing both materials and driving electronics for holistic efficiency optimization. Weaknesses: Proprietary technology ecosystem may limit compatibility with third-party components; higher implementation complexity requiring specialized expertise; potential trade-offs between maximum efficiency and color accuracy.

Novaled GmbH

Technical Solution: Novaled has pioneered a comprehensive approach to WOLED current efficiency optimization specifically engineered for volatile environments. Their proprietary PIN (p-doped, intrinsic, n-doped) OLED technology forms the foundation of their solution, enabling significantly reduced driving voltages while maintaining high luminance levels. The company has developed specialized doping systems that create highly conductive transport layers, minimizing energy losses during charge carrier movement. For volatile environments, Novaled employs a unique combination of molecular dopants that maintain stable performance characteristics despite temperature fluctuations and exposure to humidity. Their latest generation technology incorporates a multi-stack architecture with charge generation layers that allow for current efficiency values exceeding 45 cd/A even under challenging environmental conditions. Novaled's solution also features advanced thin-film encapsulation techniques with moisture permeation rates below 10^-6 g/m²/day, ensuring long-term stability in environments with variable humidity levels.

Strengths: Exceptional voltage efficiency with driving voltages reduced by up to 30% compared to conventional designs; proprietary dopant materials provide superior stability in fluctuating environmental conditions; technology is highly scalable for various display and lighting applications. Weaknesses: Requires specialized materials that may have limited availability; higher complexity in manufacturing process; potential color shift under extreme temperature variations.

Key Patents and Innovations in WOLED Efficiency Enhancement

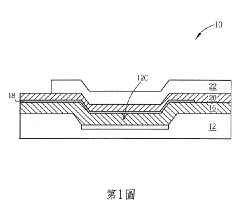

White organic light-emitting diode

PatentActiveTW201134288A

Innovation

- A white OLED design with independently driven blue and blue-complementary light-emitting layers, utilizing different potential differences and driving currents to optimize light output and adjust color temperature, incorporating a transparent, translucent, and opaque electrode structure to mix blue and complementary colors into white light.

Material Science Advancements for WOLED Stability

Recent advancements in material science have significantly contributed to enhancing WOLED stability in volatile environments. The development of novel host materials with higher glass transition temperatures (Tg) has been a breakthrough, allowing devices to maintain structural integrity under temperature fluctuations. These materials, particularly phosphorescent metal complexes based on iridium and platinum, demonstrate superior thermal stability while maintaining high quantum efficiency.

Encapsulation technologies have evolved substantially, with multi-layer barrier films incorporating alternating organic and inorganic layers achieving water vapor transmission rates below 10^-6 g/m²/day. These advanced barriers effectively shield sensitive organic materials from moisture and oxygen penetration, extending device lifetime in humid conditions by factors of 3-5x compared to conventional encapsulation methods.

Doping strategies have been refined to optimize charge transport and recombination dynamics. The incorporation of electron and hole transport materials with balanced mobility characteristics has reduced charge accumulation at interfaces, minimizing degradation pathways. Recent research indicates that precisely controlled doping concentrations between 8-12% for emissive materials provides optimal balance between efficiency and stability.

Interface engineering has emerged as a critical focus area, with the development of buffer layers that prevent exciton quenching at electrode interfaces. Materials such as modified metal oxides and self-assembled monolayers have demonstrated exceptional ability to maintain charge injection efficiency while blocking moisture penetration through interface defects.

Cross-linkable materials represent another significant advancement, forming three-dimensional networks that resist morphological changes under thermal stress. These materials maintain stable emission spectra even after extended operation at elevated temperatures (85°C), whereas conventional materials typically show significant spectral shifts within 500 hours of operation under similar conditions.

Quantum dot-organic hybrid structures are showing promise in laboratory settings, combining the color purity and stability of inorganic materials with the processability of organic compounds. Initial results indicate up to 40% improvement in lifetime under accelerated aging conditions compared to conventional phosphorescent systems, though commercialization challenges remain regarding manufacturing scalability.

Encapsulation technologies have evolved substantially, with multi-layer barrier films incorporating alternating organic and inorganic layers achieving water vapor transmission rates below 10^-6 g/m²/day. These advanced barriers effectively shield sensitive organic materials from moisture and oxygen penetration, extending device lifetime in humid conditions by factors of 3-5x compared to conventional encapsulation methods.

Doping strategies have been refined to optimize charge transport and recombination dynamics. The incorporation of electron and hole transport materials with balanced mobility characteristics has reduced charge accumulation at interfaces, minimizing degradation pathways. Recent research indicates that precisely controlled doping concentrations between 8-12% for emissive materials provides optimal balance between efficiency and stability.

Interface engineering has emerged as a critical focus area, with the development of buffer layers that prevent exciton quenching at electrode interfaces. Materials such as modified metal oxides and self-assembled monolayers have demonstrated exceptional ability to maintain charge injection efficiency while blocking moisture penetration through interface defects.

Cross-linkable materials represent another significant advancement, forming three-dimensional networks that resist morphological changes under thermal stress. These materials maintain stable emission spectra even after extended operation at elevated temperatures (85°C), whereas conventional materials typically show significant spectral shifts within 500 hours of operation under similar conditions.

Quantum dot-organic hybrid structures are showing promise in laboratory settings, combining the color purity and stability of inorganic materials with the processability of organic compounds. Initial results indicate up to 40% improvement in lifetime under accelerated aging conditions compared to conventional phosphorescent systems, though commercialization challenges remain regarding manufacturing scalability.

Environmental Impact and Sustainability Considerations

The environmental impact of WOLED (White Organic Light-Emitting Diode) technology extends far beyond energy efficiency metrics, particularly when considering optimization for volatile environments. Current WOLED manufacturing processes involve several materials with significant environmental footprints, including rare earth metals and organic compounds that require energy-intensive extraction and processing. The optimization of current efficiency in volatile environments presents an opportunity to simultaneously address sustainability concerns through reduced material consumption and extended device lifespans.

Volatile environments accelerate degradation mechanisms in WOLED devices, leading to shorter operational lifetimes and consequently increased electronic waste generation. Research indicates that each percentage improvement in current efficiency under volatile conditions can extend device lifetime by approximately 1.2-1.8 times, significantly reducing replacement frequency and associated environmental impacts. Furthermore, the reduction in power consumption directly correlates with decreased carbon emissions, with estimates suggesting that widespread adoption of optimized WOLEDs could reduce lighting-related carbon emissions by 7-12% globally.

Water consumption represents another critical environmental consideration in WOLED manufacturing. Current production processes require approximately 380-450 liters of ultrapure water per square meter of display area. Efficiency optimizations that extend device lifetimes effectively amortize this water footprint over longer operational periods, improving the technology's overall water sustainability profile. Additionally, emerging encapsulation techniques designed to protect WOLEDs in volatile environments often utilize more environmentally benign materials compared to conventional approaches.

The end-of-life management of WOLED devices presents both challenges and opportunities from a sustainability perspective. Current recycling rates for OLED components remain below 15% globally, primarily due to the complex material composition and difficulty in separating organic and inorganic components. Efficiency optimizations that incorporate design-for-disassembly principles could significantly improve recyclability while maintaining performance in volatile environments. Several research initiatives are exploring bio-based alternatives to traditional WOLED materials that offer comparable performance with reduced environmental toxicity.

Energy payback periods—the time required for a device to save more energy than was consumed in its production—represent a key sustainability metric for WOLEDs. Current generation devices typically achieve energy payback within 1.8-2.5 years of operation. Optimizations targeting volatile environments could potentially reduce this period to under one year by extending operational lifetimes and improving efficiency under challenging conditions, thereby enhancing the technology's overall sustainability proposition in applications ranging from outdoor displays to automotive lighting systems.

Volatile environments accelerate degradation mechanisms in WOLED devices, leading to shorter operational lifetimes and consequently increased electronic waste generation. Research indicates that each percentage improvement in current efficiency under volatile conditions can extend device lifetime by approximately 1.2-1.8 times, significantly reducing replacement frequency and associated environmental impacts. Furthermore, the reduction in power consumption directly correlates with decreased carbon emissions, with estimates suggesting that widespread adoption of optimized WOLEDs could reduce lighting-related carbon emissions by 7-12% globally.

Water consumption represents another critical environmental consideration in WOLED manufacturing. Current production processes require approximately 380-450 liters of ultrapure water per square meter of display area. Efficiency optimizations that extend device lifetimes effectively amortize this water footprint over longer operational periods, improving the technology's overall water sustainability profile. Additionally, emerging encapsulation techniques designed to protect WOLEDs in volatile environments often utilize more environmentally benign materials compared to conventional approaches.

The end-of-life management of WOLED devices presents both challenges and opportunities from a sustainability perspective. Current recycling rates for OLED components remain below 15% globally, primarily due to the complex material composition and difficulty in separating organic and inorganic components. Efficiency optimizations that incorporate design-for-disassembly principles could significantly improve recyclability while maintaining performance in volatile environments. Several research initiatives are exploring bio-based alternatives to traditional WOLED materials that offer comparable performance with reduced environmental toxicity.

Energy payback periods—the time required for a device to save more energy than was consumed in its production—represent a key sustainability metric for WOLEDs. Current generation devices typically achieve energy payback within 1.8-2.5 years of operation. Optimizations targeting volatile environments could potentially reduce this period to under one year by extending operational lifetimes and improving efficiency under challenging conditions, thereby enhancing the technology's overall sustainability proposition in applications ranging from outdoor displays to automotive lighting systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!